Patents

Literature

69 results about "Industry 4.0" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industry 4.0 is the subset of the fourth industrial revolution that concerns industry. The fourth industrial revolution encompasses areas which are not normally classified as industry, such as smart cities for instance.

Internet + industrial 4.0 intelligent manufacturing management method and system

InactiveCN105427055AAddress changing needsQuick responseResourcesManufacturing computing systemsInformation resourceThe Internet

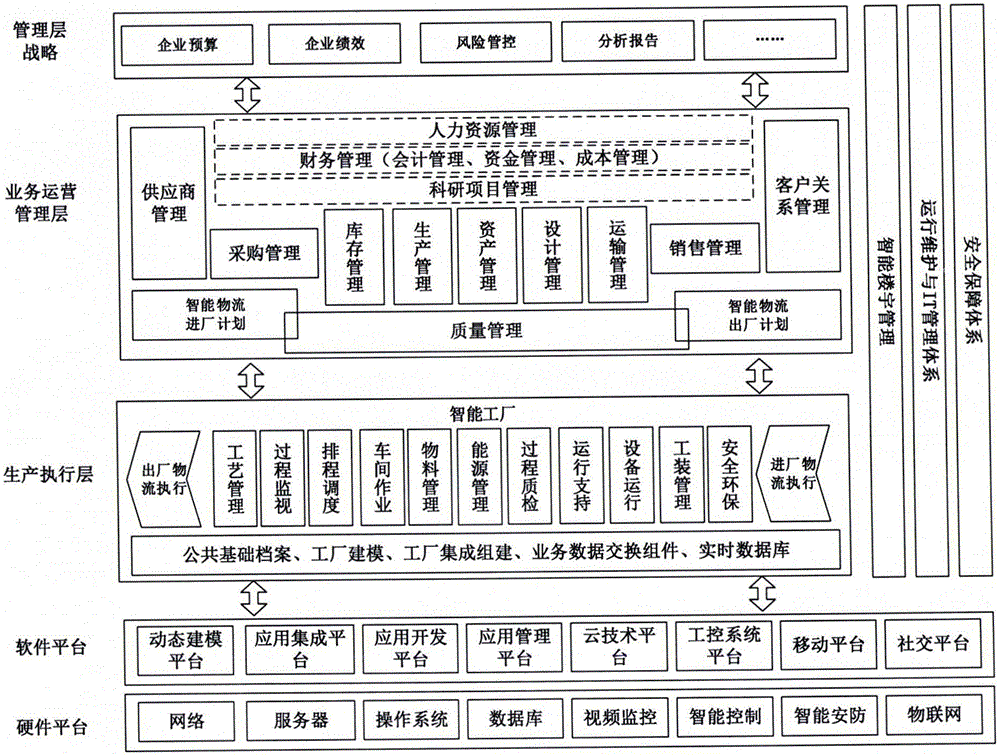

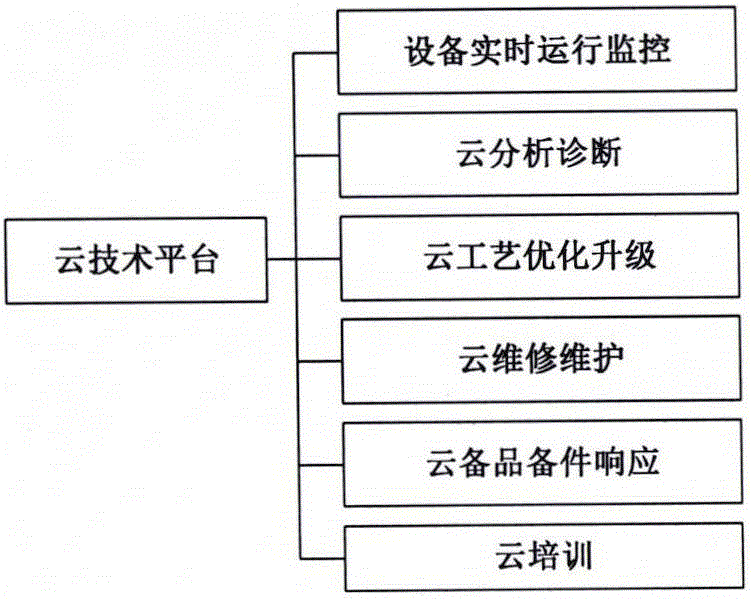

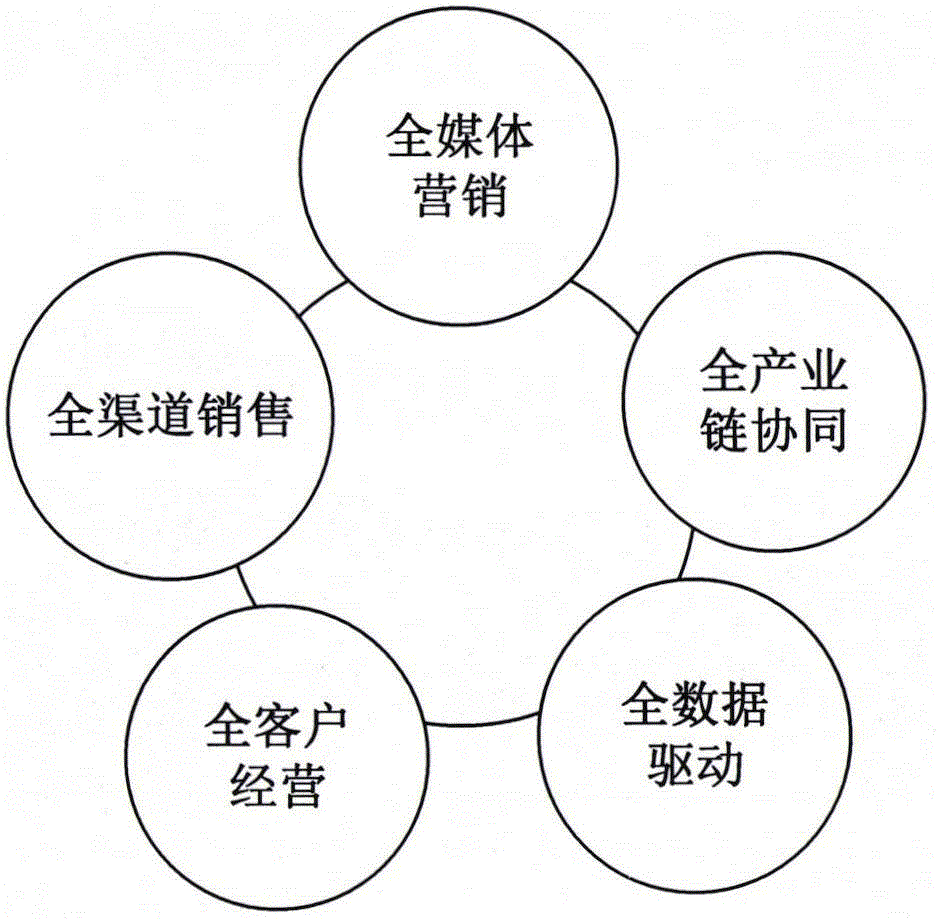

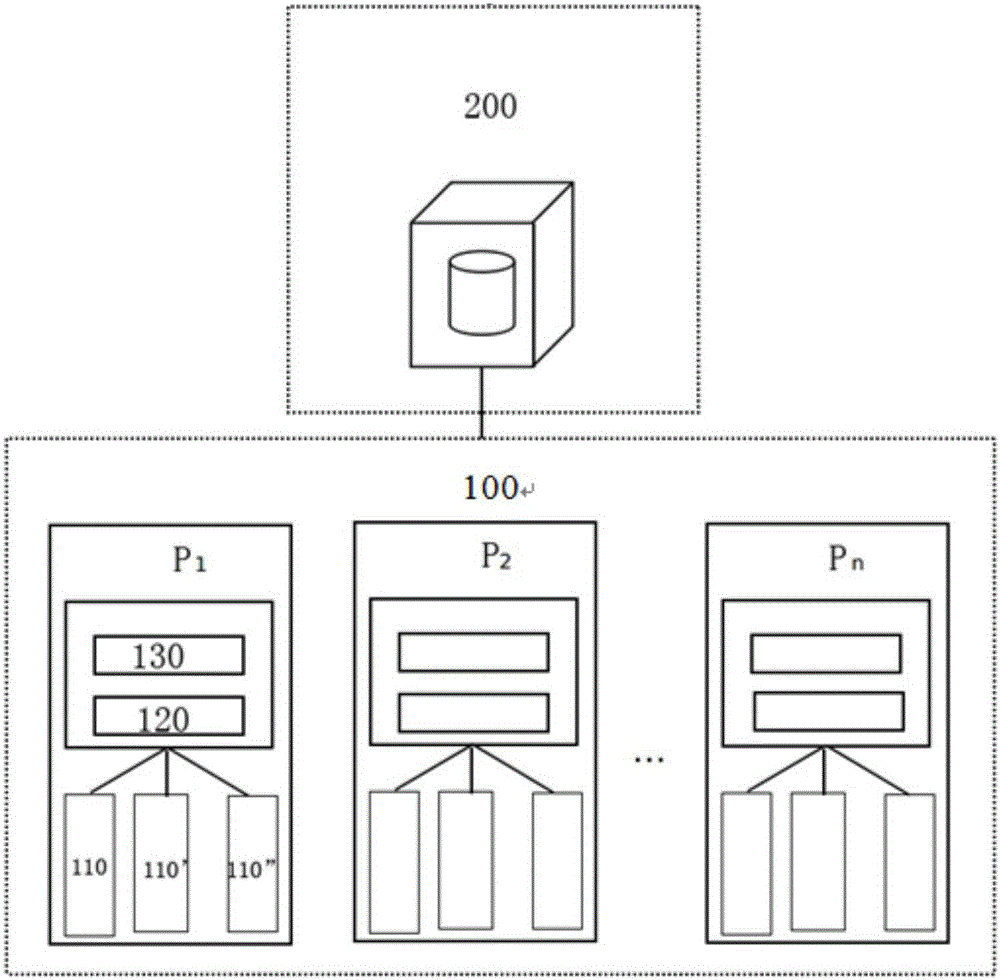

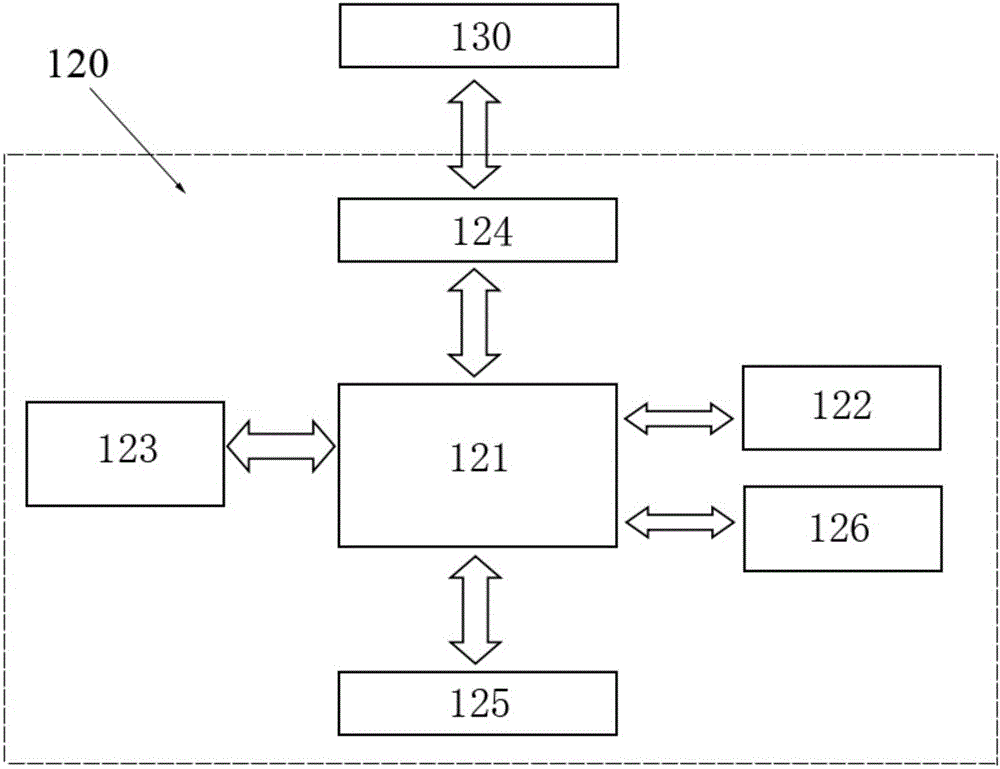

The invention discloses an Internet + industrial 4.0 intelligent manufacturing management method and a system. The Internet + industrial 4.0 intelligent manufacturing management method and the system are used to provide a comprehensive information resource service for system exploitation, testing and operation deployment. The method and system are characterized in that the Internet + industrial 4.0 intelligent manufacturing management method and the system comprise five layers of service frameworks, two safety systems and intelligent building management; the five layers of frameworks are a hardware platform layer, a software platform layer, a production manufacturing execution layer, a service operation management layer and a strategy management layer from bottom to top respectively; through the intelligent building management and a series of guarantee support auxiliary of the two systems of an operation maintenance and IT management system and safety guarantee, sensors which are located everywhere, an embedded terminal system, an intelligent control system and communication facilities form one intelligent network through a CPS. People and people, people and machine, machine and machine, and server and server can be interconnected so that transverse, vertical and end-to-end high integration is realized. A production network is constructed. Perfect fusion of virtual and real worlds is achieved and an industrial 4.0 mode of information physics fusion system construction and application is constructed.

Owner:北京中科云集科技有限公司

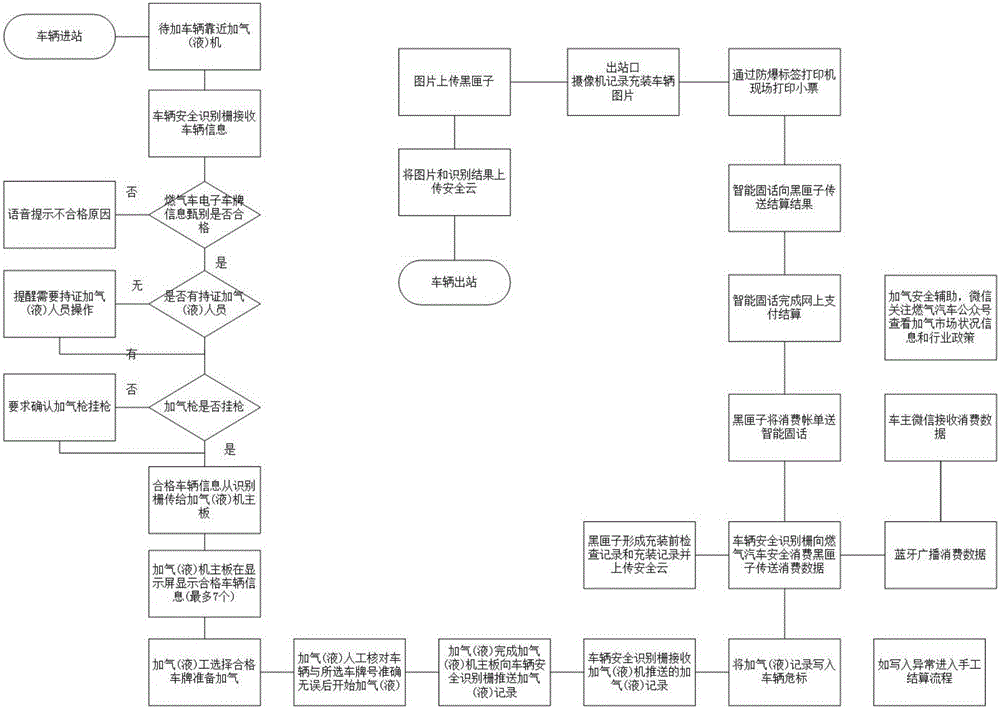

Implementation method of gas dispenser recognizing gas cylinders and controlling filling thereof

ActiveCN105782715AConsumption assuranceVessel mounting detailsContainer filling methodsGas cylinderProcess engineering

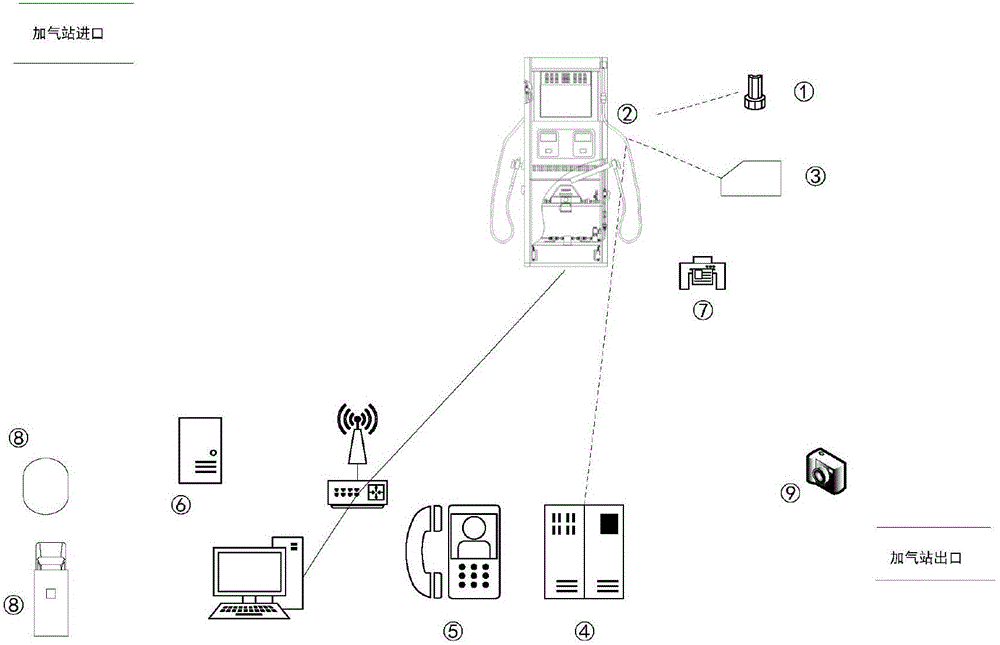

The invention discloses an implementation method of a gas dispenser recognizing gas cylinders and controlling filling thereof. The implementation method comprises identifying vehicles and gas cylinders, maintaining dangerous identifications of the vehicles and the gas cylinders, automatically recognizing the vehicles and the gas cylinders according to the dangerous identifications by the gas dispenser, carrying out gas filling by the gas dispenser according to recognition results, pushing gas filling records by the gas dispenser, and carrying out electronic settlement of gas filling. Monitoring on operation safety of gas transportation vehicles, online acquisition and monitoring on gas quality, recording on leaving vehicles at a gas station and gas filling safety consumption services are realized. According to the implementation method of the gas dispenser recognizing gas cylinders and controlling filling thereof, vehicles, gas cylinder filling consumption operation and safety production control are combined by means of Internet of Things, industry 4.0, cloud computing, and the big data technology, thereby ensuring that users are safe in consumption and can learn to keep safe in consumption. As a result, accidents of gas vehicles and gas cylinders can be reduced fundamentally.

Owner:乾元智能江苏安全技术有限公司

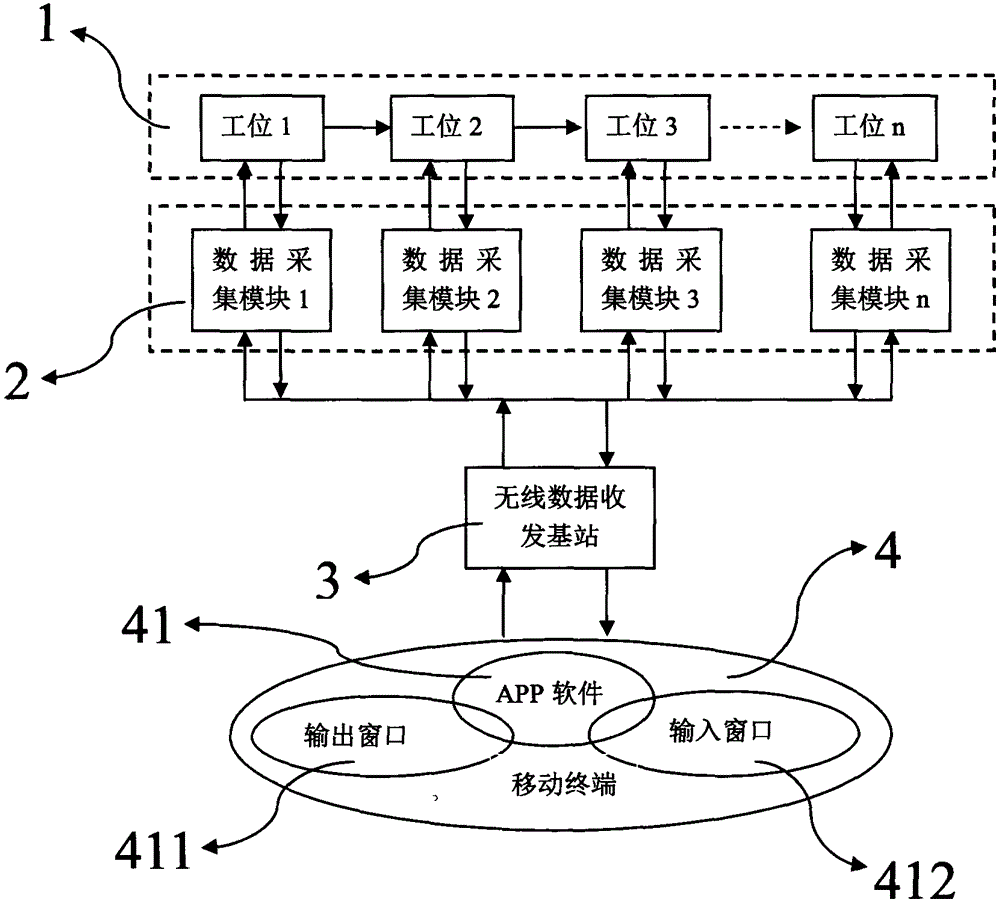

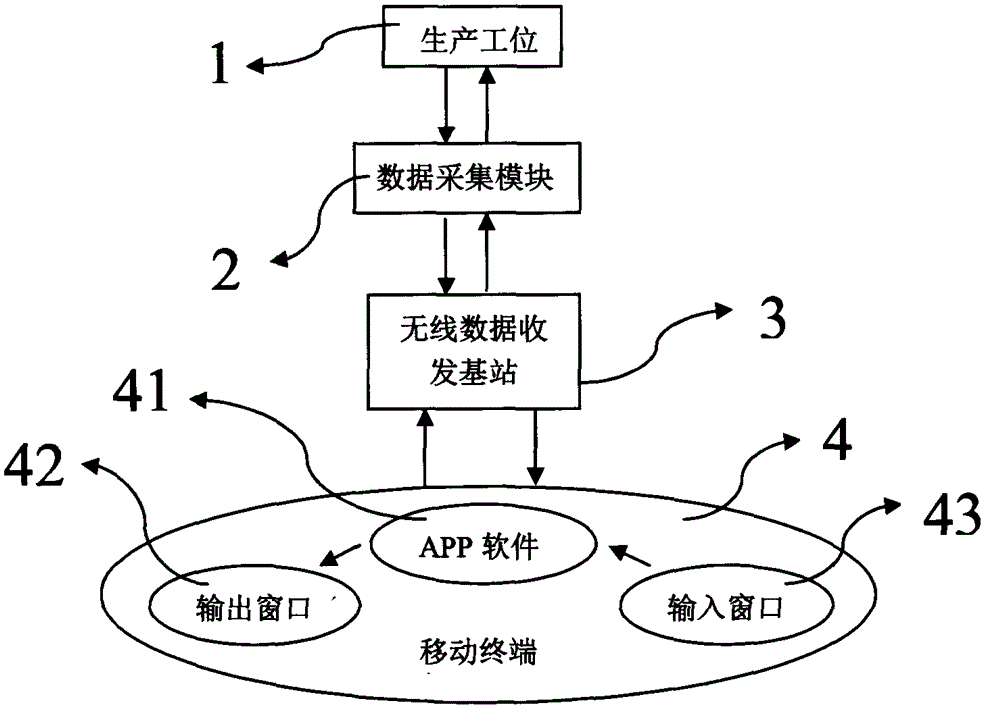

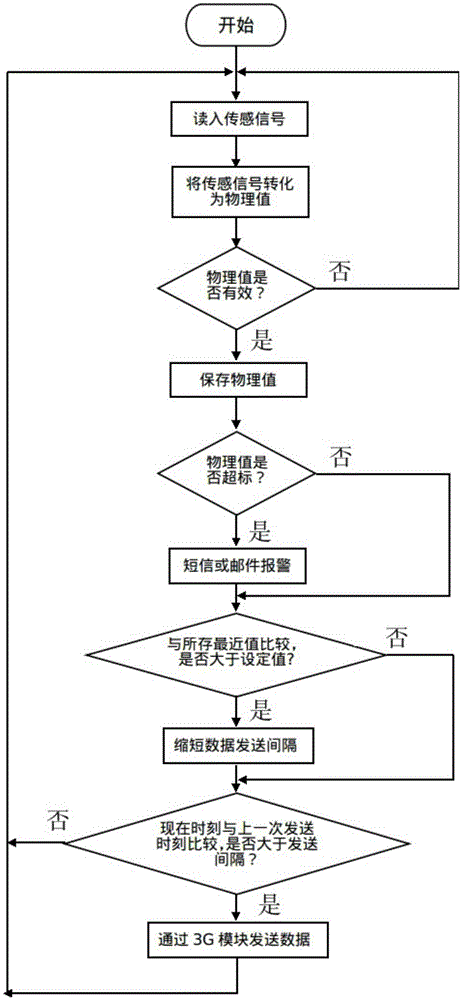

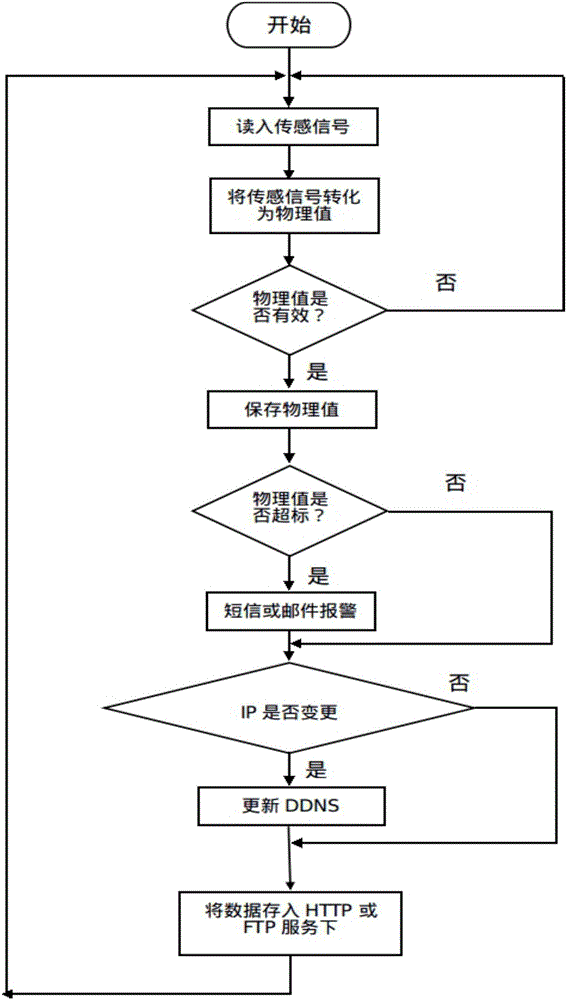

Remote monitoring method and system for industrial production

PendingCN105357299AProduction management is more convenient and efficientHigh degree of digitizationSubstation equipmentTransmissionSmart factoryWireless data

