Intelligent assembly system based on industrial 4.0 technology platform

An assembly system and technology platform technology, applied in the field of intelligent assembly system based on Industry 4.0 technology platform, can solve problems such as high cost, achieve the effect of strong practicability, avoid mutual damage, and good user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

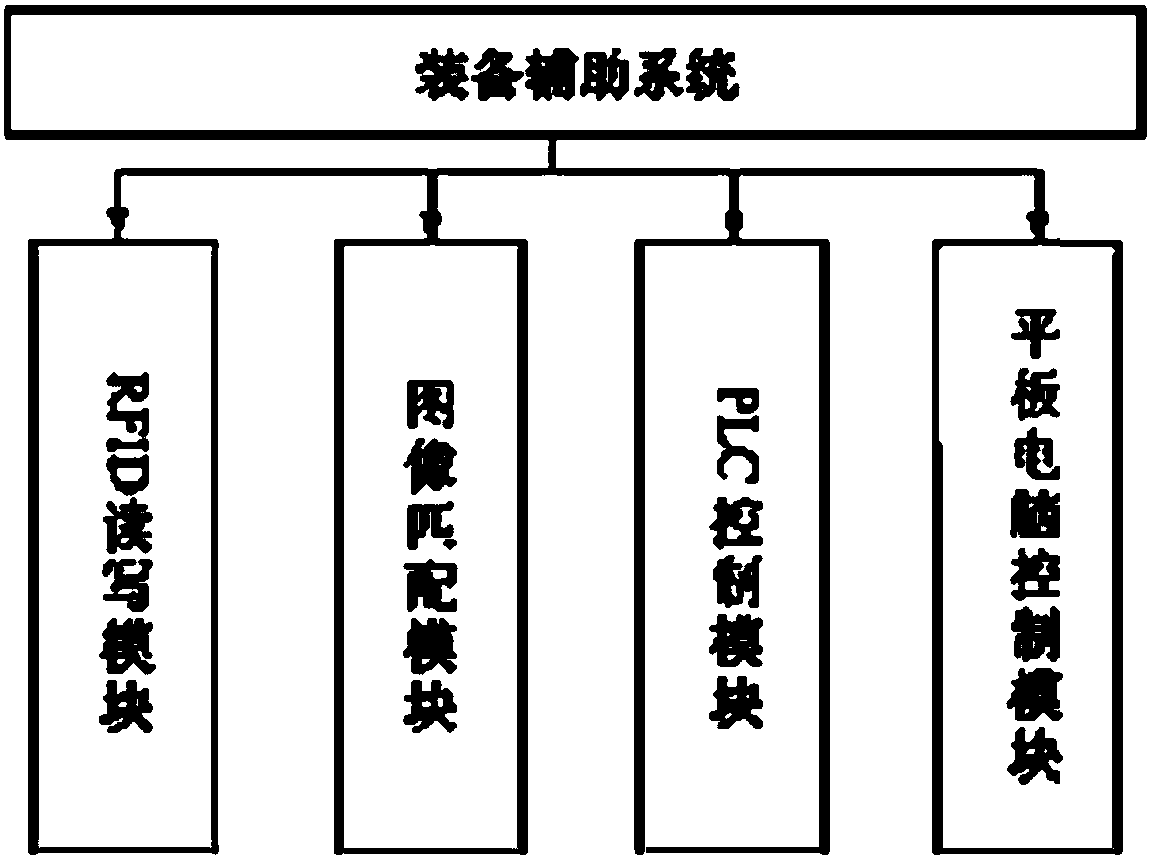

[0042] An intelligent assembly system based on the industry 4.0 technology platform, such as figure 1 shown, including:

[0043] Parts assembly points and parts conveying equipment;

[0044] Also includes:

