Patents

Literature

34 results about "Smart bin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

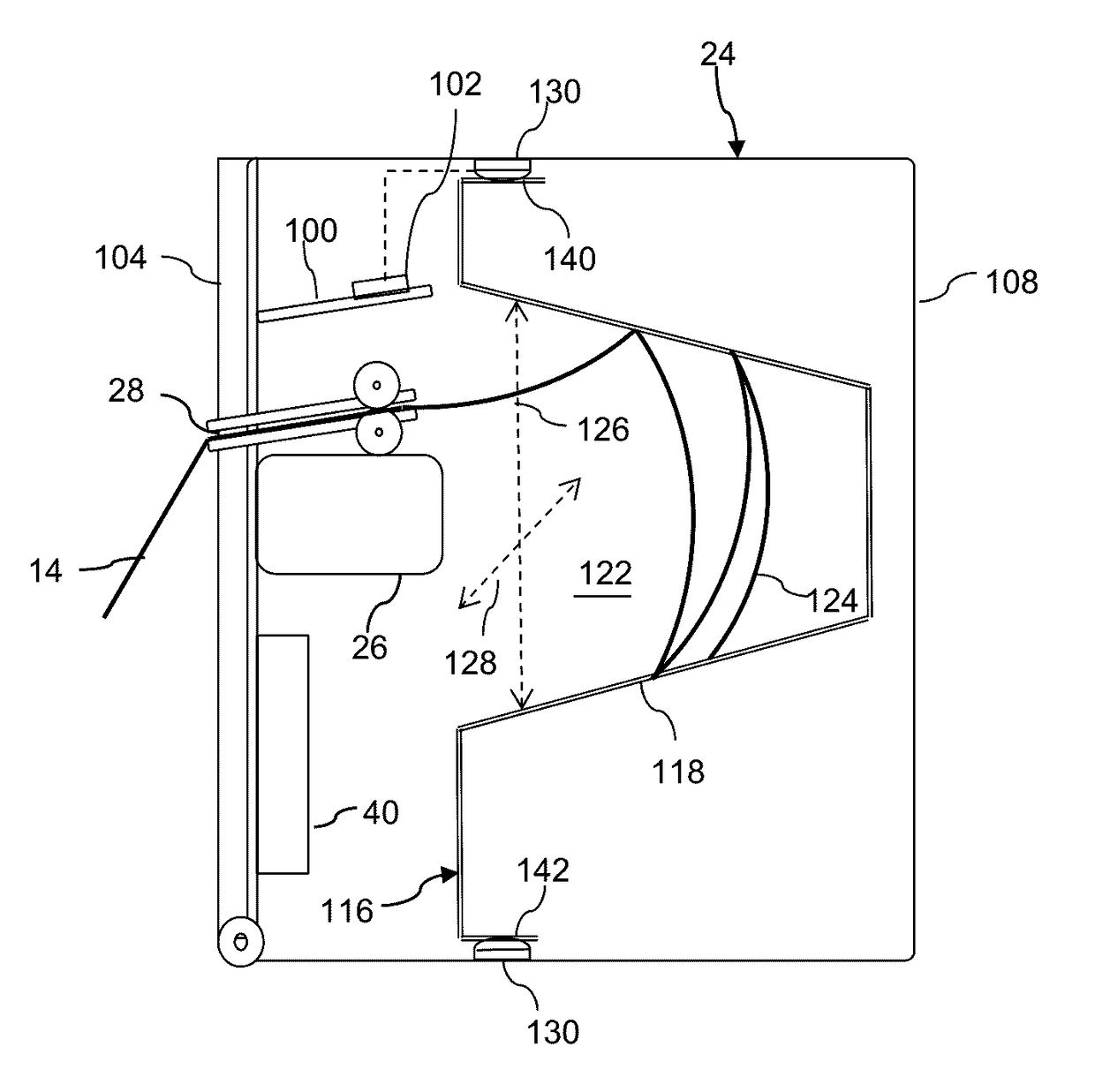

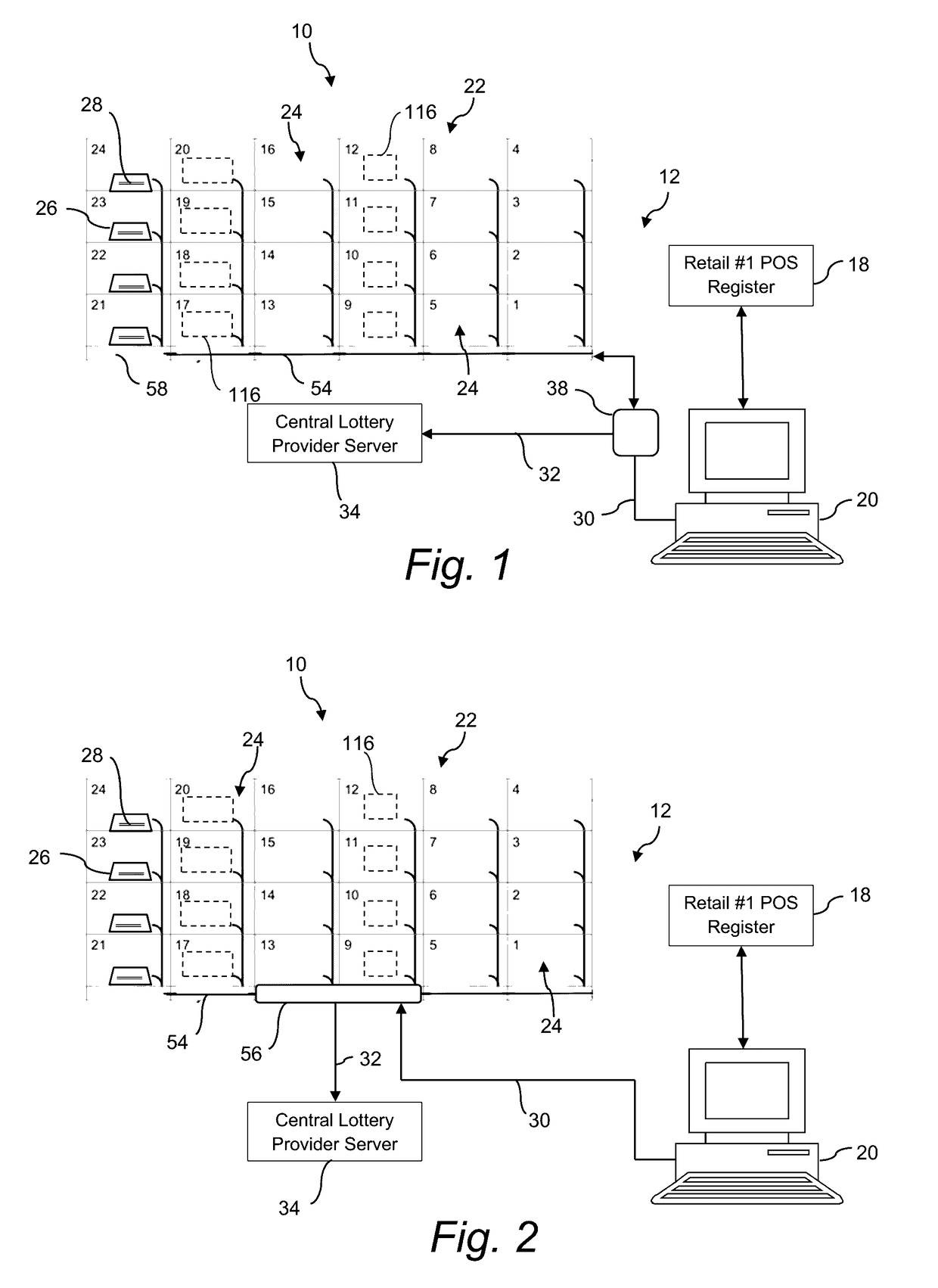

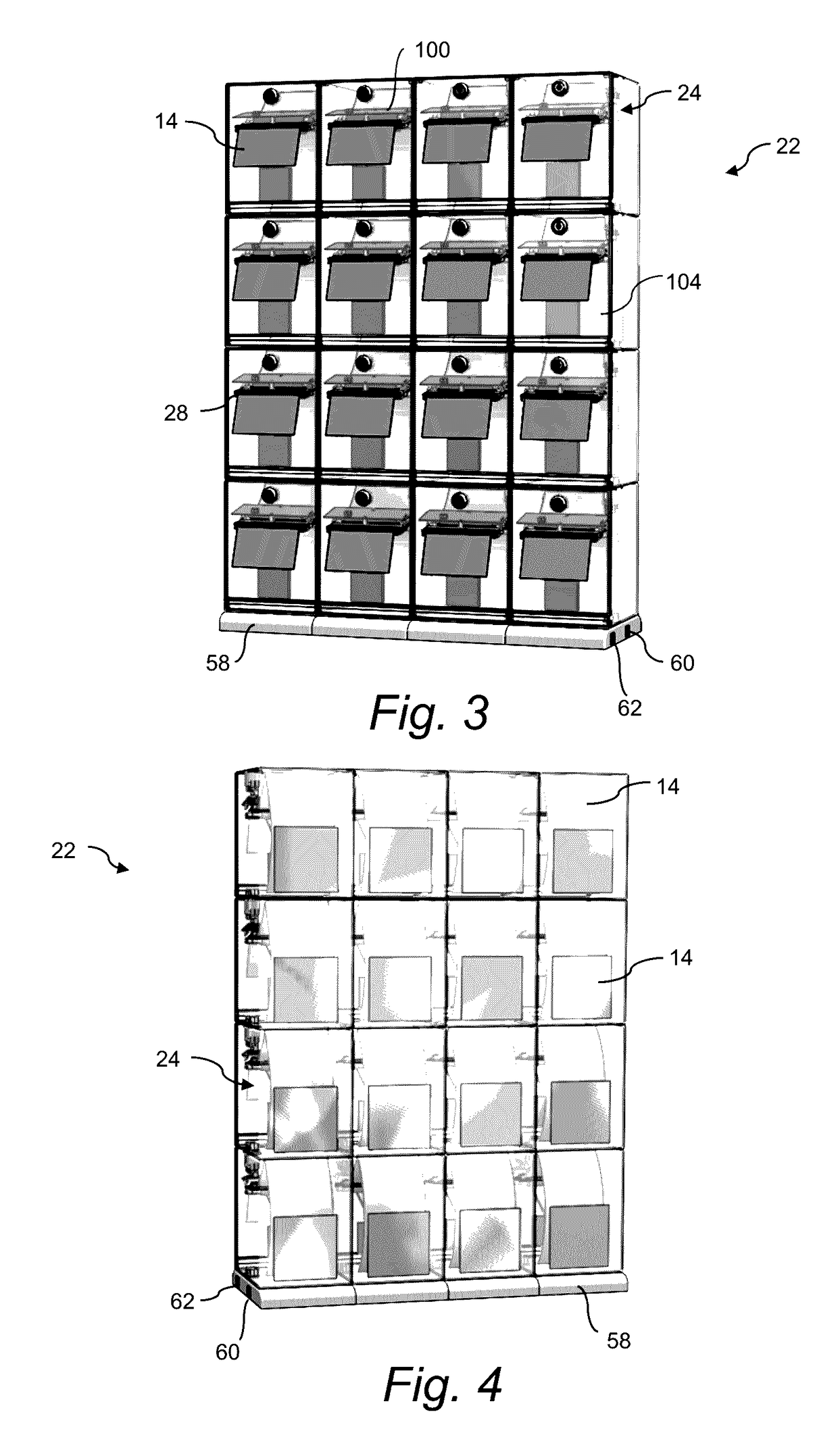

Smart bin lottery ticket dispenser with varying ticket size inserts

ActiveUS9685026B1Sure easyImprove versatilityLottery apparatusCoin-freed apparatus detailsEngineeringSmart bin

A lottery ticket dispenser array includes a plurality of separate bins, with each bin defined by a housing having a defined first internal space for receipt of first stack of interconnected lottery tickets. A plurality of different sized bin inserts are also provided, with each bin insert insertable into the bin housings and defining a second internal space that is less than the first internal space of the housing for receipt of a second stack of lottery tickets having a lesser individual length than the first stack of lottery tickets. A controller within each bin housing recognizes placement and size of the bin insert within the housing. The controller is in communication with an electronic drive mechanism to modify operation thereof to accommodate the lesser individual length of the lottery tickets in the second stack of lottery tickets.