The invention discloses a remote monitoring method and system for industrial production. The remote monitoring system mainly comprises a data acquisition module for performing data acquisition and data processing on the data generated by production stations, a wireless data receiving and sending base station for performing wireless receiving and sending on the data, a mobile terminal (mobile Internet equipment, such as a smart phone and the like) with a function of receiving and sending wireless data, and APP software mounted on the mobile terminal. The remote monitoring system adopts the wireless transmission technology; the mobile terminal is used as the terminal point and the source point of information for performing remote monitoring on the industrial production fields, so that the remote monitoring system is novel and creative; by adoption of the system, the real-time remote monitoring and control on production posts by industrial production administrators can be realized; and the remote monitoring system is an important production auxiliary management system of an industrial 4.0 system and is the important component of smart factories.

Owner:郑州弗曼智能设备科技有限公司

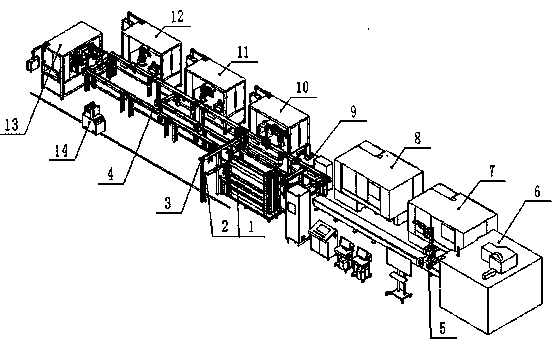

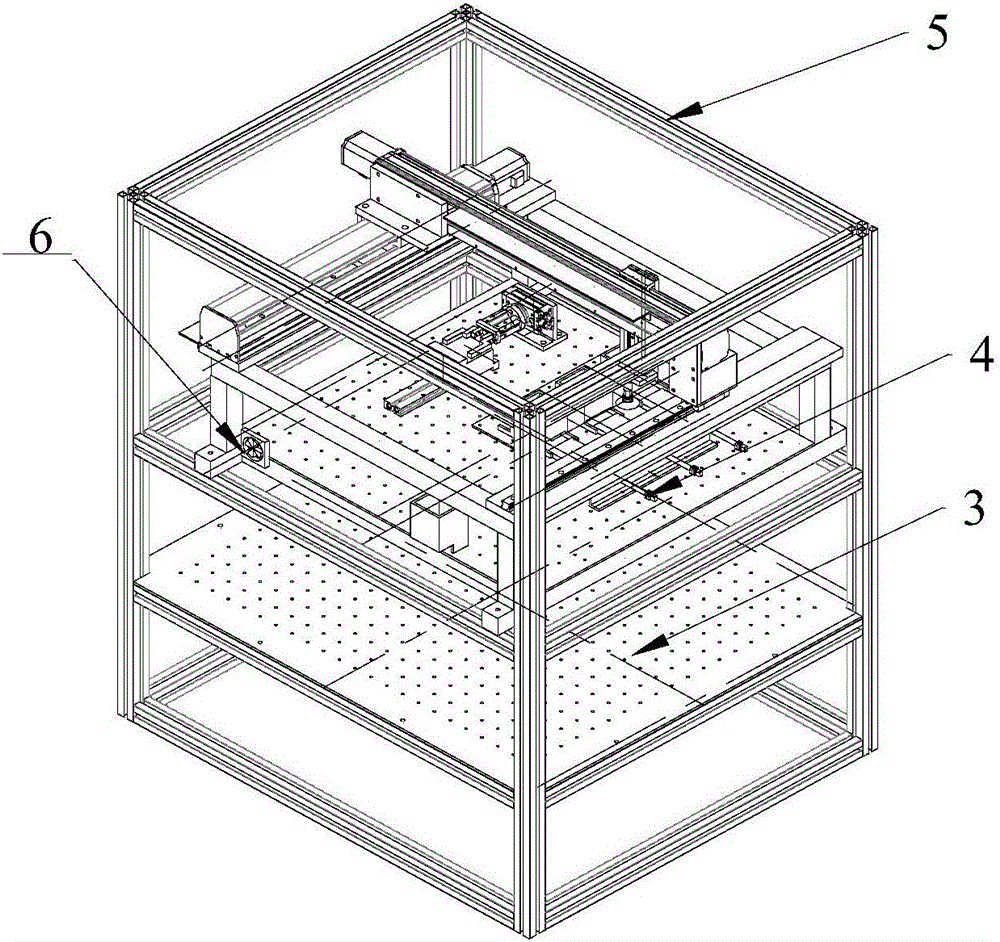

Intelligent manufacturing technology and application and production training system and method

InactiveCN109615967ARealize intelligenceEasy to optimizeCosmonautic condition simulationsEducational modelsProduction lineManufacturing technology

The invention relates to an intelligent manufacturing technology and an application and production training system and method, and aims to provide an intelligent manufacturing and production trainingand education combined flexible production system technology, so as to solve the problems of high cost, low efficiency and low benefit of a traditional production mode. The invention reflects an unmanned production system generated by industrial upgrading of a robot-oriented industry 4.0, and intelligent measures such as intelligent warehousing, AGV and an industrial visual identification system are fully used to jointly form an extensible automatic flexible production line.

Owner:SHANDONG DOLANG TECH EQUIP

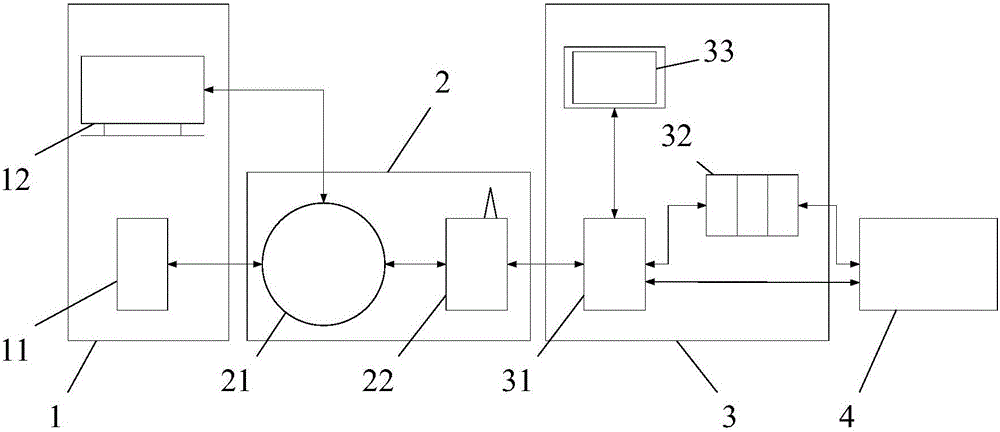

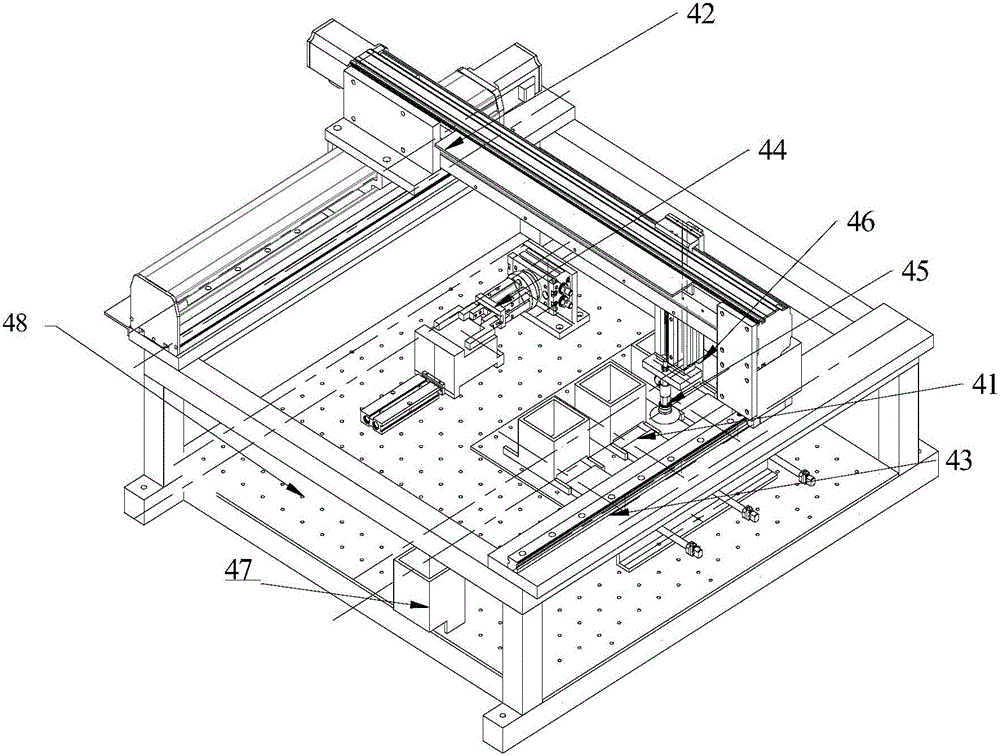

Intelligent laser engraving system based on industry 4.0

ActiveCN105933449AHigh movement accuracyLarge carving areaTransmission systemsTransmissionThird generationThe Internet

The invention relates to an intelligent laser engraving system based on industry 4.0, relating to laser engraving equipment. A user module, a communication module, an electric control module and a mechanical module are arranged; the user module is provided with a mobile phone client side and an ERP management system; the ERP management system is connected to an internet and keeps real-time connection with a cloud server; the communication module is simultaneously connected to the user module and the electric control module; the communication module is provided with the cloud server and a 3G router; the electric control module is connected to the mechanical module; the electric control module is provided with a PLC, a servo driver and a HMI touch screen; and the mechanical module is provided with a warehouse entry area, a linear module, a linear guide rail, a processing station, a vacuum suction cup, a laser, a warehouse-out area and a load base. Personalized products can be customized according to requirements; manual operation is unnecessary from payment to order to processing completion; the production efficiency is high; the processing state can be monitored in real time more comprehensively; the movement precision is high; the engravable area is relatively large; and thus, the beauty of products is improved easily.

Owner:XIAMEN UNIV

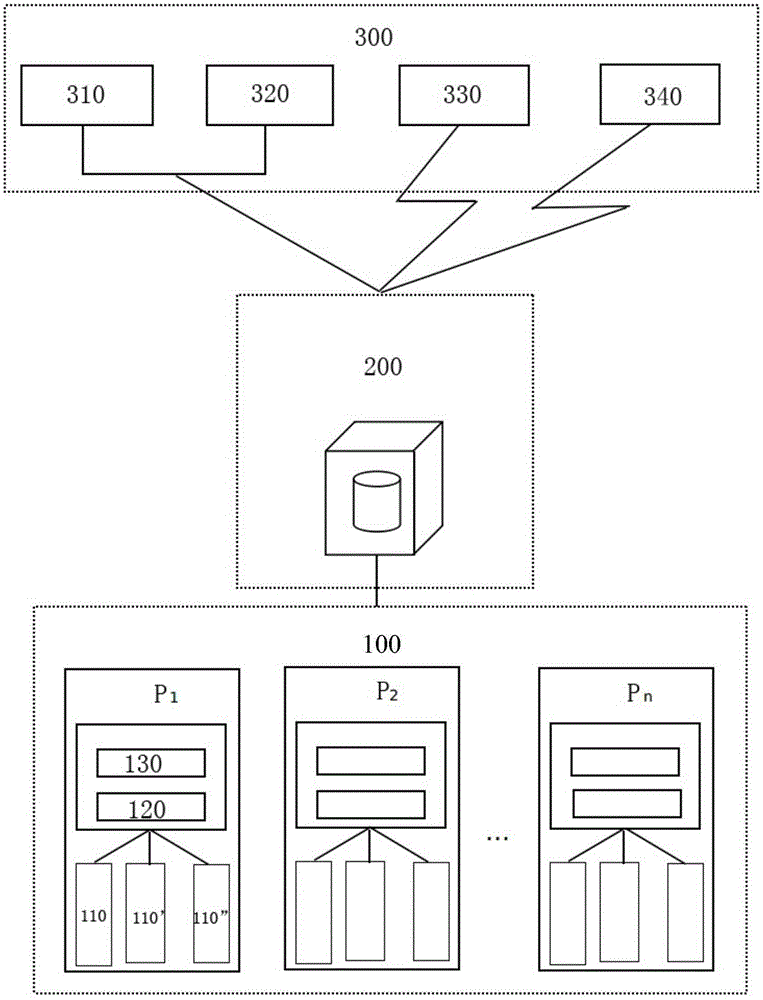

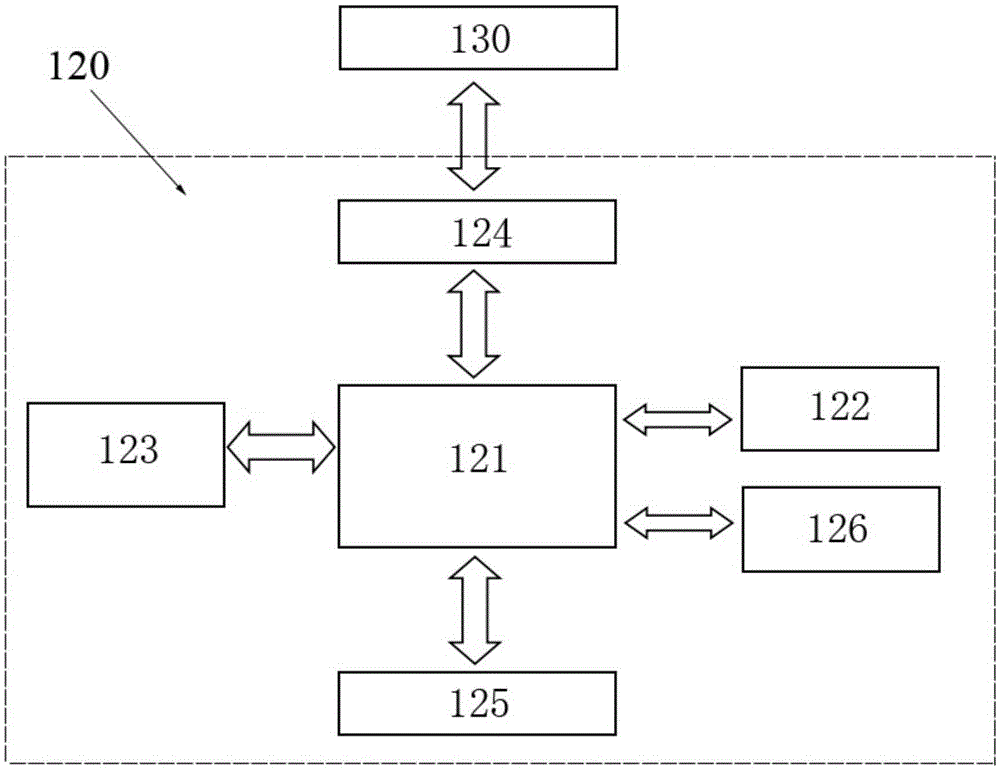

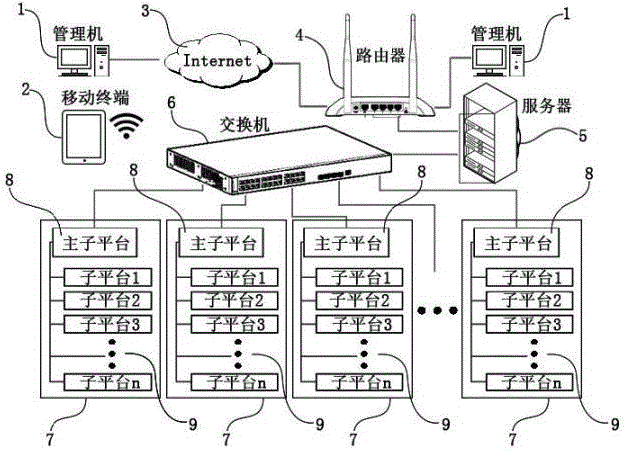

Cloud of things online monitoring general platform system

InactiveCN105334842AVersatilityHigh economic valueElectric testing/monitoringCloud of thingsSoftware system

The invention discloses a cloud of things online monitoring general platform system comprising a data acquisition system, a cloud data center and a client side. The data acquisition system comprises an onsite data acquisition and transmission hardware device and embedded software which operates on the acquisition board of the onsite data acquisition and transmission hardware device. The cloud data center comprises a computer equipment and software system which is used for data storage and cloud services. The client side comprises a computer and a mobile terminal. The client side is arranged at a user side and communicates with the cloud data center so as to transmit a request to a data storage and cloud service system to perform information inquiring. According to the cloud of things online monitoring general platform system, social value is high, economic value is high, environmental value is high and use is convenient so that the cloud of things online monitoring general platform system is suitable for environment online monitoring, disaster prevention online monitoring and production online monitoring, such as water quality online monitoring, water level and rainfall online monitoring, factory environmental hygiene online monitoring, industrial 4.0 platform, agricultural internet of things and vehicle and vessel transport real-time monitoring and intelligent household, etc.

Owner:SUZHOU FUMI INFORMATION TECH CO LTD

Production line information integration and control practice platform of intelligent manufacture

The invention relates to a production line information integration and control practice platform of intelligent manufacture. The practice platform is characterized by comprising a feeding and sorting integrated workstation, an industrial robot workstation, a multifunctional storage workstation and an intelligent production and manufacture management system. According to the technical scheme provided by the invention, the practical platform enables students to follow the development trends in intelligent manufacture and application of new technology, convenience is provided for optimization of teaching schemes, the platform can also help students develop learning interests and develop thinking, and thus, high-quality skill-orientated talents suitable for production line information integration and control, urgently needed by enterprises, and meeting requirements for intelligent factories and intelligent production in China manufacture 2025 plans in industry 4.0 can be cultivated.

Owner:ZHEJIANG TIANHUANG TECH INDAL

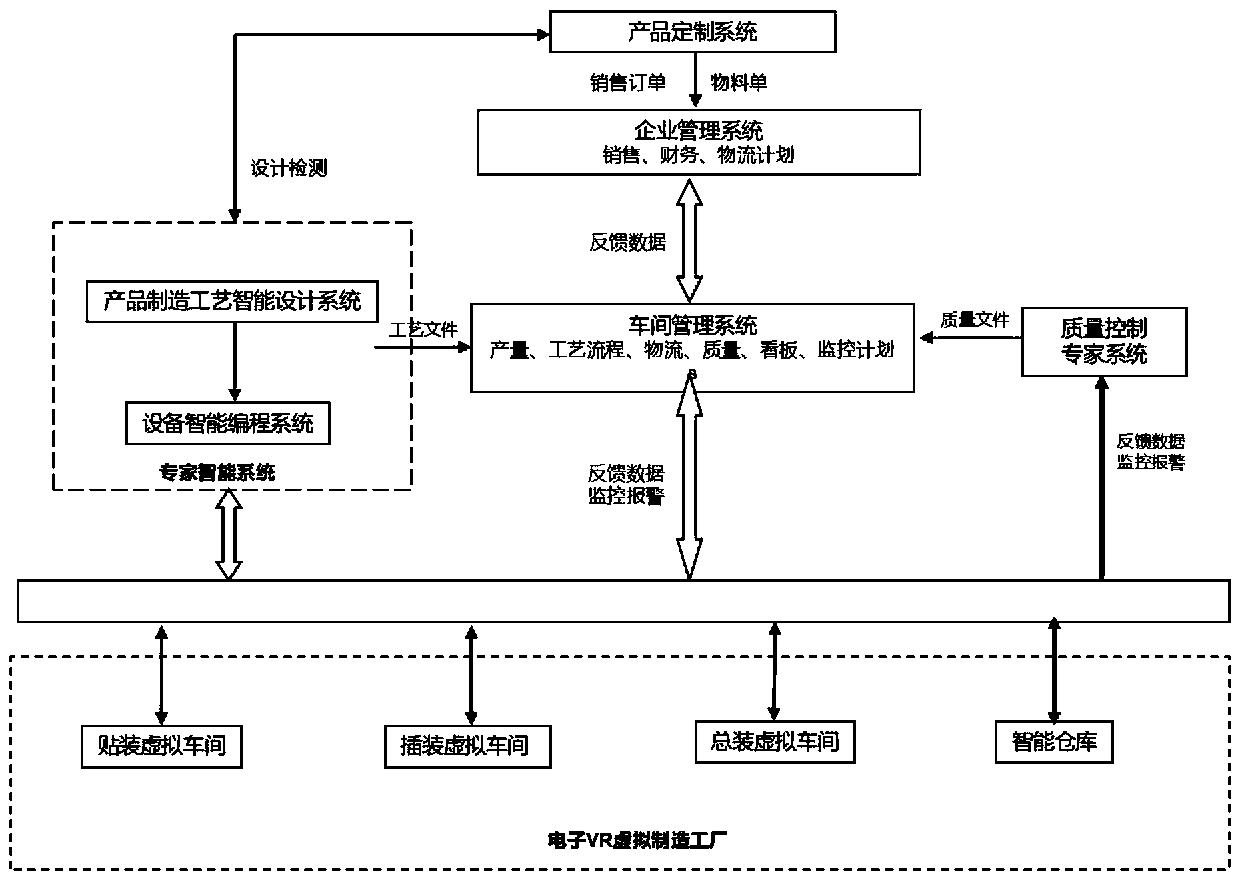

Virtual electronic intelligent manufacturing factory control system and control method thereof

ActiveCN109782714AIntelligentVersatilityTotal factory controlProgramme total factory controlControl systemQuality control

The invention discloses a virtual electronic intelligent manufacturing factory control system and a control method thereof. The virtual electronic intelligent manufacturing factory control system comprises a product customization system, an enterprise management system, a workshop management system, an expert intelligent system, a quality control expert system, an electronic VR virtual manufacturing factory and the Internet for connecting the systems in a mutual communication manner. The system and the method have certain intelligence, universality, simplicity and reliability, and a brand newfeasible method for realizing an industrial 4.0-based virtual electronic intelligent manufacturing factory is provided. The system is suitable for electronic production enterprise upgrading innovationand college and university school training teaching.

