Full-automatic license plate production line

A fully automatic, production line technology, applied in the direction of layered products, lamination, feeding devices, etc., can solve the problems of low factory production efficiency, consumption of human resources, insufficient information and data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

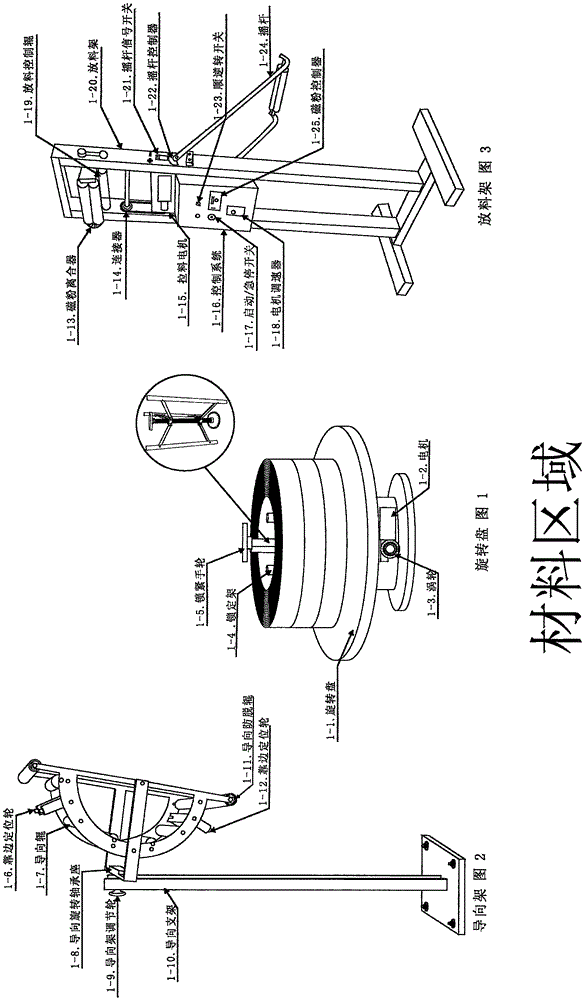

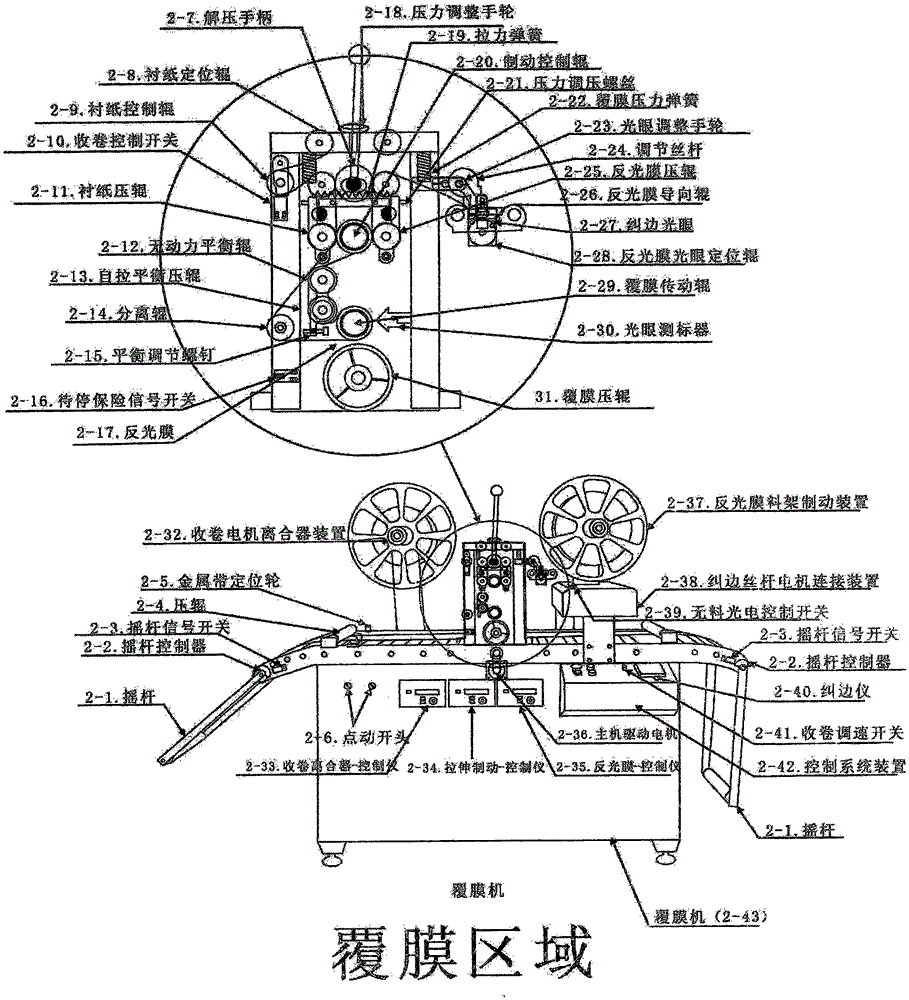

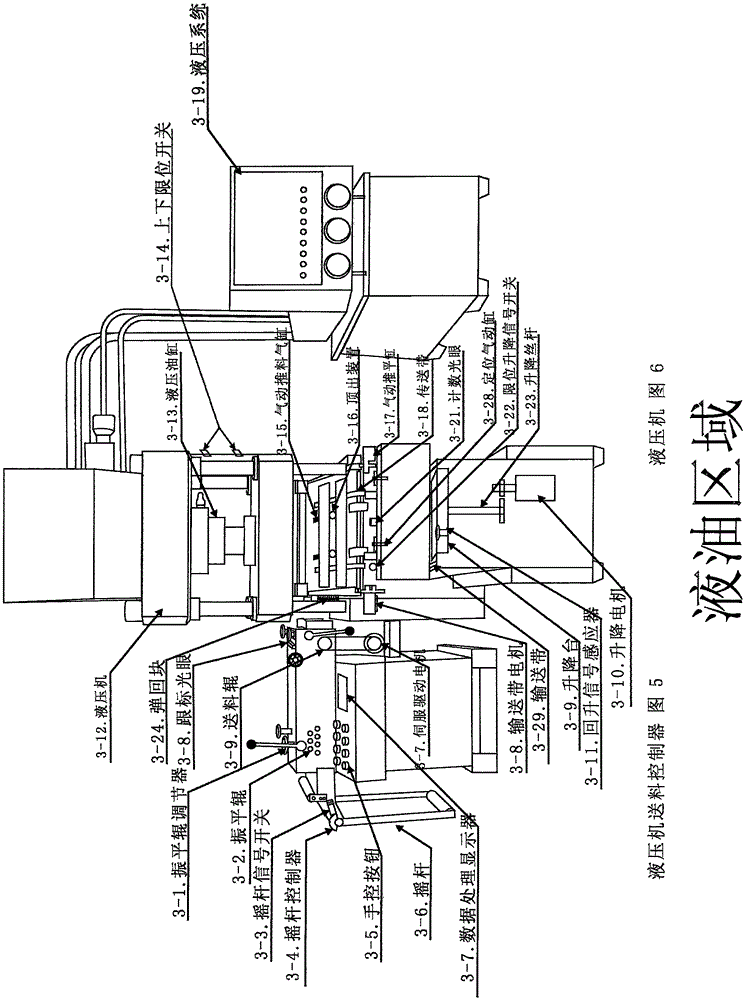

[0019] The fully automatic production line for license plate of the present invention consists of guide frame ( Figure 1 ), rotating disc ( Figure II ), feeding rack ( Figure three ),Laminating machine( Figure four ), hydraulic press feed controller ( Figure five ) and hydraulic press ( Figure six )composition.

[0020] Such as Figure 1 , two , three shown. The locking frame fastens the license plate metal band on the rotating disc (1-1). The automatic discharge device is composed of the discharge rack (3), and the control system (1-16) changes the position of the rocker controller (1-22) according to the lifting and lowering of the rocker (1-24) to sense the rocker signal switch ( 1-21), the signal is transmitted to the control system (1-16), and the control system receives instructions to drive the motor (1-2) to rotate the loose belt. The torque driven by the pulling motor (1-15) is transmitted to the connector (1-14) and the input end of the magnetic powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com