Owner:SCI GAMES LLC

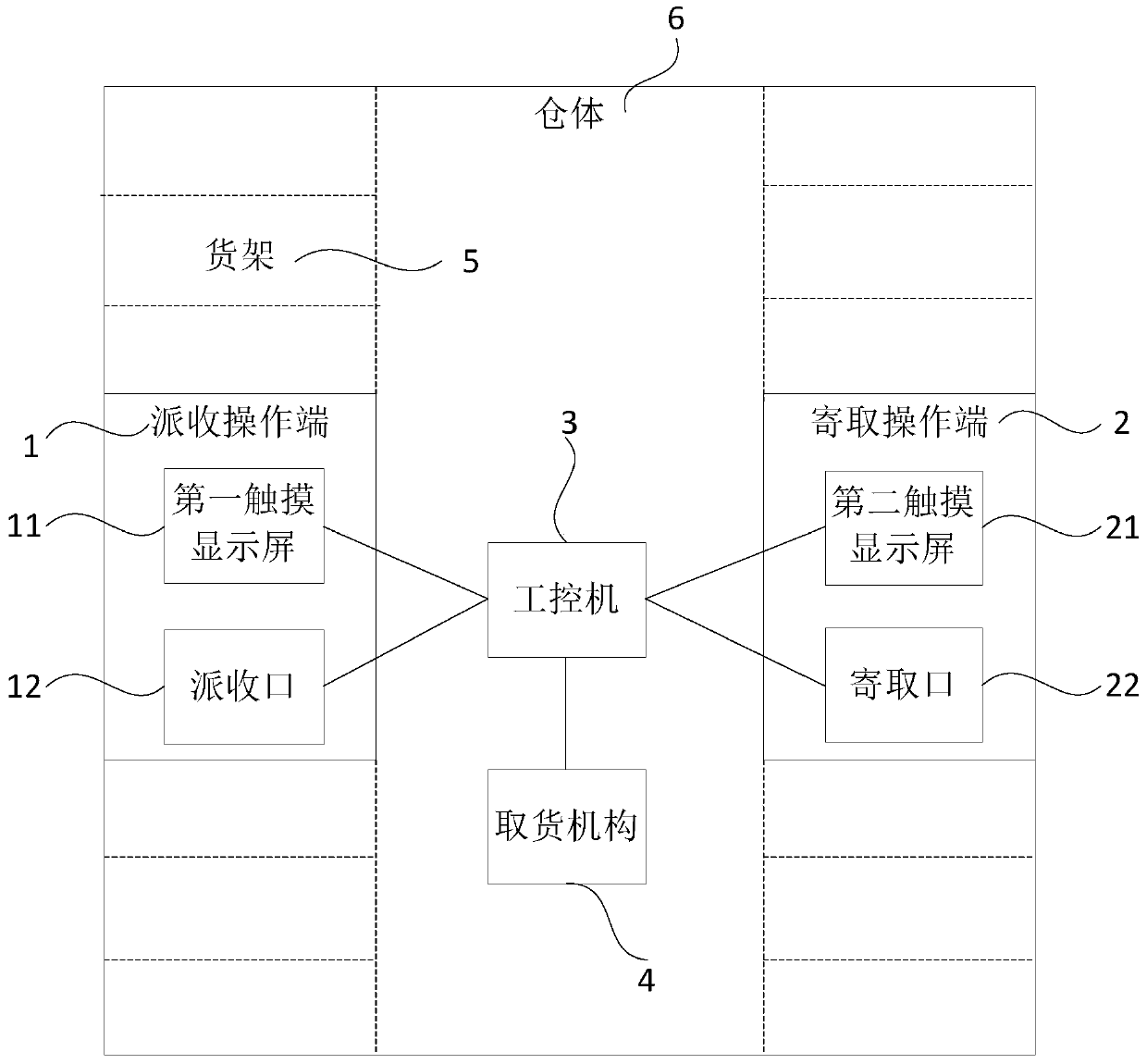

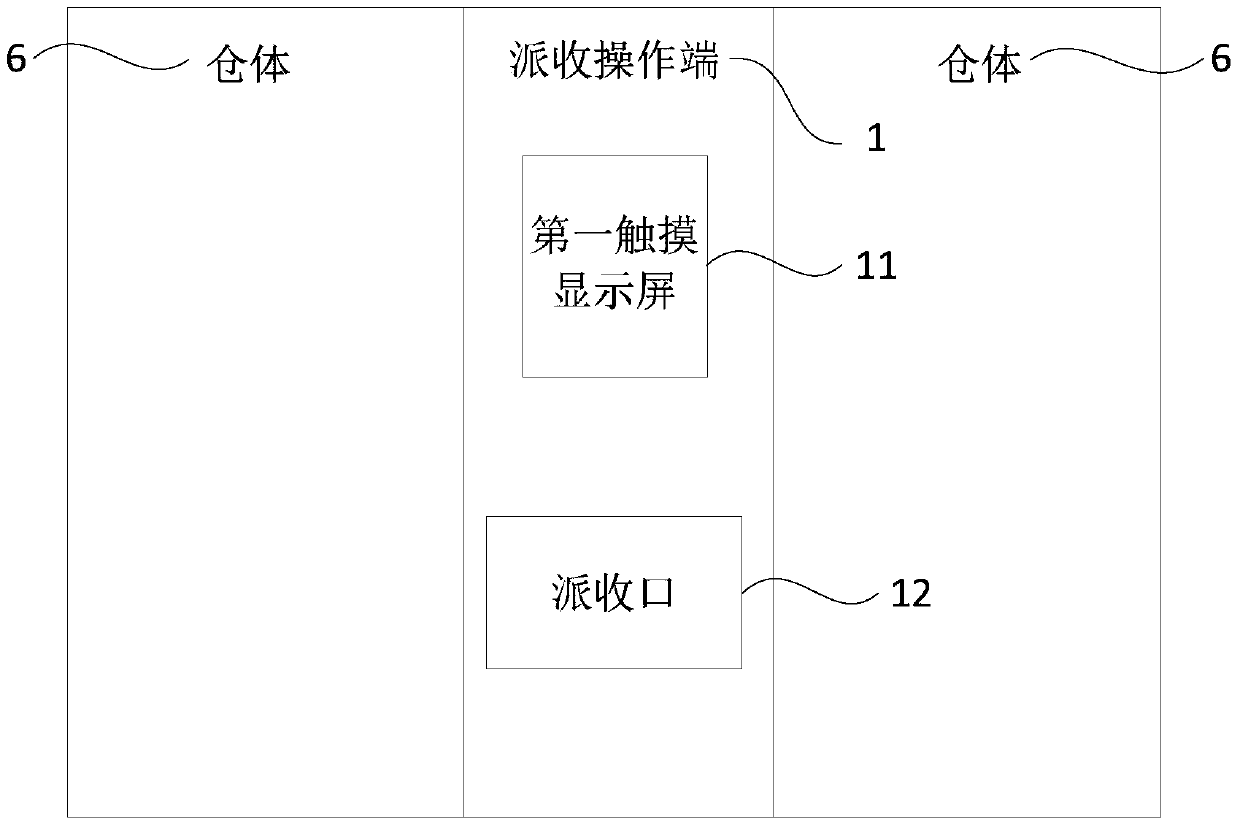

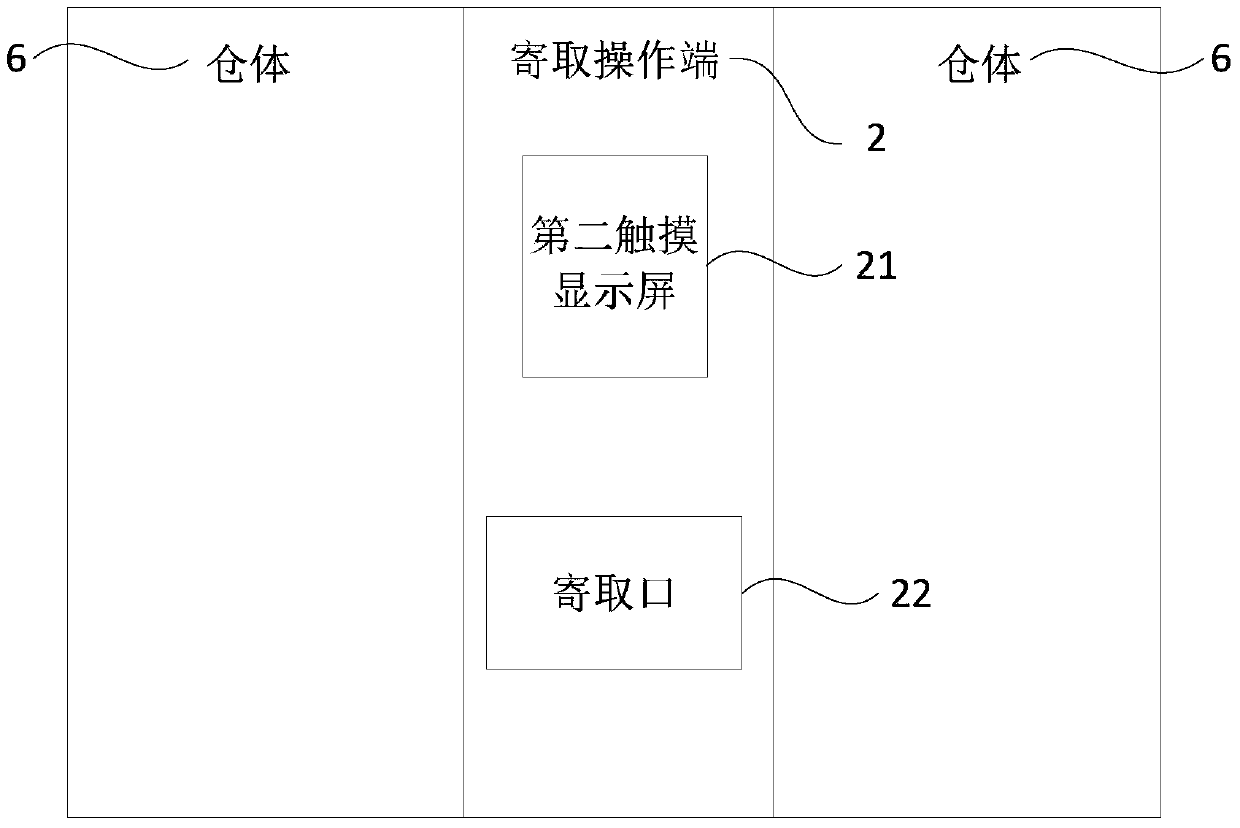

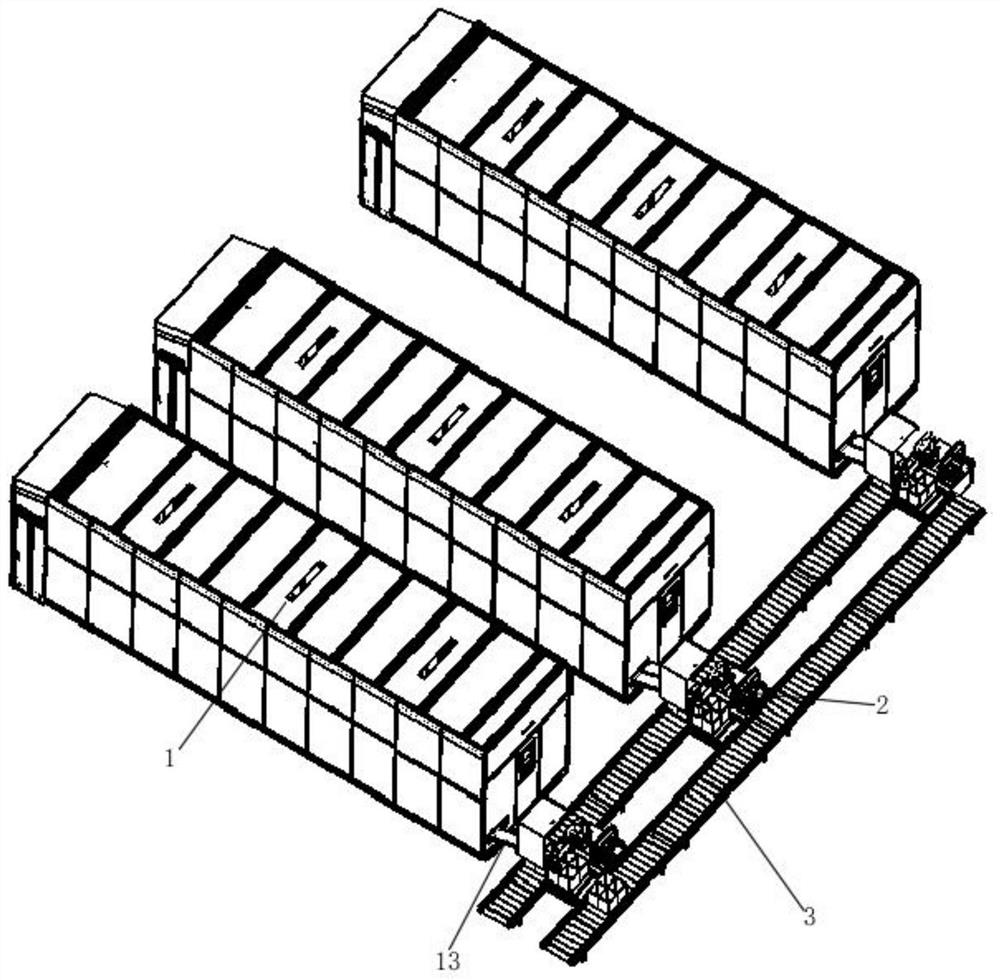

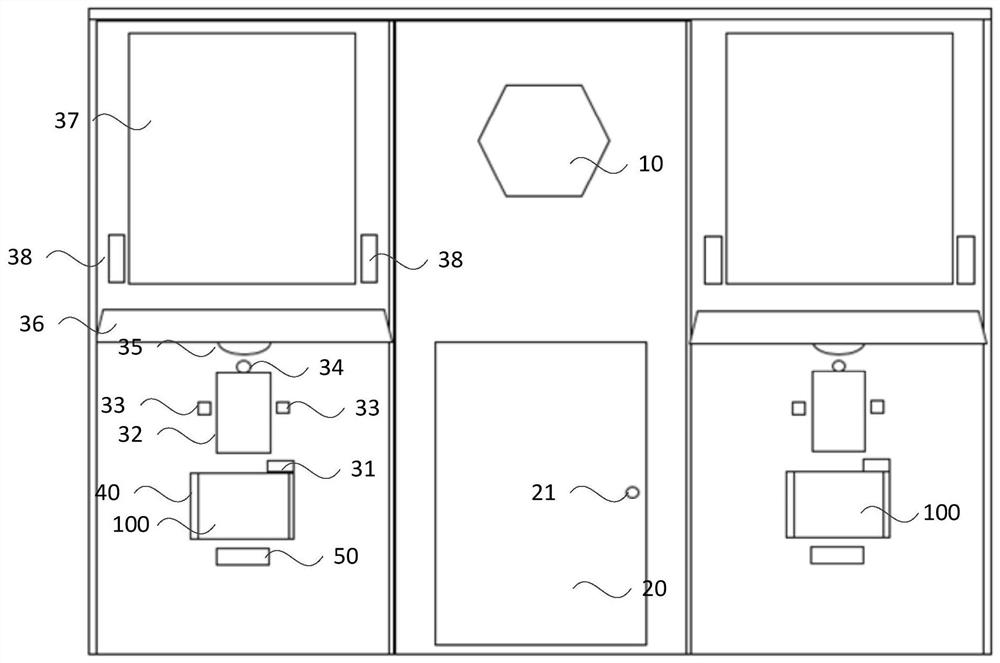

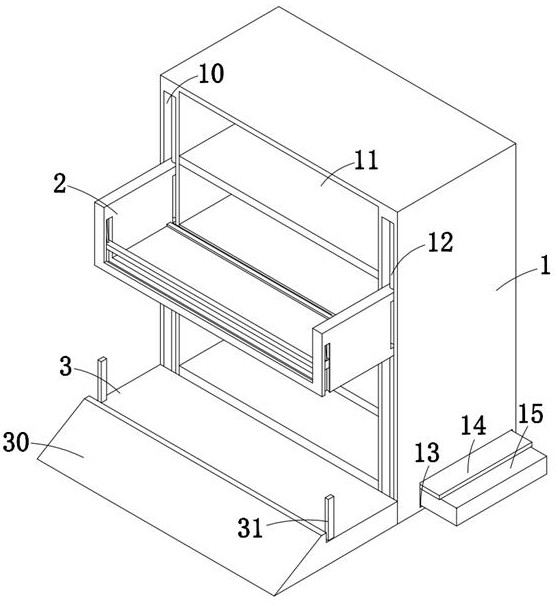

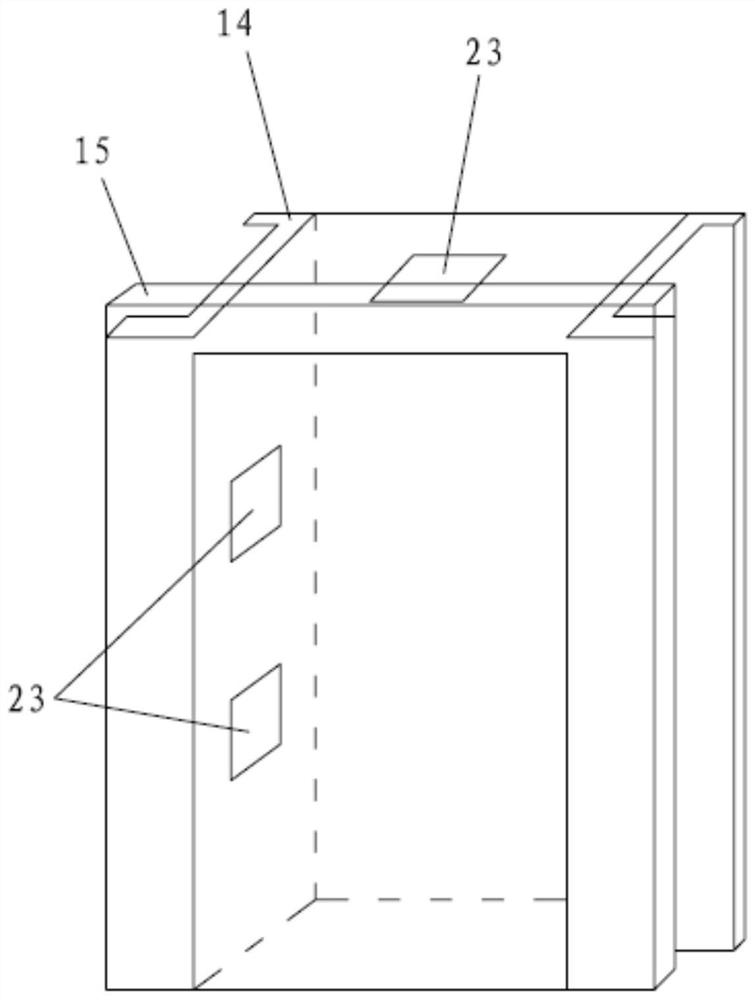

Intelligent warehouse, delivery method of intelligent warehouse and pickup method of intelligent warehouse

The invention discloses an intelligent warehouse, a delivery method of the intelligent warehouse and a pickup method of the intelligent warehouse. The intelligent warehouse comprises a delivery and receiving operation end, a sending and pickup operation end, an industrial personal computer, a pickup mechanism, a goods shelf and a warehouse body. The warehouse body is connected with the delivery and receiving operation end and the sending and pickup operation end, the industrial personal computer is located in the warehouse body and is used for receiving the delivery and receiving information sent by a first touch display screen, receiving the sending and pickup information sent by a second touch display screen, controlling the opening and closing of a delivery and receiving port and controlling the opening and closing of a sending and pickup port. In the embodiment of the invention, a courier and a common user can respectively complete the delivery and receiving service and the sendingand pickup service at different operation ends, especially for a closed area with the extremely strict entrance guard safety, the problem that the courier inconveniently enters and exits from the closed area, is solved, the express service requirements of the users in the closed area are met, and the use area of the intelligent warehouse and the audience groups are greatly expanded.

