Intelligent bin tray transfer system and method thereof

A turnover system and material tray technology, applied in the field of warehousing applications, can solve the problems of increasing labor intensity of operators, reducing production efficiency, increasing production costs, etc., and achieve good market promotion value, improve production efficiency, and increase transportation volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

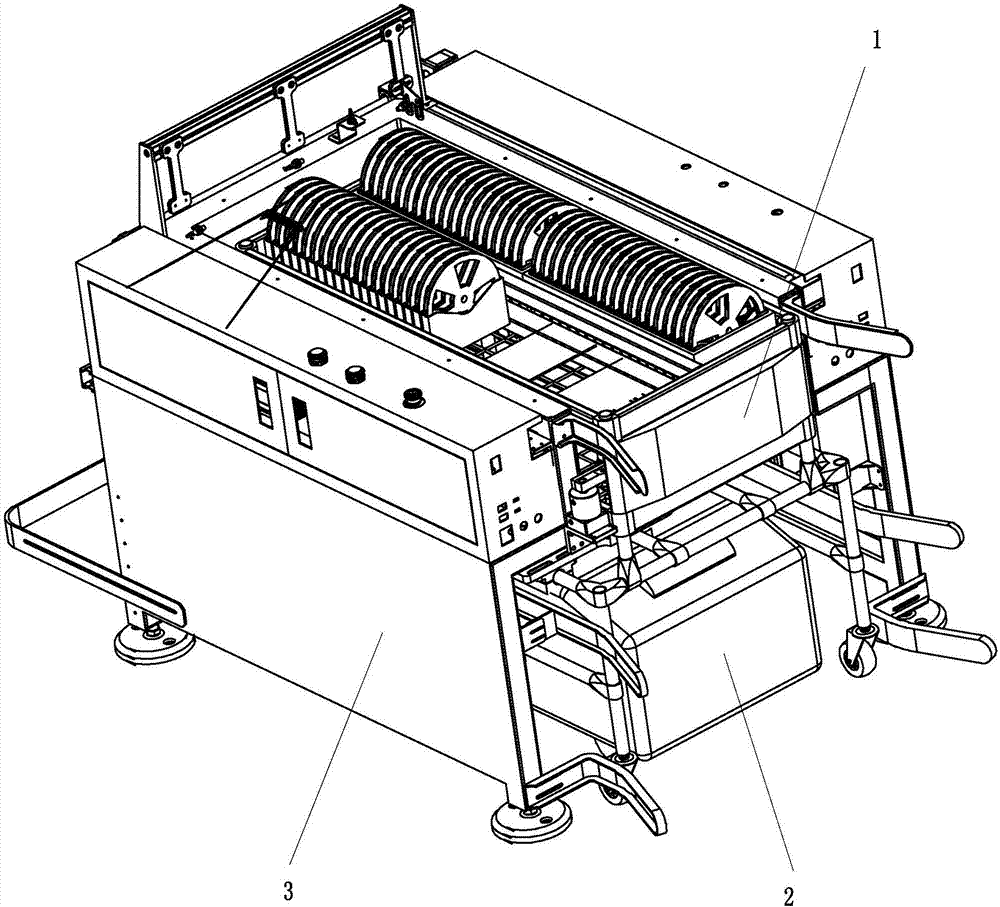

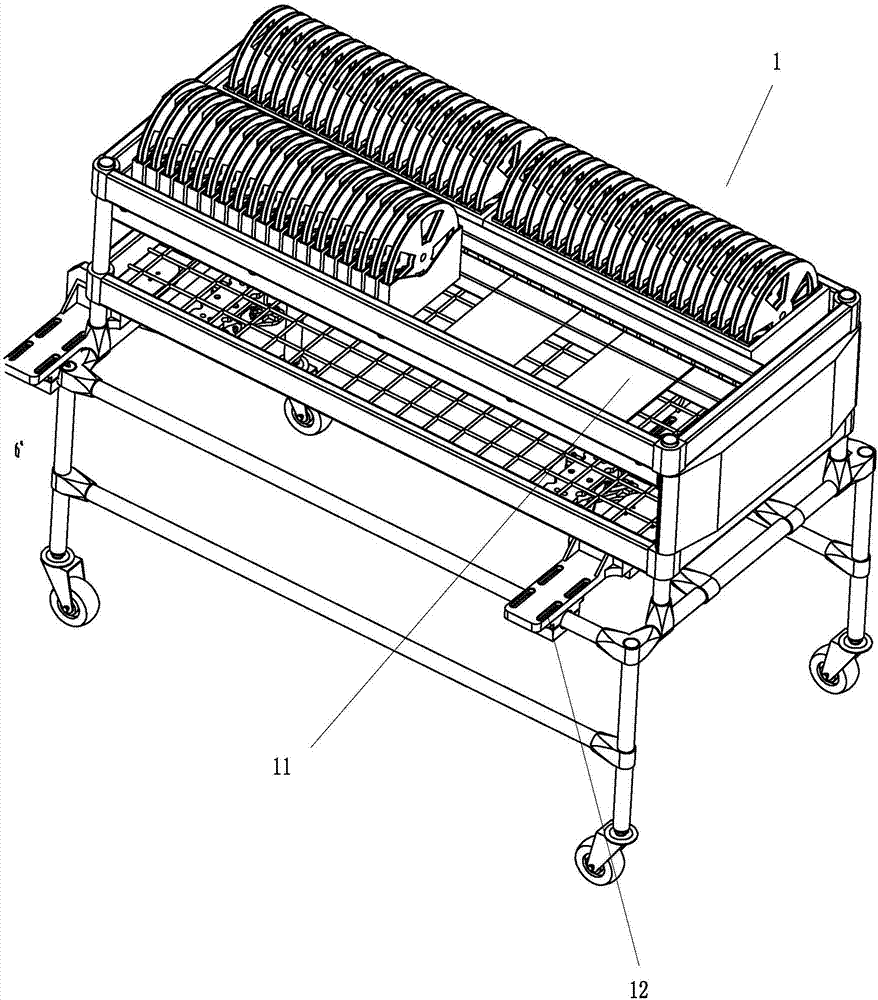

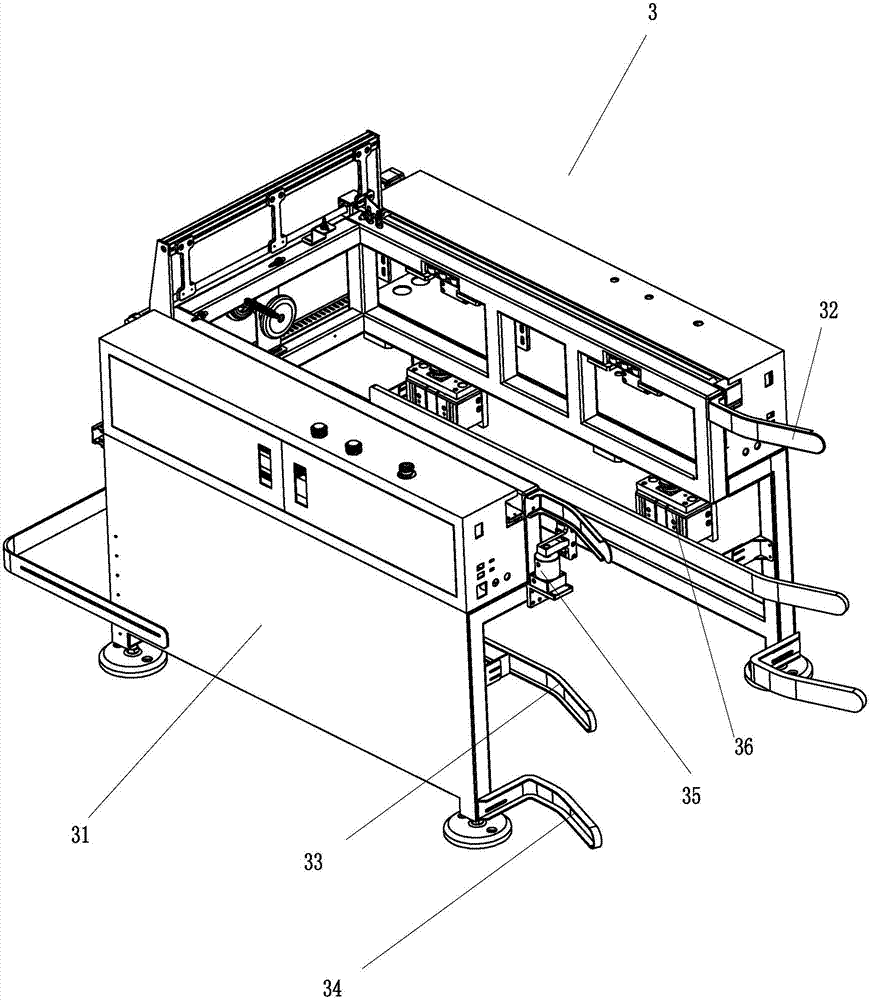

[0034] like Figure 1 to Figure 3 As shown, the intelligent warehouse tray turnover system disclosed by the present invention includes a control mechanism, a turnover mechanism 1, a transport mechanism 2, a feeding mechanism and a positioning mechanism 3, and the control mechanism is respectively connected to the transportation mechanism 2, the discharging mechanism and the positioning mechanism 3, The transport mechanism 2 is detachably connected to the turnover mechanism 1, and the turnover mechanism 1 can be connected to the positioning mechanism 3 in a movable manner. The turnover mechanism 1 is provided with a placement part 11 for placing the storage tray, and the positioning mechanism 3 is provided with a positioning mechanism. The automatic centering and positioning device of 1 and the automatic lifting device for lifting and revolving mechanism 1, and the position of the discharging mechanism corresponding to the placement part 11 is set on one side of the positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com