Individualized pattern customized steel plate for household appliance and preparation method thereof

A manufacturing method and steel plate technology, applied in special decorative structures, decorative arts, printing, etc., can solve the problems of being unsuitable for large-scale flow production, unable to meet the diversification of users, and unfavorable for the era of individualization, so as to achieve efficient sample preparation and improve The effect of high coloring rate and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

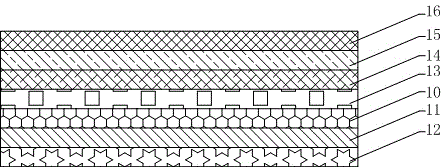

[0050] refer to figure 1 As shown, this embodiment is a custom-made steel plate with personalized patterns for household appliances. As can be seen from its cross-sectional schematic diagram, PCM is used as the substrate 10, and the bottom of the substrate 10 is sequentially composed of a chemical treatment layer 11 and a back paint from the inside to the outside. Layer 12, the upper surface of the substrate 10 is a chemical treatment layer 13, a primer layer 14, a topcoat+penetrating ink layer 15, and a protective film layer 16 from inside to outside. PCM is a white prepainted steel sheet for home appliances.

[0051] A personalized pattern is printed on the steel plate, and the personalized pattern penetrates into the topcoat+penetrating ink layer 15 . The personalized pattern can be any pattern that the user likes to make on the home appliance, such as a postmark pattern, a star pattern, a green tree pattern or a user's photo, or it is designed by a home appliance pattern ...

Embodiment 2

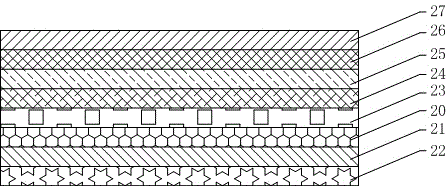

[0066] refer to figure 2 As shown, this embodiment is a custom-made steel plate with a personalized pattern for household appliances. It can be seen from its cross-sectional schematic diagram that VCM is used as the substrate 20, and the bottom of the substrate 20 is sequentially composed of a chemical treatment layer 21 and a back paint from the inside to the outside. Layer 22, the upper surface of the substrate 20 is a chemical treatment layer 23, an adhesive layer 24, a PVC layer 25, a PET layer+permeable ink layer 26, and a protective film layer 27 from inside to outside. VCM is a colored laminated steel plate coated with a white color-like film for home appliances. There is pearlescent powder on the white color-like film of VCM, and the particle size of the pearlescent powder is 30 μm.

[0067] A personalized pattern is printed on the steel plate, and the personalized pattern penetrates into the PET layer+permeable ink layer 26 . The personalized pattern can be any patt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com