Owner:SHENZHEN HIVE BOX TECHNOLOGY CO LTD

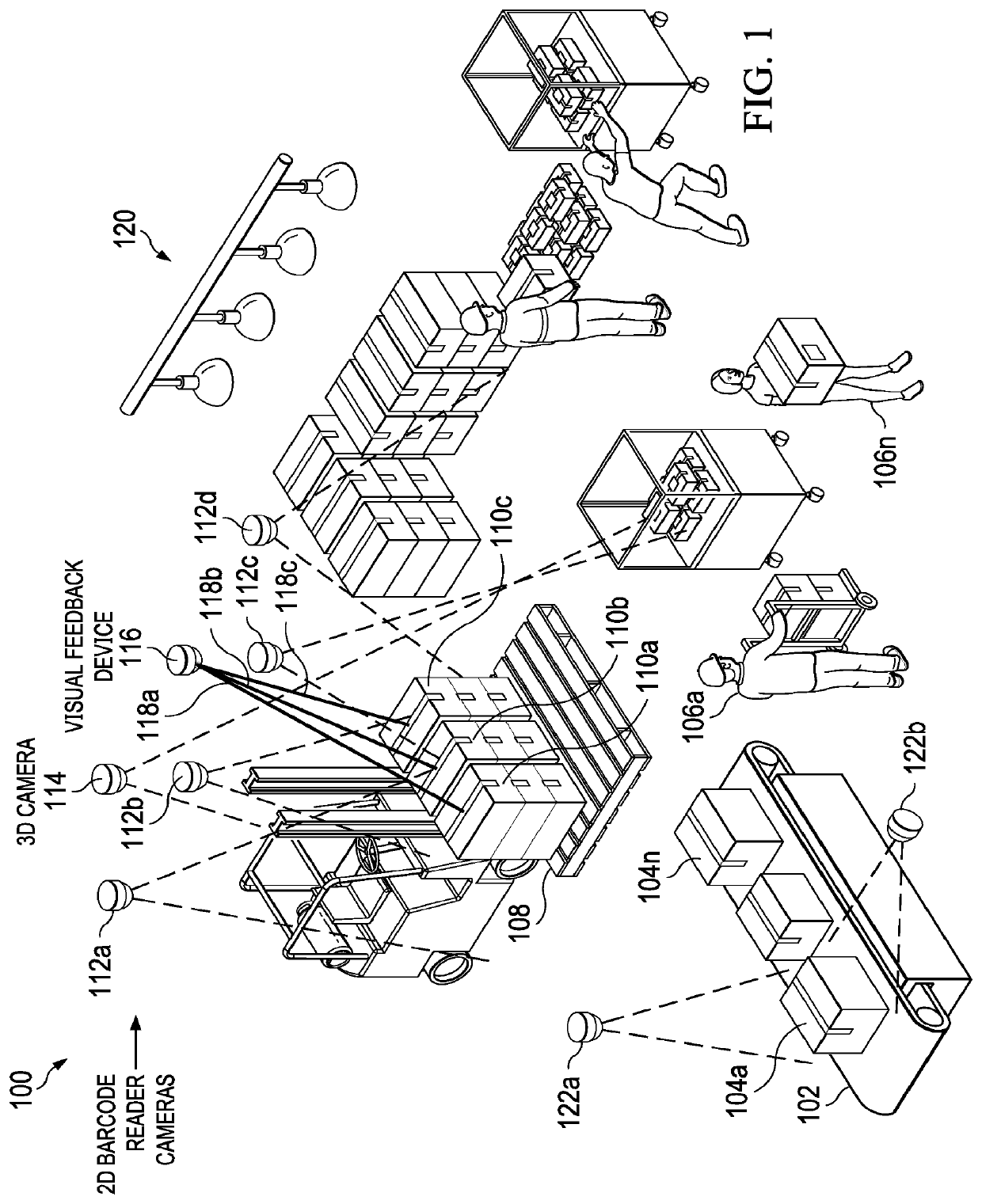

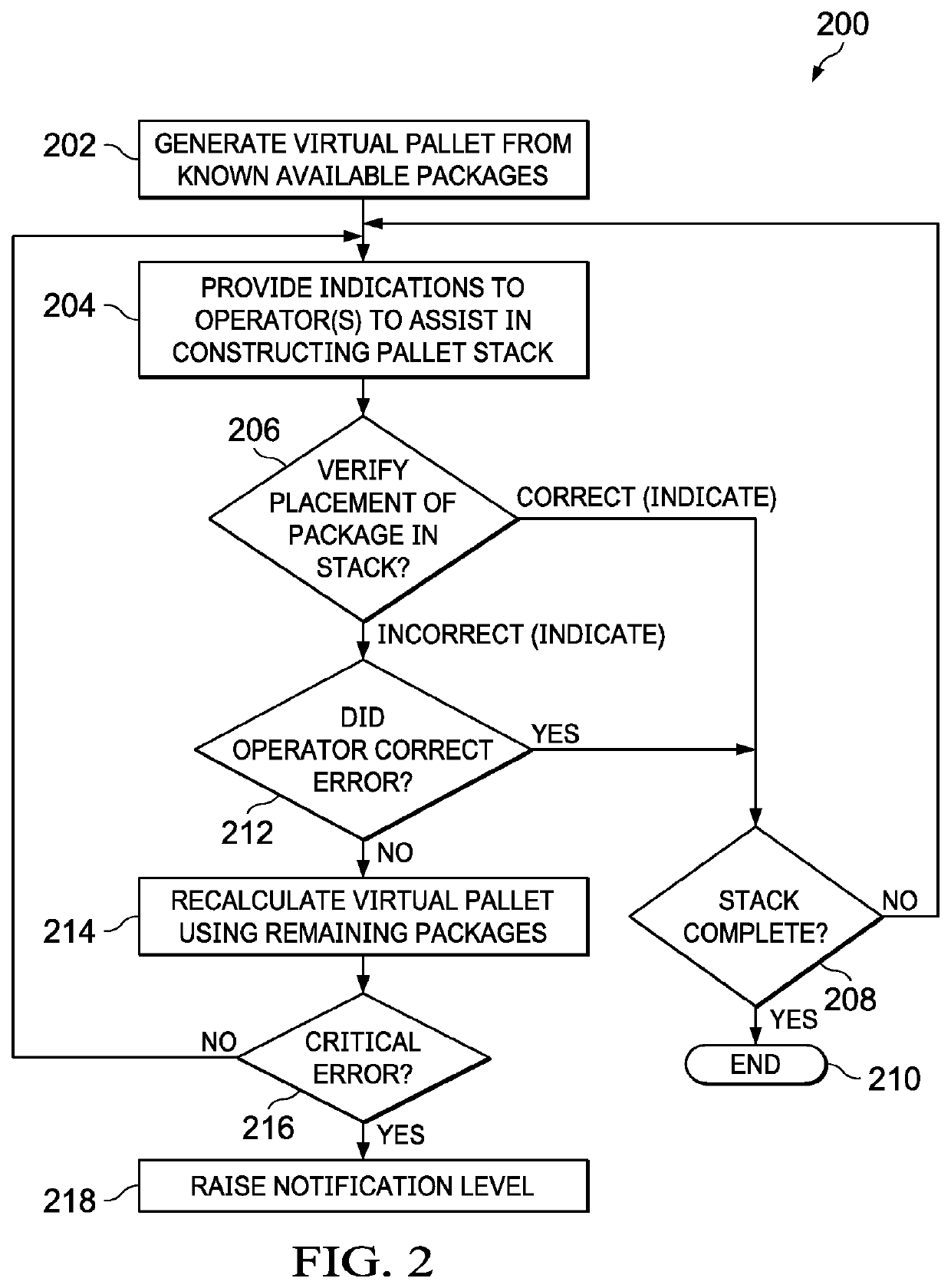

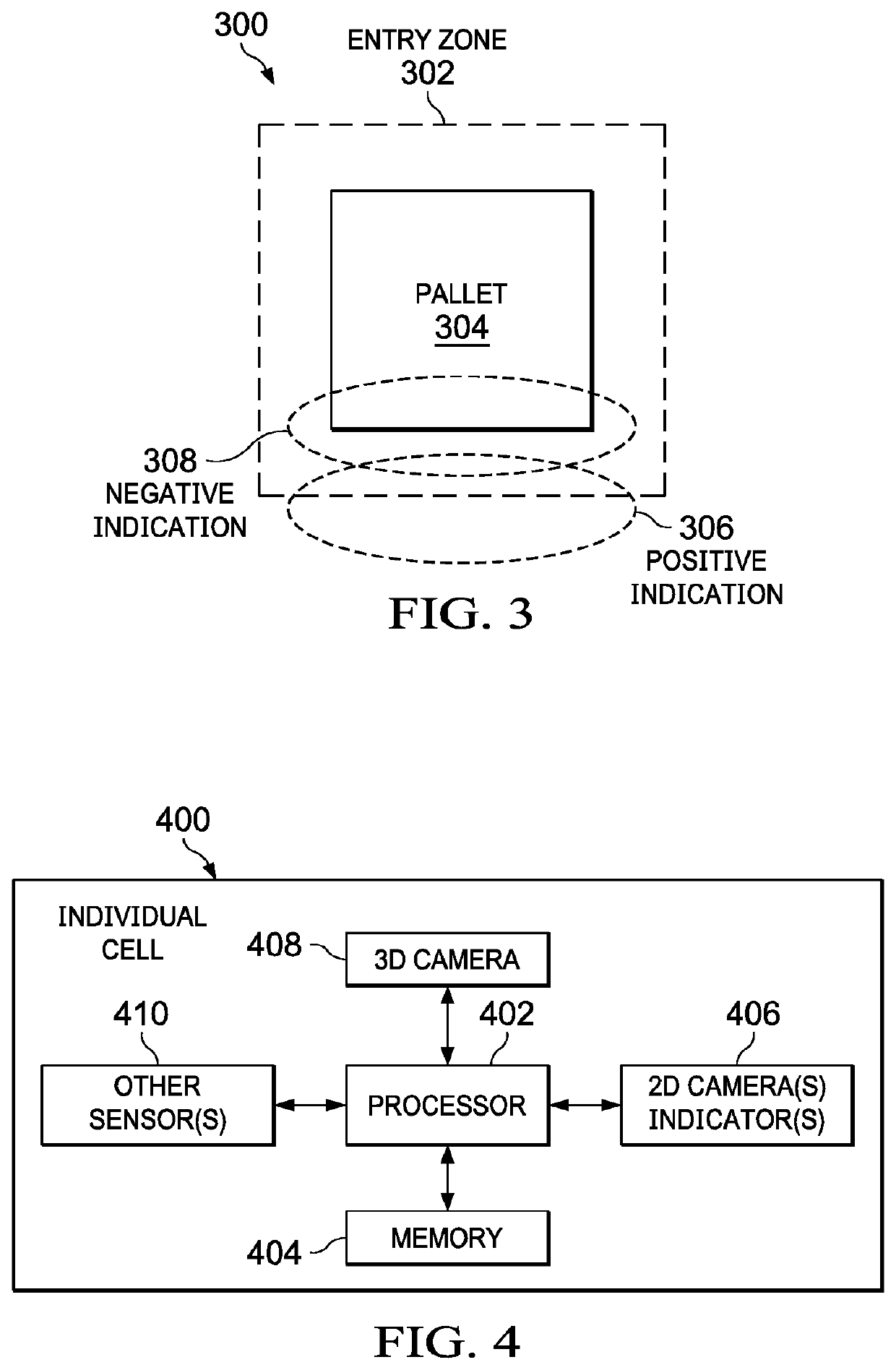

Smart warehouse, conveyor, and pallet management system

PendingUS20220073280A1Efficient and accurate and safer operationLow costConveyorsStacking articlesSmart binOperating system

A system and computer-implemented method for pallet management and constructing a pallet stack may include generating a virtual pallet stack using virtual packages having sizes and shapes corresponding with known available actual packages. In response to identifying an actual package to be placed on a pallet, an indication may be provided to a worker where the identified actual package is to be placed on the pallet stack based on the location of a corresponding virtual package on the virtual pallet stack.