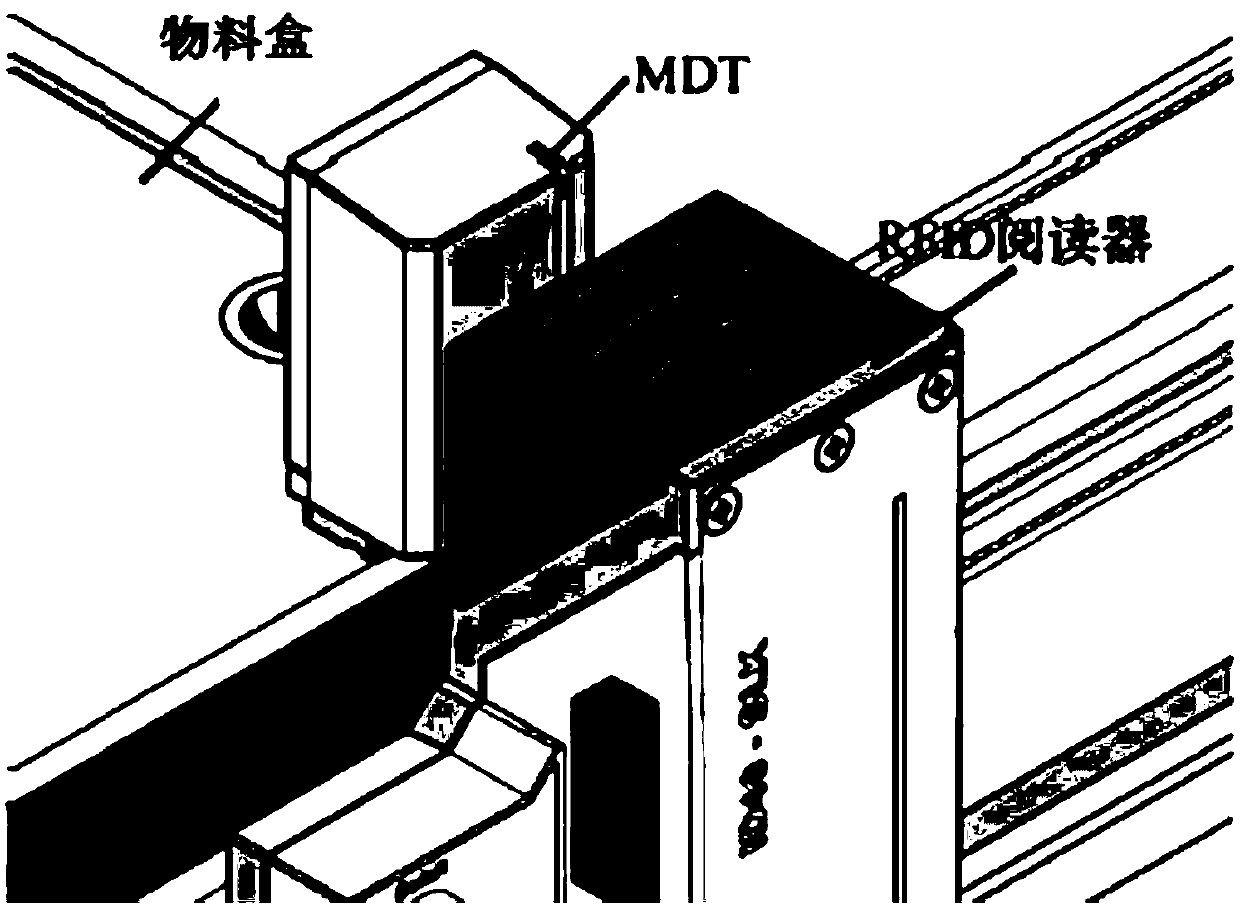

[0045] The parts identification module is installed at the parts assembly point and on the parts conveying equipment to identify the type and quantity of parts;

[0046] The image matching module is set at the parts assembly point and is used to detect whether the assembly result of the parts is correct.

[0047] Identify the types of parts through the part recognition module,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com