Owner:CHANGZHOU AUTOSMT INFORMATION TECH

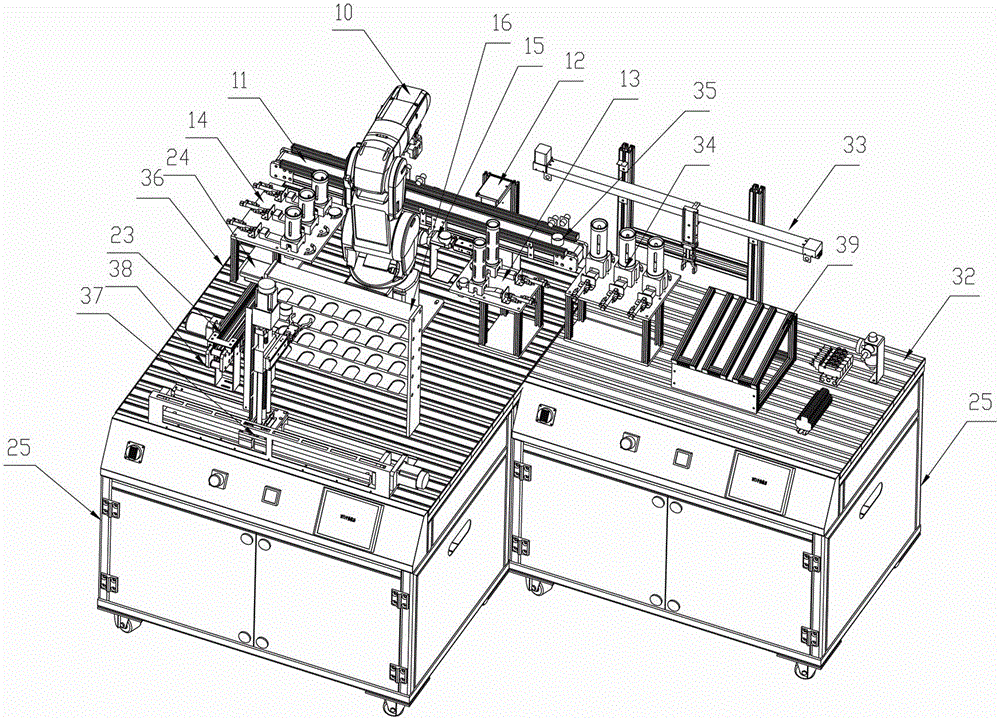

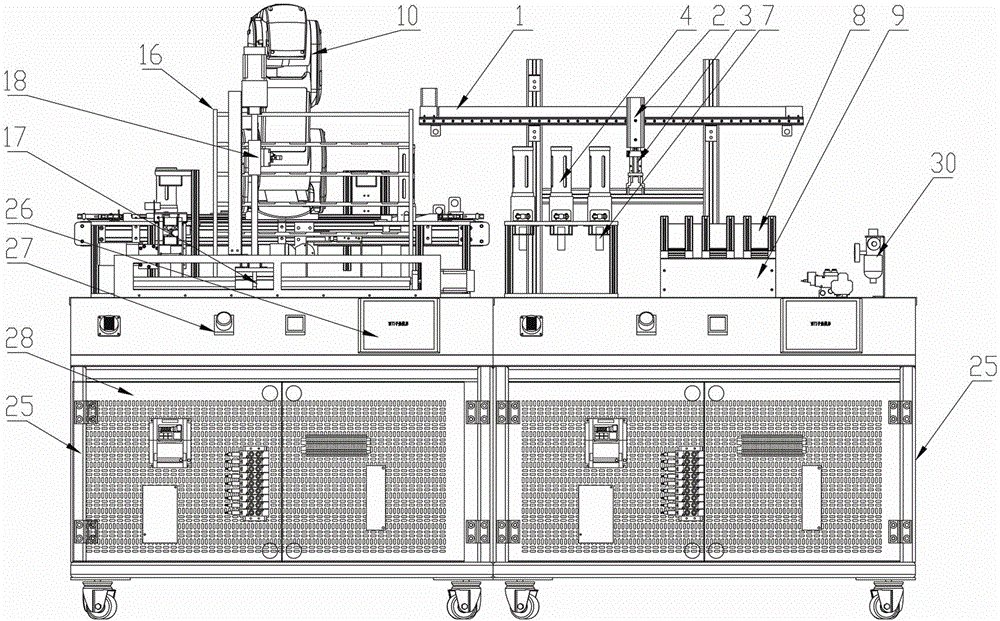

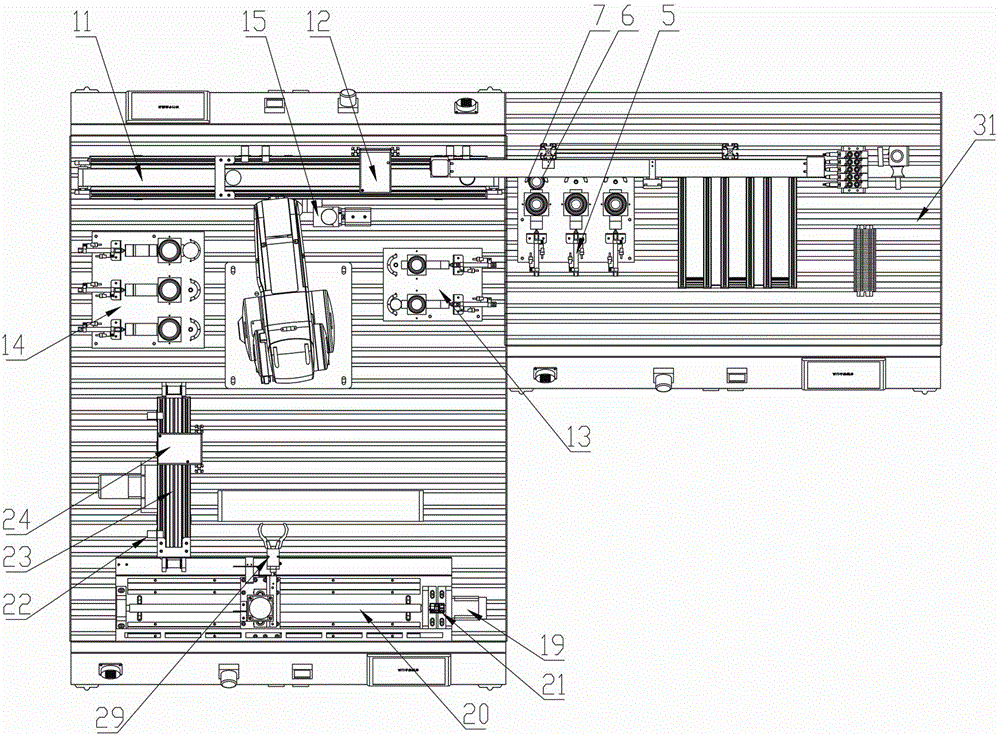

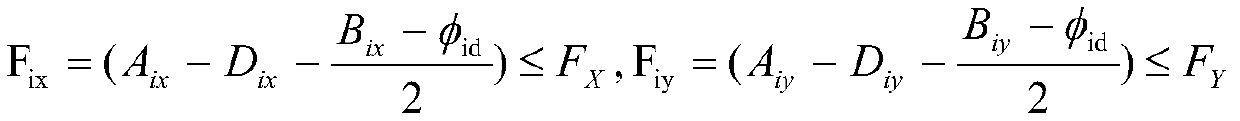

Micro intelligent factory experiment and research platform

PendingCN107145132ARealize intelligent warehousingRealize intelligenceElectric/hybrid propulsionTotal factory controlInterconnectivityProduction line

The invention belongs to the machine processing field and more particularly, to a micro intelligent factory experiment and research platform, comprising a production line system, a stereoscopic warehouse system, a sorting system, a manually assembling system, a transporting and dividing system, and an AGV material sending system. The micro intelligent factory experiment and research platform of the invention utilizes the industrial internet of things, the industrial service network and the intelligent-control-related technologies to make the platform intelligent and unattended by people. Compared with the traditional manufacturing mode, the platform allows for deeper and wider perceptions about the internet interconnectivity and more intelligence. The platform of the invention takes stamps, chesses, souvenirs and other handcrafts as its processing objects, and can realize the full processing and producing of work pieces including intelligent storage, intelligent manufacturing, intelligent detecting and intelligent assembly, making the platform more suitable for the manufacturing mode for the industrial 4.0 generation.

Owner:深圳市元创兴科技有限公司

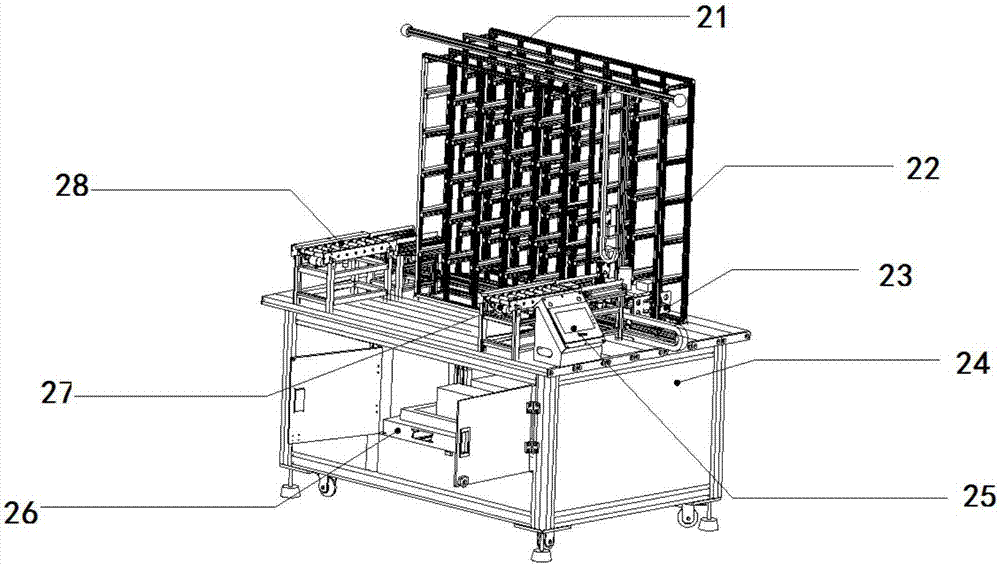

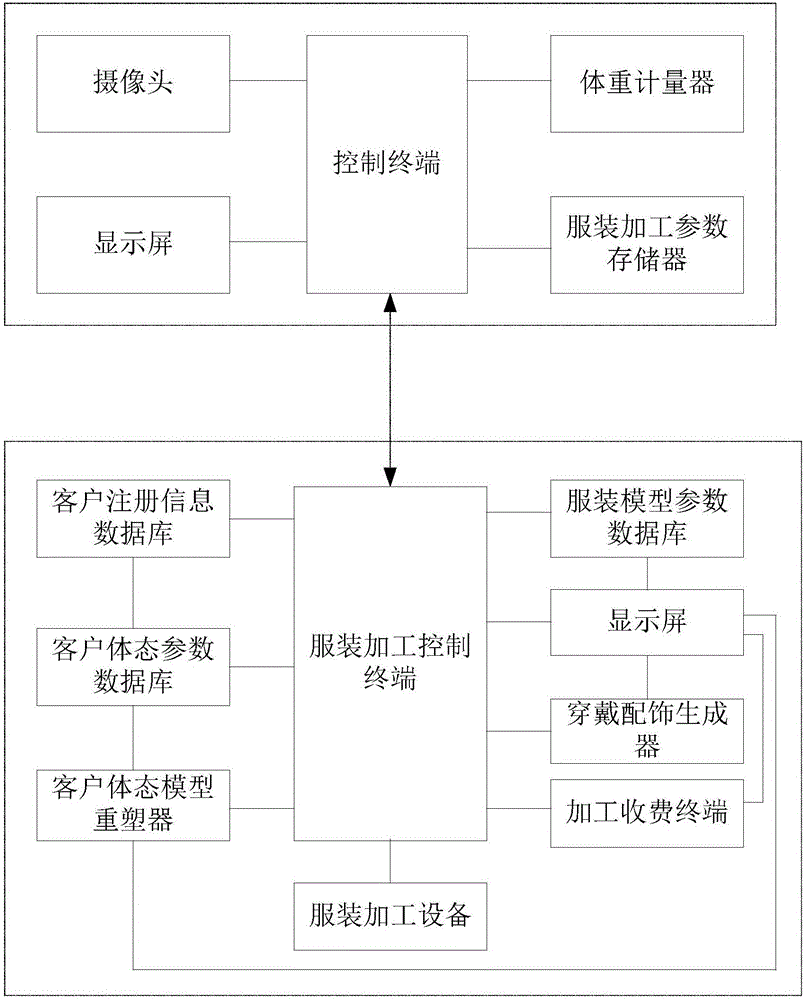

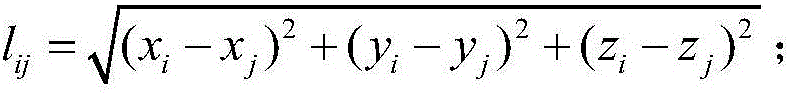

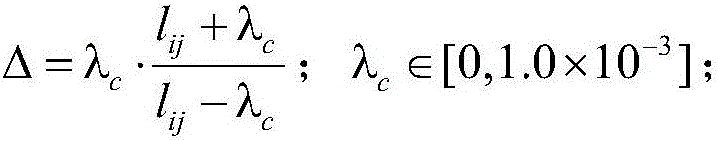

Individualized clothes intelligent processing method based on industry 4.0

ActiveCN106846124AEnhanced Stereoscopic RealismMeet the three-dimensional effect requirements for observing virtual clothing modelsDesign optimisation/simulationBuying/selling/leasing transactionsPersonalizationModel parameters

The invention relates to an individualized clothes intelligent processing method based on industry 4.0, wherein the individualized clothes intelligent processing method is used for an individualized clothes intelligent processing system which is composed of a client subsystem and a clothes factory subsystem. According to the individualized clothes intelligent processing method, through constructing a virtual clothes model and rebuilding a client body three-dimensional model, and performing loading, matching and fusion on the virtual clothes model and the client body three-dimensional model, the client body three-dimensional model which wears a target virtual clothes model is generated and displayed to a client. When the client satisfies the client body three-dimensional model which is displayed on a display screen, a clothes processing step is performed. Furthermore a clothes model parameter database in the clothes factory subsystem records the clothes parameter adjusting process of the client, thereby realizing designing according to the figure of a customer, and furthermore enabling the customer to participate in a clothes designing process and realizing individualized clothes processing for aiming at the customer.

Owner:NINGBO UNIV

Internet of things passive data acquisition system

InactiveCN105137891AHigh economic valueVersatilityProgramme controlComputer controlData acquisitionWater quality

The invention discloses an internet of things passive data acquisition system comprising data acquisition devices of front-end acquisition points and a data request module which is arranged at a cloud data center. The data acquisition devices comprise sensors which are used for acquiring data, a control panel which is used for controlling the sensors, and a communication module which is used for transmitting the acquired data. The data request module transmits requests to the target acquisition points so as to perform data transmission. The internet of things passive data acquisition system is high in social value, high in economic value, high in environmental value and convenient to use and is suitable for environment online monitoring, disaster prevention online monitoring and production online monitoring, such as water quality online monitoring, water level and rainfall online monitoring, factory environment hygiene online monitoring, real-time monitoring of an industrial 4.0 platform, an agricultural internet of things and vehicle and vessel transportation and intelligent household.

Owner:SUZHOU FUMI INFORMATION TECH CO LTD

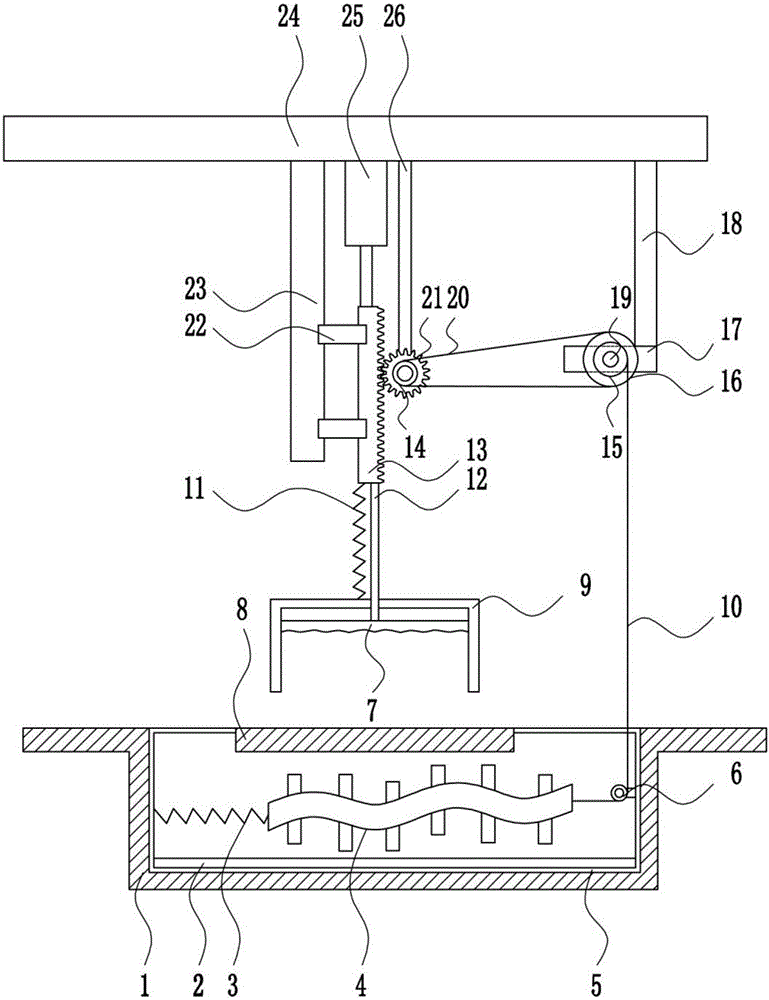

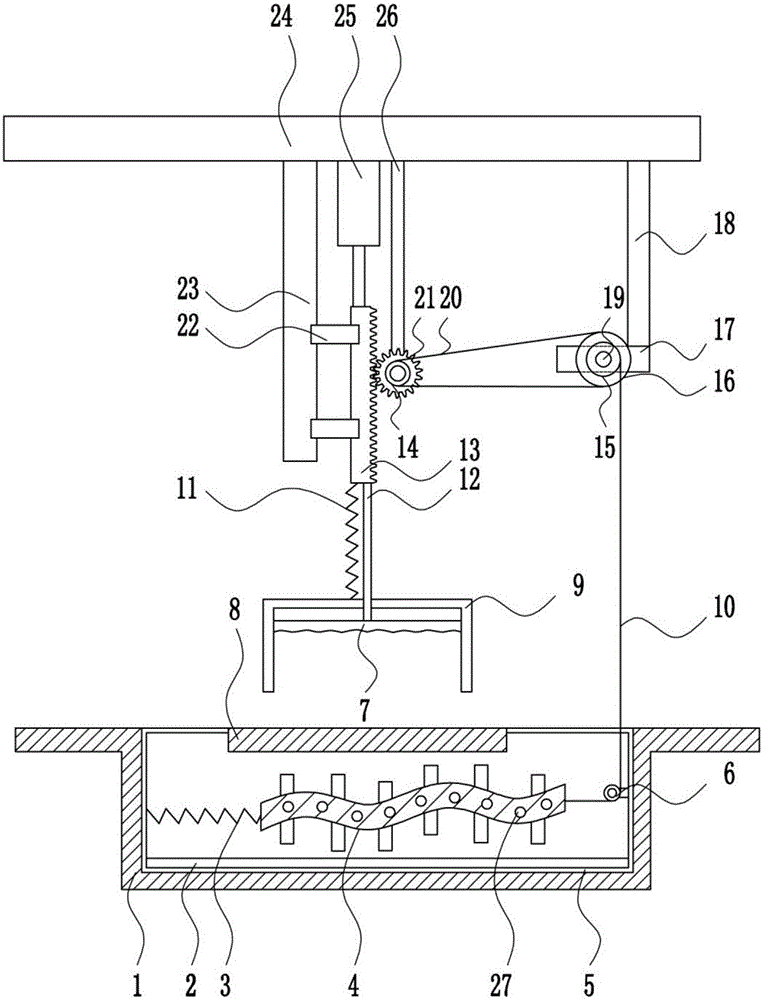

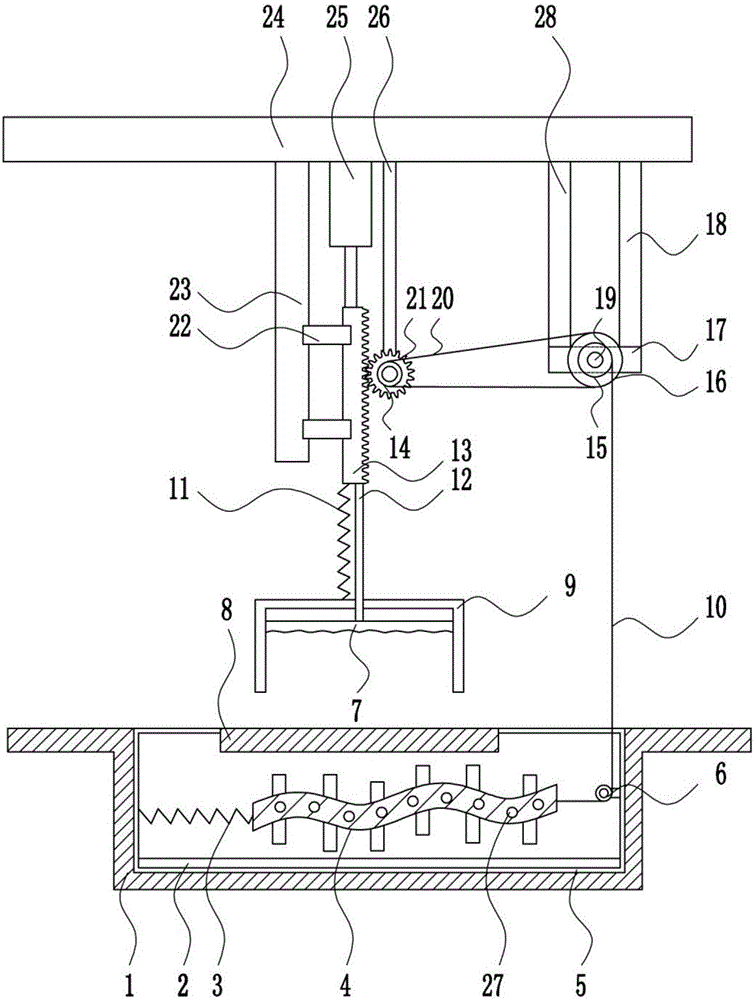

Molding device for mosaic tile manufacturing

ActiveCN106272901AImprove the heating effectGood up and down movementShaping press ramEngineeringConductor Coil

The invention relates to a molding device, in particular to a molding device for mosaic tile manufacturing. The molding device for mosaic tile manufacturing is high in manufacturing and molding efficiency. In order to achieve the above technical aim, the molding device for mosaic tile manufacturing comprises a base, a heating plate, a first elastic piece, a heat homogenizing plate, a hot water box, a pulley, a pressing plate, a heat conductive plate, a die, a pull rope, a second elastic piece, a connecting rod, a rack, a small belt wheel, a winding wheel, a large belt wheel, a bearing pedestal, a first fulcrum bar, a rotating shaft, a flat belt, a gear, a sliding block, a sliding rail, a jacking plate, an air cylinder and a second fulcrum bar; and the hot water box is placed in the base. The molding device has the beneficial effects that the manufacturing and molding efficiency can be improved, operation is simple, the service life of the device is long, certain resources can be saved, industrial automation is conveniently achieved, and early reaching of industry 4.0 in China is facilitated.

