Continuous weighing metering feeder and measurement method for flow speed of feeder

A technology of metering feeding and weight, which is applied in the field of feeding machines, can solve the problems of low feeding speed control accuracy, actual material output error, and residual feeding machines, etc., to achieve easy networking and easy Easy maintenance and wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

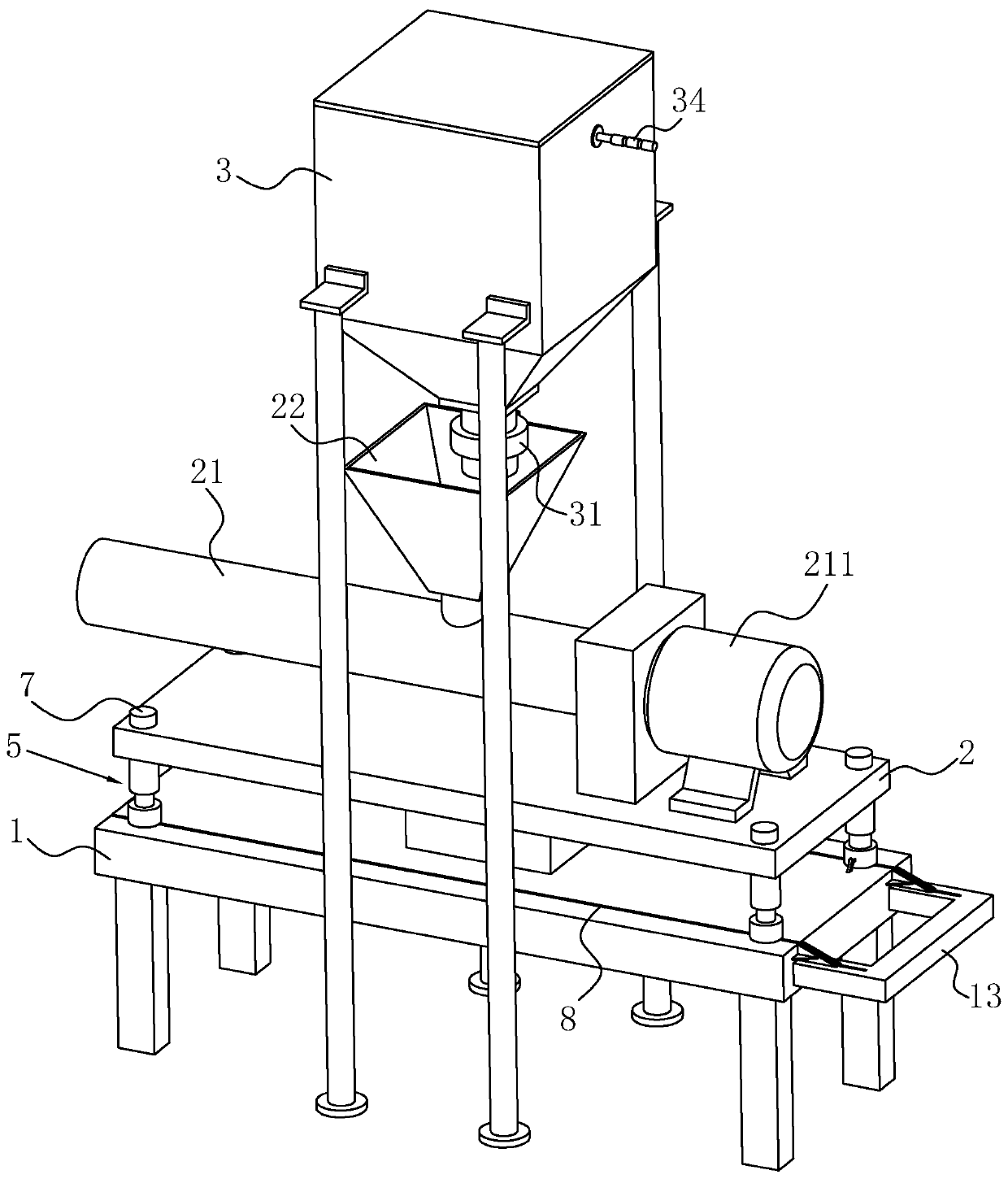

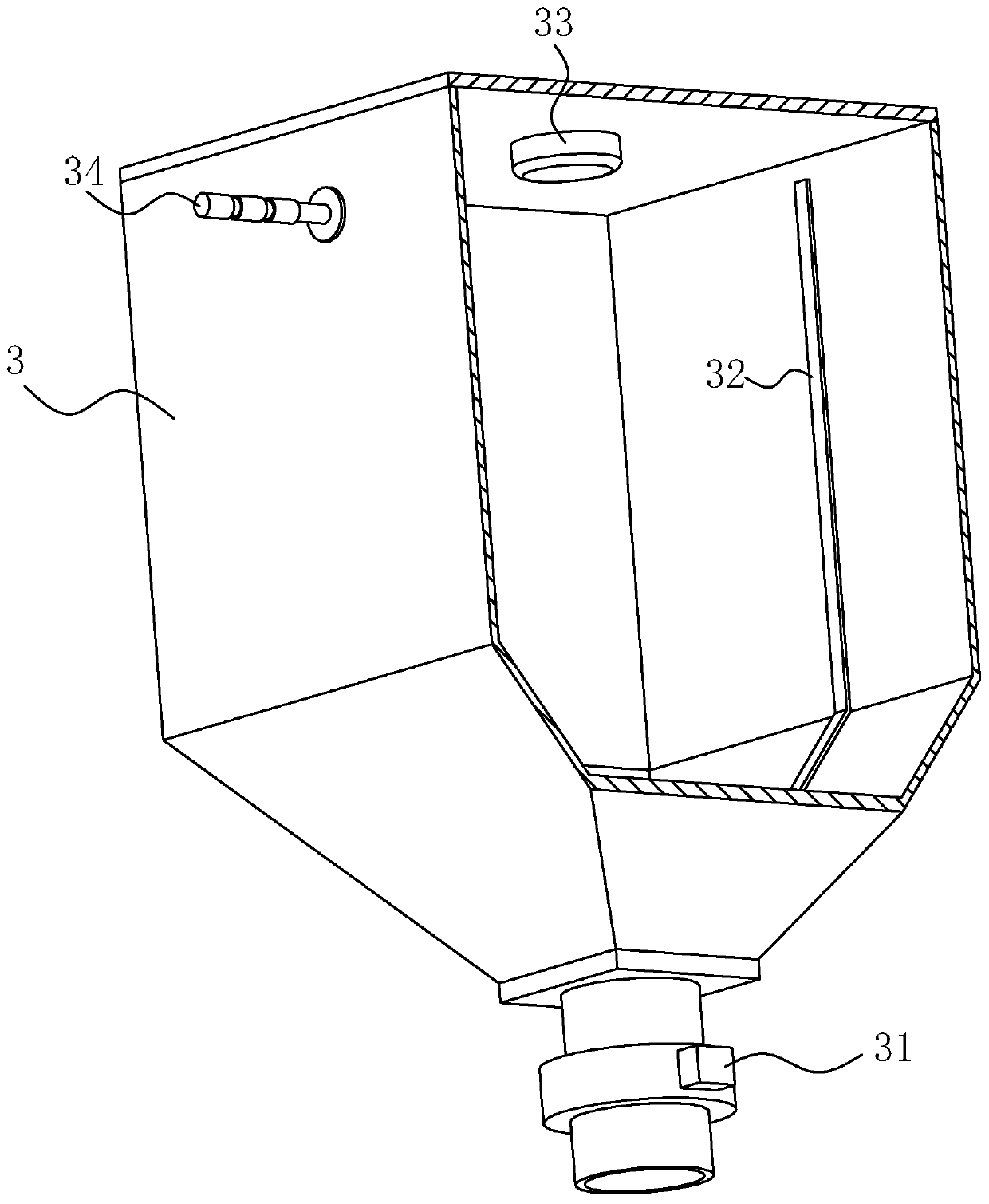

[0046] refer to figure 1 , is a kind of continuous weighing and metering feeding machine disclosed by the present invention, comprising several conveying units, each conveying unit comprising a base 1, a screw conveyor 21 is arranged on the base 1, and a feeding material is provided on the top of the screw conveyor 21 The bucket 22 is provided with an auger for conveying materials in the bolt conveyor, and the screw conveyor 21 is provided with a motor 211 for driving the auger to rotate. During operation, the motor 211 drives the auger to rotate, and the raw material in the feed hopper 22 is conveyed Going out, there is a storage hopper 3 above the feed hopper 22, the storage hopper 3 is fixed independently, without any connection with the feed hopper 22, the raw materials to be processed are stored in the storage hopper 3, and an opening is provided at the bottom of the storage hopper 3, The opening is set toward the feed hopper 22, and a feeding valve 31 that controls the o...

