Manufacturing device and manufacturing method of numerically controlled arbitrary-paired chain

A technology for manufacturing devices and chains, which is applied to the manufacturing devices and manufacturing fields of CNC arbitrary matching chains, which can solve problems such as breakthroughs in concepts and manufacturing processes, uncontrollable product quality, time-consuming and labor-intensive problems, and achieve the effect of omitting unstable factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

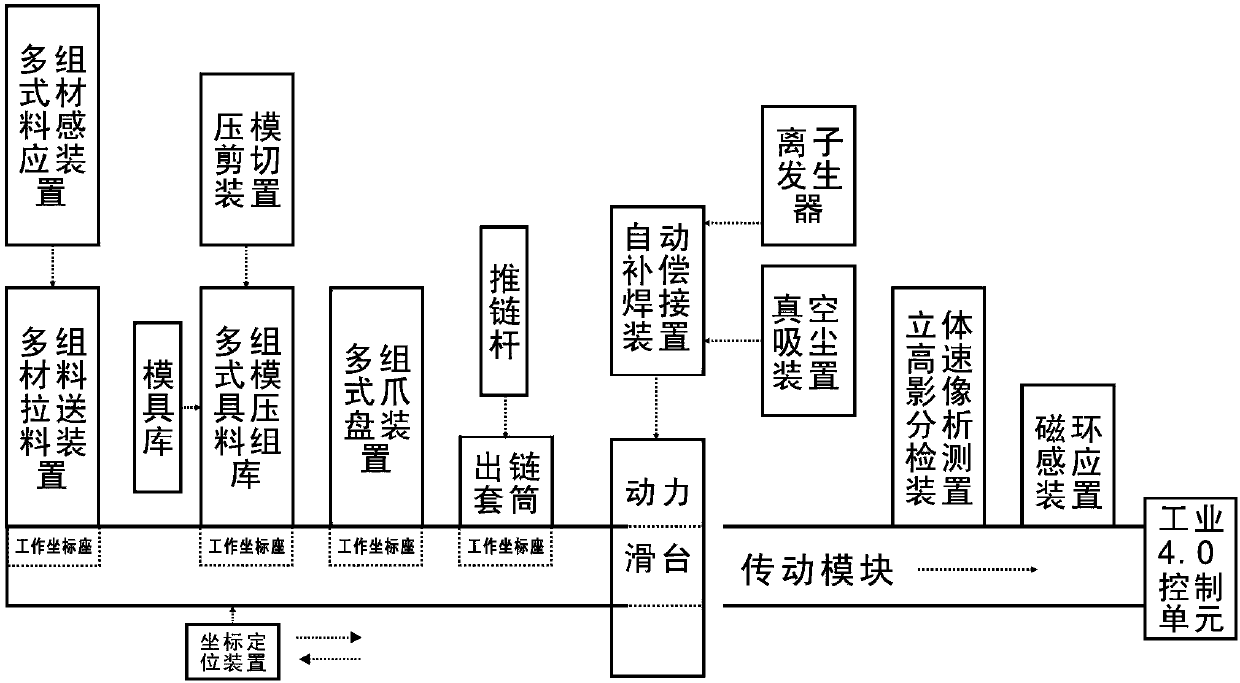

[0050] In order to better illustrate the technical features, technical solutions and functional effects of the present invention, the present invention will be further described below in conjunction with the accompanying drawings; please refer to the accompanying drawings.