Owner:福建省春秋陶瓷实业有限公司

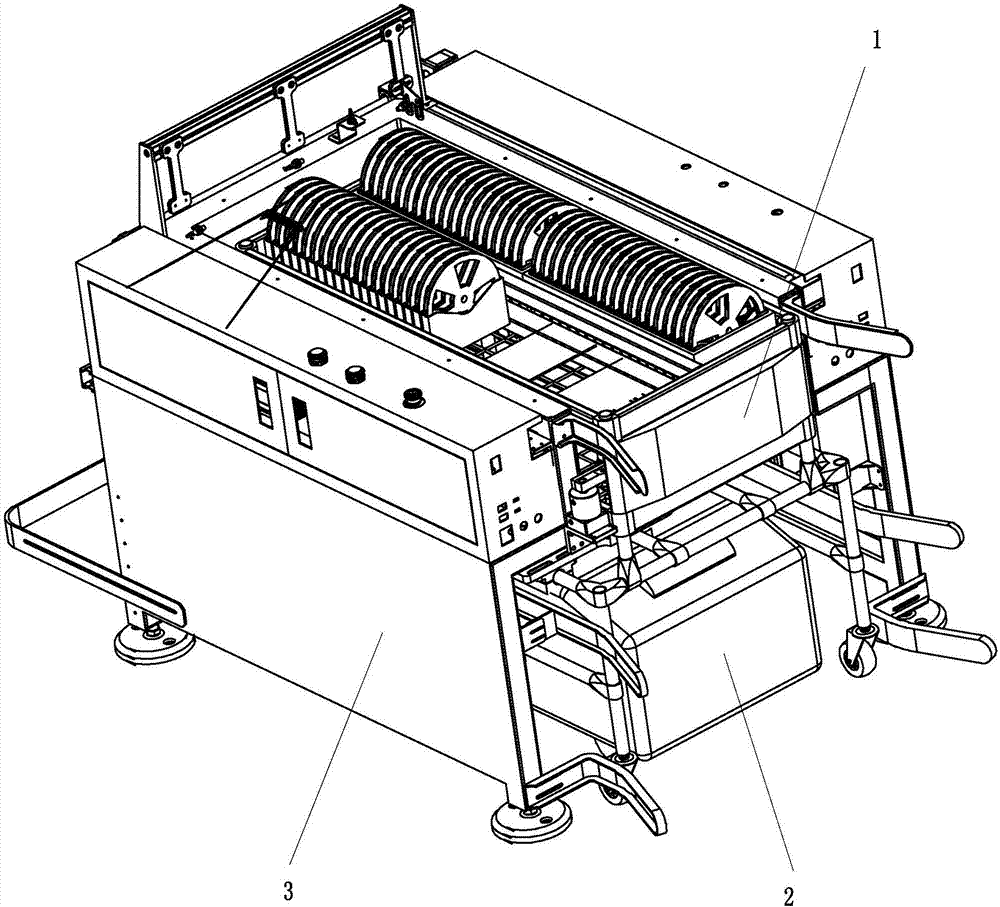

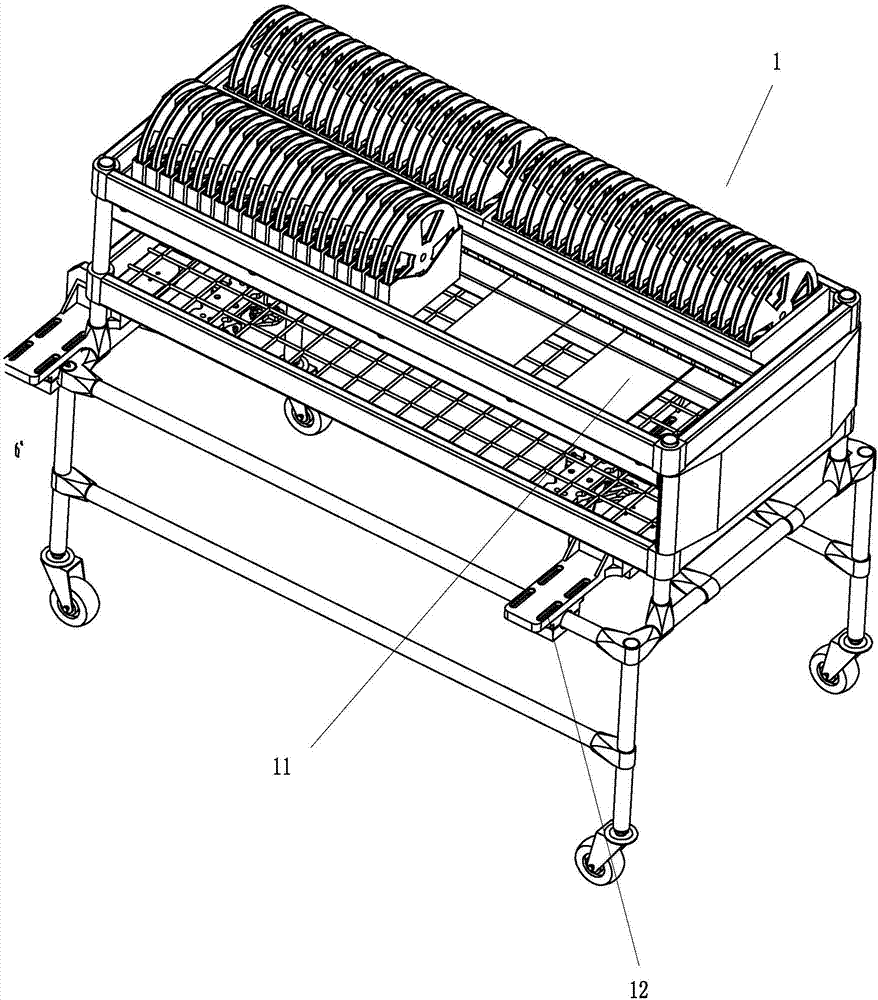

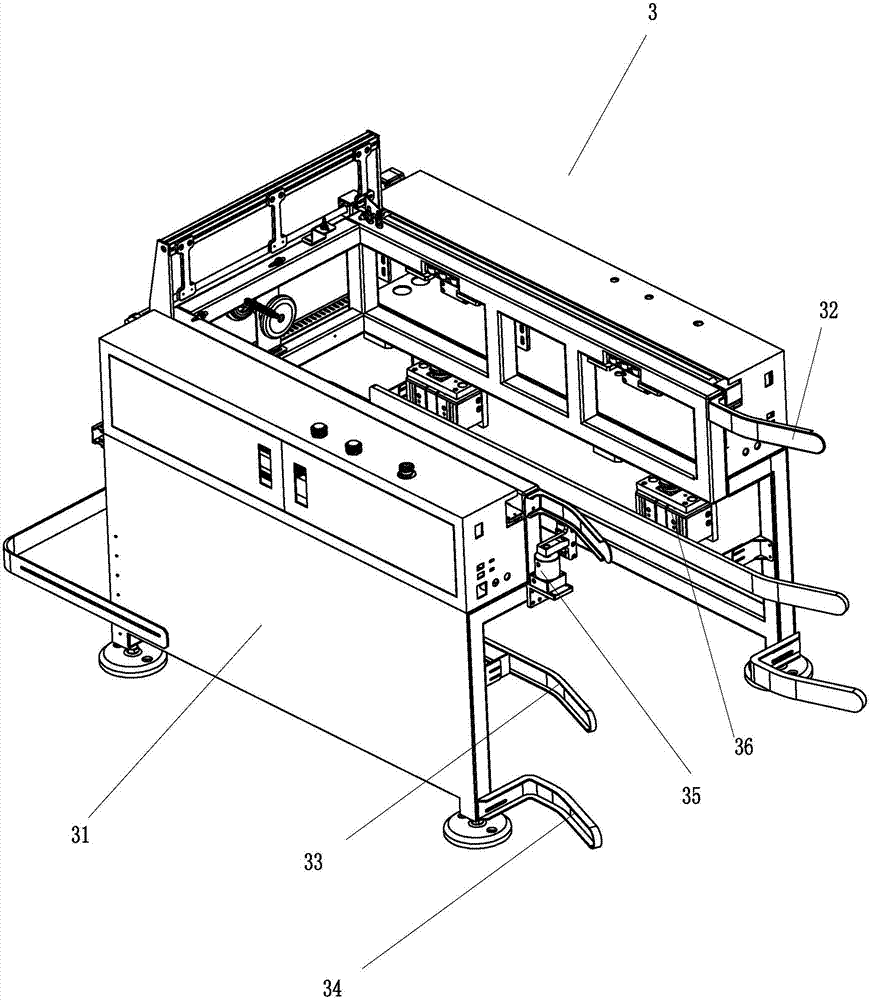

Belt cleaning dedusting machine set

The invention provides a belt cleaning dedusting machine set, and belongs to the field of dedusting cleaning equipment. The belt cleaning dedusting machine set comprises a head pulley cleaning assembly, a discharging trolley cleaning machine set, a tail pulley cleaning assembly and a smart control system, wherein the head pulley cleaning assembly, the discharging trolley cleaning machine set and the tail pulley cleaning assembly are connected with the smart control system. A modular design is adopted by the belt cleaning dedusting machine set, so that the working environment can be cleaned, and the service lives of a field detection element and an electronic element are prolonged; the friction among a material-transporting belt and head-tail pulleys, a pulling wheel, a tensioning wheel, a compressing wheel, a supporting roller and the like is reduced; the service lives of the components are at least prolonged by 3 times; a full automatic system is adopted, so that industrial 4.0-level unattended operation is realized, the running cost of an enterprise is lowered greatly, and the working environment of enterprise staff is improved. The configurations of equipment can be added and reduced according to field conditions, and the aim of cleaning is fulfilled according to the dust concentration.

Owner:江苏晟菲环境科技有限公司

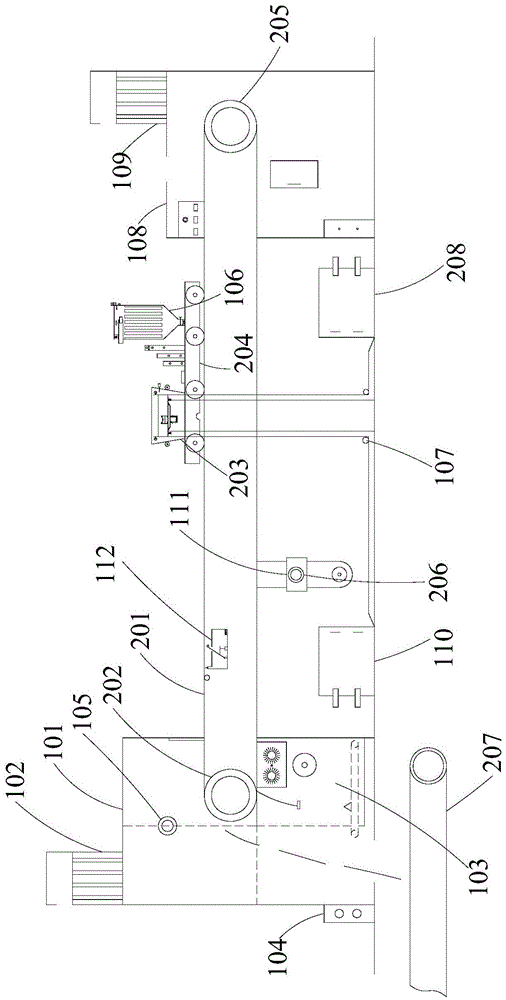

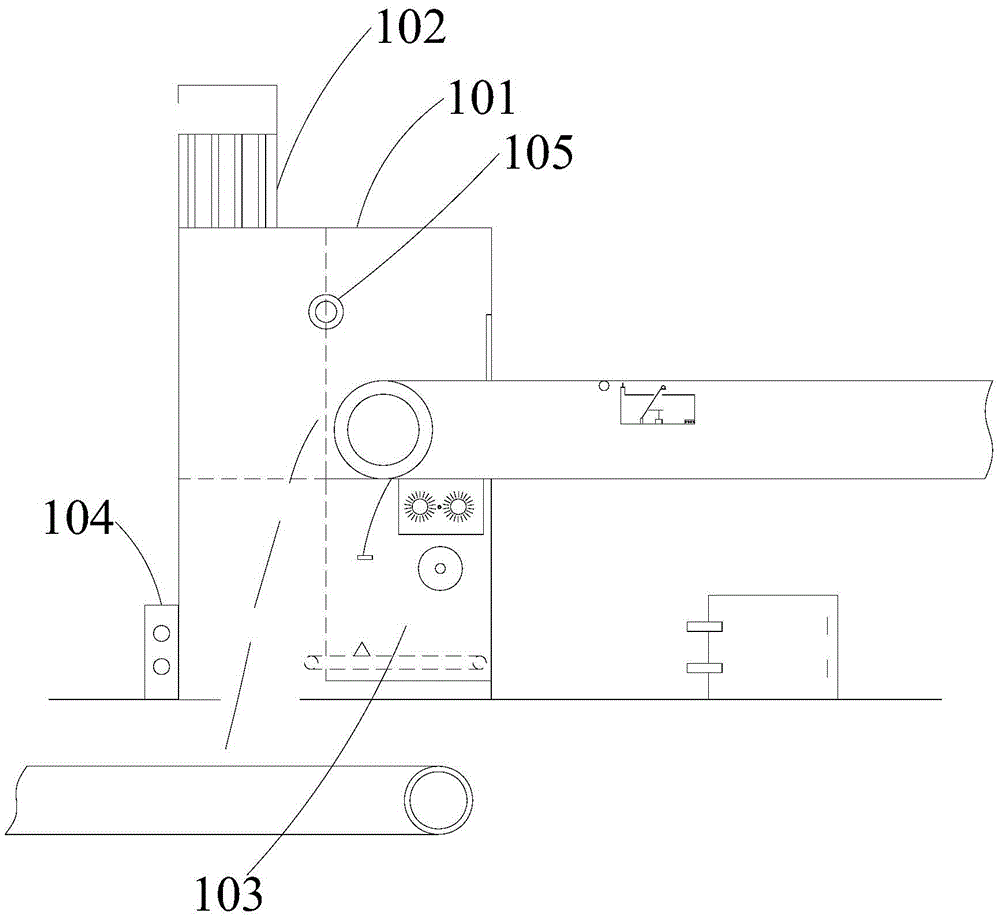

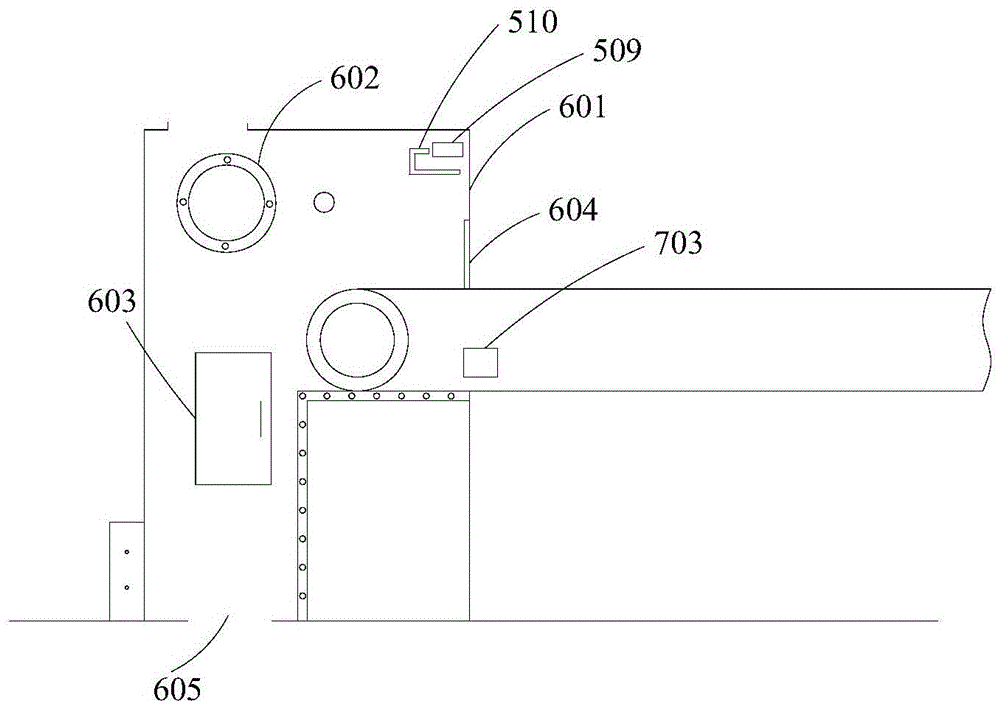

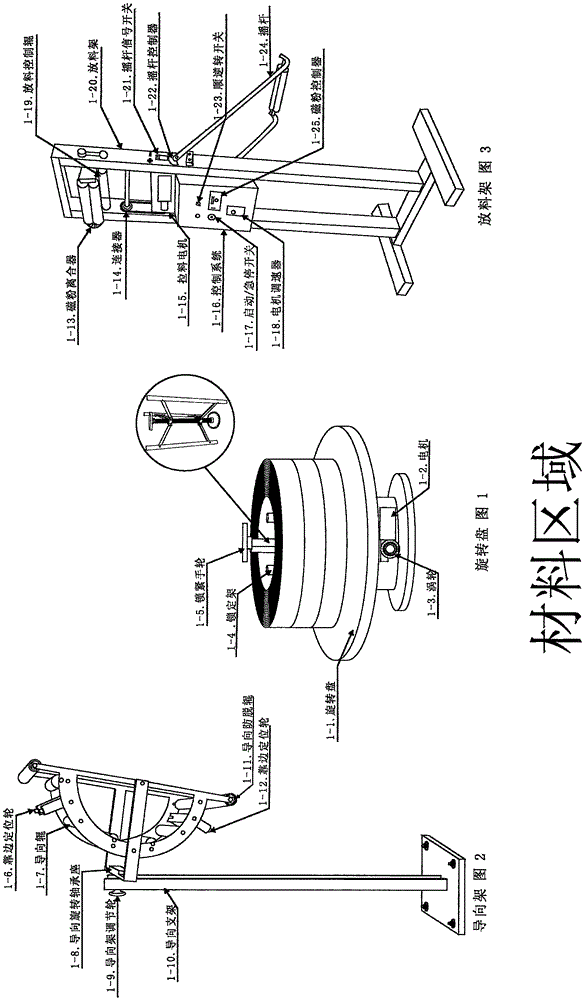

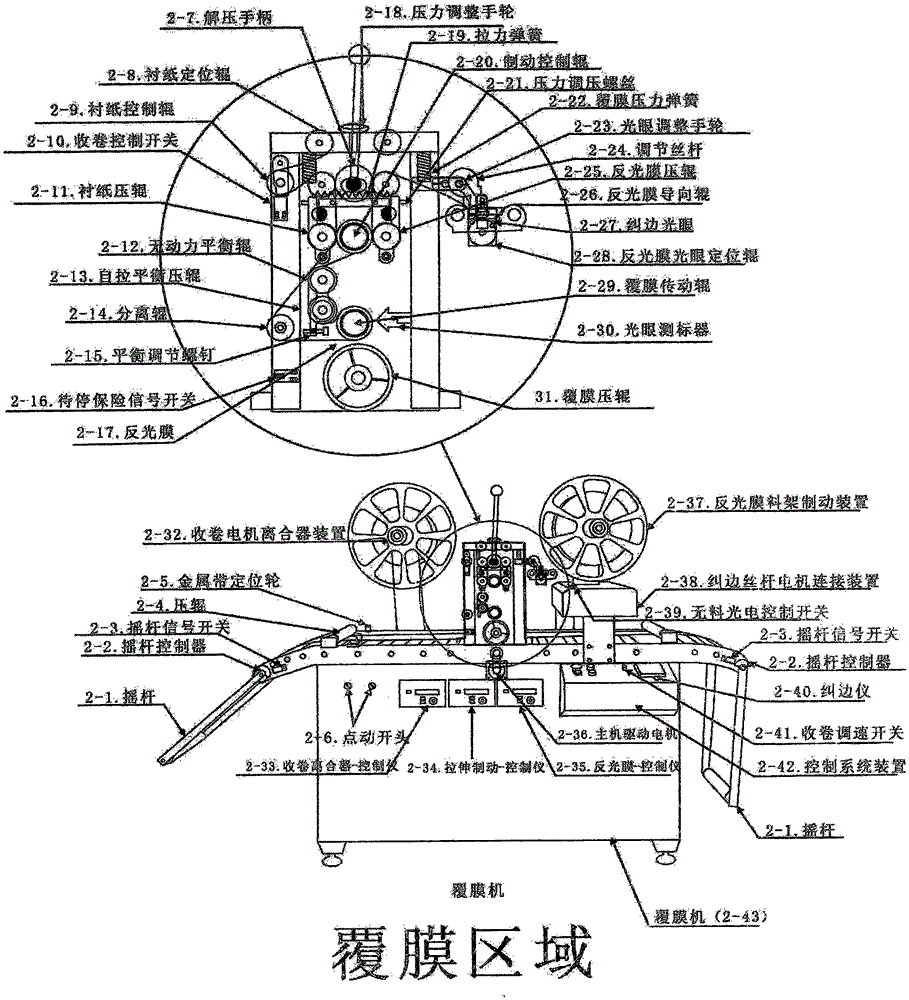

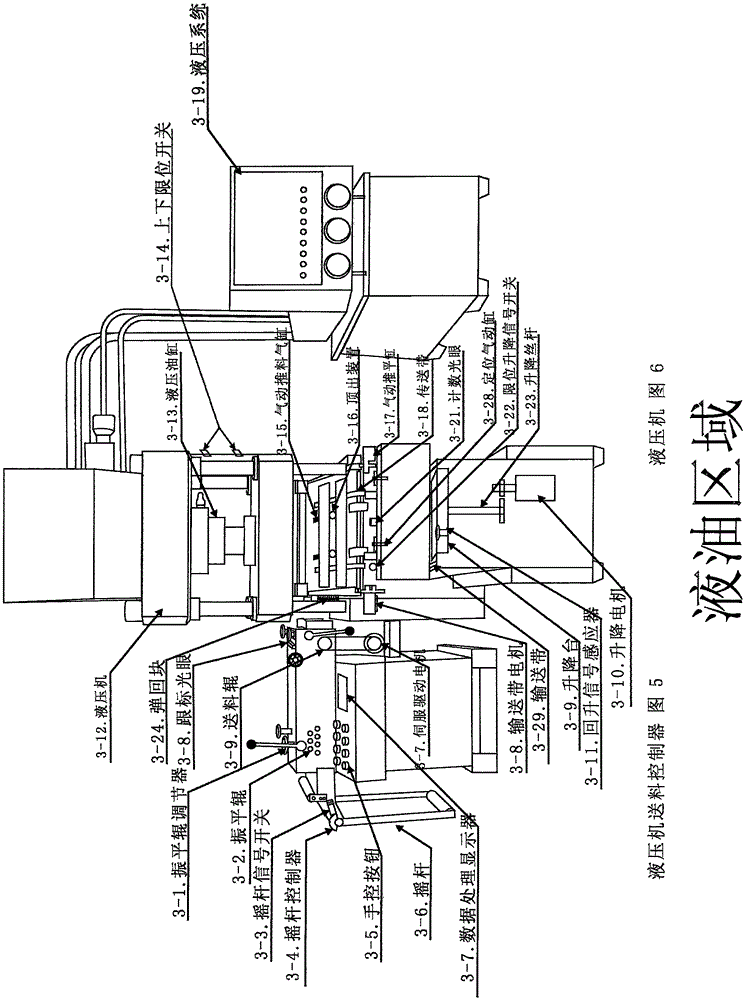

Full-automatic license plate production line

ActiveCN105562513ASolve the problem of easy stretching and deformationControl stretchLamination ancillary operationsMetal-working feeding devicesProduction linePunching

The invention discloses a full-automatic license plate production line. The structure of the full-automatic license plate production line consists of a guide rack, a rotating plate, a discharging rack, a laminating machine, a hydraulic machine feeding controller and a hydraulic machine. The full-automatic license plate production line is characterized in that according to the scheme of the production line, manual operation can be replaced completely, materials are conveyed automatically, edge correction alignment is carried out to control stretching deformation of a reflecting film, conveying and punching are implemented to shape products, superposition counting is carried out to implement automatic production and stopping, so that production efficiency and production safety are greatly improved, the productive force is emancipated, and cost is reduced. The production line is intelligent and optimized in structure and convenient to produce, aims to fill up domestic market vacancy on automatic license plate production lines, and improves production innovation power and product competitiveness of the license plate production industry in the international industry 4.0 tide.