Owner:DATALOGIC USA INC

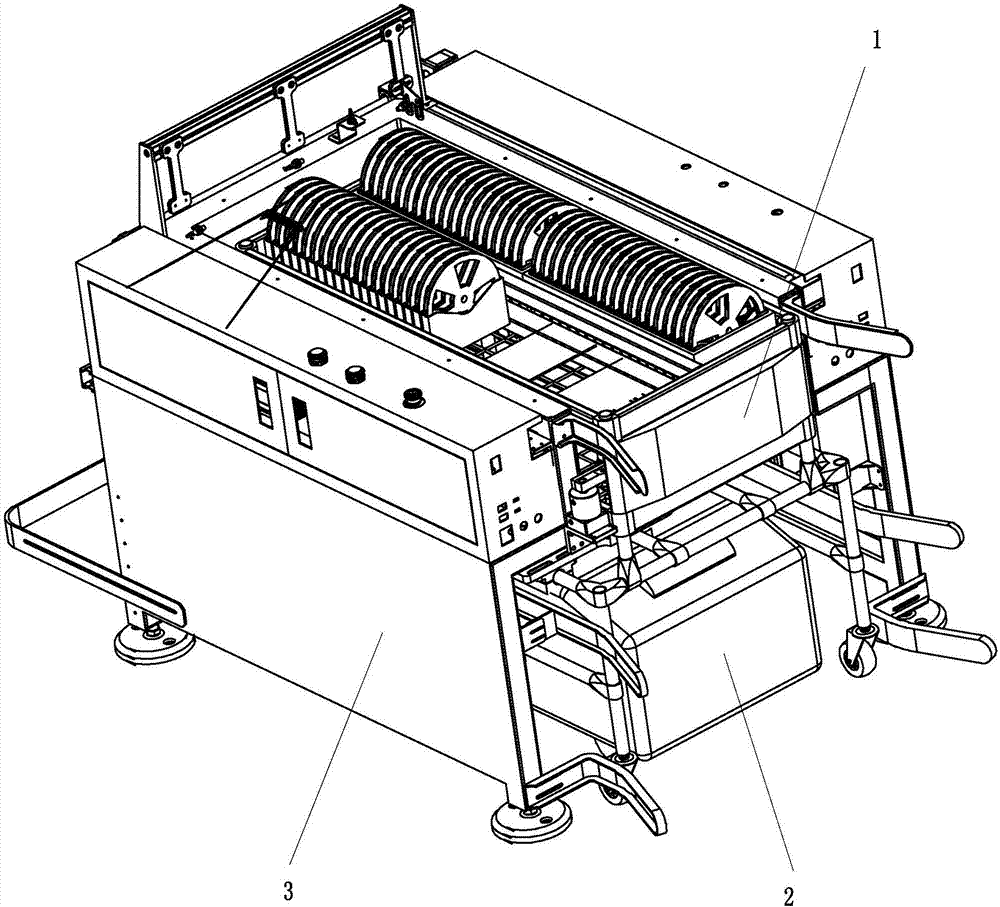

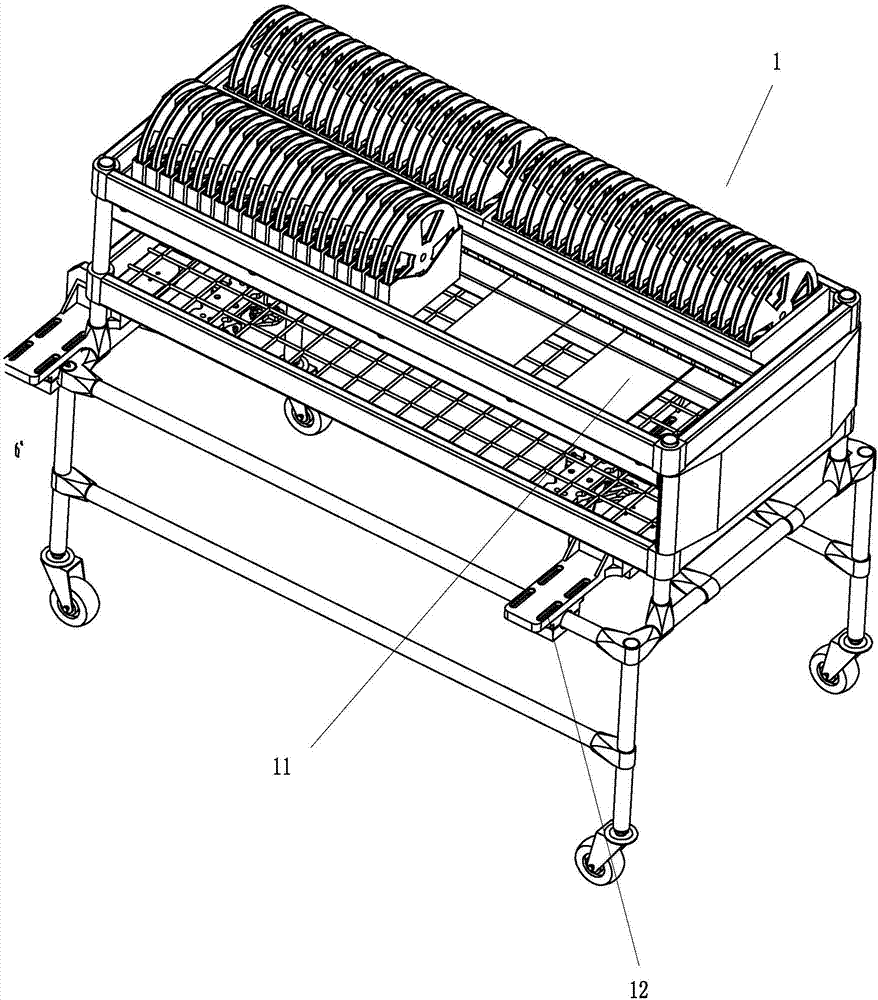

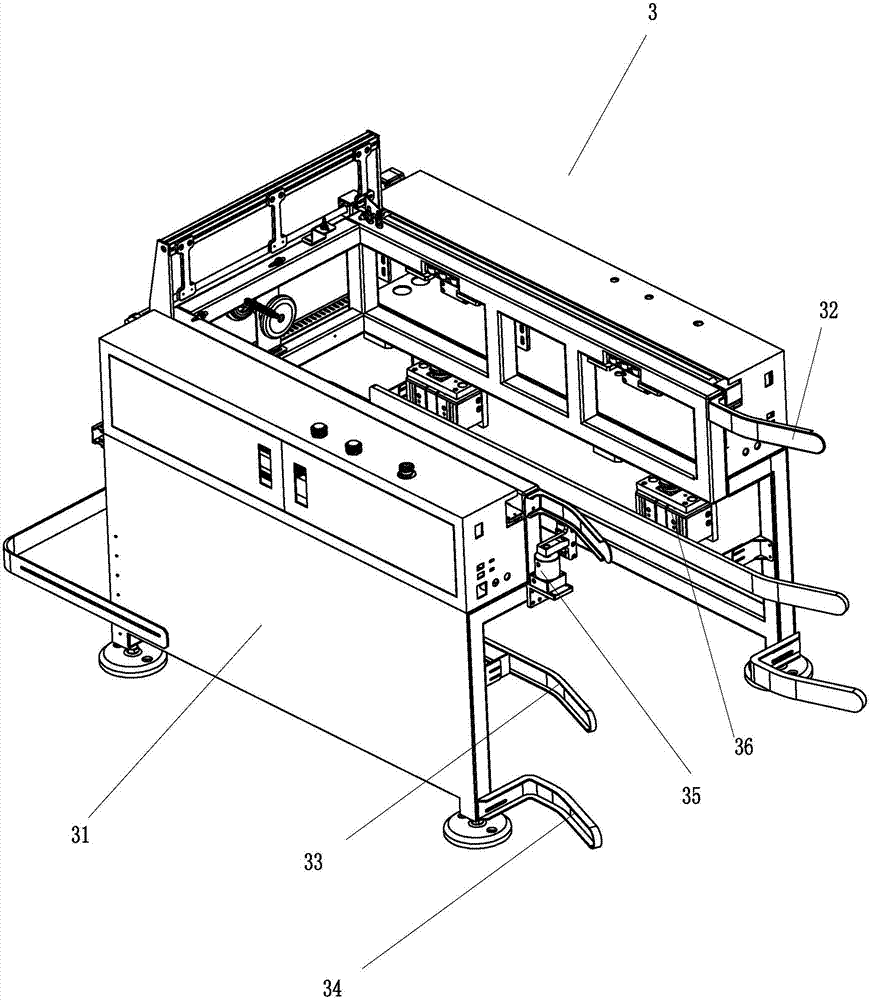

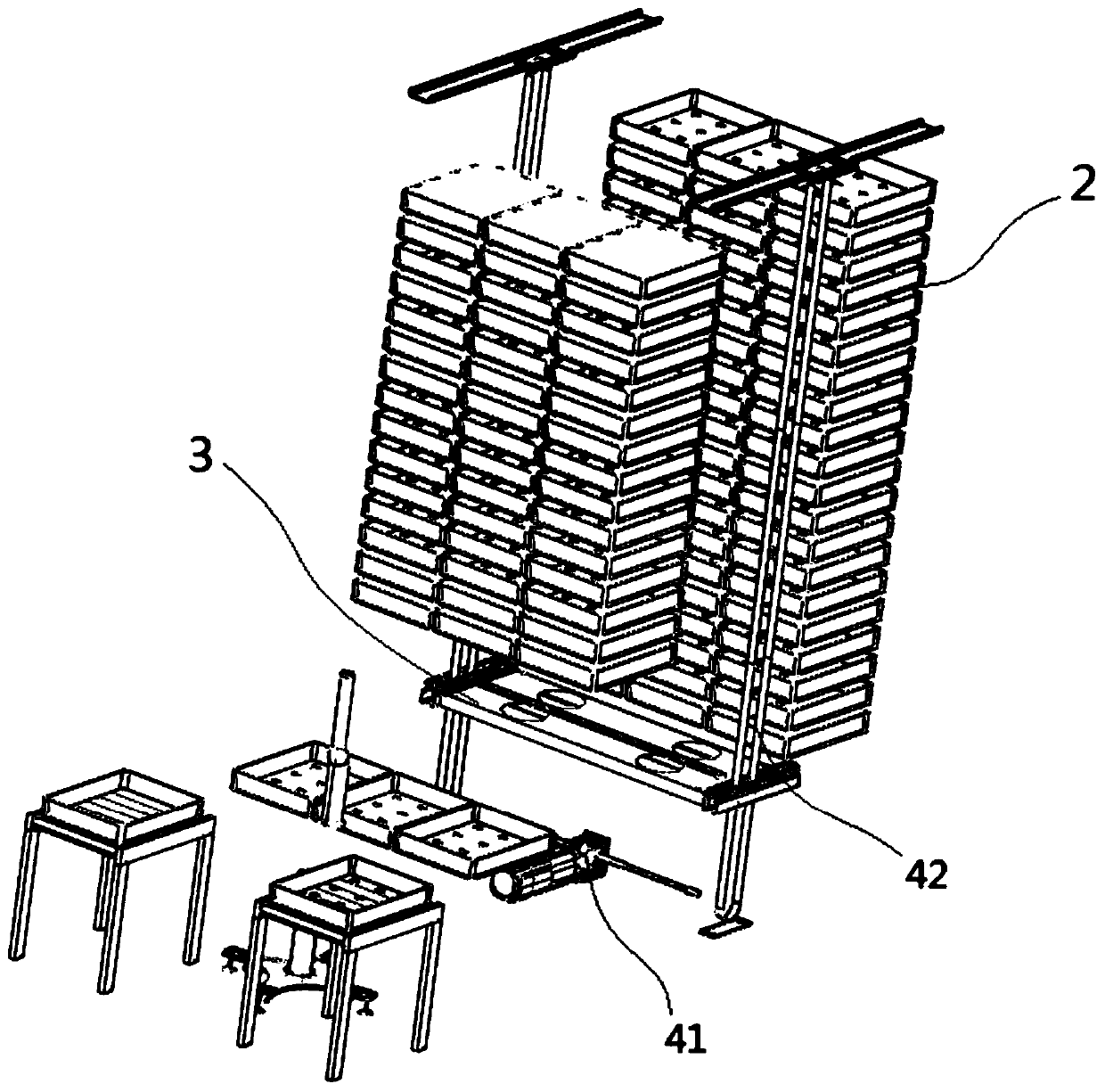

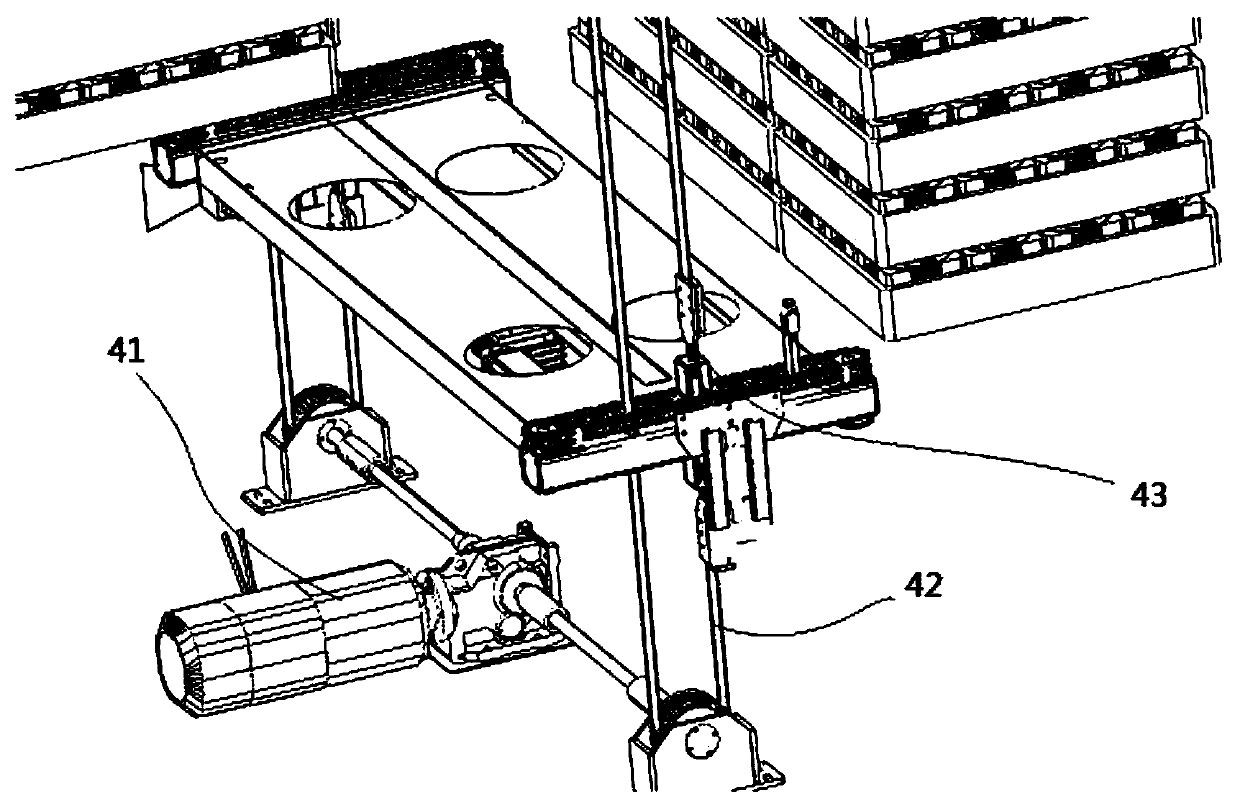

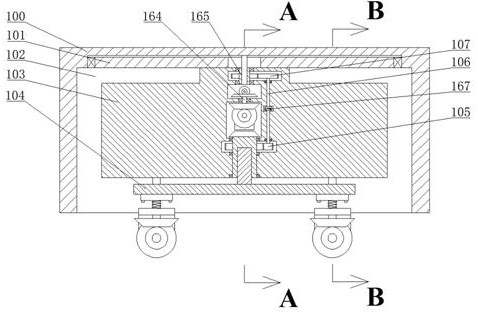

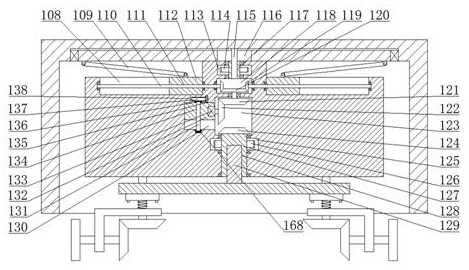

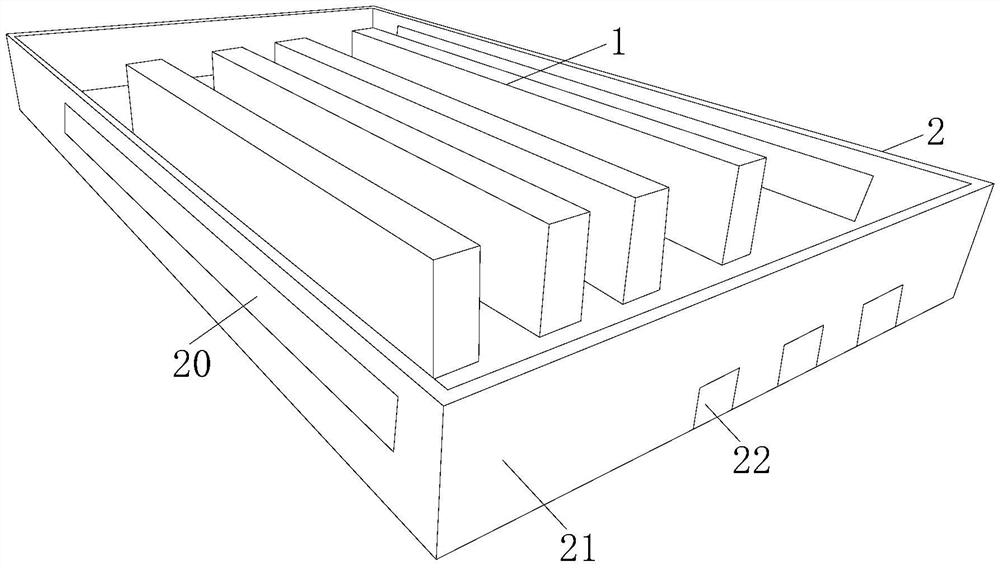

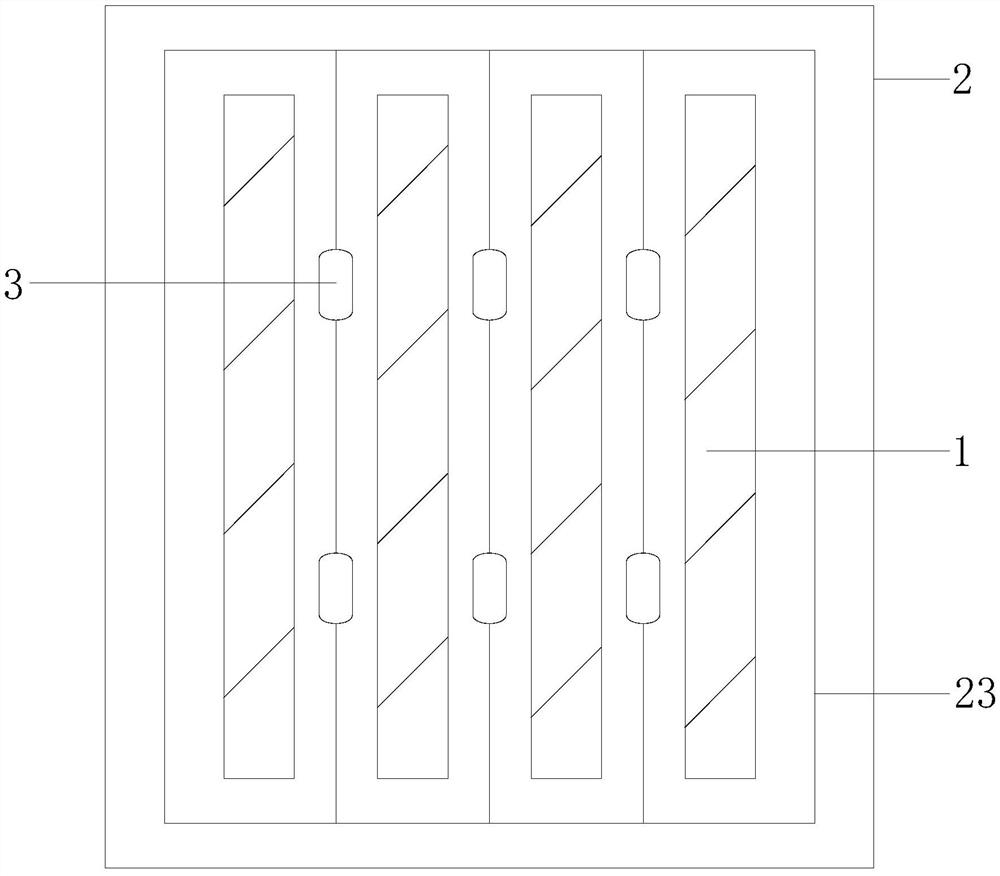

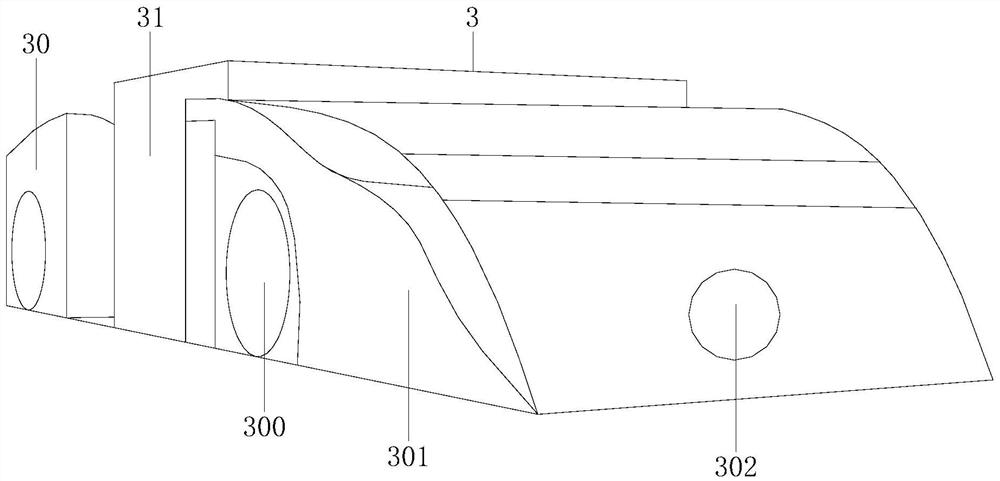

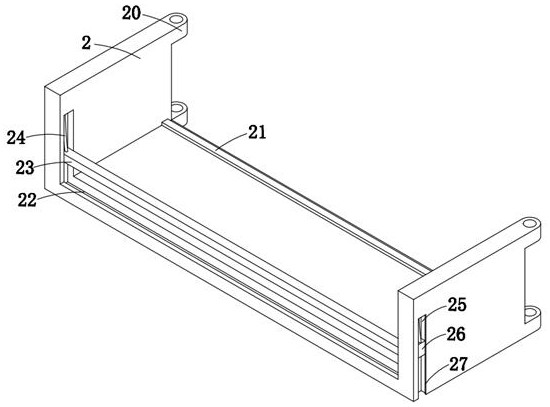

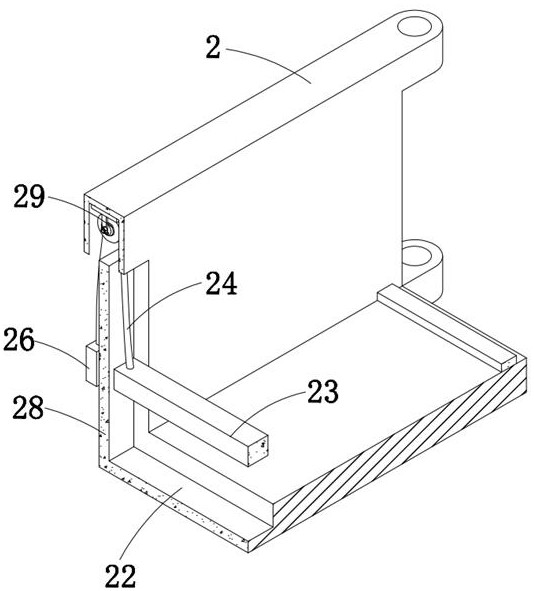

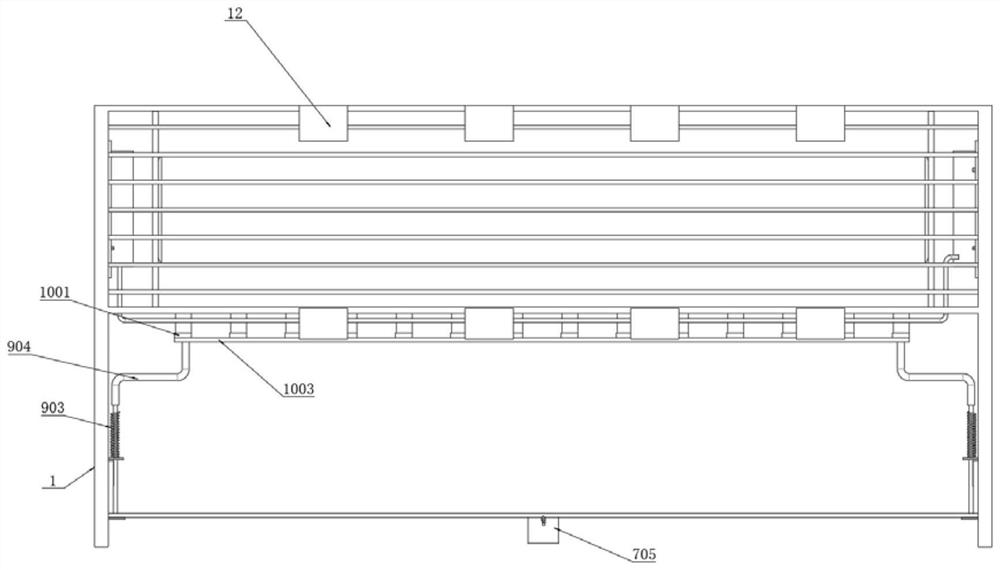

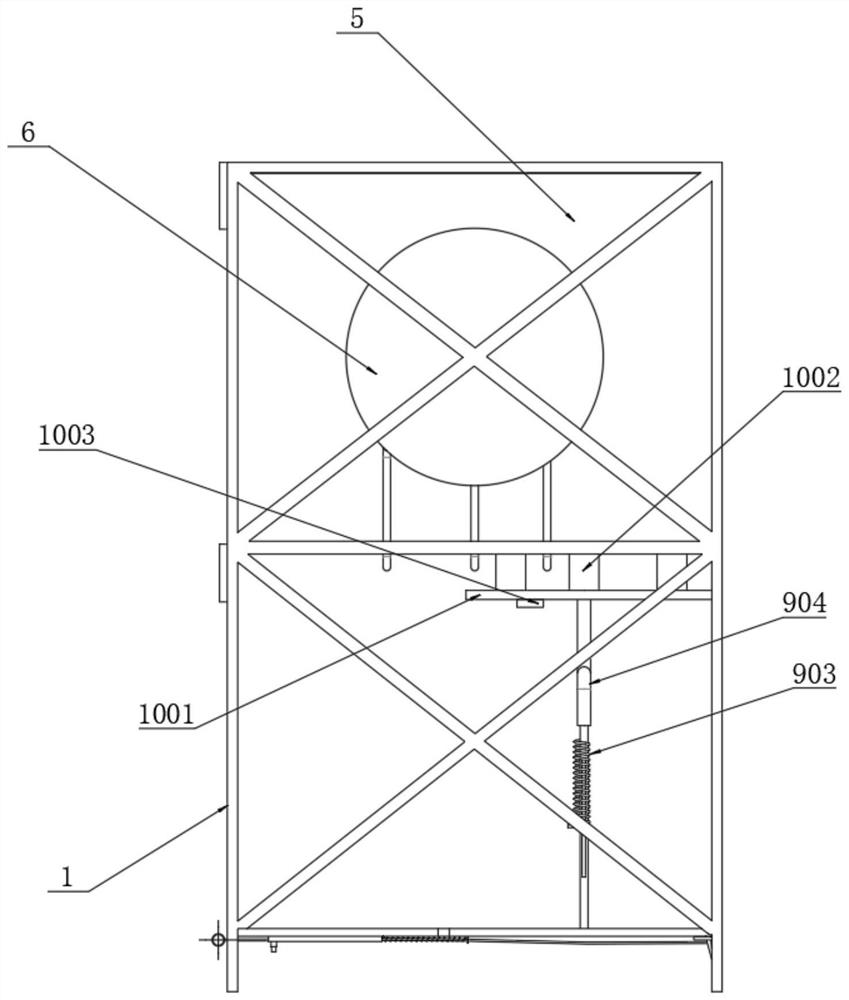

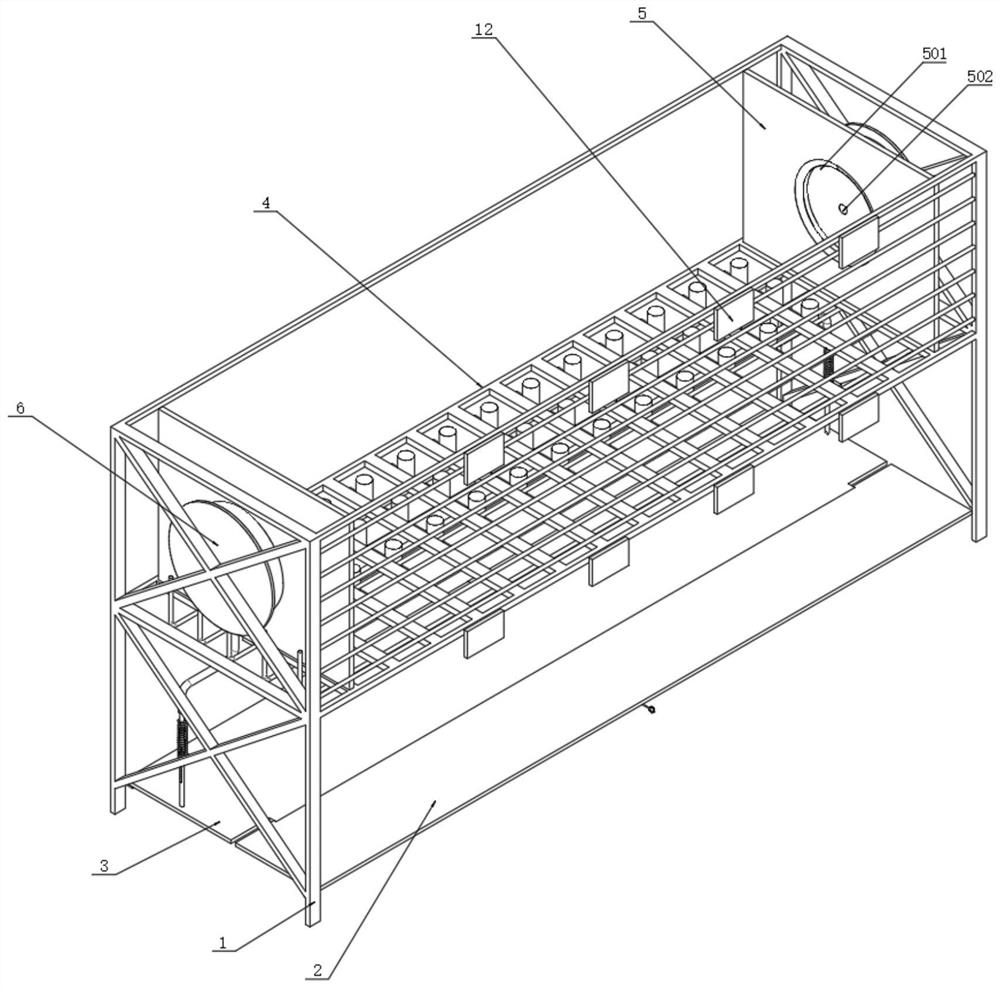

Intelligent bin tray transfer system and method thereof

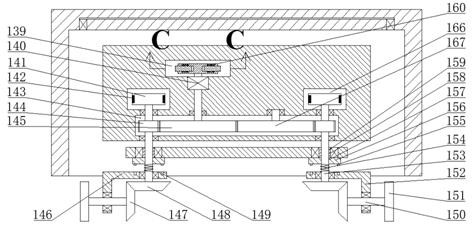

The invention discloses an intelligent bin tray transfer system. The intelligent bin tray transfer system comprises a control mechanism, a transfer mechanism, a transportation mechanism, an emptying mechanism and a positioning mechanism. A method comprises the following steps: (S1) the transportation mechanism drives the transfer mechanism to enter the positioning mechanism; (S2) the transportation mechanism leaves away; (S3) the transfer mechanism is ascended; (S4) the transfer mechanism is centered and positioned; (S5) materials are emptied; (S6) the transportation mechanism enters the positioning mechanism, and is connected with the transfer mechanism; (S7) the transfer mechanism is descended; (S8) the transportation mechanism drives the transfer mechanism to leave from the positioningmechanism; and (S9) the step (S1) is returned to for renewed actuation. The Intelligent bin tray transfer system and the method thereof achieve full-automatic tray transfer and circulating operation,realize unmanned workshop and precise transportation, increase the tray conveying quantity, prominently improve the production efficiency, reduce the production cost, reduce the labor intensity of operators, meet industrial 4.0 demands, accelerate optimal upgrading of industrial structures, and achieve excellent market popularization value.

Owner:福建宏泰智能工业互联网有限公司

Material intelligent storage and access method

The invention discloses an intelligent warehousing and access method for materials, which includes the following steps: coding of materials; a feeder delivering a material tray containing materials to a material discharging platform at a material feeding window of an intelligent warehouse; a manipulator of the intelligent warehouse Automatically grab materials and store them into the bin of the smart warehouse at the address specified by the material management software system; when discharging materials, the robot takes out the material tray from the bin address specified by the warehousing system and transports it to the material conveyor belt of the smart warehouse. The material conveyor belt transports the material tray to the discharging port of the smart warehouse to complete the discharging of the smart warehouse. The intelligent material warehousing and access method of the present invention can achieve precise access to multiple materials or a single material through the combined use of an intelligent warehouse and a material management software system. It has a high degree of automation and will not cause wrong materials or material losses. Reduce the problem of sluggish materials, improve the efficiency of material access, save manpower, and help improve production efficiency and reduce production costs.