Embodiment 2

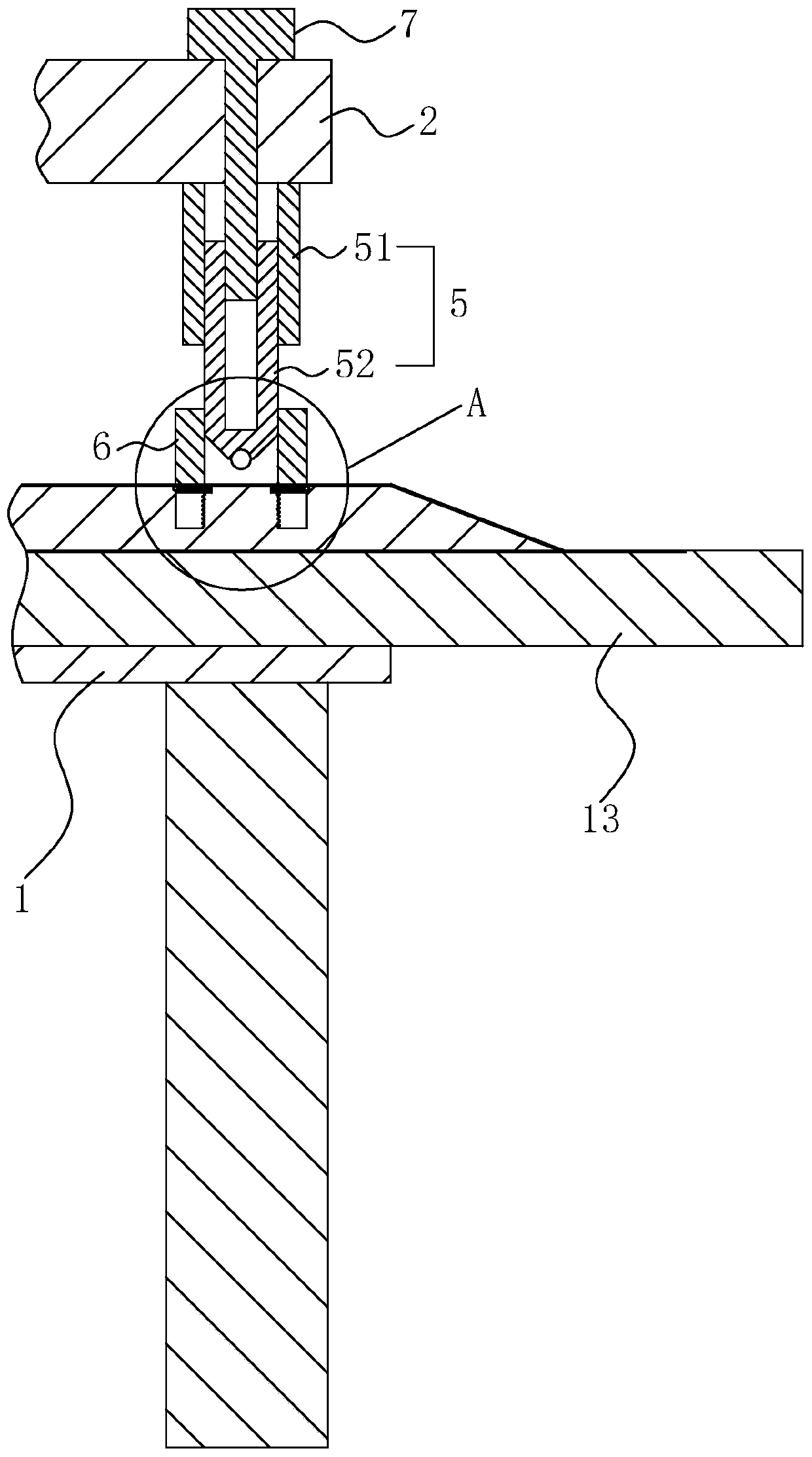

[0056] A continuous weighing and metering feeder, the difference from Embodiment 1 is that in this embodiment, refer to figure 1 as well as image 3 , the bottom of the screw conveyor 21 is provided with a base plate 2, the base plate 2 abuts against the load cell 4, the load cell 4 is fixed on the base 1 and is set corresponding to the center of the base plate 2, and the four corners of the base plate 2 are fixed with guide rods 5 perpendicular to the base plate 2 , the length of the guide rod 5 can be stretched, and the base 1 is fixed with a guide sleeve 6 sleeved outside the guide rod 5. Due to the limit of the guide rod 5 and the guide sleeve 6, the bottom plate 2 can only move along the vertical direction when it is vibrated. Sliding in the same direction can ensure that the load cell 4 is always at the center of the bottom plate 2, thereby ensuring the detection accuracy of the load cell 4, and because the guide rod 5 and the guide sleeve 6 are set in the vertical direc...

Embodiment 3

[0066] A method for measuring the flow rate of a feeder, comprising step S1, the load cell 4 records T 1 Sec weight W 1 , W 1 The unit is kg, after the load cell 4 detects, the W 1 The value is sent to the PLC.

[0067] Then enter step S2, when the time reaches T 2 Seconds later, the load cell 4 measures the weight as W 2 , W 2 The unit is also kg, then the weight sensor will W 2 The value is sent to the PLC;

[0068] When W 1 with W 2 After the value of the value is passed into the PLC, enter step S3, the program in the PLC will be based on T 2 —T 1 The weight change over the time period, that is, W 1 with W 2 The difference of the current feeder material output flow rate can be obtained, and the real-time flow rate is (W 1 -W 2 ) / (T 2 -T 1 ) × 3600 kg / h, using the weight lost within a certain period of time to calculate the flow rate, real-time and continuous detection of the flow rate can be realized, and the control accuracy of the PLC to the motor 211 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com