Owner:傅化旺

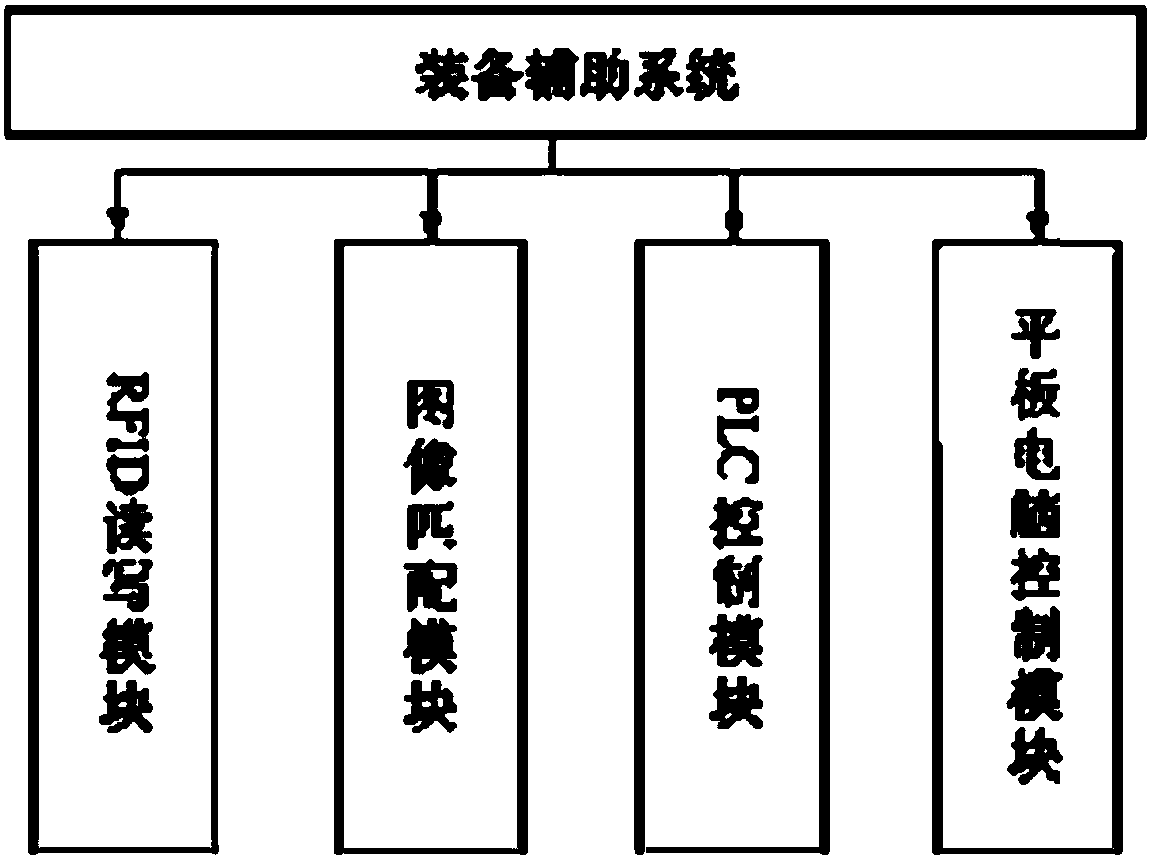

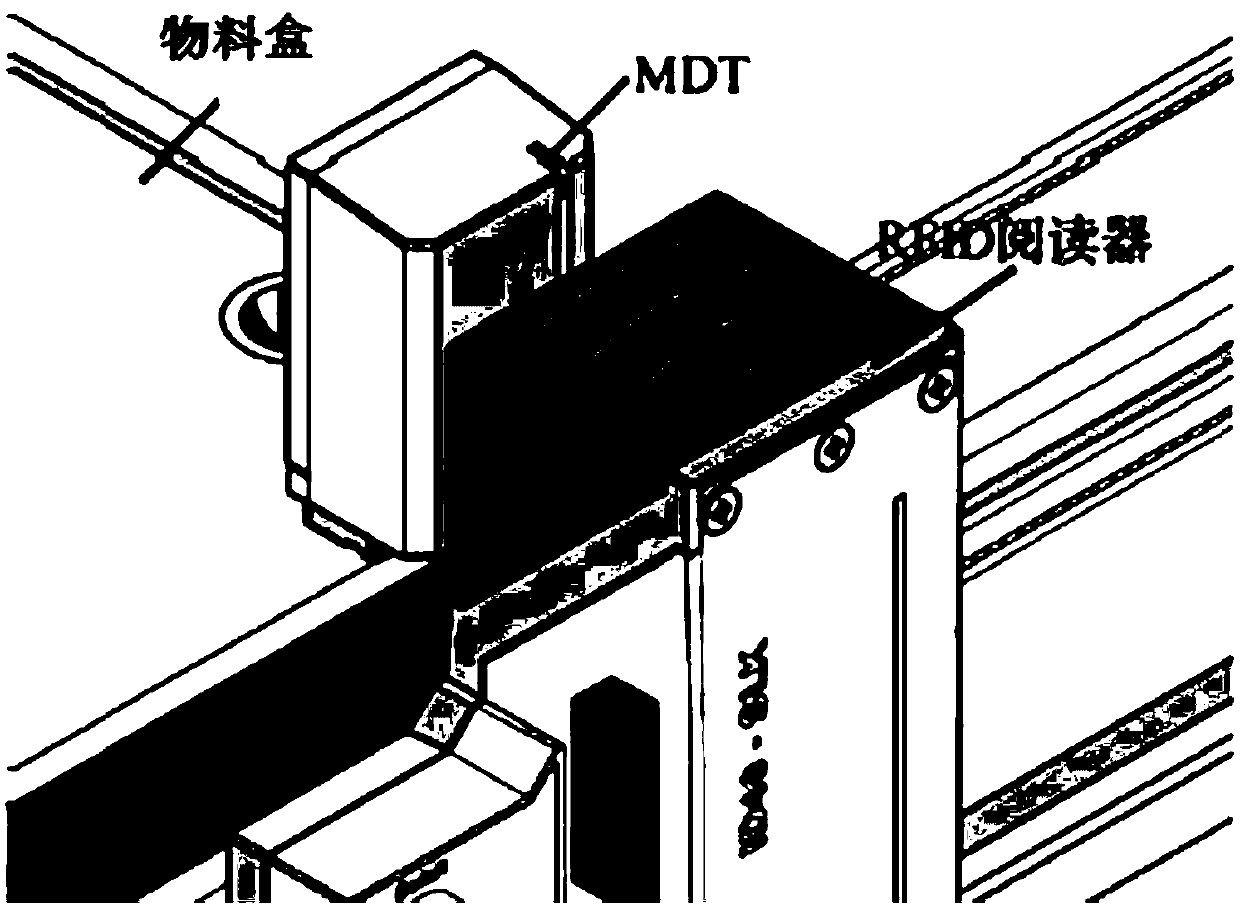

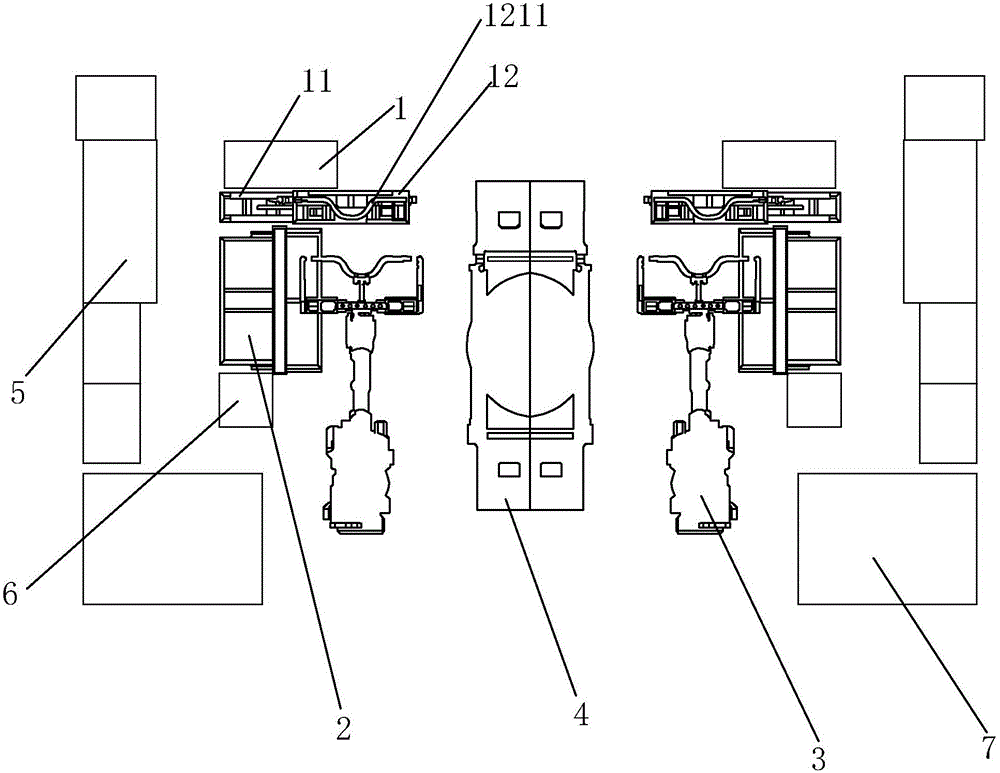

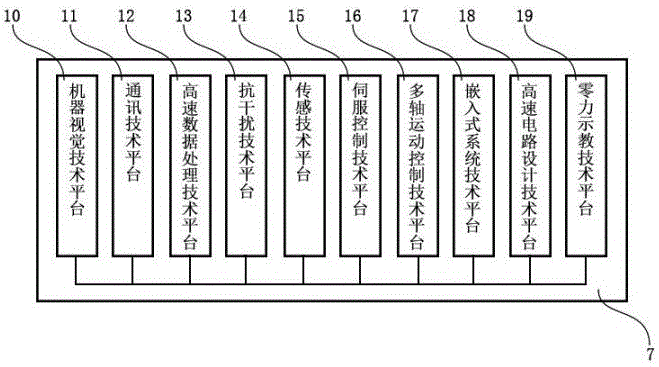

Intelligent assembly system based on industrial 4.0 technology platform

InactiveCN107891257AHigh degree of intelligenceImprove delivery efficiencyAssembly machinesMetal working apparatusPart typeComputer module

The invention relates to an intelligent assembly system based on an industrial 4.0 technology platform. The intelligent assembly system based on the industrial 4.0 technology platform comprises a partassembly point and a part conveying equipment, and further comprises part identifying modules arranged on the part assembly point and the part conveying equipment for identifying the part type and number, and an image matching module arranged on the part assembly point for detecting if assembly results of parts are correct. Compared with the prior art, as the part identifying module identifies the part type, the identifying task in the intelligent industry is realized; and meanwhile, as the image matching module realizes the assembly checking, the whole assembly intelligence degree is improved.

Owner:TONGJI UNIV

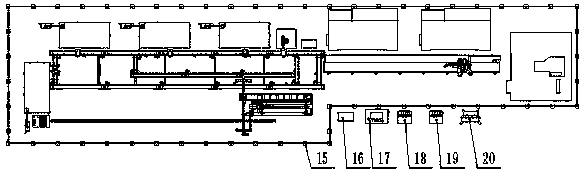

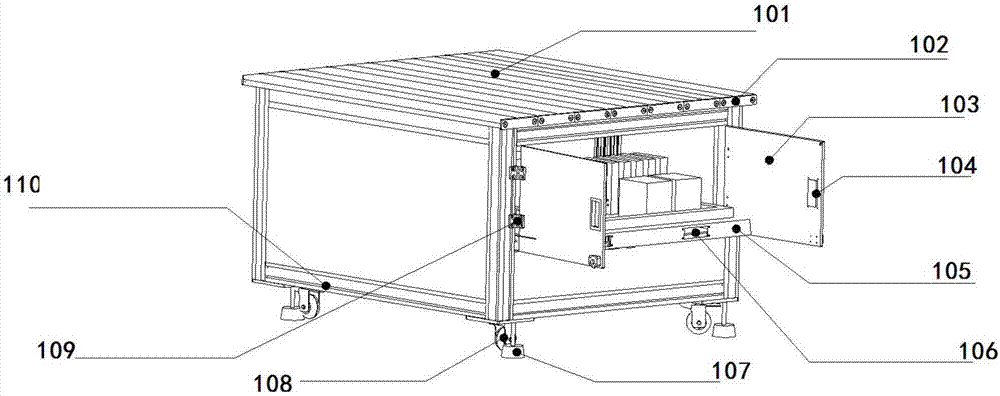

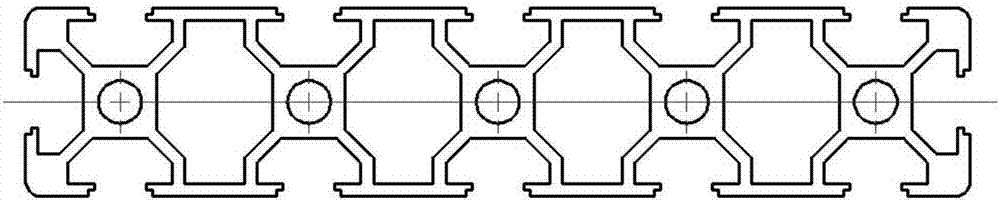

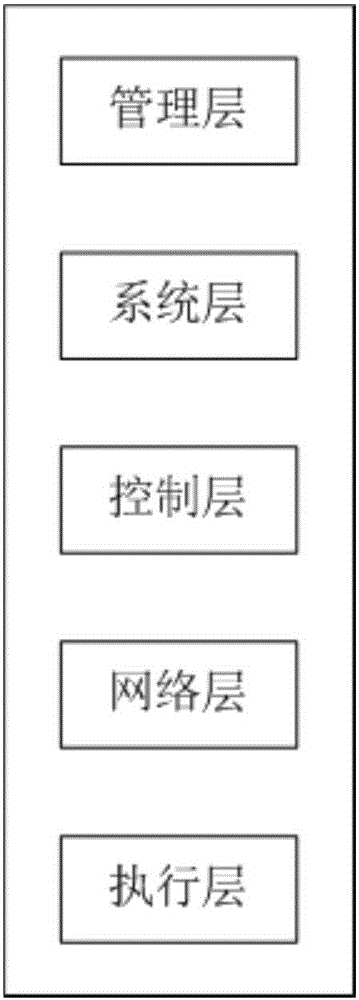

Linear type industrial 4.0 training system

PendingCN106774211ARealize multi-batch and small-batch productionTotal factory controlProgramme total factory controlProduction lineControl layer

The invention discloses a linear type industrial 4.0 training system. The system comprises a management layer, a system layer, a control layer, a network layer and an execution layer. The training system equipment can independently select raw materials according to requirements of clients for processing, detection, assembly, transportation and the like and automatically selects different technologies according to different products in the processing and assembly process, the advanced manufacturing concept is embodied, and a production line becomes intelligent. Multi-batch and small-batch production can be realized.

Owner:陕西维视数字图像技术有限公司

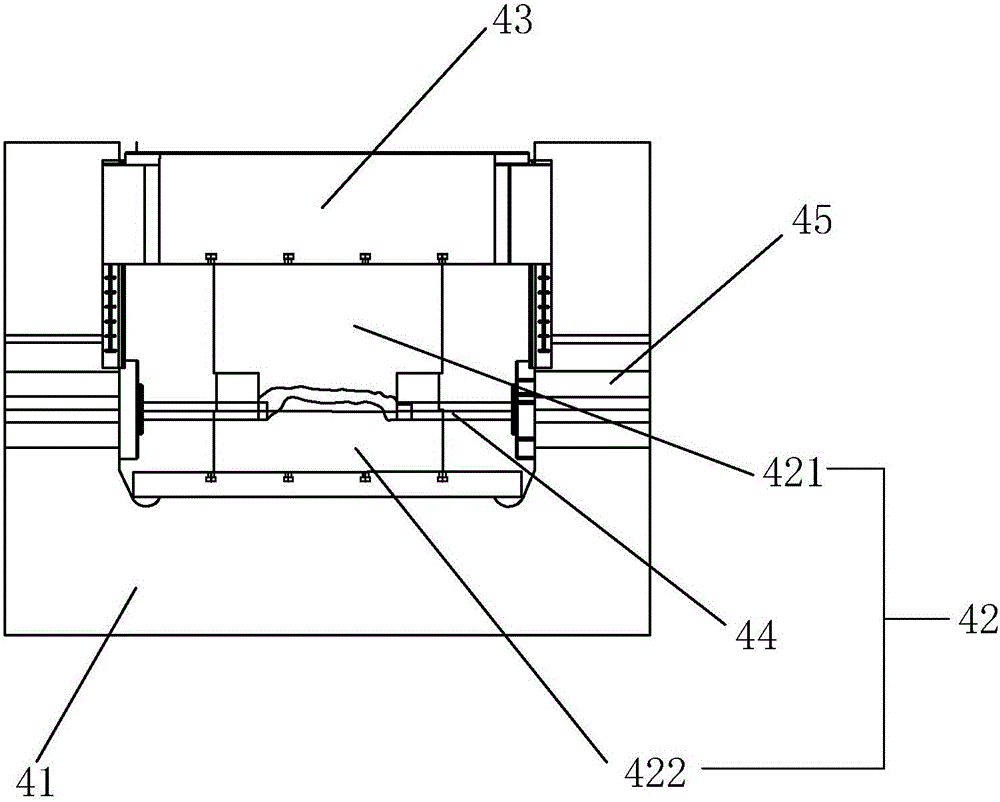

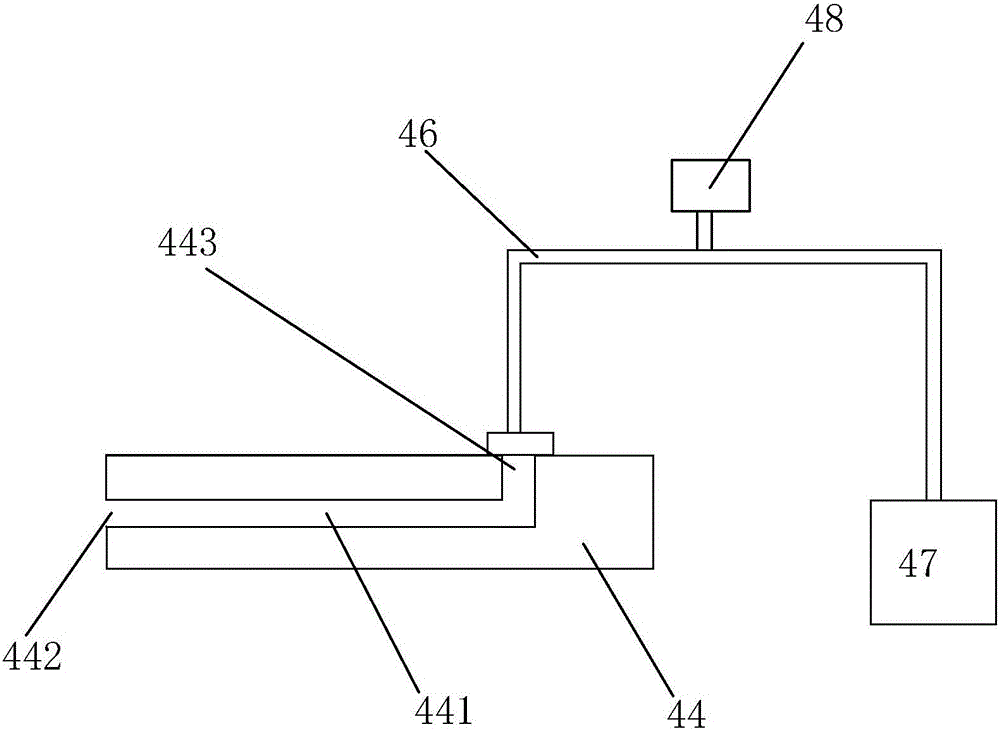

Internal high-pressure forming production line for pipes in intelligent factory

InactiveCN105107923AImprove work efficiencyShorten production timeMetal working apparatusProduction lineAlarm message

The invention discloses an internal high-pressure forming production line for pipes in an intelligent factory. The internal high-pressure forming production line for the pipes in the intelligent factory accords with assumption of intelligent factories in 'industry 4.0'. All processes of the whole production line can be deployed by a numerical production control system, and all signals are controlled through sensors; different alarm messages can be emitted for failures of any single machine in the production line, and workers can perform repair and adjustment in the first time; besides, an automatic detection mechanism is arranged on a feeding mechanism to detect whether the shapes and the lengths of the pipes accord with forming molds, detection results can be transmitted to internal high-pressure forming equipment automatically, initial positions of machining of the pipes of different lengths are set automatically, and accordingly the work efficiency is greatly improved; finally, at least two molds are arranged on an internal high-pressure forming machine so that multiple pipes can be machined at the same time, the work efficiency is improved, and the total production time can be shortened exponentially during the production of large-batch pipes.