Owner:SUZHOU I STOCK INTELLIGENT TECH

Flexible bin allocation method for electric power materials

PendingCN113011813AIntelligent operationImplement standardized storageCo-operative working arrangementsLogisticsSmart binElectric power

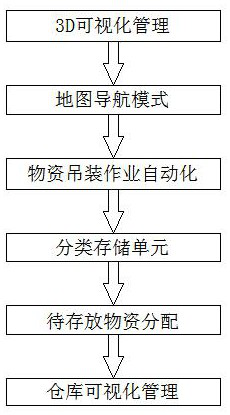

The invention discloses a flexible bin allocation method for electric power materials, and the method comprises the steps: counting a current material storage condition through 3D visual management, and building a 3D model; creating a map navigation mode, and achieving accurate navigation of the driving track of the forklift in the warehouse; arranging a main control device and a positioning device arranged on a fine positioning crane body, so that automation of material hoisting operation is completed; classifying and designing storage units of the materials, and storing different to-be-stored materials in the storage units of the corresponding types; according to the type, the number and the size of the arriving material and the material storage condition 3D model of the current warehouse, allocating the to-be-stored materials to the corresponding storage allocation position; and achieving the visual management of the warehouse by sensing equipment. Warehouse business development requirements are combined, automatic and intelligent facilities and equipment are taken as a basis, a 3D visual management system is taken as a means, warehouse visual management, intelligent operation and standardized storage are realized, and a power grid leading intelligent warehouse is formed.

Owner:JIANGSU ANFANG ELECTRIC POWER TECH

Unmanned warehouse goods transportation matching method and device

ActiveCN111027902AImprove solution efficiencyImprove matching efficiencyLogisticsSmart binReal-time computing

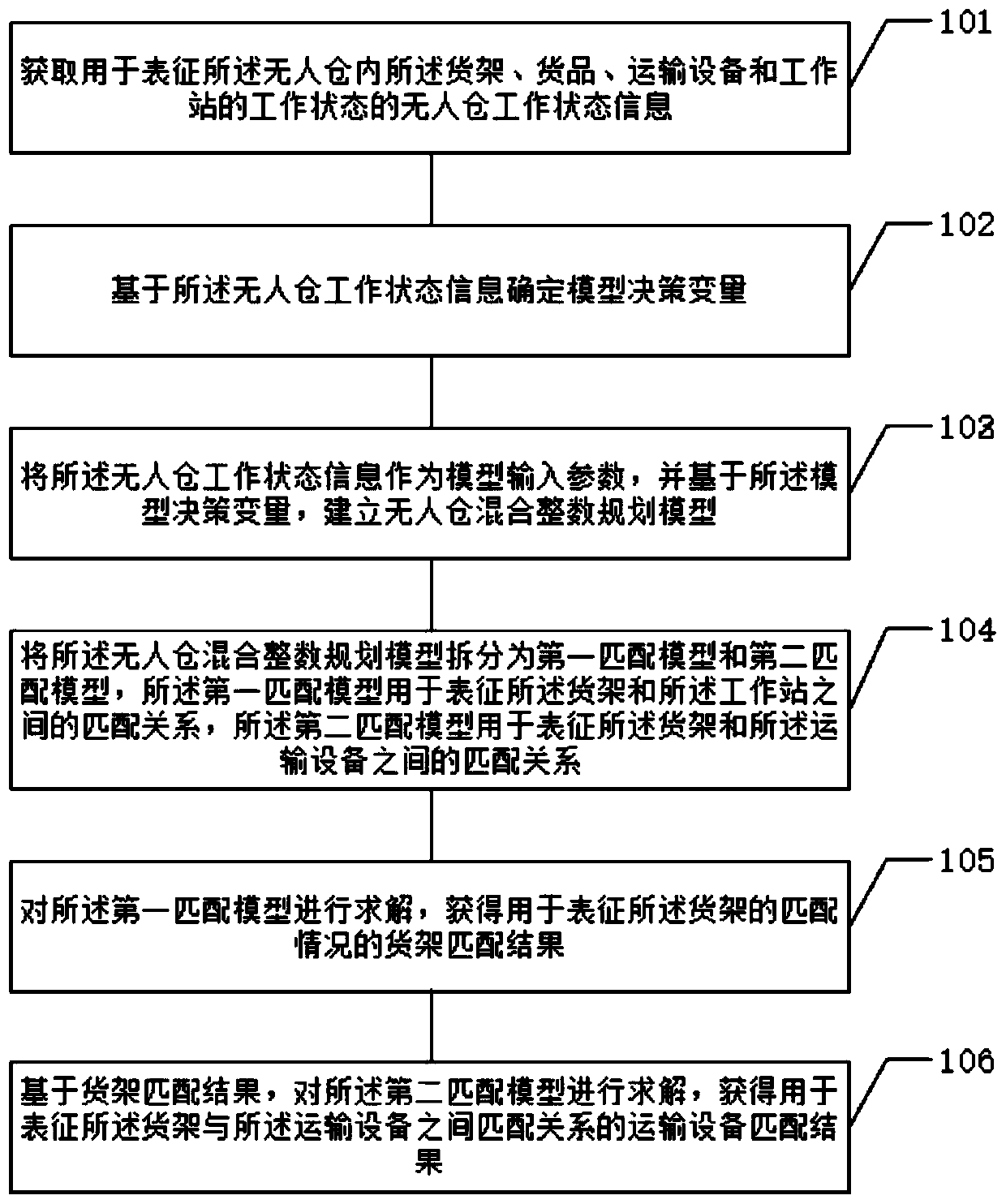

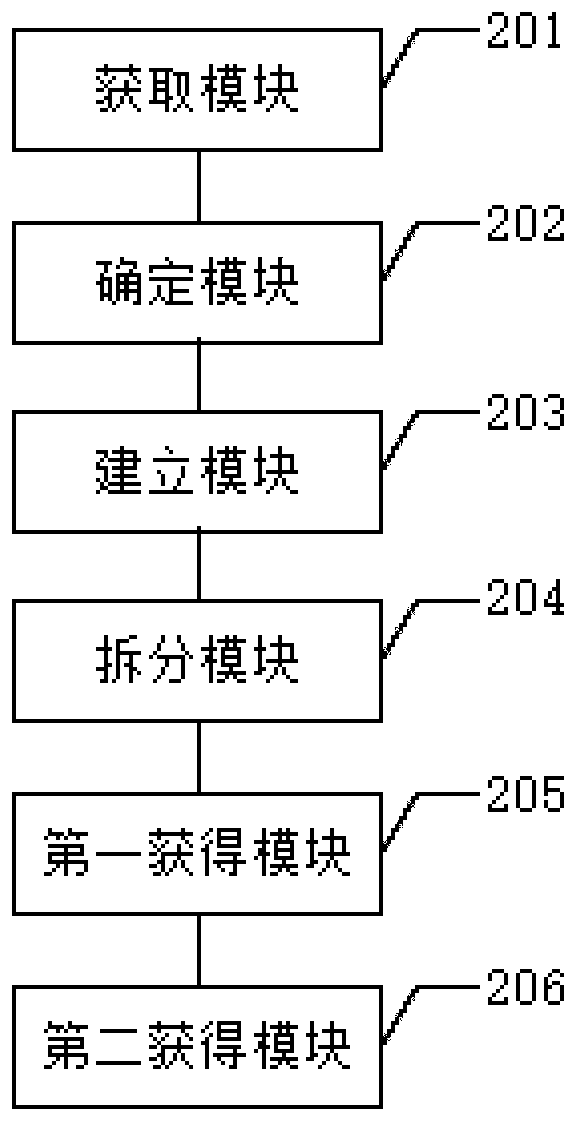

The invention relates to the technical field of intelligent warehousing, in particular to an unmanned warehouse goods transportation matching method and device, and the method comprises the steps: obtaining unmanned warehouse working state information which is used for representing the working states of a goods shelf, goods, transportation equipment and a workstation in an unmanned warehouse; determining a model decision variable based on the unmanned cabin working state information; taking the unmanned cabin working state information as a model input parameter, and establishing an unmanned cabin mixed integer programming model based on a model decision variable; splitting the unmanned warehouse mixed integer programming model into a first matching model and a second matching model, wherein the first matching model is used for representing the matching relation between the goods shelf and the workstation, and the second matching model is used for representing the matching relation between the goods shelf and the transportation equipment; solving the first matching model to obtain a goods shelf matching result used for representing the matching condition of the goods shelf; and based on the shelf matching result, solving the second matching model to obtain a transportation equipment matching result used for representing the matching relationship between the shelf and the transportation equipment.