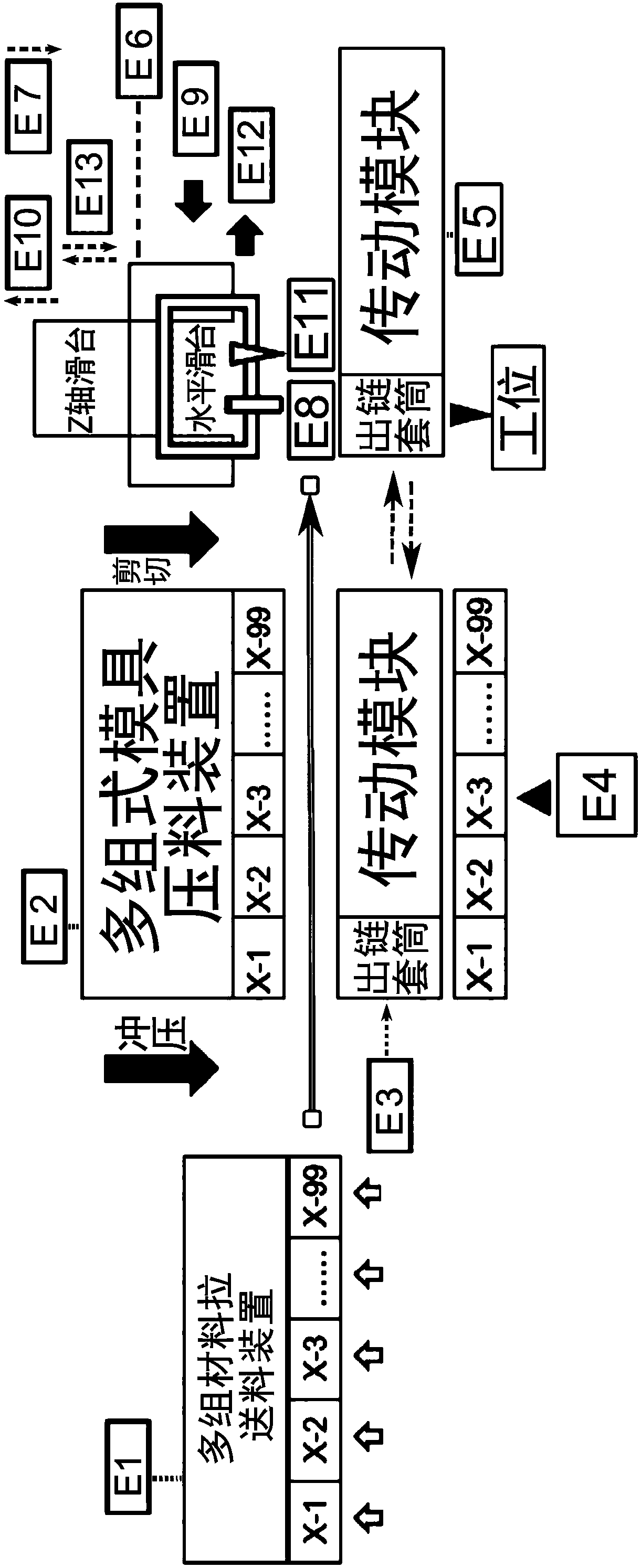

[0051] attached figure 1 It is a schematic flow diagram of the product chain link action (schematic diagram of the chain link flow from material to semi-finished product). In the figure, 0 = origin position, I = work position, I ① = ① of work position. The feature of work position is the control of multi-tasking position, so it appears I=I①-I arbitrary station, such as 0-I-0 station is: origin-station-origin:

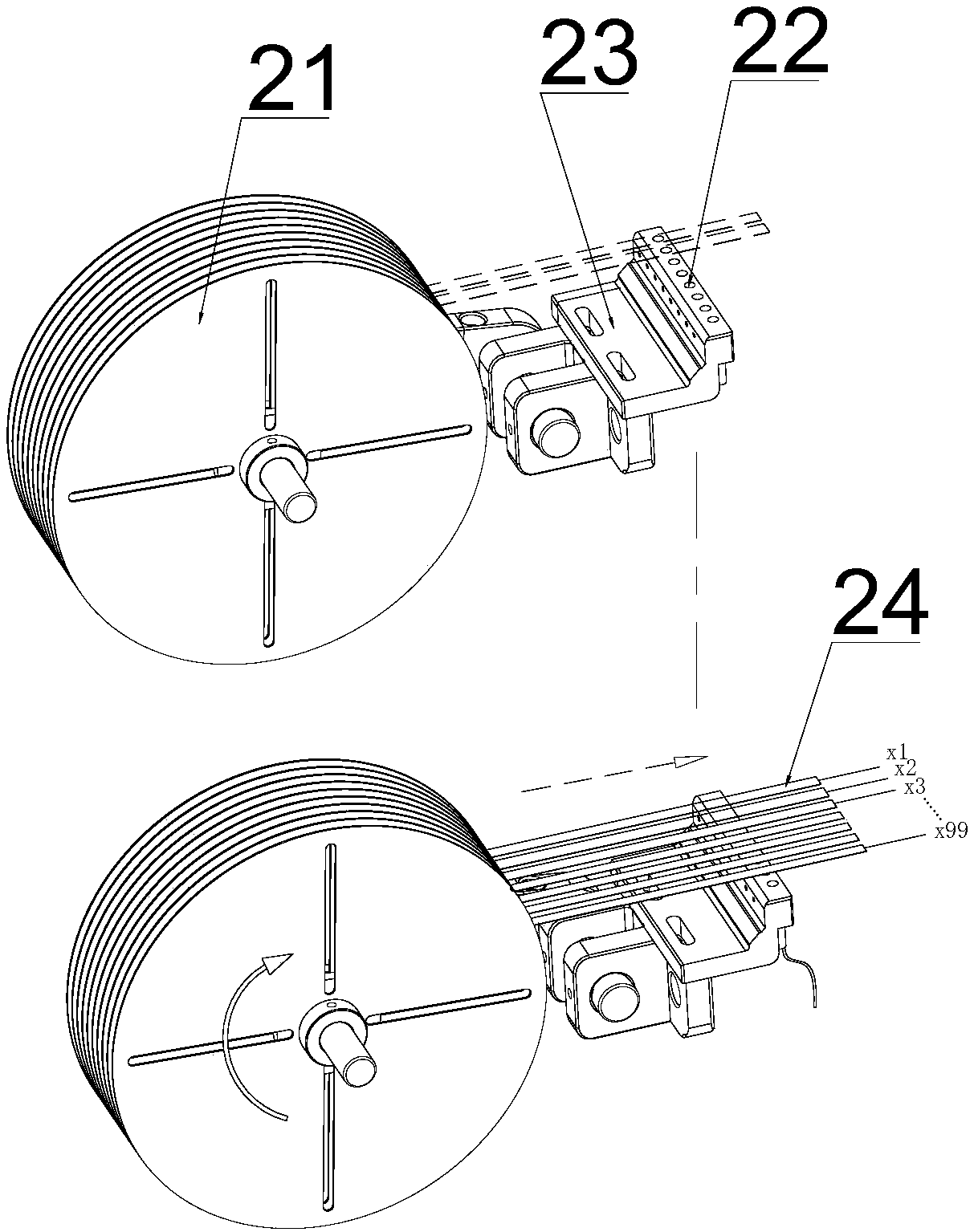

[0052] E1: Multiple groups of material pulling and feeding devices (multiple groups of material pulling and feeding devices, one or more feeding bars), multiple groups of material pulling and feeding devices feed according to the program, and the rest of the multi-groups of material pulling and fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com