Owner:ZHEJIANG MOTORBACS TECH

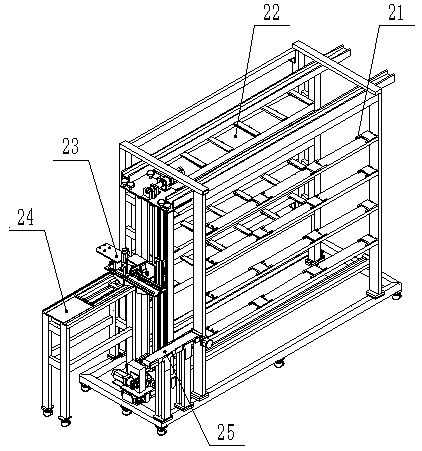

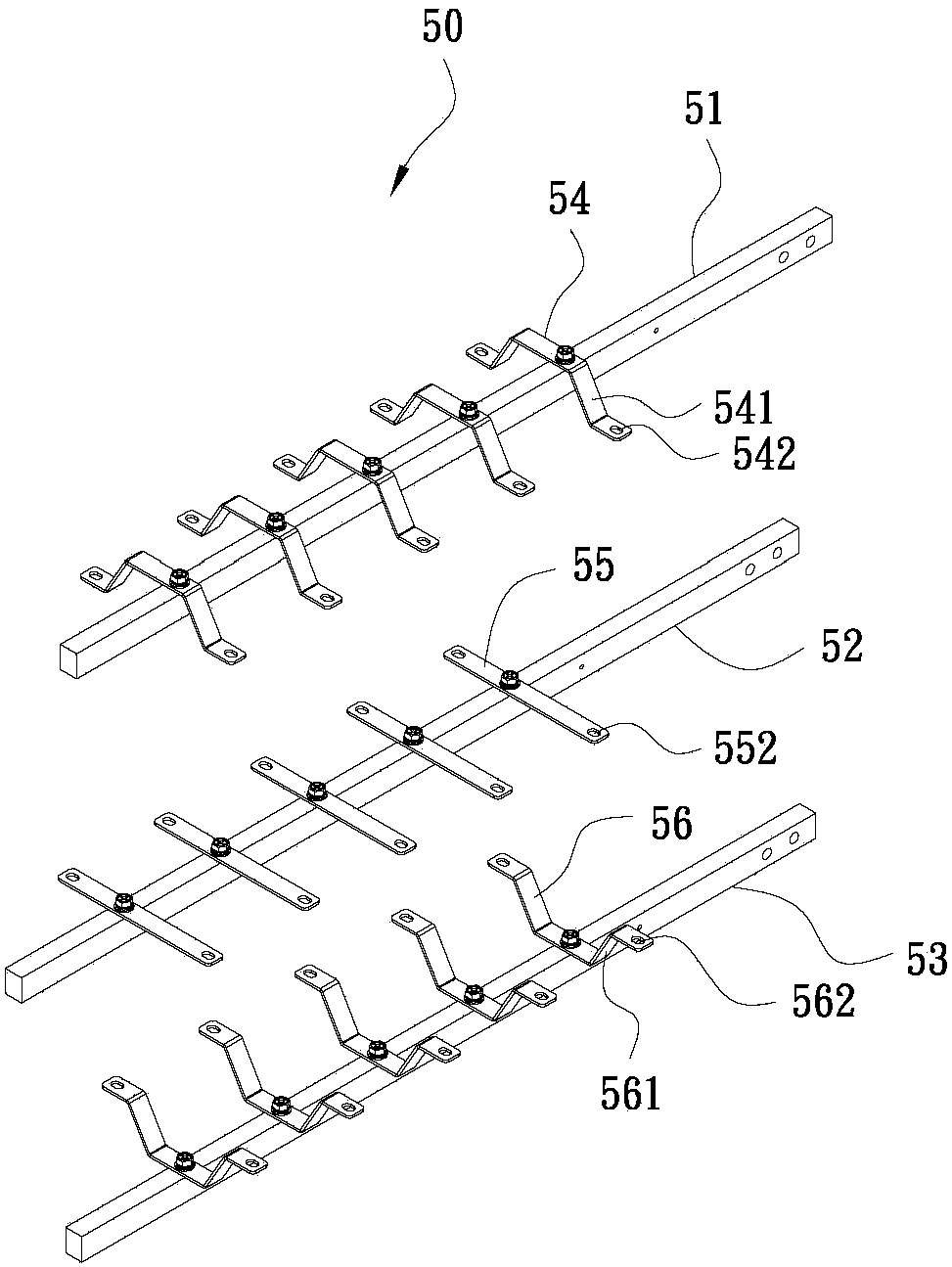

Intelligent bin tray transfer system and method thereof

The invention discloses an intelligent bin tray transfer system. The intelligent bin tray transfer system comprises a control mechanism, a transfer mechanism, a transportation mechanism, an emptying mechanism and a positioning mechanism. A method comprises the following steps: (S1) the transportation mechanism drives the transfer mechanism to enter the positioning mechanism; (S2) the transportation mechanism leaves away; (S3) the transfer mechanism is ascended; (S4) the transfer mechanism is centered and positioned; (S5) materials are emptied; (S6) the transportation mechanism enters the positioning mechanism, and is connected with the transfer mechanism; (S7) the transfer mechanism is descended; (S8) the transportation mechanism drives the transfer mechanism to leave from the positioningmechanism; and (S9) the step (S1) is returned to for renewed actuation. The Intelligent bin tray transfer system and the method thereof achieve full-automatic tray transfer and circulating operation,realize unmanned workshop and precise transportation, increase the tray conveying quantity, prominently improve the production efficiency, reduce the production cost, reduce the labor intensity of operators, meet industrial 4.0 demands, accelerate optimal upgrading of industrial structures, and achieve excellent market popularization value.

Owner:福建宏泰智能工业互联网有限公司

Platform integrating robot general technology education, experiments, and scientific researches

InactiveCN105701745APerfect technologyComprehensive and in-depth technologyData processing applicationsSimulationNetwork management

Provided is a platform integrating robot general technology education, experiments, and scientific researches. The platform comprises a plurality of experiment kit groups, a network management system, and course data. Each experiment kit group is composed of a plurality of child platform. Each child platform focuses on displaying, educating, experimenting, and researching one robot general technology. The network management system at least comprises six subsystems including a user system, an experiment kit management system, an order system, a plan system, a course system, and a borrowing and returning system. The course data comprises experiment kit course data, network management system course data, and platform using example course data. The platform prevents a complicated robot representation form, focuses on the essence of robot development, comprehensively teaches robot technology, performs intelligent manufacturing experience teaching by the network management system, contributes to fast nurturing robot technical research and technical application talents with comprehensive technology and industrial 4.0 concepts.

Owner:FOSHAN XINHENGCUI MATERIAL TECH CO LTD

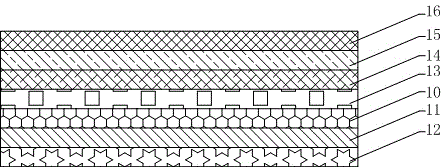

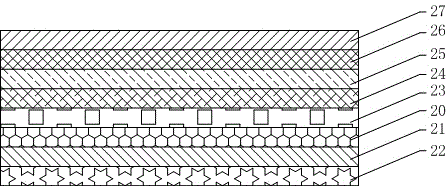

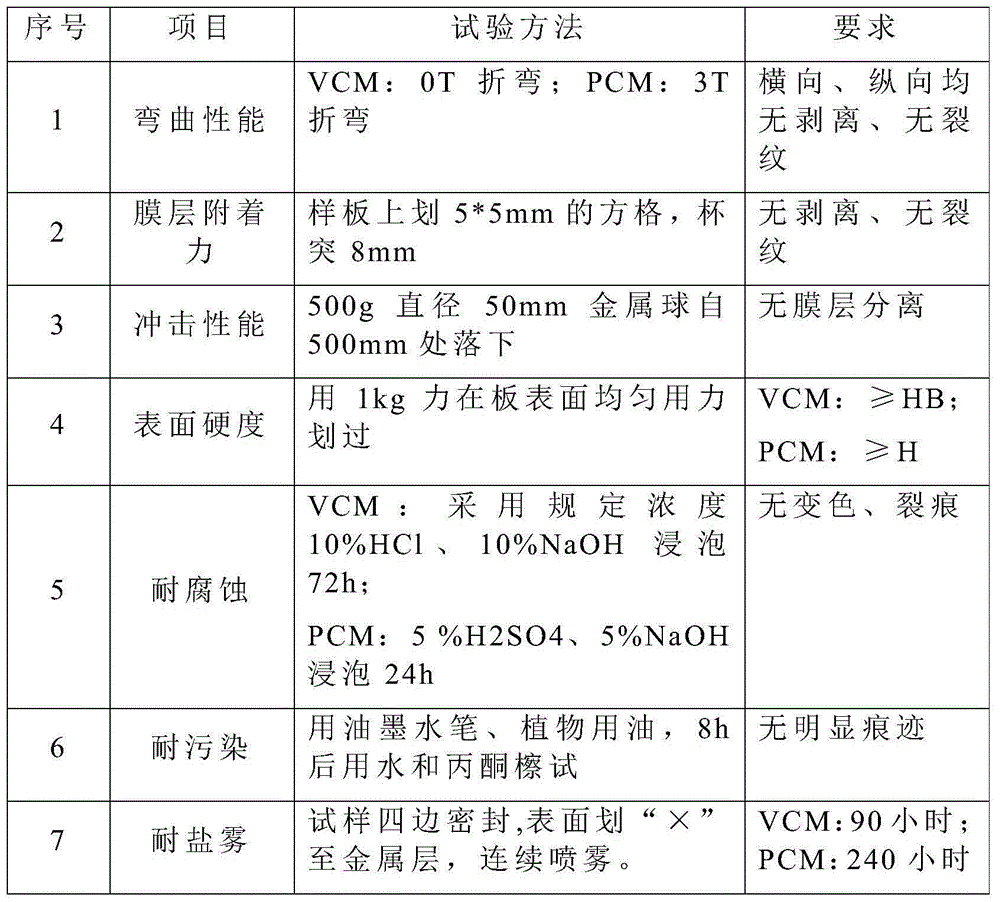

Individualized pattern customized steel plate for household appliance and preparation method thereof

InactiveCN106183598AHigh coloring rateMeet the requirementsSpecial ornamental structuresOther printing apparatusPaymentPersonalization

The invention provides an individualized pattern customized steel plate for a household appliance. The steel plate comprises a base plate body which is made of a household appliance white precoated steel plate or a household appliance color laminated steel plate pasted and covered with a white group color film. The invention further provides a manufacturing method for the steel plate. The technological process comprises the steps of 1, base plate unwinding; 2, pretreatment; 3, back paint coating; 4, front film covering and priming paint or finish paint coating; 5, winding and cutting; 6, printing ink penetration treatment; and 7, protective film covering. By means of the manufacturing method for the steel plate, any patterns favored by a user can be printed on a household appliance plate in a short time, and real individualization is achieved; the degree of dyeing of the steel plate is high, the patterns are clear, the performance is good, and the household appliance using requirements are met; the various individualized requirements of terminal users are fully considered and met, coming of the industrial 4.0 time is welcomed, and the quick and efficient effect is achieved; machining is easy, sample preparation is efficient, the situation that only one to two weeks need to be taken from on-line payment to delivery is achieved, and the period from user customization, ordering to arrival of goods is greatly shortened.

Owner:青岛河钢复合新材料科技有限公司 +1

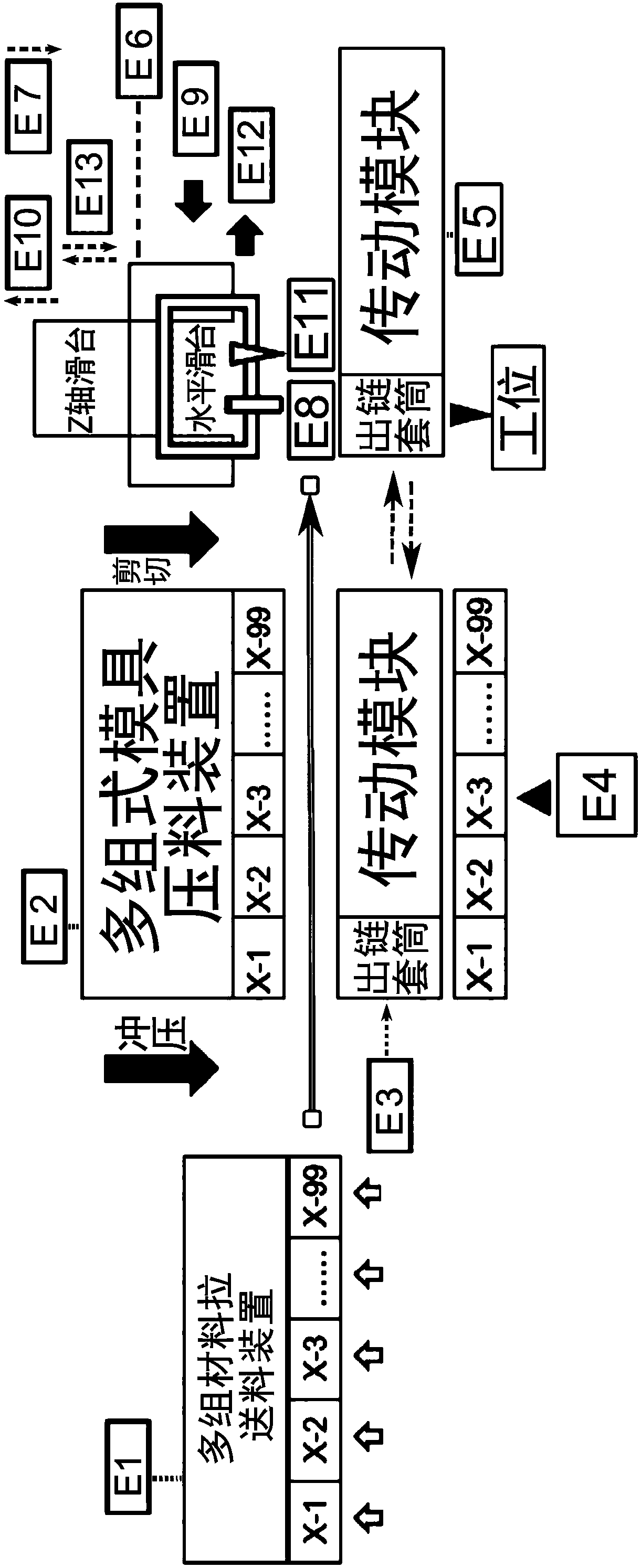

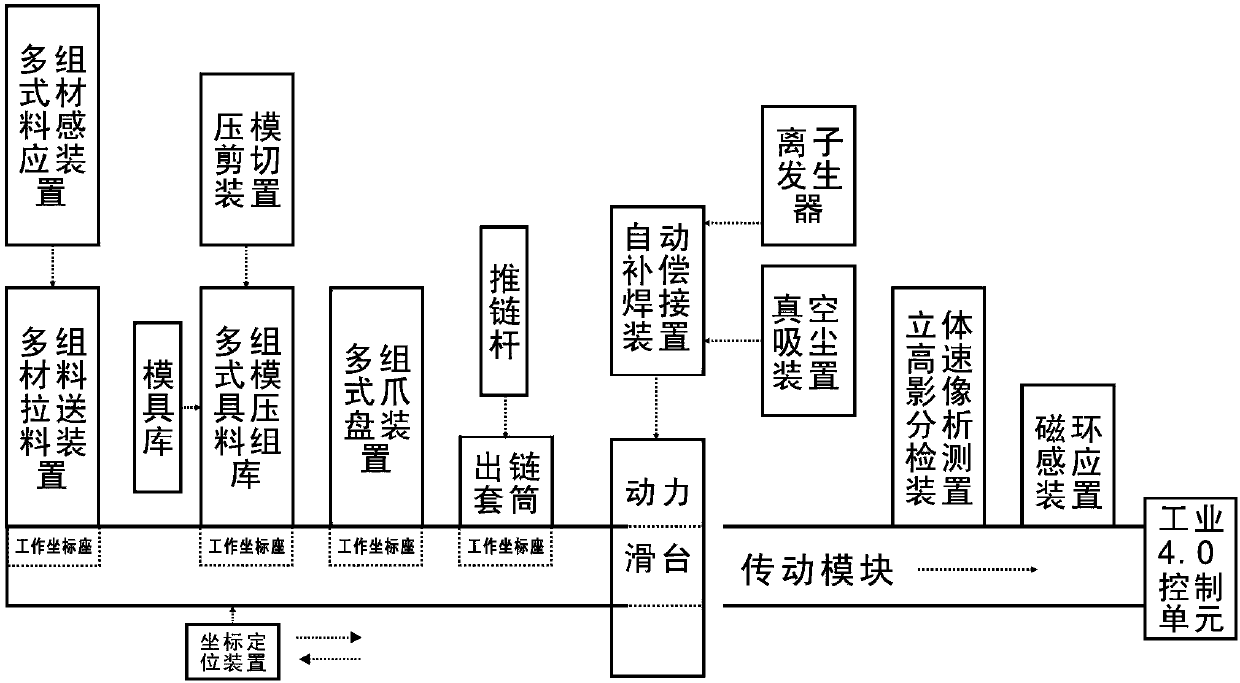

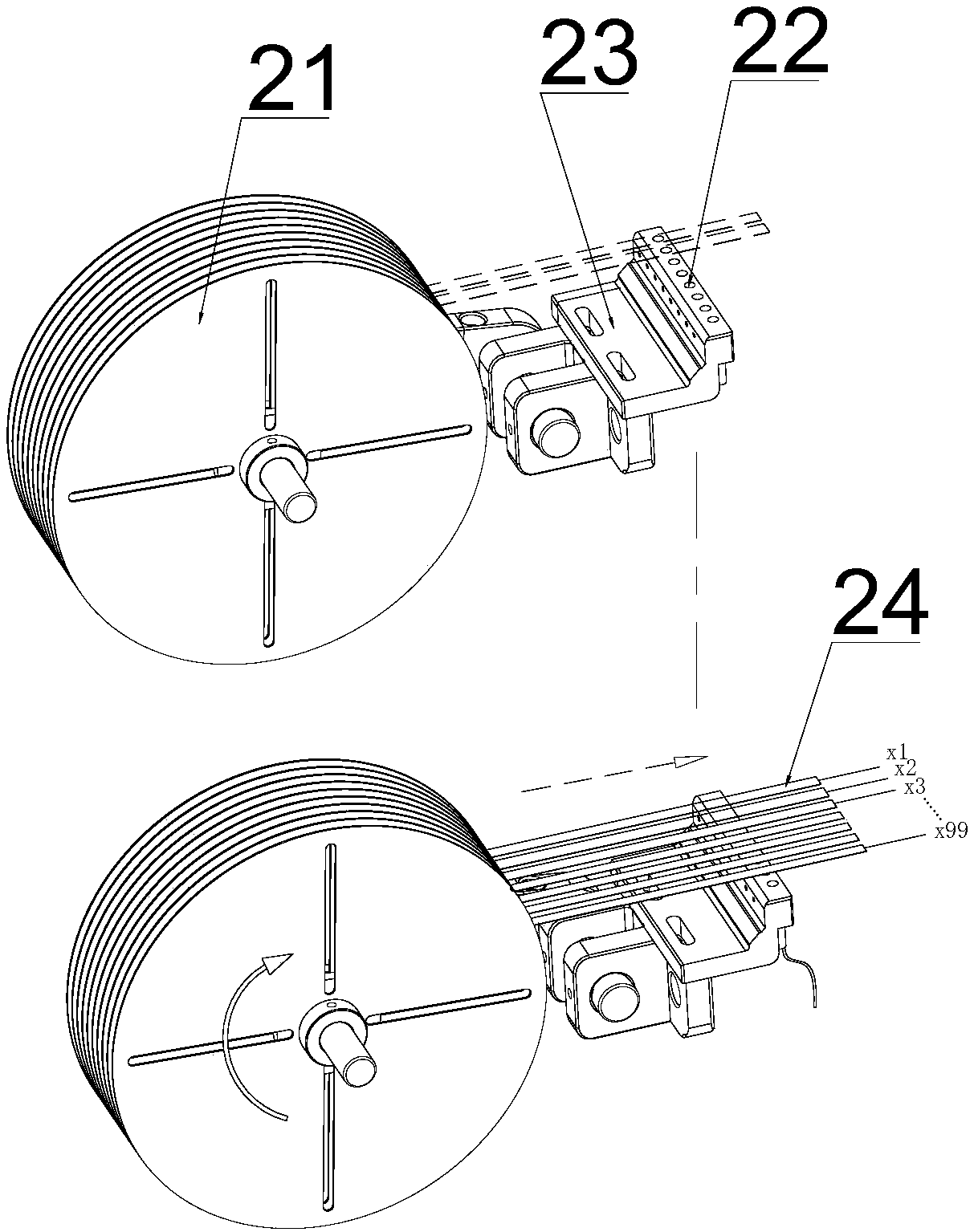

Manufacturing device and manufacturing method of numerically controlled arbitrary-paired chain

ActiveCN107942952AOmit unstable factorsChange the internal and external structureNumerical controlComputer modulePairing

The invention relates to a manufacturing device and manufacturing method of a numerically controlled arbitrary-paired chain, so that the standard procedures of the chain post-processing process are met and the fashionable design of random pattern and color pairing is realized, and the perfect appearance and personalized cultural connotation are built. The manufacturing device comprises a machine bench; a transmission module is installed on the machine bench; a plurality of working coordinate seats are installed on the transmission module; coordinate positioning devices capable of identifying the working coordinate seats correspondingly are arranged on the transmission module; and the transmission module is connected with multiple groups of material transport devices, a multi-group die pressing device, a multi-group claw device, an out-of-chain sleeve device, and an industrial 4.0 control unit and the like. According to the invention, when the manufacturing device and manufacturing method are applied to one chain link, more than one different design, different patterns, different colors, and different matched pairs can be made; and stories needing to be expressed can be expressed onone chain by different markets and different cultures.

Owner:郑海宁

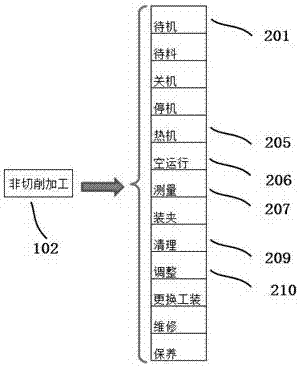

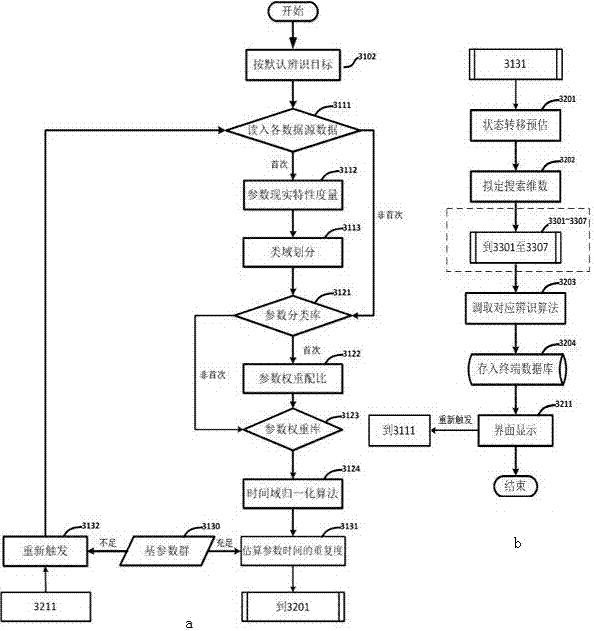

Machine manufacture device cutting state identification and data processing method

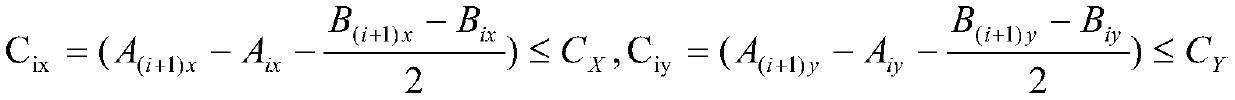

The application discloses an overall solution for machine manufacture device cutting state identification and a normalization processing method for on-site real time data so as to distinguish a cutting processing state and a non-cutting processing state. According to the method, a machine manufacture device state identification object-oriented refinement system is given, and a complete identification solution flow is given with an aim to identify cutting processing and non-cutting processing states; based on the refinement system and the solution flow, a complete data source is built, all data is subjected to standardization preprocessing of a unified form, and data that is collected and gathered in real time on site is classified into a base parameter group and a non-base parameter group according to technology system characteristics. According to the method, adjusting rules are respectively given for the base parameter group and the non-base parameter group; additionally, a data interpolation method is given for vacant positions at head and tail ends and a middle end; the method is suitable for the field of establishment of an on-site data collection and data preprocessing and intelligent information system of a machine manufacture and production system Internet-of-Things and an industrial 4.0 front end and data mining and data processing in an industrial Internet-of-Things.