Owner:上海万筹科技有限公司

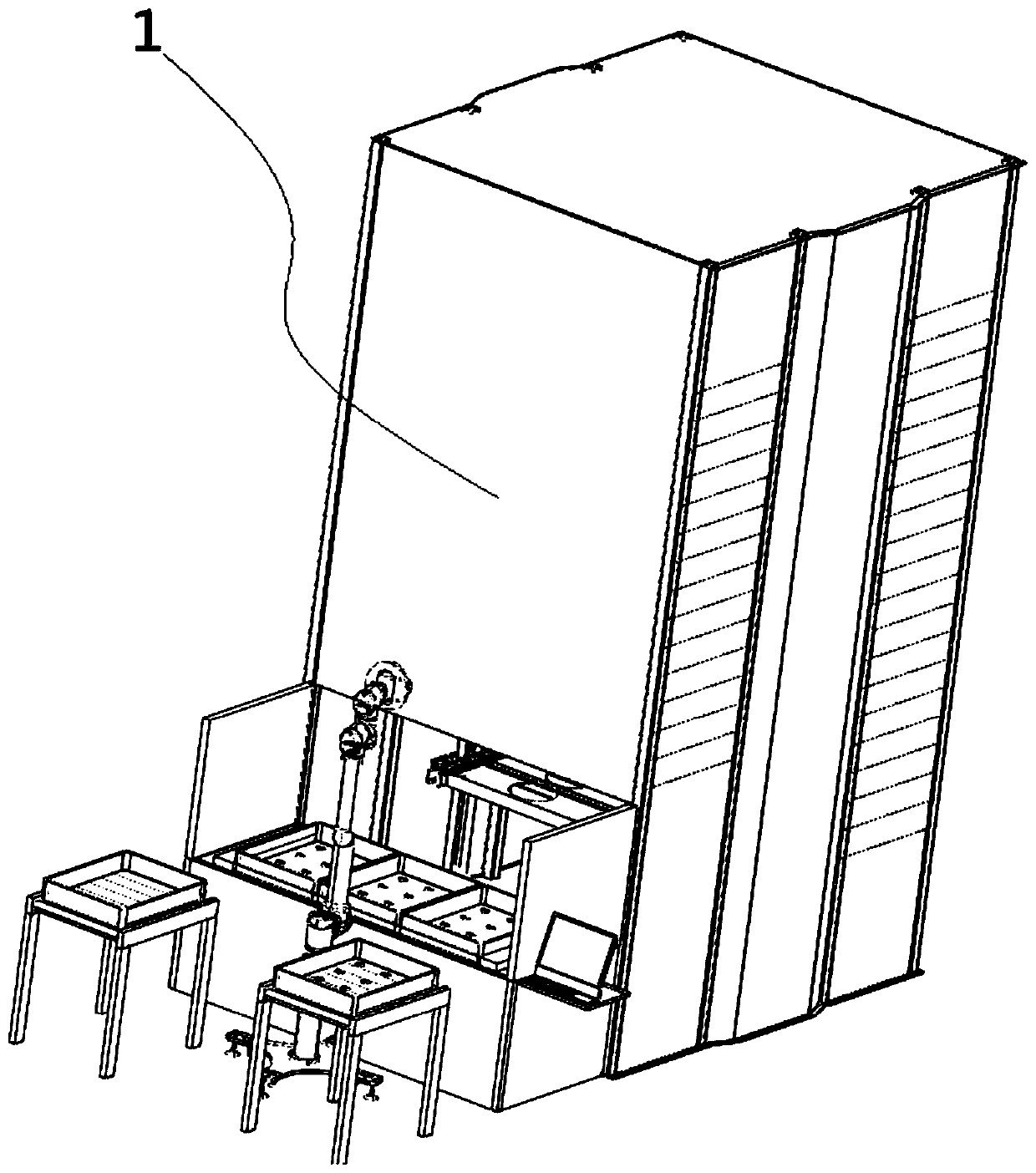

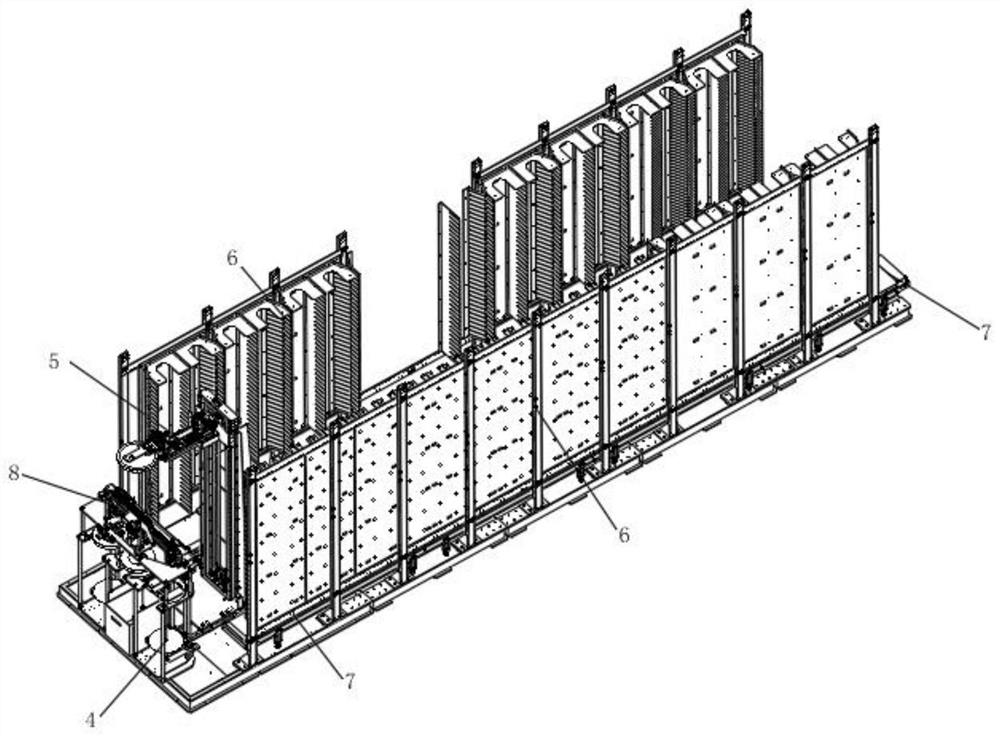

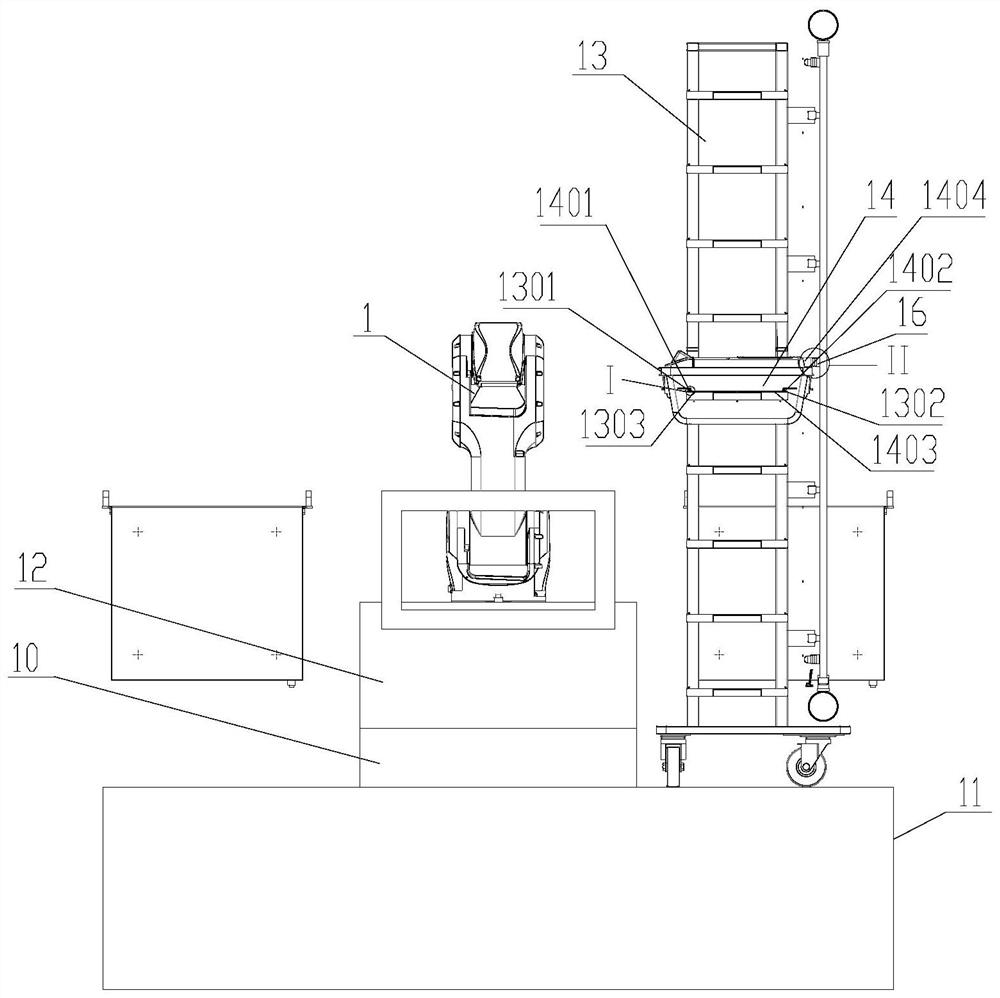

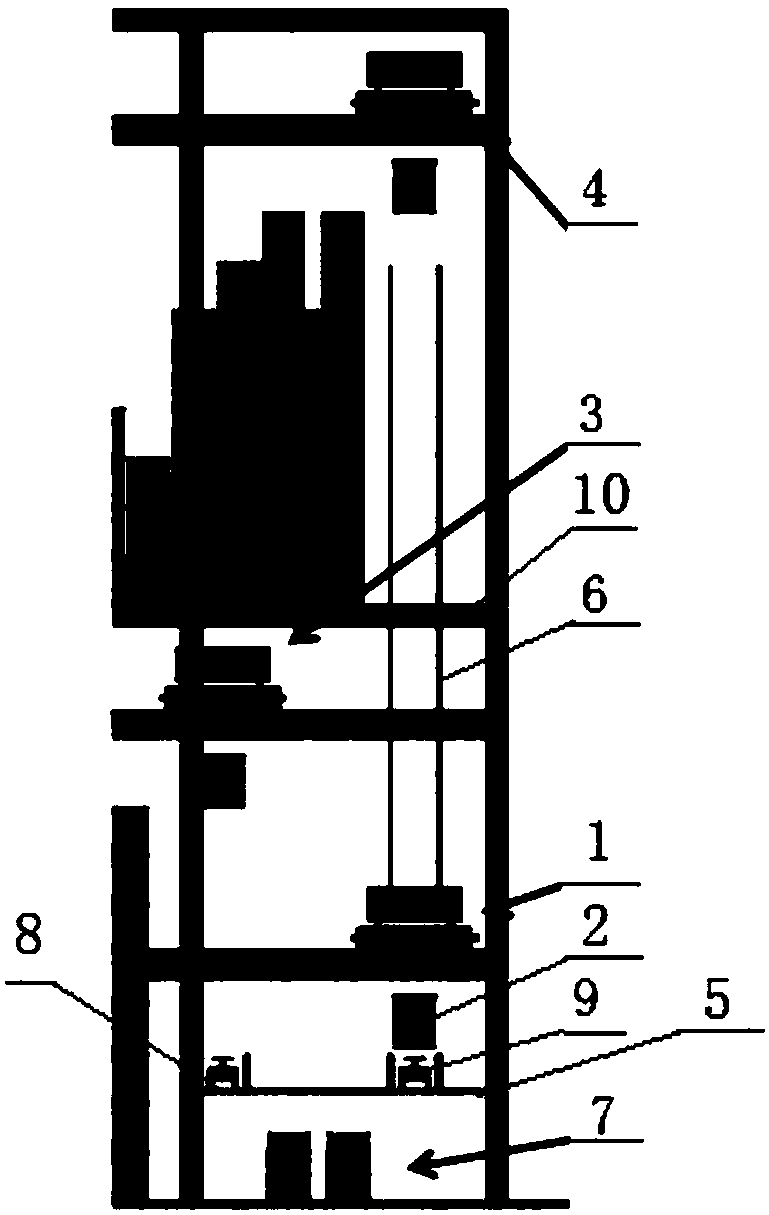

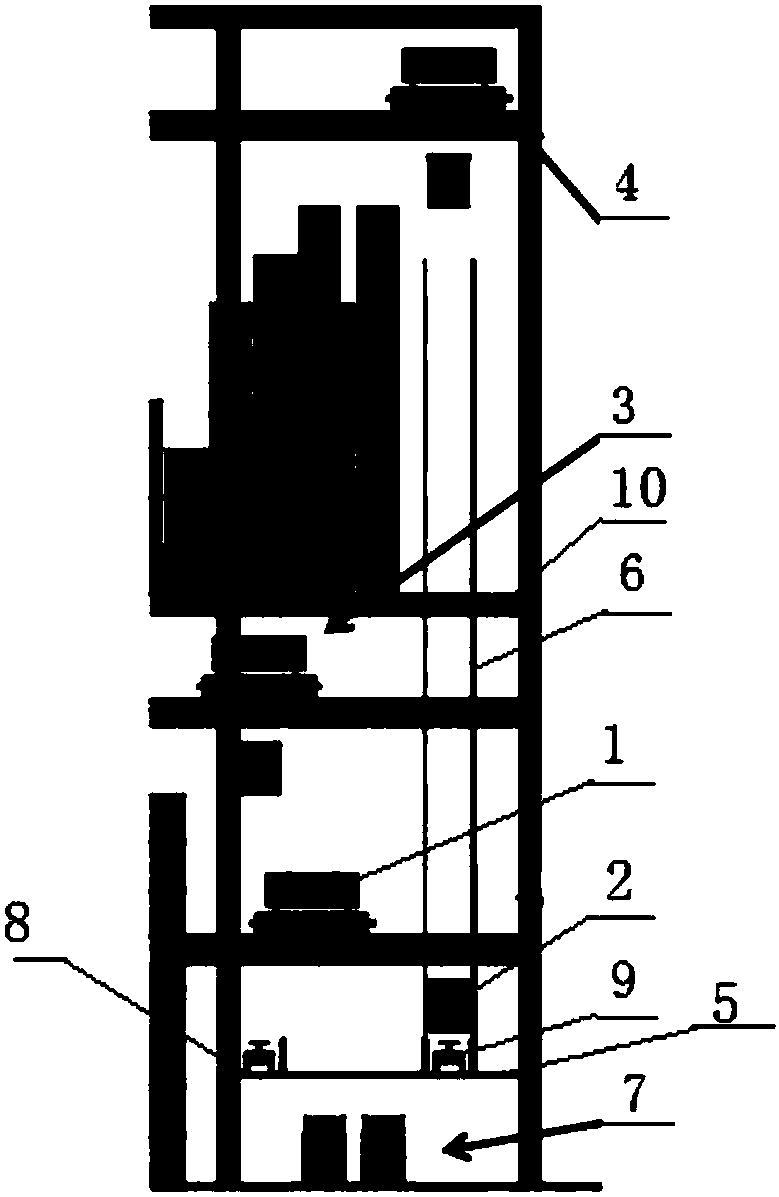

Vertical lifting, intelligent storage and material tray storage method

The invention provides a vertical lifting, intelligent storage and material tray storage method, and provides vertical bin intelligent storage. A bin body is arranged to be of a vertical structure, the vertical space of a factory building is fully utilized, and the occupied area of the storage is reduced under the same storage quantity. Matched with the vertical storage function, a platform, a platform lifting mechanism and a horizontal platform transferring mechanism are arranged. Material trays are transferred into material boxes of electrostatic boxes of trays through a mechanical arm, thetrays are transferred to the platform through a roller mechanism on the platform, and then the trays are transferred to a designated tray rack position through a vertical lifting mechanism. Through the information binding of an upper computer system, the material trays and the material boxes, the positioning of a certain material tray of a certain material box on the storage tray rack is realized,and the discharging of the material trays is realized according to the indication information.

Owner:SUZHOU I STOCK INTELLIGENT TECH

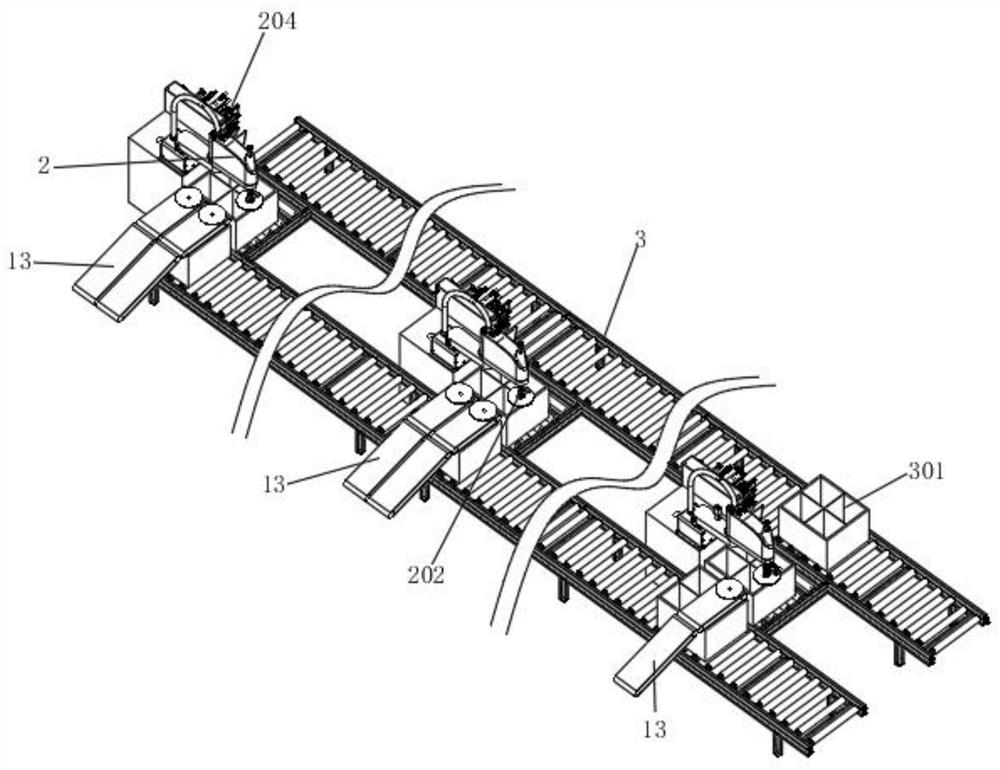

Intelligent material storing and sorting integrated mechanism based on precision control system

InactiveCN113525994AReduce labor intensityImprove access efficiencySortingStorage devicesControl systemComputer printing

The invention relates to an intelligent material storing and sorting integrated mechanism based on a precision control system. The intelligent material storing and sorting integrated mechanism based on the precision control system comprises multiple storing bins and a roller conveying line, wherein a corresponding loading conveying belt and a corresponding labeling manipulator are arranged between each storing bin and the roller conveying line, loading lead screw modules, automatic storing and taking manipulators, storing racks and feeding conveying belts are arranged in the storing bins, supports are arranged at the upper portions of the loading lead screw modules, material moving linear modules and CCD cameras are arranged at the upper portions of the supports, lifting air cylinders are fixedly connected with moving tables of the material moving linear modules, sponge suction cups are fixedly connected with piston rods of the lifting air cylinders, and label printers are fixedly connected with sides of all the labeling manipulators. The intelligent material storing and sorting integrated mechanism based on the precision control system has the beneficial effects that code scanning detection, rack storing, material disc taking out, labeling and packaging can be automatically conducted on material discs, the labor intensity of workers is relieved, the storing and taking efficiency is improved, and the conditions of missing detection, wrong material sorting, wrong labeling and missing labeling are avoided.

Owner:苏州派迅智能科技有限公司

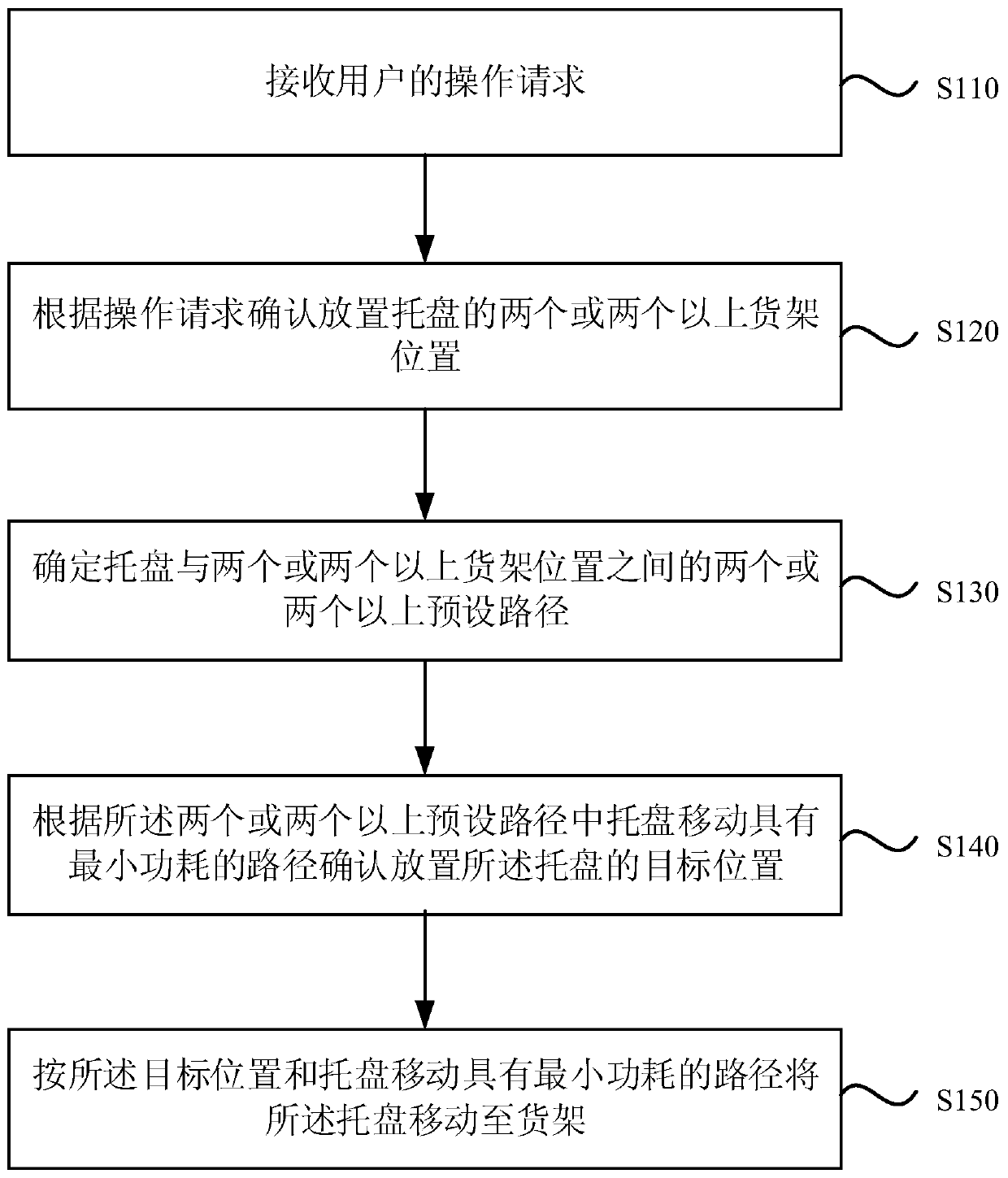

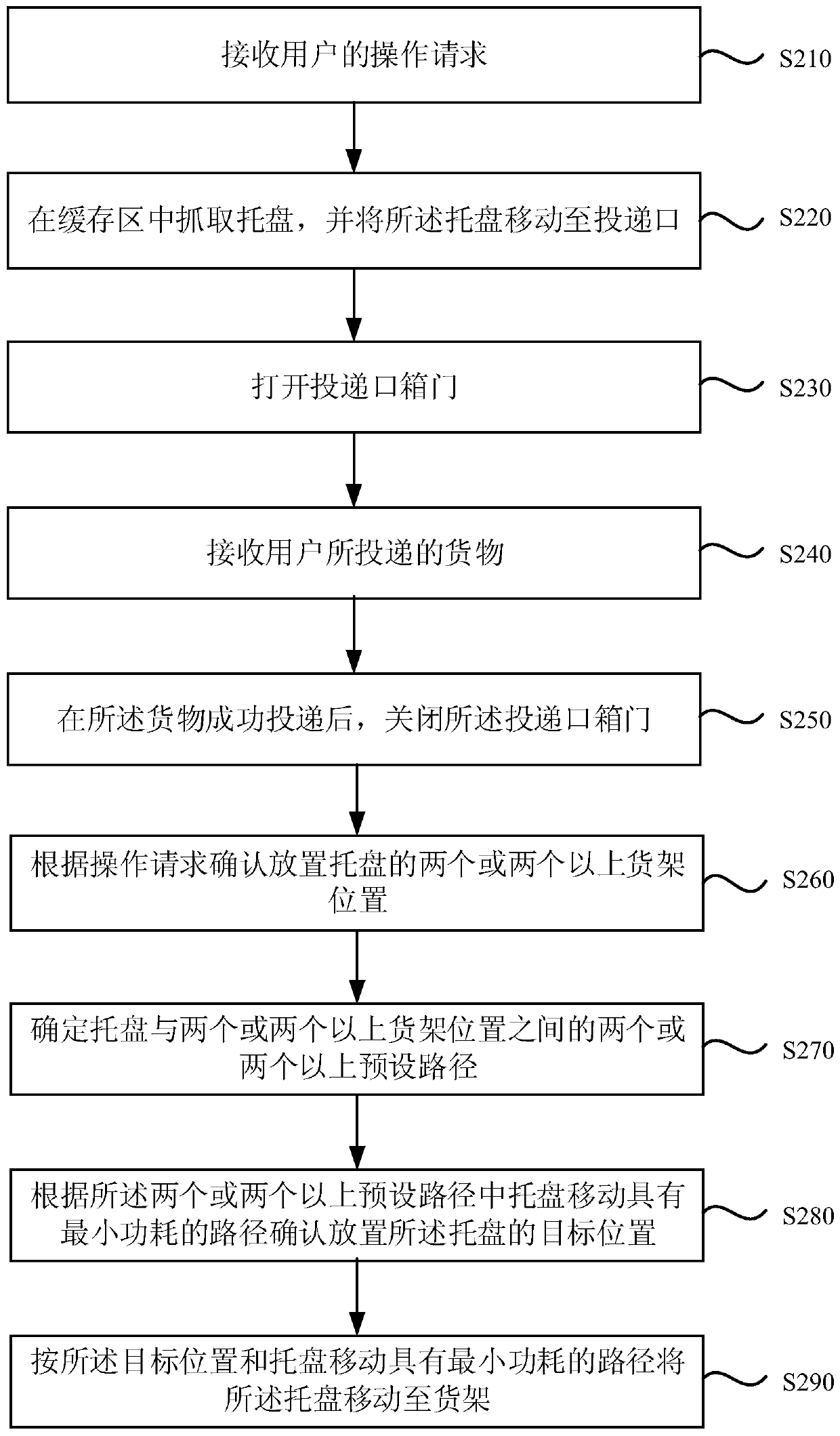

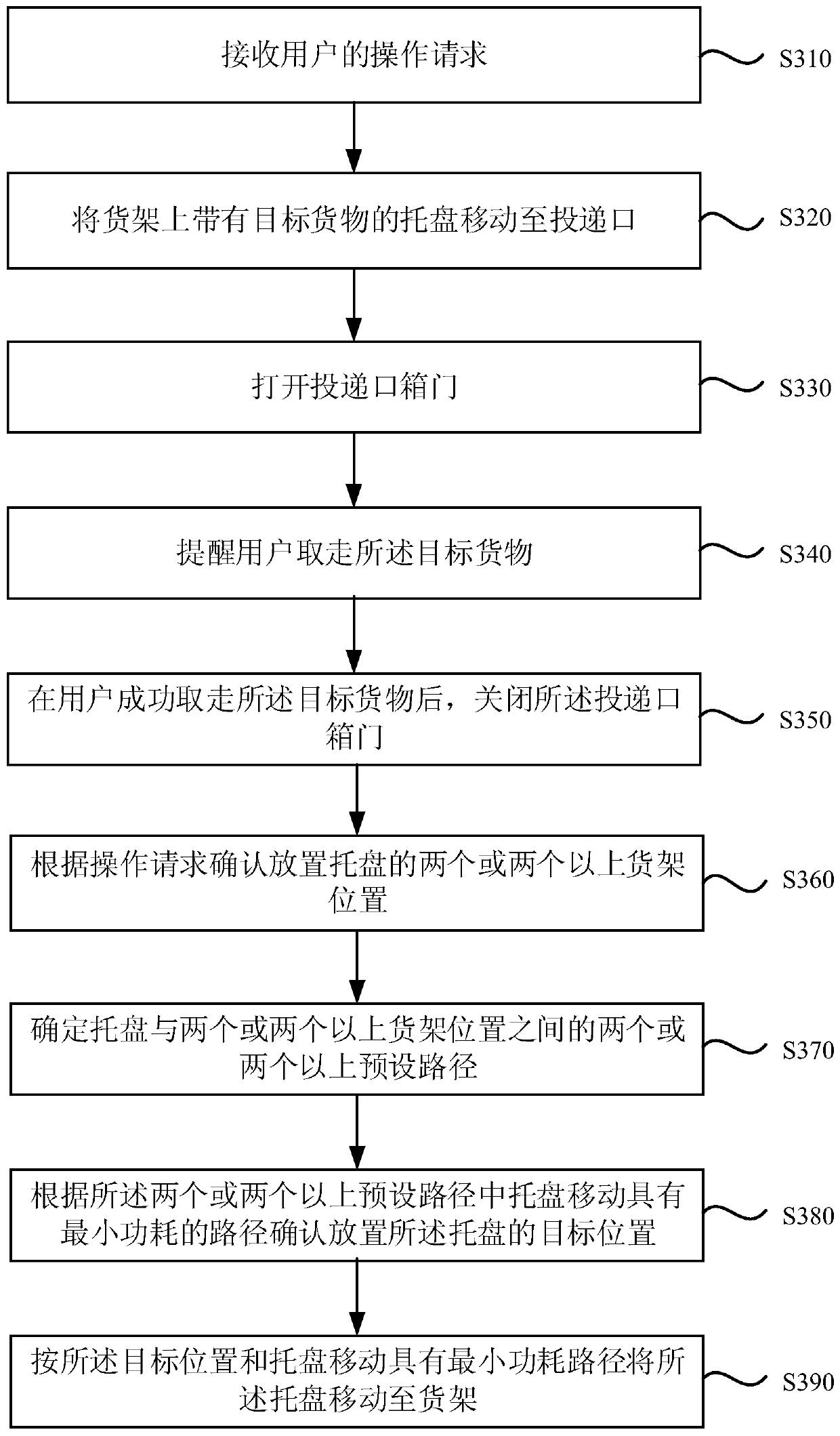

Method and device for goods storing and fetching, intelligent bin and storage medium

The embodiment of the invention provides a method and a device for goods storing and fetching, an intelligent bin and a storage medium. The method for goods storing and fetching mainly comprises the following steps that an operation request from a user is received; two or more goods shelf positions placing a tray are confirmed according to the operation request; two or more preset paths between the tray and the two or more goods shelf positions are determined; a target position placing the tray is determined according to a path with the minimum power consumption of the tray moving in the two or more preset paths; and the tray is moved to a goods shelf according to the target position and the path with the minimum power consumption of tray moving. Through the above method, automatic storageand fetch of goods are achieved, and the unnecessary power consumption waste is avoided.

