Automatic welding system for flexible circuit boards

An automatic welding and circuit board technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large space occupation and high equipment cost, and achieve the effect of mass automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

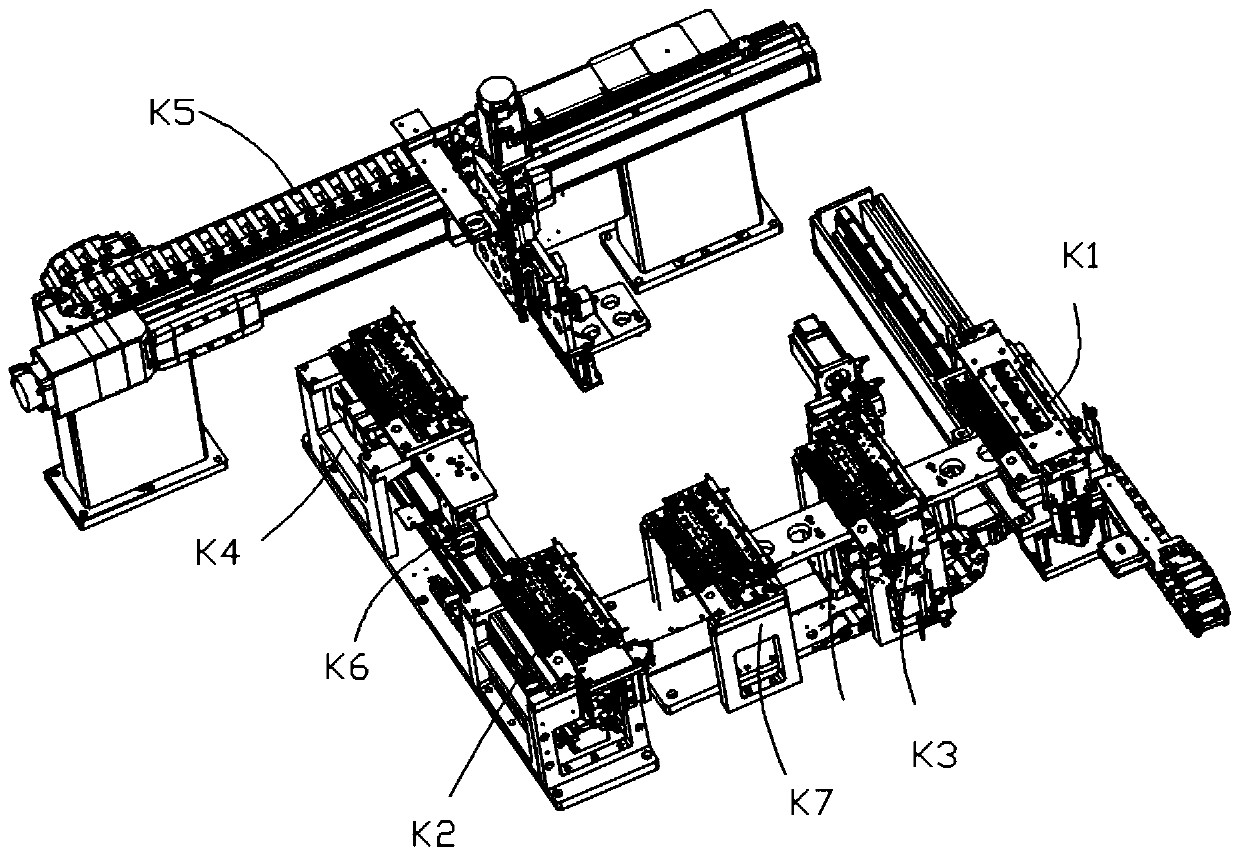

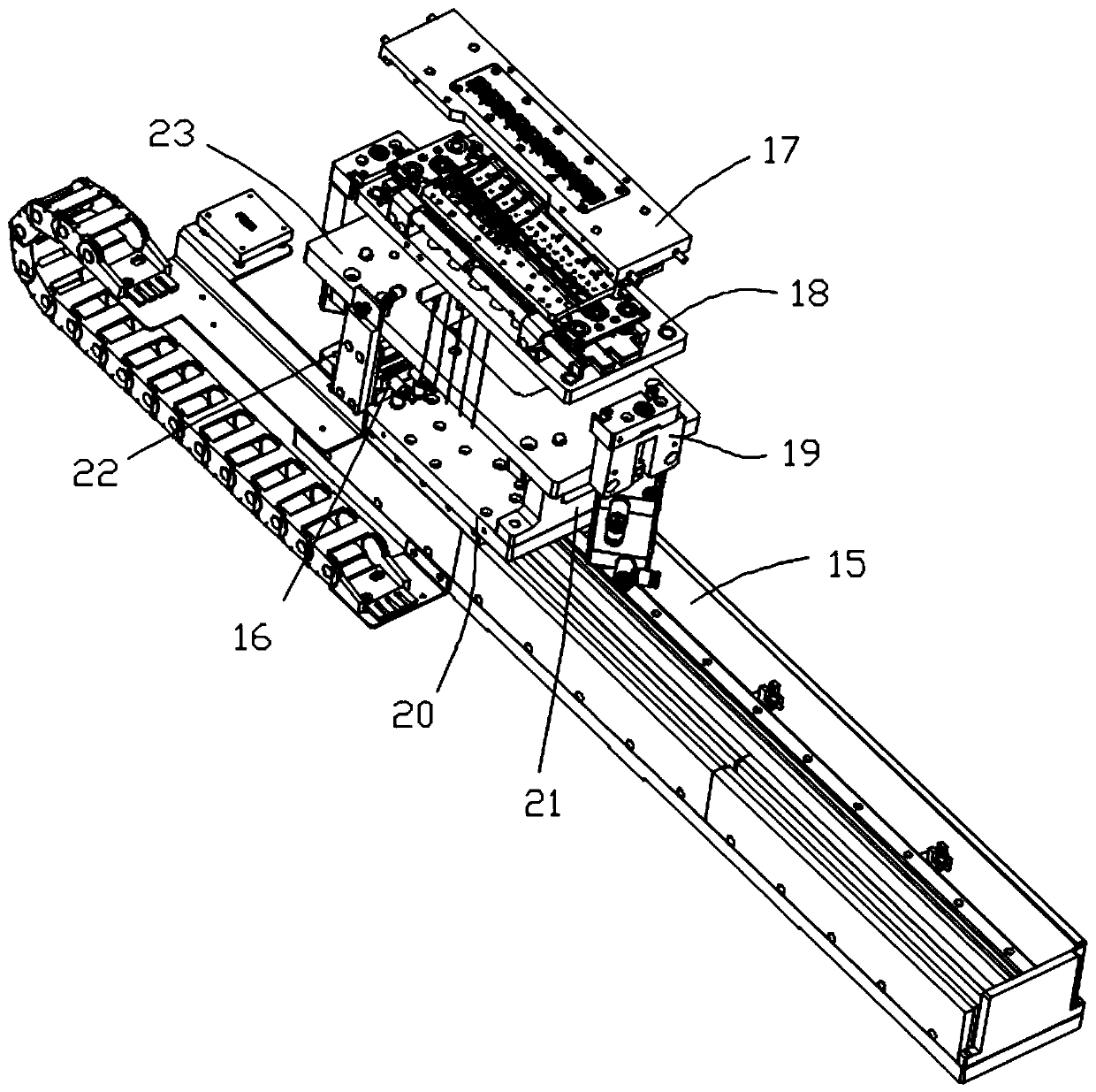

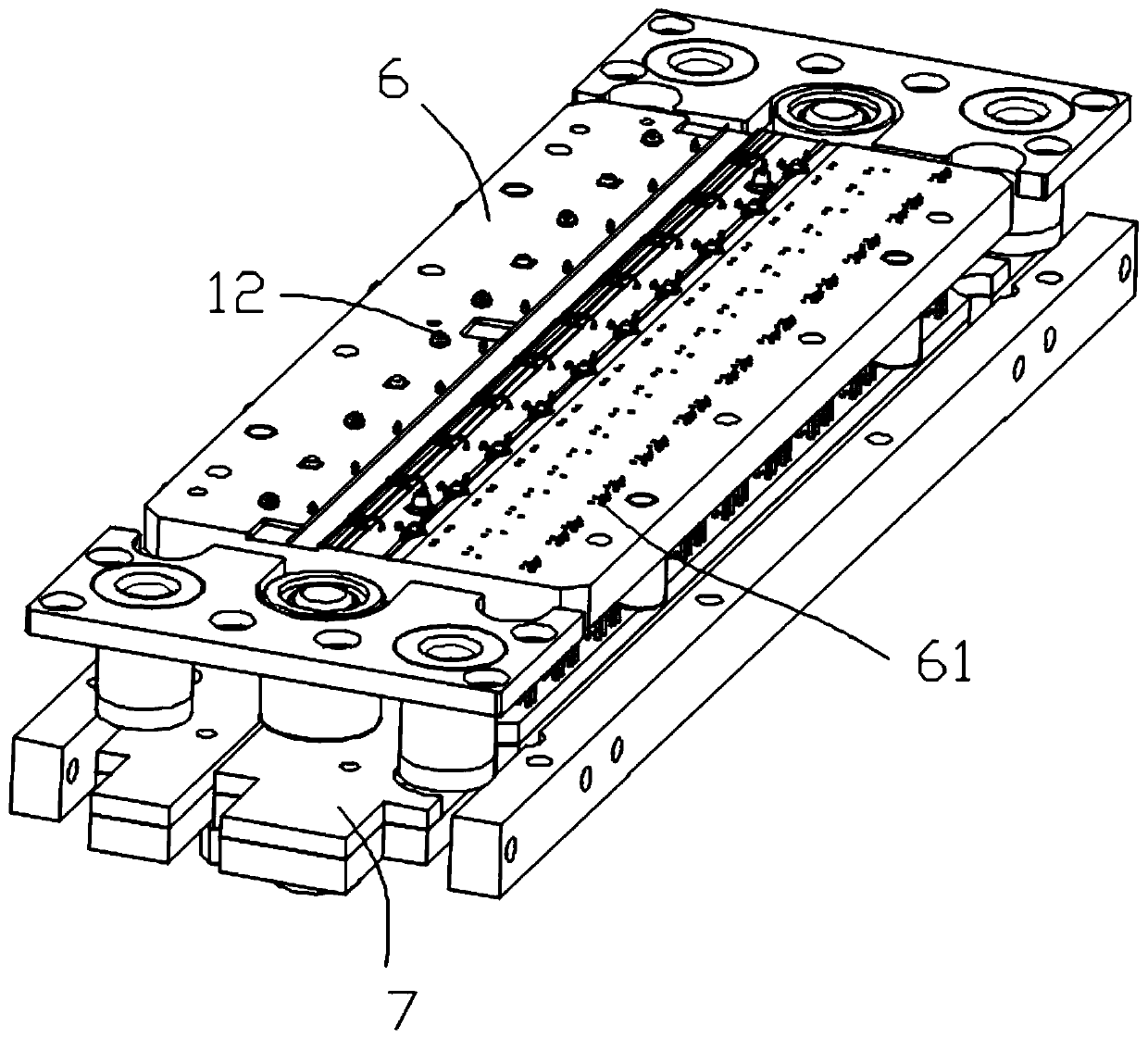

[0045] An automatic welding system for flexible circuit boards, applied to the automatic welding of flexible circuit boards preferably including flexible circuits, substrates, tongues and carrier plates, including: welding station K1, welding mechanism and multiple loading and unloading stations K2, K3, K4 , a plurality of loading and unloading stations K2, K3, K4 and welding station K1 are configured to receive and position fixtures, the fixtures are configured to locate the whole or part of multiple flexible circuit boards, and the welding mechanism is arranged above the welding station K1 to The flexible circuit board on the jig is welded; multiple sets of automatic loading and unloading mechanisms are configured to automatically store, automatically load and automatically unload the sub-components of each flexible circuit board and the welded flexible circuit board; multiple jigs The transfer mechanism is configured to transfer jigs between loading and unloading tables K2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com