Owner:WUXI MICRO RES

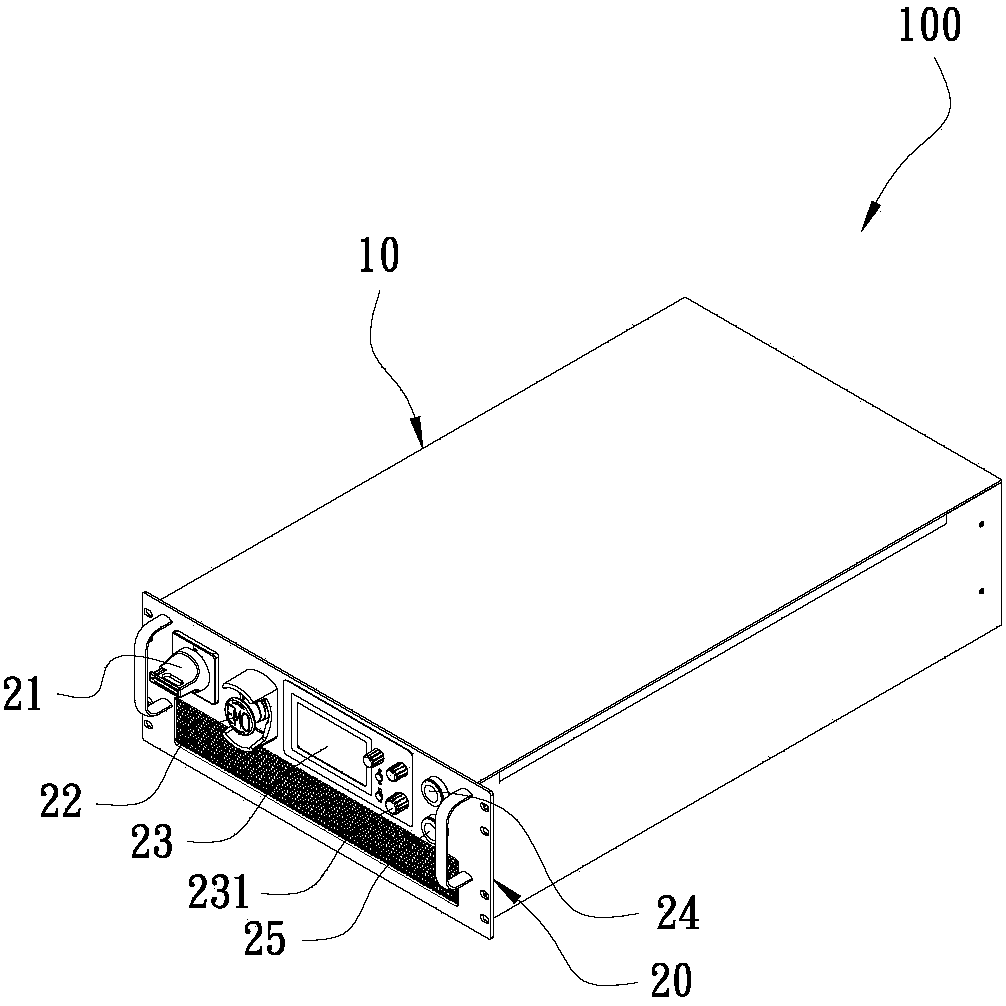

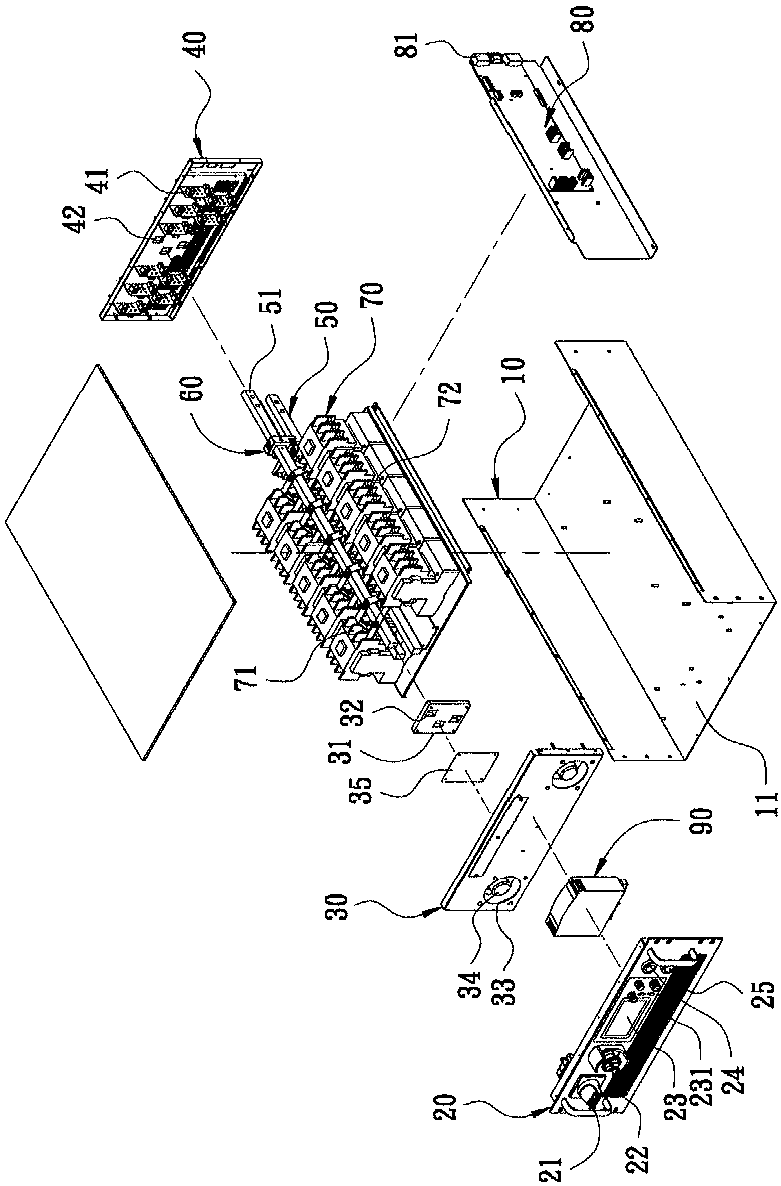

Programmable AC power source distribution device

ActiveCN109426188AMaintain qualityMaintain securityProgramme controlBus-bar/wiring layoutsDistribution controlNetwork connection

The invention relates to a programmable AC power source distribution device. A circuit board with network connection and used for measuring different power parameters is arranged in a casing, the circuit board is connected with a panel, and can be connected with the external network, a bus group is arranged in the inner middle of the casing, and provided with a current detector, and electromagnetic switches are arranged in the two sides of the bus group in the casing, and can be switched ON / OFF by the panel or remote network. Thus, the programmable AC power source distribution device can monitor the quality of a power source, has the advantage of programmable automatic power source distribution control, and satisfies the requirements of industrial 4.0 network and automation.

Owner:CHYNG HONG ELECTRONICS

Automatic film releasing and bottle feeding machine for penicillin bottles

PendingCN108688917ASolve the labor-intensiveImprove work efficiencyConveyorsConveyor partsTemperature controlEngineering

The invention provides an automatic film releasing and bottle feeding machine for penicillin bottles, and belongs to the technical field of food and drugs. The automatic film releasing and bottle feeding machine for the penicillin bottles comprises a rack, a sleeve frame bottle pushing mechanism, a film releasing mechanism, a film pulling mechanism, a bottle pushing mechanism, a telescopic temperature control electric heating cutter cutting mechanism, a conveying belt device and a control box; the conveying belt device is arranged at the bottom of the rack; the telescopic temperature control electric heating cutter cutting mechanism is arranged on the inner side of the conveying belt device; the bottle pushing mechanism is arranged on the upper portion of the conveying belt device; the film pulling mechanism is arranged on the upper portion of the bottle pushing mechanism; the film releasing mechanism is arranged on the upper portion of the film pulling mechanism; and the sleeve framebottle pushing mechanism is arranged on the upper portion of the film releasing mechanism. Through the successful use of the automatic film releasing and bottle feeding machine for the penicillin bottles, multiple uncontrollable factors that as manual dismounting of packs and manual feeding of small bottles are needed for bottle washing machines on washing, drying and filling linkage lines of pharmaceutical factories, the labor intensity is high, hands are prone to being injured due to manual film cutting, and the bottles are prone to falling off when the small bottles are pushed manually aresolved, the working efficiency is improved, the progress is improved for unmanned production of the pharmaceutical factories and Industry 4.0, no similar product exists on the current domestic market,and the automatic film releasing and bottle feeding machine for the penicillin bottles is domestically initiative.

Owner:上海开歌智能科技有限公司

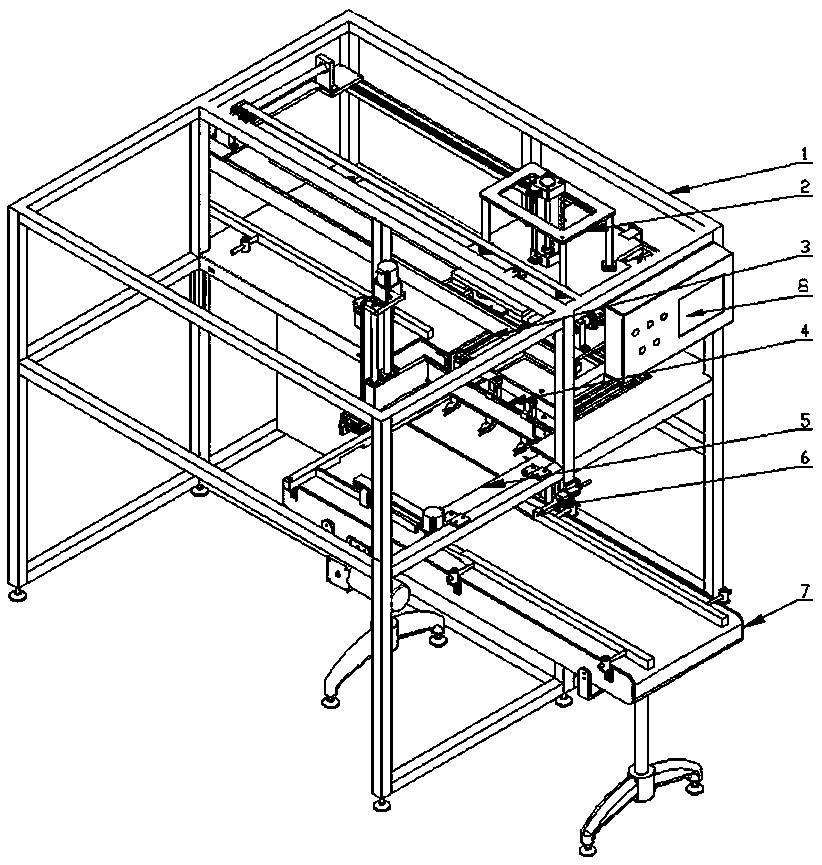

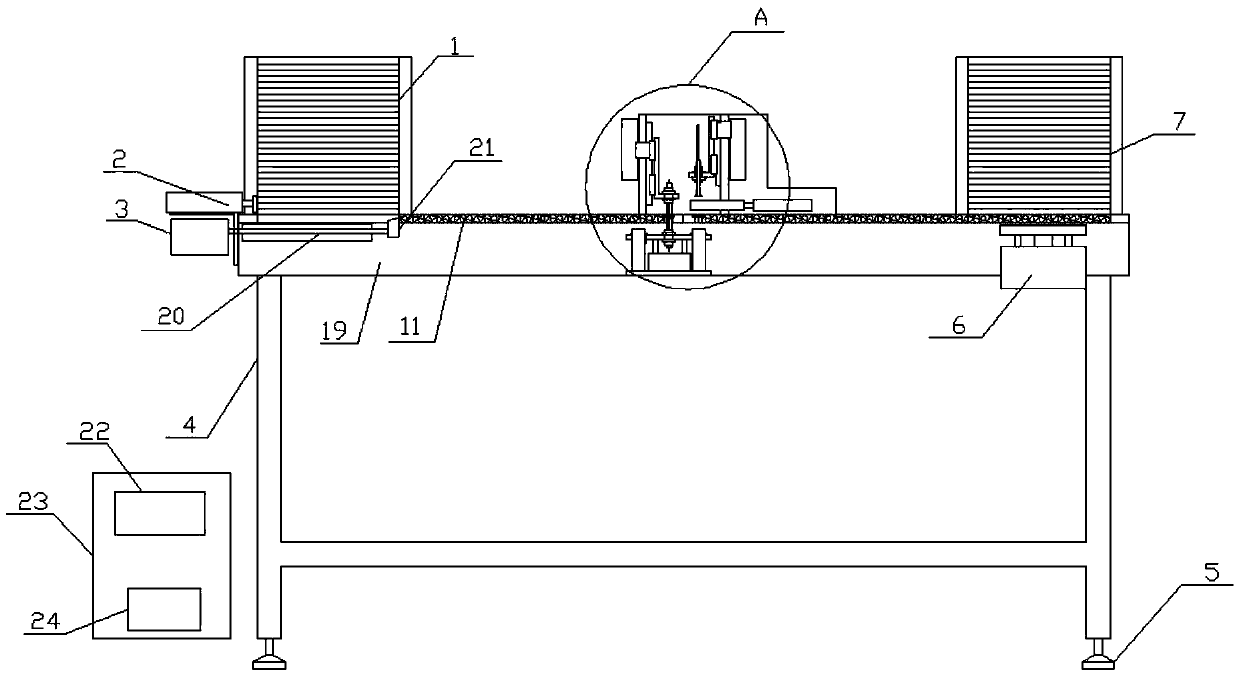

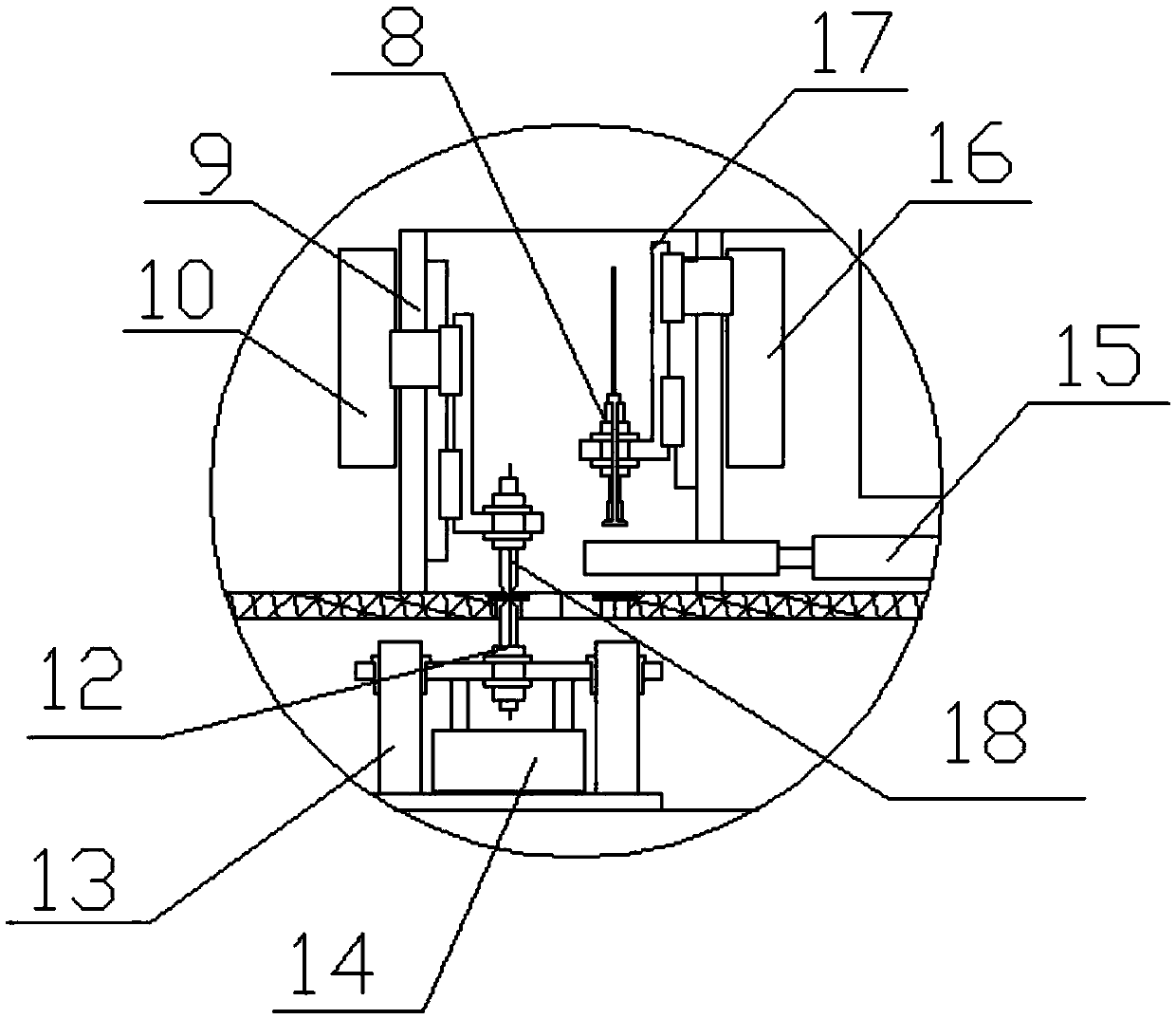

Automatic detection machine for production of button batteries and capacitors

The invention discloses an automatic detection machine for the production of button batteries and capacitors, which comprises an underframe and a platen arranged on the top of the underframe, a plurality of fixture plates which can slide along the platen are arranged on the platen, a discharger and a receiver are respectively arranged on the left side and right side of the platen, an upper detector and a defective product collector are arranged on the tops of the fixture plates, and a lower detector is arranged on the bottoms of the fixture plates. When the fixture plates pass the upper detector and the lower detector, the batteries or capacitors are detected, analyses are then carried out, a quality inspector can extract and provide detected data to an application business at any time to ensure quality and for tracking, moreover, once a defective product is discovered, a control unit can control a vacuum cup to suck out the defective product, the whole process is carried out in an automatic way, and compared with conventional detection machines, the automatic detection machine can generate more accurate data, has higher speed, greatly increases detection efficiency, meets the requirement of industry 4.0, and saves manpower cost.