Owner:SHENZHEN HIVE BOX TECHNOLOGY CO LTD

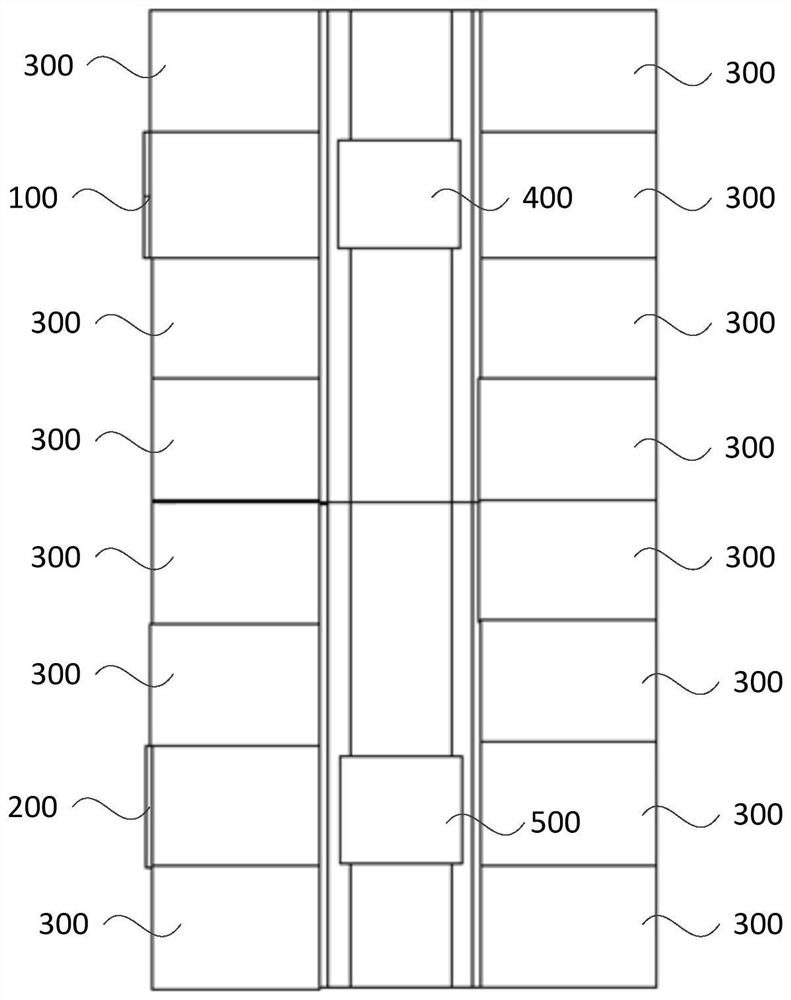

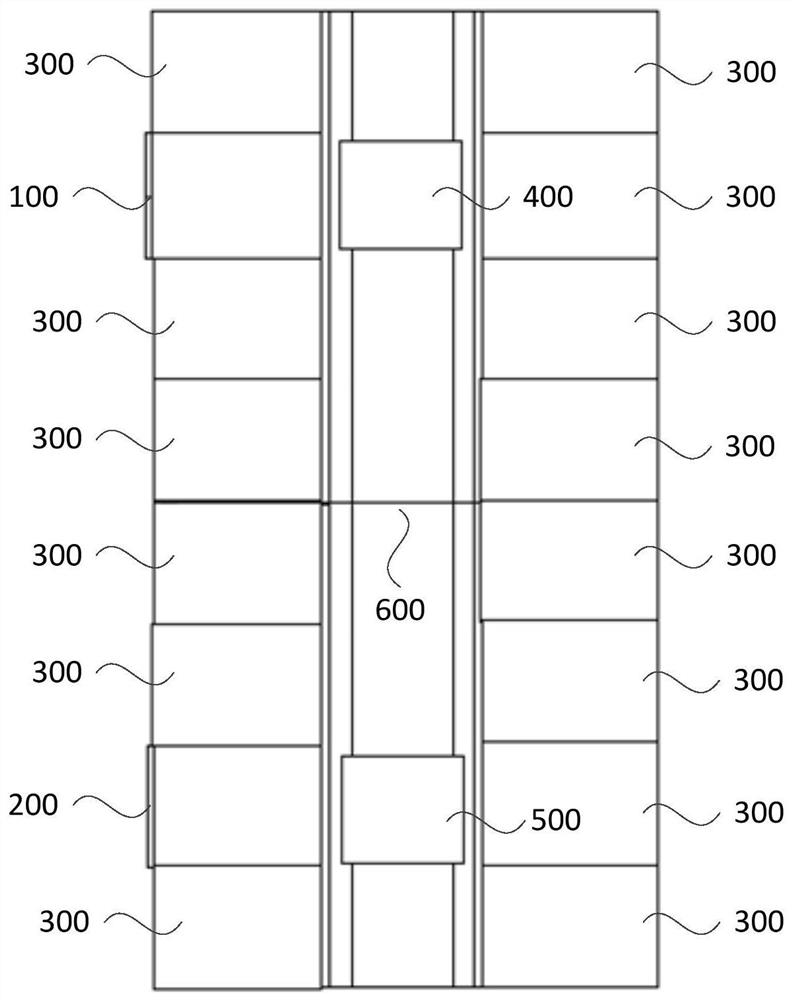

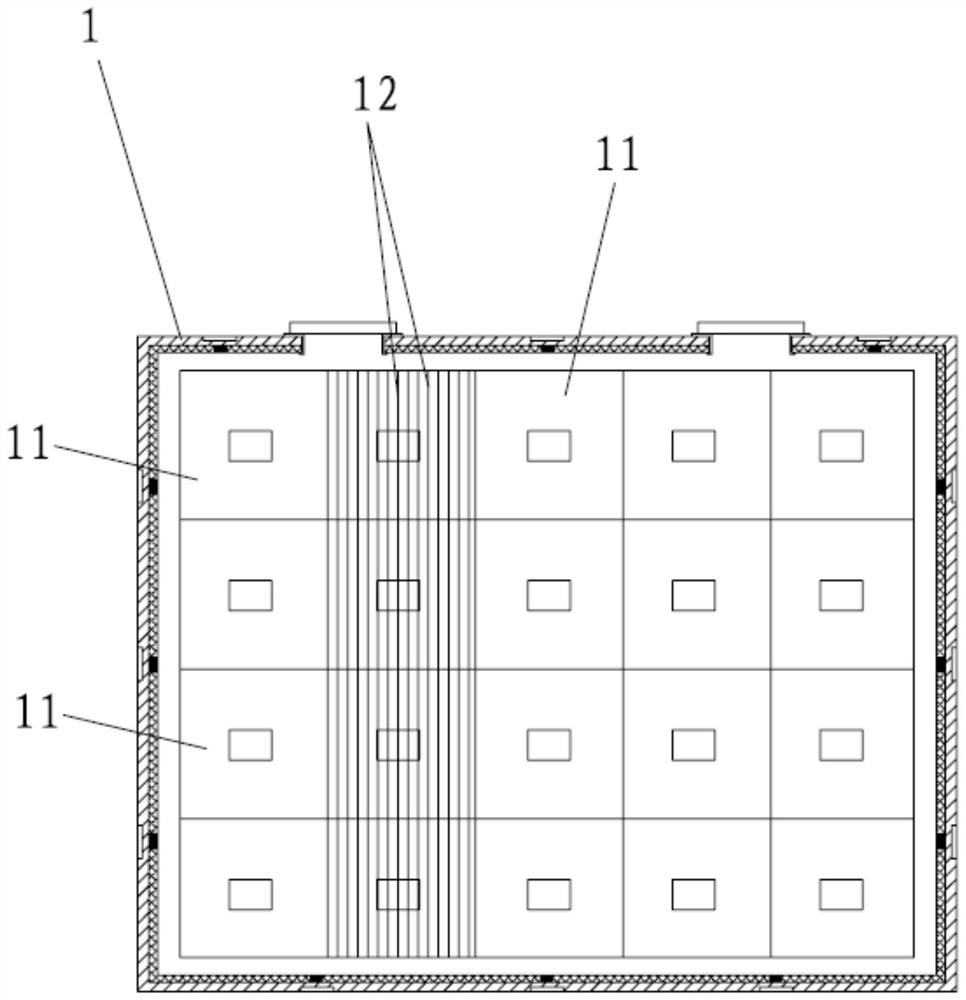

Multi-cell intelligent warehouse and delivery and pickup method

InactiveCN111839155AImprove pick-up efficiencyConveyorsKitchen equipmentSoftware engineeringMechanical engineering

The embodiment of the invention discloses a multi-cell intelligent warehouse and a delivery and pickup method. The multi-cell intelligent bin comprises a first cell; a second cell; a plurality of storage mechanisms, wherein each storage mechanism comprises a storage chamber and a tray; a first walking mechanism used for carrying the tray to move articles placed by a first user from the first cellopening to the storage chamber to be stored so as to complete article delivery, or carrying the tray to move the articles to the first cell opening to be provided for a second user so as to complete article pickup; and a second walking mechanism used for carrying the tray to move the articles placed by the first user from the second cell opening to the storage chamber for storage so as to finish delivery, or carrying the tray to move the articles to the second cell opening so as to provide the articles for the second user so as to finish pickup. According to the embodiment of the invention, the delivery and pickup efficiency of the intelligent warehouse is improved.

Owner:SHENZHEN HIVE BOX TECHNOLOGY CO LTD

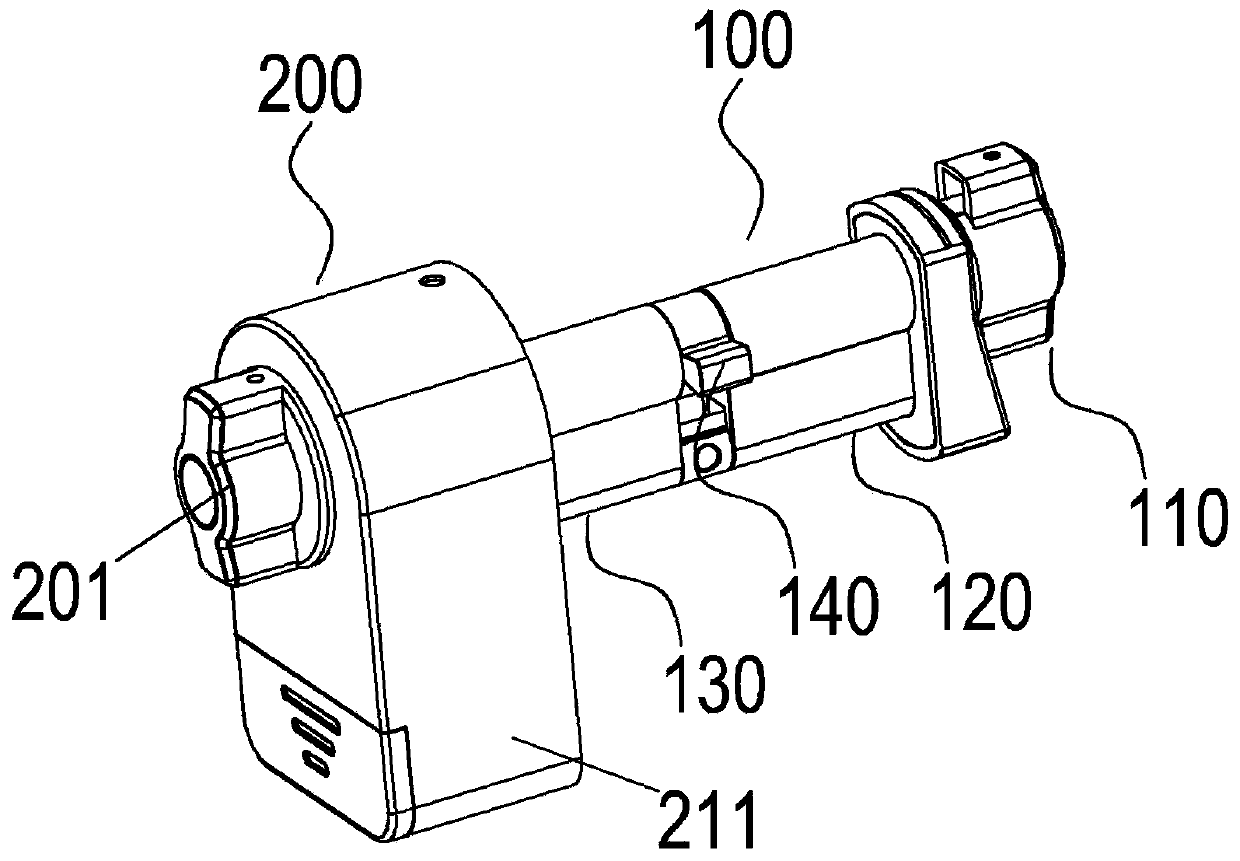

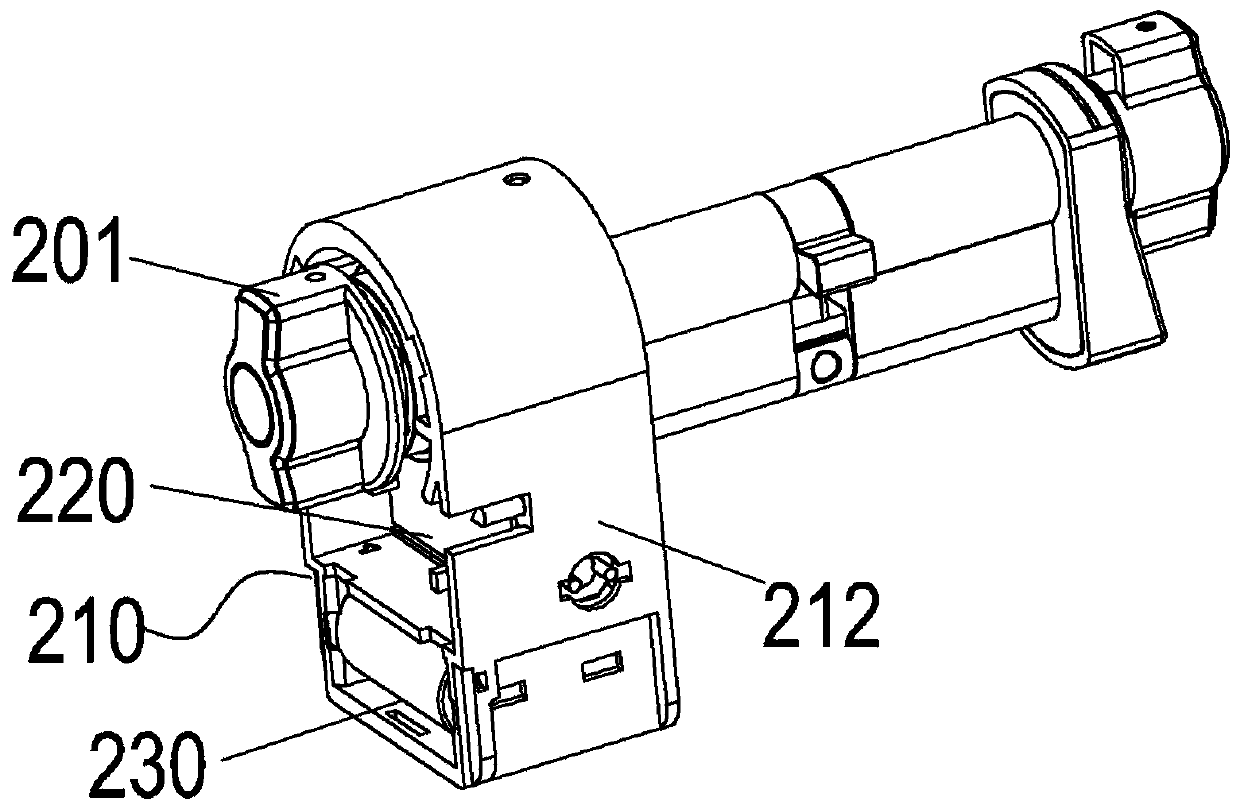

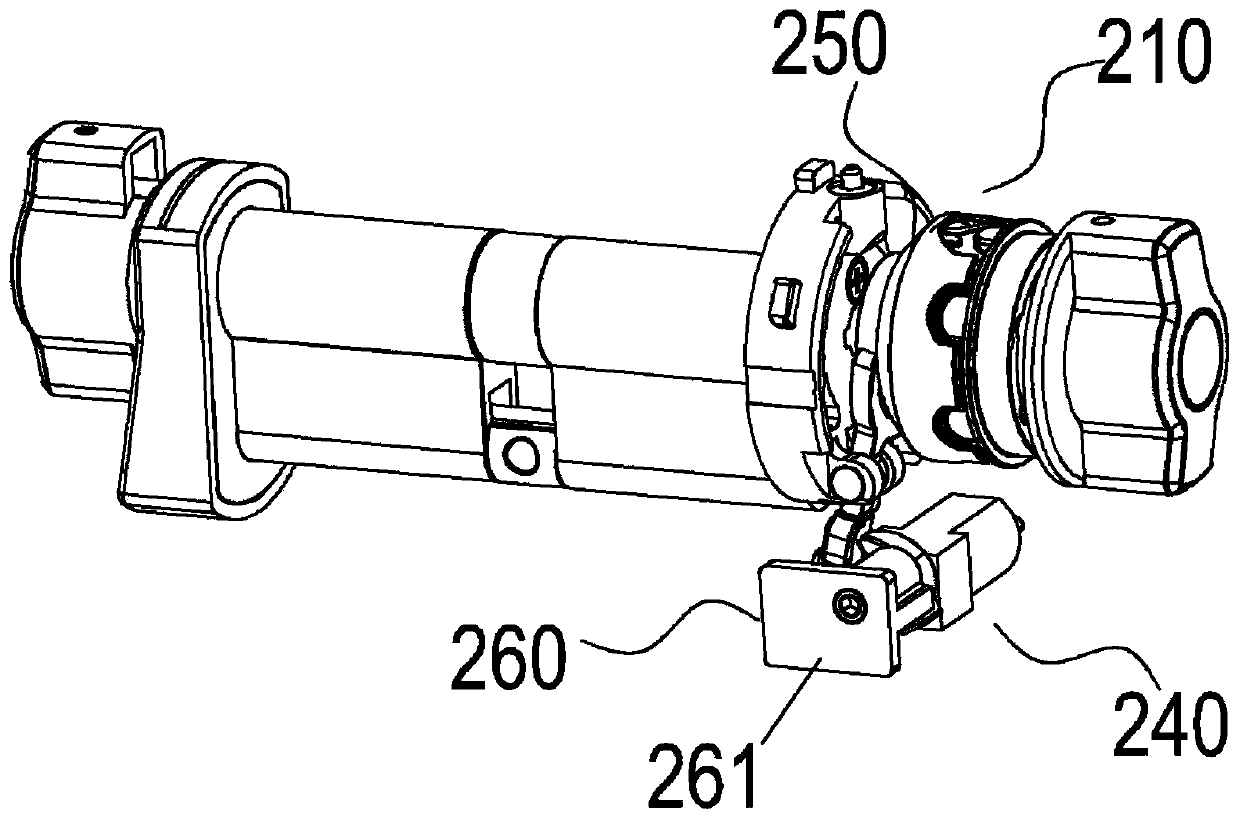

Intelligent lock

InactiveCN110242120ASimple structureEasy to useNon-mechanical controlsLock casingsPasswordEngineering

The invention discloses an intelligent lock. The intelligent lock comprises a lock body and a rear panel part. The rear panel part is arranged at the right end of the lock body and comprises an intelligent assembly and a handle. The intelligent assembly comprises an outer shell. An inner shell is arranged in the outer shell and is divided into an intelligent bin and a power source bin. The intelligent bin is arranged at the upper end of the inner shell and comprises a control mechanism and a transmission mechanism. The lock body comprises a handle structure, an outer lock shell and an inner lock shell. The intelligent lock can be installed on a door without punching new holes and can be unlocked through a password, fingerprints and card reading after being used to replace an original lock. Moreover, a mechanical lock mode and an intelligent lock mode are combined, are relatively independent and are not limited by the direction of door locking, and a door can be opened leftwards or rightwards by changing the direction of a ratchet wheel.