Owner:GUANGDONG BIYOUTE ELECTRONICS TECH CO LTD

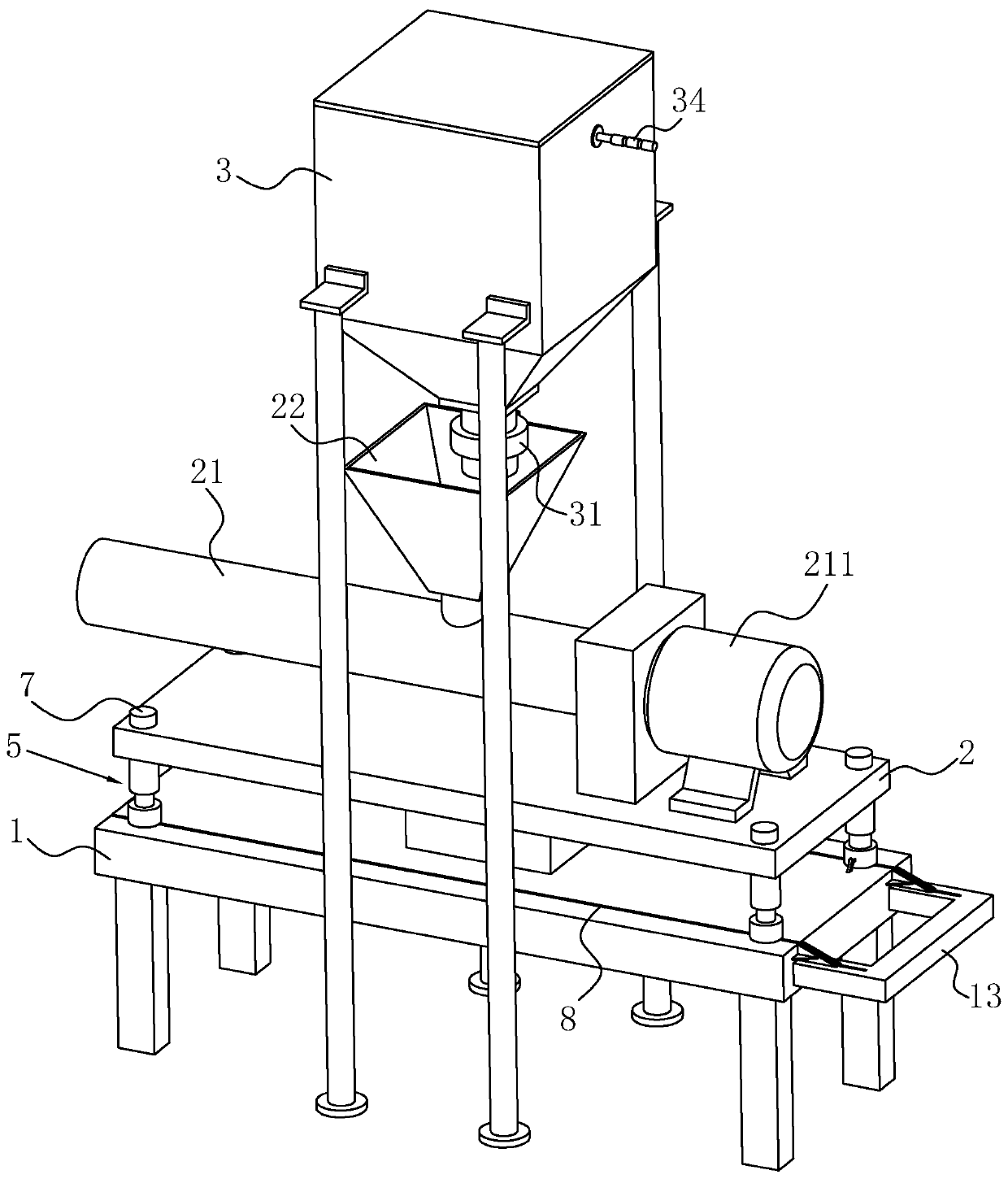

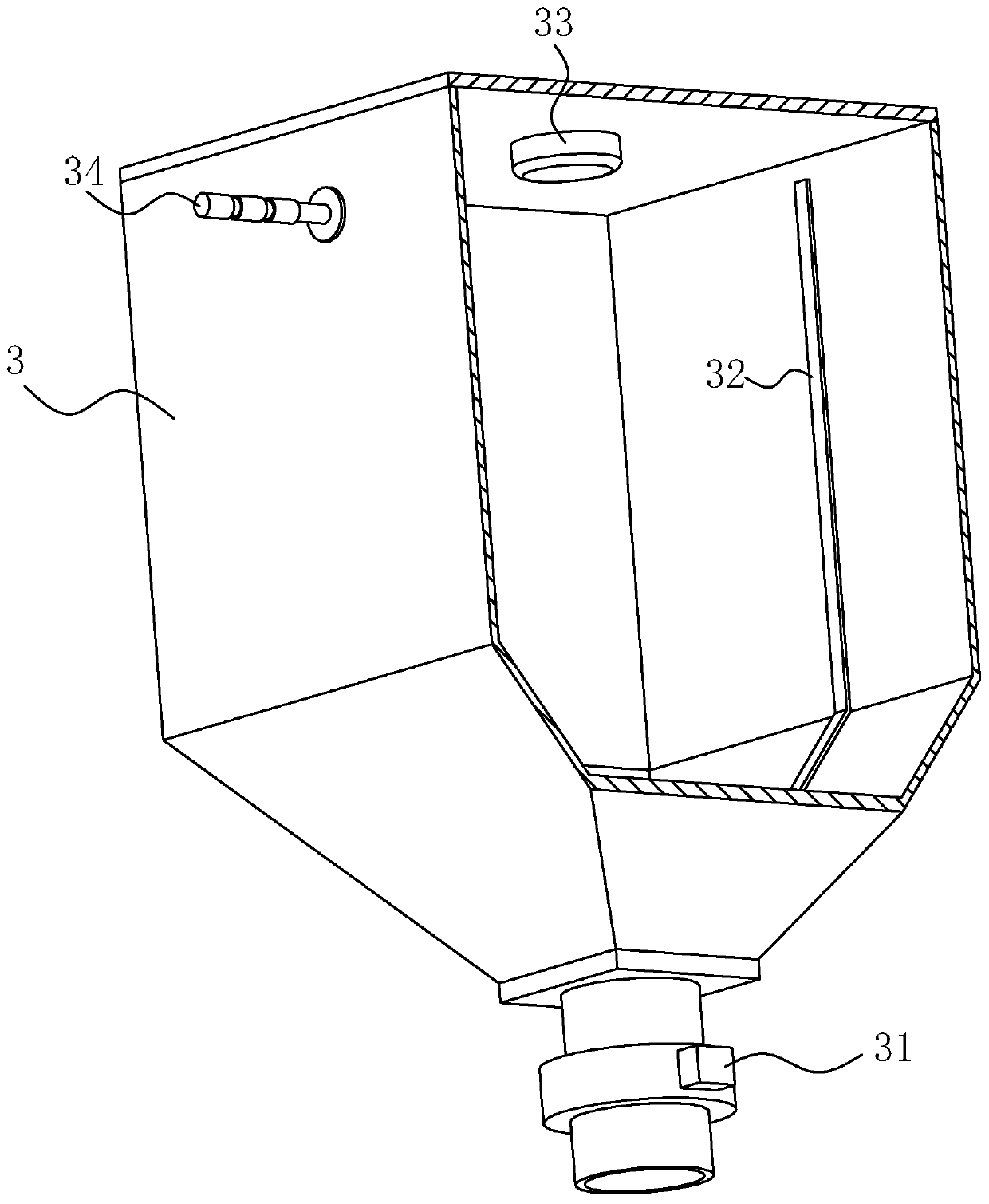

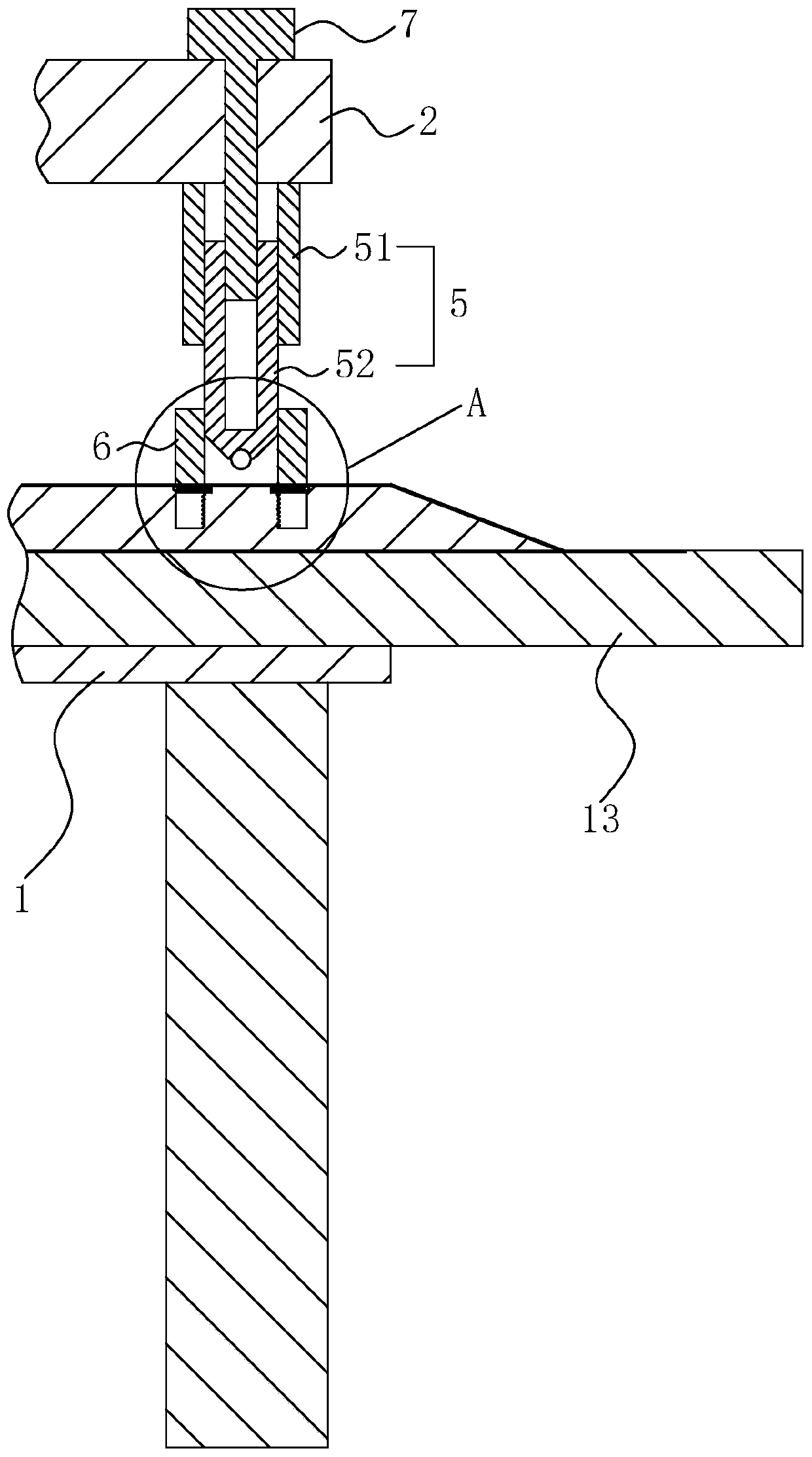

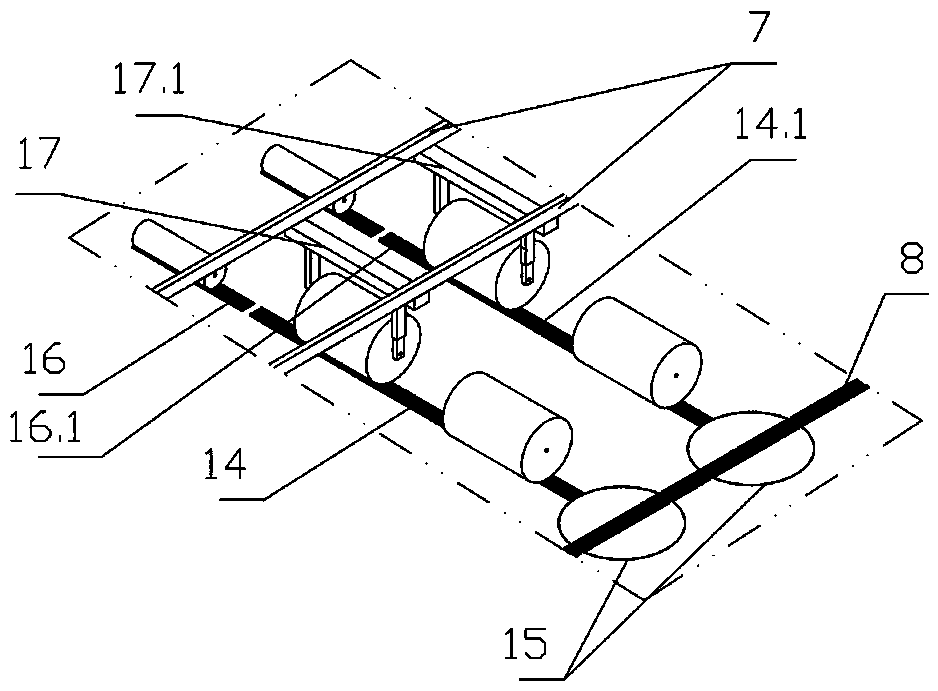

Continuous weighing metering feeder and measurement method for flow speed of feeder

ActiveCN110329791AEasy wiringIncrease data transfer rateDevices using time traversedLoading/unloadingEngineeringData transmission

The invention relates to a continuous weighing metering feeder. The continuous weighing metering feeder comprises multiple conveying units, each conveying unit comprises a base, and a spiral conveyoris arranged on each base and comprises a feeding hopper and a storage hopper arranged above the feeding hopper; a weighing sensor is connected between each spiral conveyor and the corresponding base,and the feeder further comprises controllers connected with the weighing sensors; motors of the spiral conveyors are connected with the controllers, and supplement valves are arranged at the bottoms of the storage hoppers, connected with the controllers and driven by the controllers to move. By adopting an Ethernet communication technology, wiring is simple, the data transmission speed is high, the data transmission distance is long, the real-time capability and anti-interference capacity are high, the system work is stable, and networking and maintenance are easily conducted. The system can be well controlled in real time, data can be well displayed in real time, important data required by a user is stored, convenience is provided for maintenance of the user, and by using Ethernet communication and advantages of an existing network, the service is provided for the user in time. The feeder is integrated with the industry 4.0.

Owner:南京恒高挤出装备有限公司

Full-automatic paper supply system of corrugated paper board production line

InactiveCN108608682ARealize unmanned operationSave work spaceMechanical working/deformationMechanical conveyorsProduction lineButt joint

The invention discloses a full-automatic paper supply system of a corrugated paper board production line. The full-automatic paper supply system comprises a paper supplementation area arranged at thefront end of the corrugated paper board production line and connected with a body paper warehouse in a butt joint manner, and multiple paper supplementation position paper roll conveying passageways are arranged in the paper supplementation area. A body paper roll conveying passageway is arranged on one side of an overbridge frame of the corrugated paper board production line in the longitudinal direction. Paper feed conveying passageways are arranged at positions corresponding to all paper supply positions of the corrugated paper board production line correspondingly. The paper feed end of each paper feed conveying passageway is connected with the body paper roll conveying passageway through a logistics turning plate. Suspension type body paper frames of the same structure are perpendicularly arranged at the positions, corresponding to the paper feed conveying passageways, on the overbridge frame of the corrugated paper board production line correspondingly. The full-automatic paper supply system has the beneficial effects that unmanned operation is achieved for all the paper supply positions of the corrugated paper board production line, body paper rolls only need to be placed inplace in a body paper bin according to numbers, and technical support is provided for industrial 4.0 mode production of the corrugated paper board production line; and meanwhile a large quantity of operation places, manpower and material resources are saved, and the operation environment is improved.

Owner:HENAN XINDOUCAI PRINTING

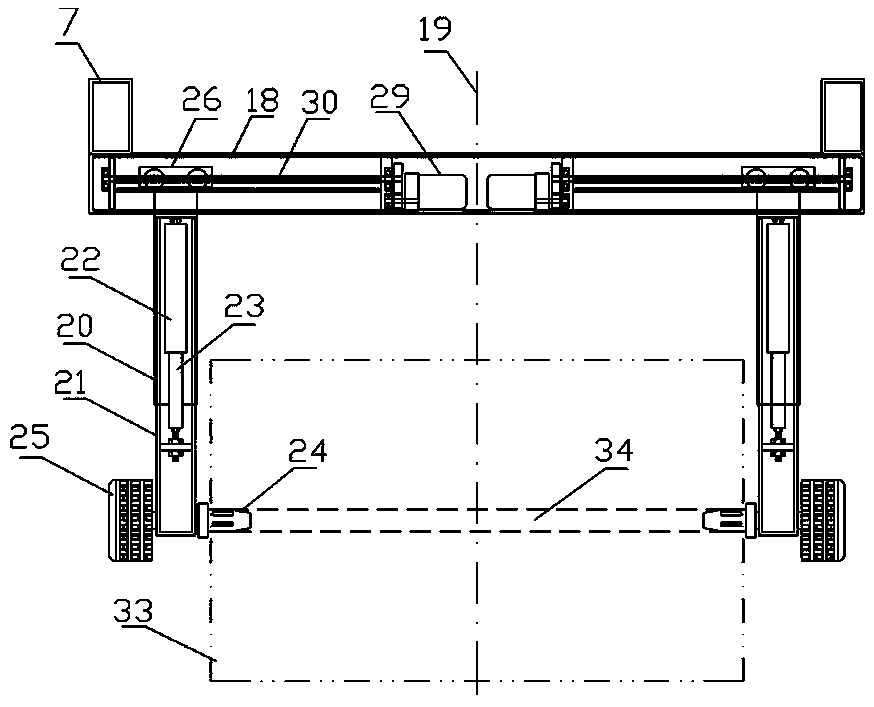

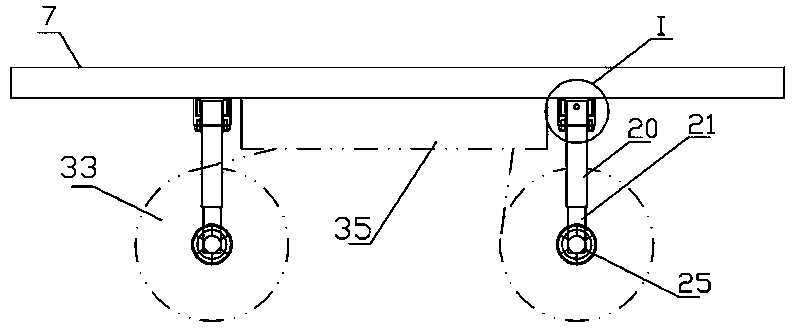

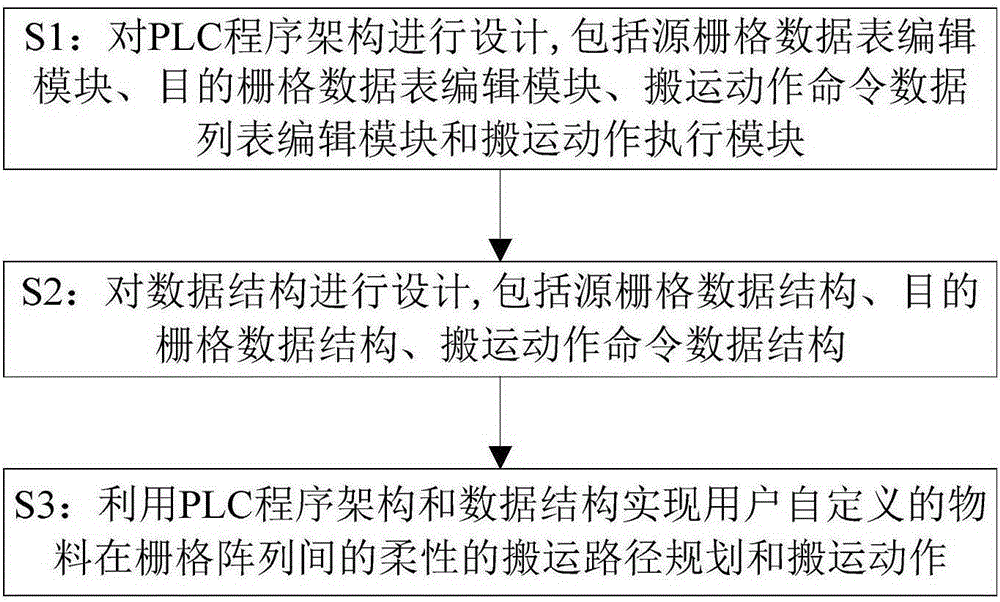

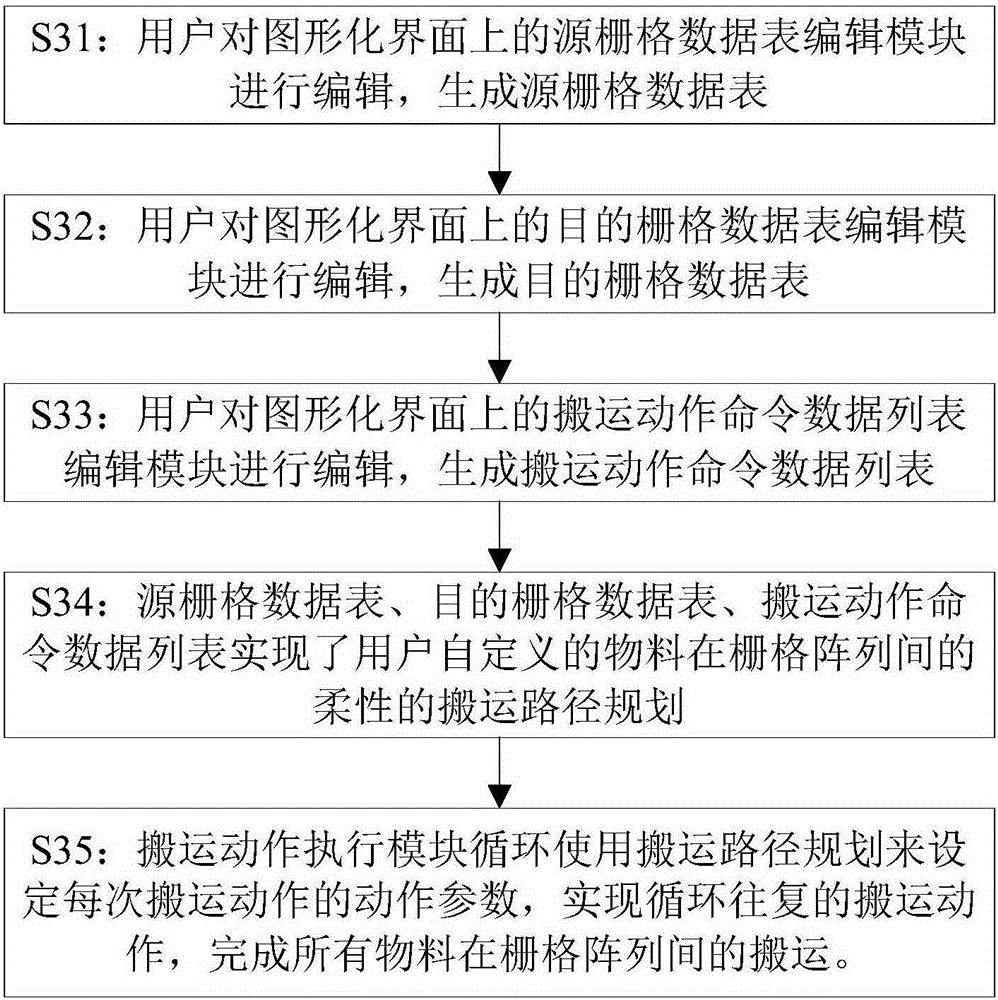

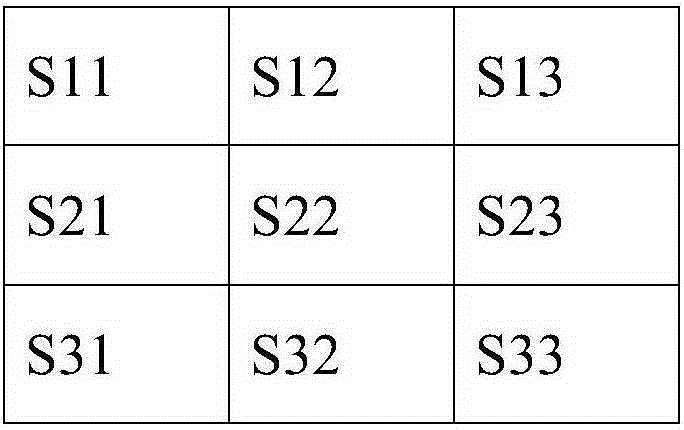

PLC programming method used in material carrying among grid arrays

ActiveCN105302057AReduce storage capacityLower skill requirementsProgramme control in sequence/logic controllersProduction lineInteractive graphics

The invention discloses a PLC programming method used in material carrying among grid arrays, wherein by separating programs and data structures required by a material carrying movement among the grid arrays, planning for a user's customized flexible carrying route of materials among the grid arrays is realized by a source grid data table, a target grid data table and a carrying movement order list, and the source and target grid data tables and the carrying movement order list are compiled and generated by a man-computer interactive graphic interface. In comparison with a traditional method that a PLC code is compiled for each grid combination to realize the route planning for the material carrying among grids, the method provided by the invention is characterized in that a PLC storage capacity occupied by addition of each grid combination is small, an PLC can support the much more grid combinations, operations for combination increase are simple and rapid, requirements put forward by industrial 4.0 large-scale customized production for production line changing can be satisfied, and requirements for skills of staffs in charge of equipment utilization and maintenance are reduced.

Owner:SUZHOU HEROIC AUTOMATION TECH

Method for brewing white spirit by virtue of probiotics

InactiveCN108117956AGreat tasteHigh in nutrientsAlcoholic beverage preparationGround temperatureFiber

The invention discloses a method for brewing white spirit by virtue of probiotics. The method comprises the following steps: S1, selecting and cleaning raw materials; S2, moistening the raw materials;S3, smashing; S4, steaming the raw materials; S5, cooling; S6, burdening; S7, pretreating a fermentation tank; S8, putting into a pit, and fermenting; S9, managing a pit tank; S10, distilling; and S11, warehousing. The method disclosed by the invention has the advantages that production technological parameters in a process of brewing the white spirit by virtue of the probiotics are strictly controlled, and three or more than three probiotics are adopted for fermentation, so that content of crude fibers in wine of fermented grains is reduced, nutritional ingredients of fermentation products are increased, taste of brewed white spirit is improved, the whole process is closed, no pollution is produced, no aldehyde is produced, compound probiotics are adopted for fermentation, industrial 4.0standard is met, and a temperature control mode that a ground temperature environment of ground cylinder fermentation is simulated by adopting water temperature of inner and outer jackets, so that afermentation temperature control mode and fermentation temperature control effect are relatively good, adjustment of temperature required by fermentation is guaranteed, operation is simple, and the method disclosed by the invention is applicable to extensive popularization.

Owner:深圳国科酒业有限公司

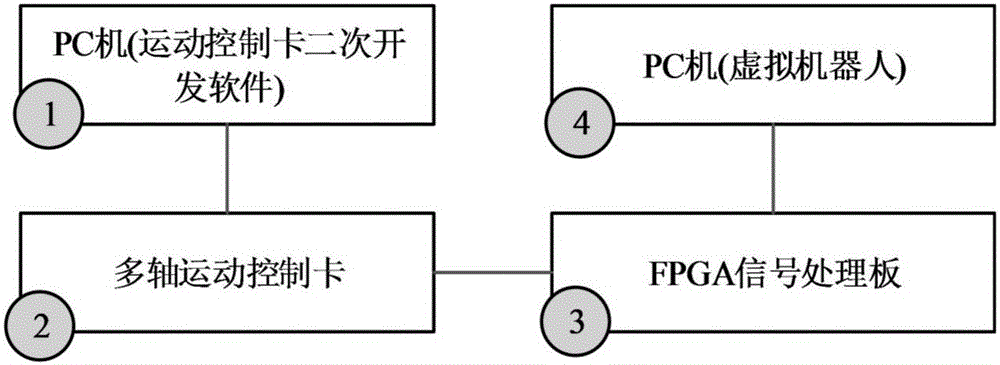

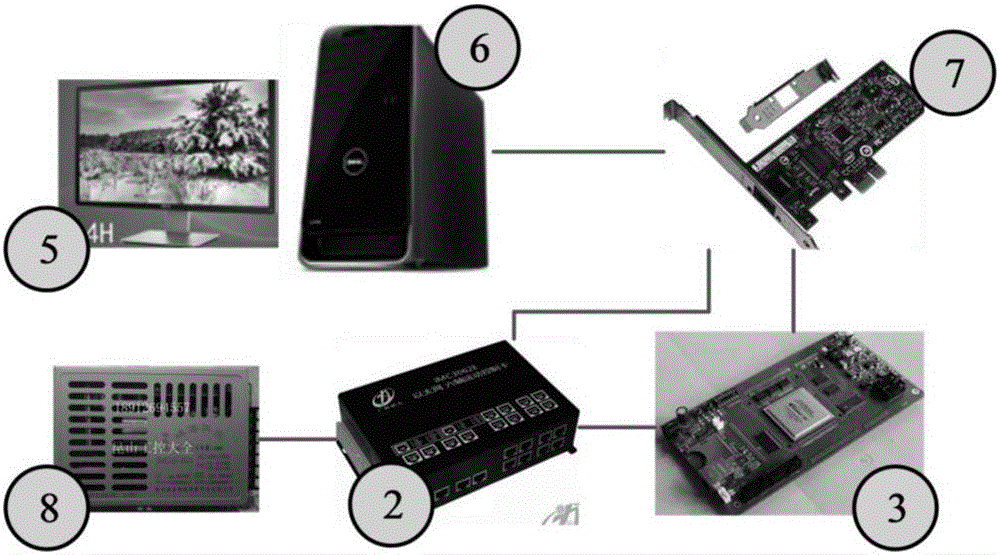

Multi-axis motion control technology education platform

Disclosed is a multi-axis motion control technology education platform. The multi-axis motion control technology education platform comprises a multi-axis motion control card, secondary development software, a virtual robot, a signal processing board and course data. The multi-axis motion control card has multiple ground-layer numerical control functions and provides a secondary development function database; the secondary development software comprises a motion control module and a management module; the virtual robot is software which provides virtual digital three-dimensional robot so as to simulate an actual robot; and the signal processing board is in charge of converting command signals of the motion control card for a robot driving system into input signals of the virtual robot, and at the same time, converting output signals of the virtual robot into feedback signals identifiable by the motion control card. According to the invention, the multi-axis motion control technology education platform avoids a complex robot representation form, focuses on the essential foundation of robot development, performs comprehensive education teaching of a multi-axis motion control technology in robot technologies, at the same time, is integrated with an industry 4.0 and intelligent manufacturing ideas, is provided with a platform management module and avoids an "island" problem.

Owner:FOSHAN XINHENGCUI MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com