Owner:徐钜祥

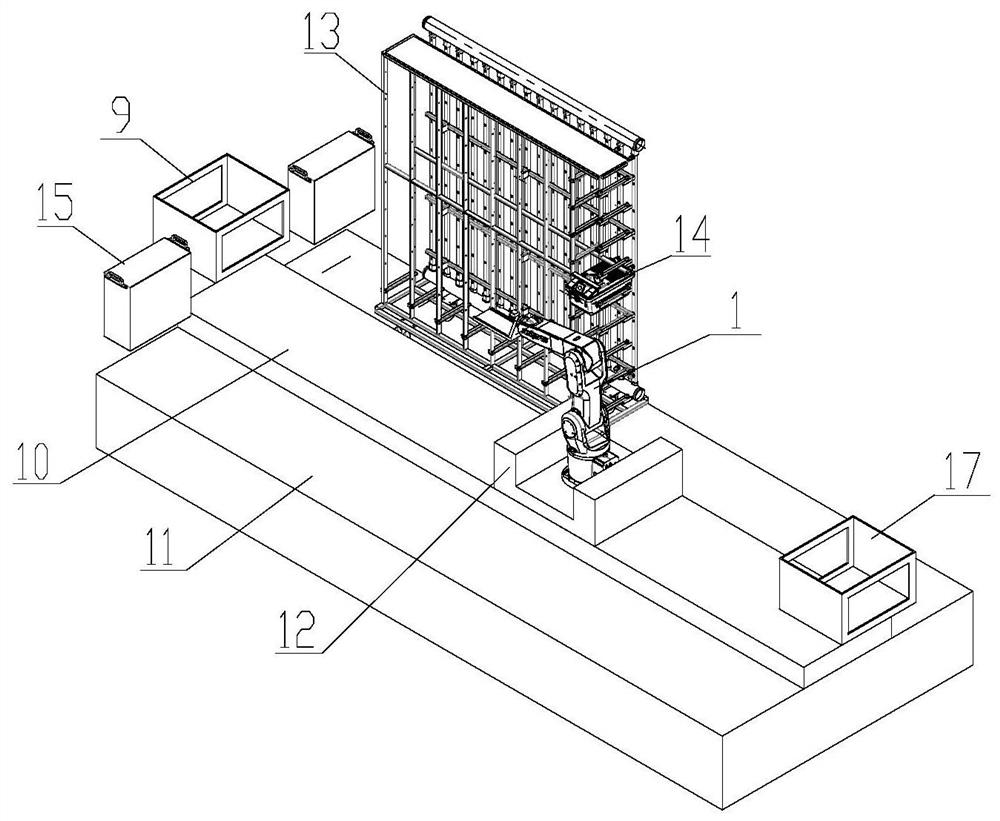

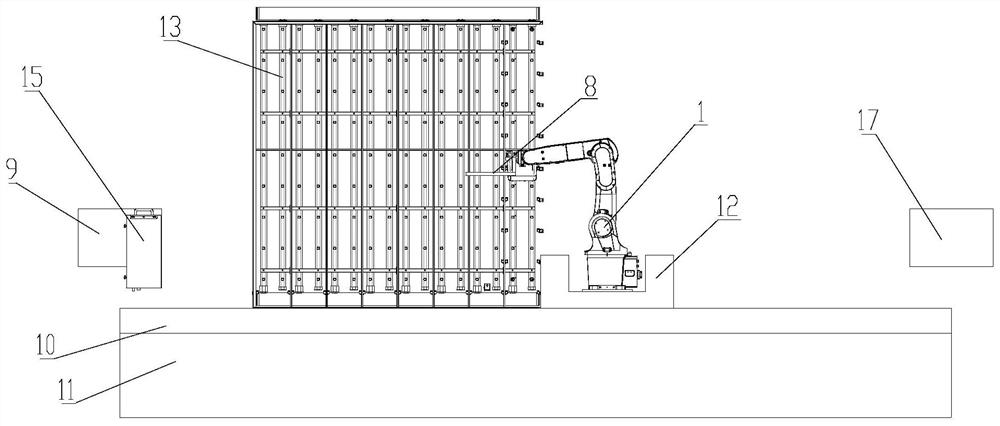

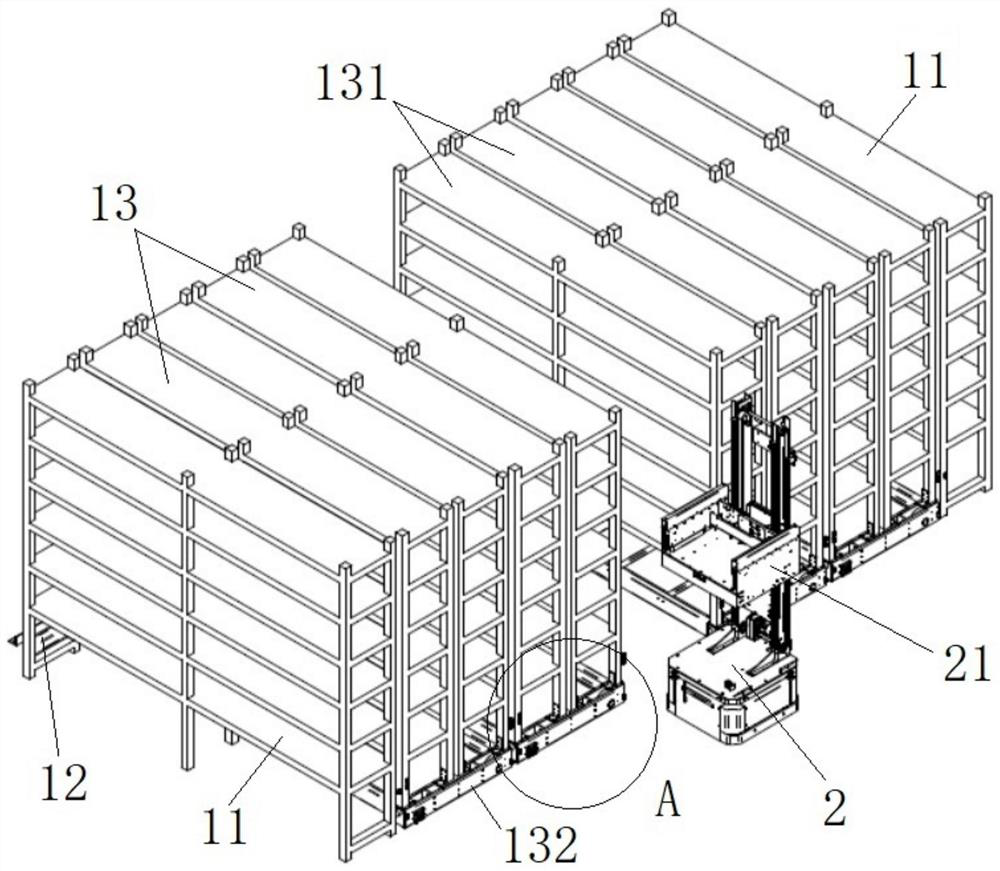

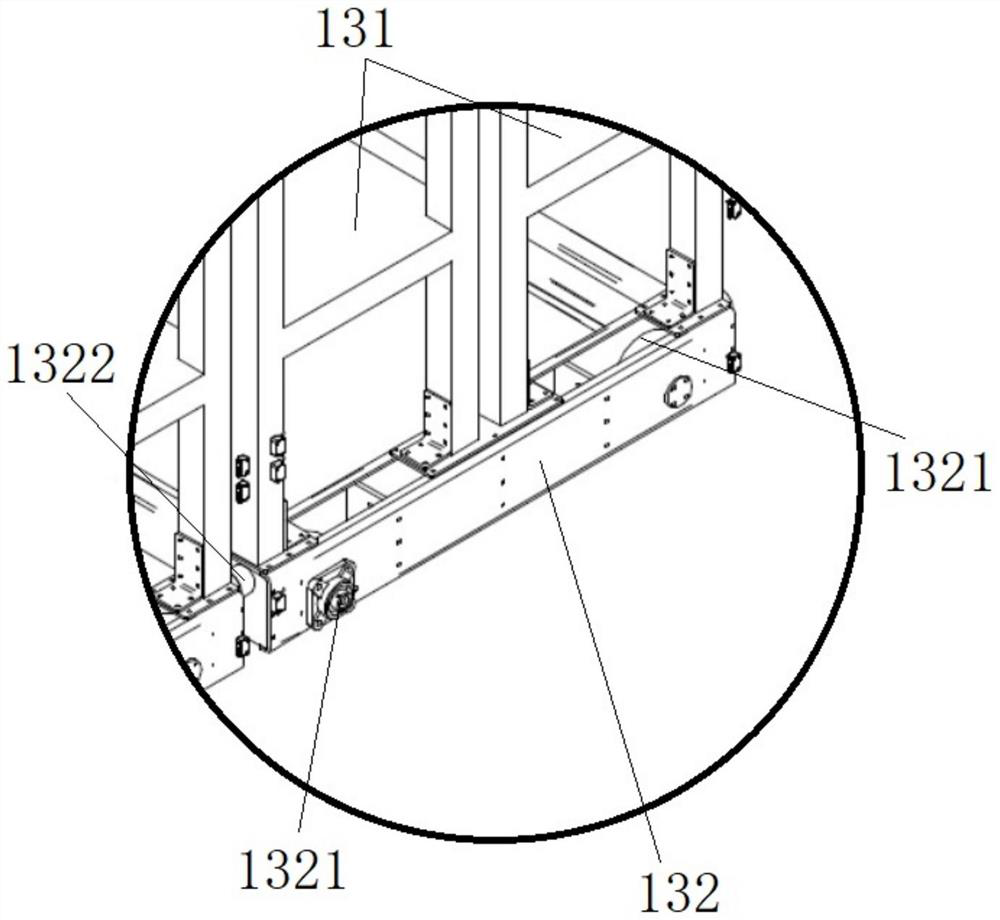

An intelligent warehouse robot picking and placing system and method thereof

ActiveCN112520281BIncrease productivityImprove production safetyStorage devicesLogistics managementControl engineering

The invention relates to automated logistics equipment, in particular to an intelligent storage robot pick-and-place system and a method thereof. Including the robot, the pick-up window, the slide track, the slide table, the shelf and the delivery window, the pick-up window and the delivery window are respectively set at both ends of the slide track, and There are shelves, and the robot is slidingly connected with the slide track through the slide table. The slide table can be lifted up and down. The robot is used to place the boxes in the picking window on the shelf and take out the boxes on the shelf and transport them to the delivery window. Inside. The invention improves production efficiency and safety, saves energy and reduces emissions, and meets environmental protection requirements.

Owner:天津新松机器人自动化有限公司

a smart device

ActiveCN110329762BIngenious and reasonable structureEasy to useConveyor partsLogistics managementStructural engineering

The invention provides an intelligent device. The device comprises a machine body and a first cavity which is formed in the machine body and provided with a downward opening, a rotating disc is rotatably arranged in the top wall of the first cavity, a through hole which is through up and down is arranged in the rotating disc, a vehicle body is arranged in the first cavity, first sliding cavities are symmetrically formed in the top wall of the vehicle body front and back, and first sliding blocks which can slide front and back are arranged in the first sliding cavities. A combined type tray forintelligent warehouse logistics is more reasonable and ingenious in whole structure, and quite convenient to use, cargo carrying is achieved, meanwhile, independent rotation of wheels is used for adjusting the moving direction of the device, operation is convenient, device stability is high, and the higher use and popularization value is achieved.

Owner:上海申雪供应链管理有限公司

Intelligent warehouse logistics robot path planning method based on L-shaped path trend improved A-STAR algorithm

ActiveCN113778097AEasy to Control SteeringRuntime smoothingPosition/course control in two dimensionsVehiclesPathPingLogistics management

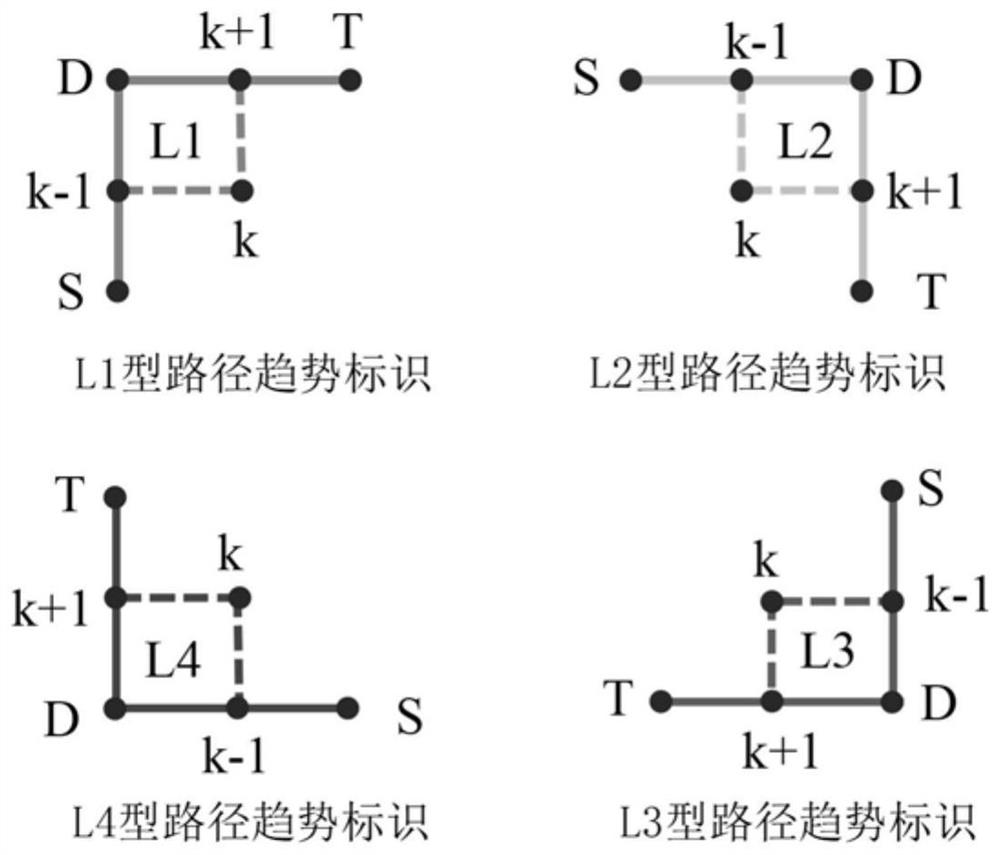

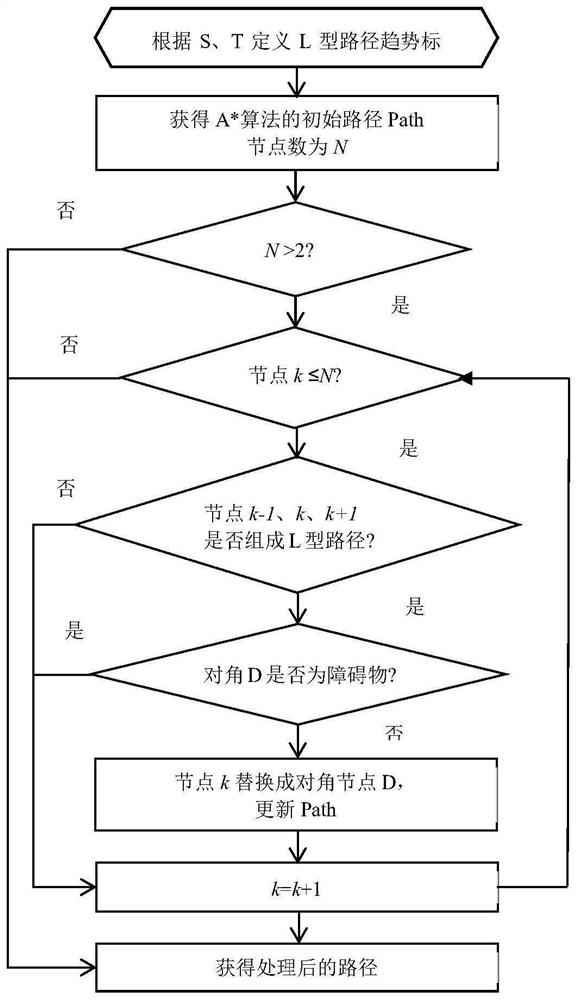

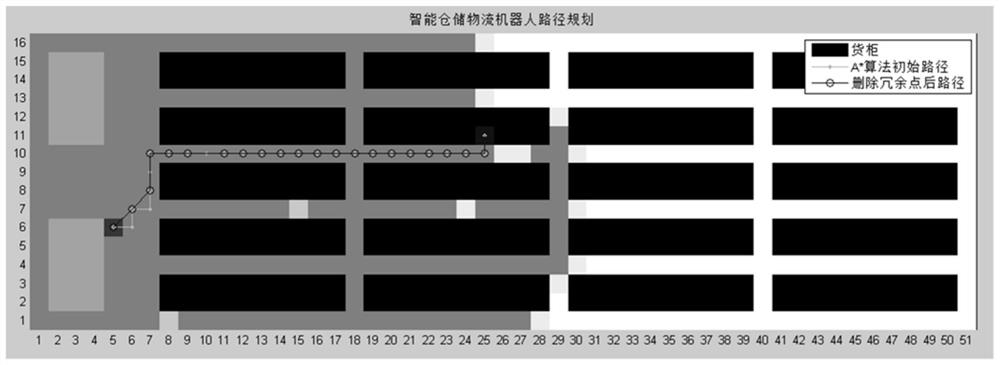

The invention discloses an intelligent warehouse logistics robot path planning method based on an L-shaped path trend improved A-STAR algorithm, and the method comprises the steps: carrying out the optimization through a path trend identifier according to a principle that a local path is consistent with a path trend formed by S and T as much as possible after an initial path is planned through the A-STAR algorithm; in the local path, when three adjacent nodes k-1, k and k+1 form an L-shaped link, judging whether the L-shaped link is matched with the current L-shaped path trend identifier or not, if so, judging whether a diagonal node D of a middle node k of the local link is an obstacle or not, and if not, replacing the node k with the diagonal node D. According to the L-shaped path trend improved A-STAR calculation method provided by the invention, the turning frequency and the accumulated turning angle of a local path in path planning of the intelligent warehouse logistics robot can be effectively reduced at a small algorithm running time cost.

Owner:LONGYAN UNIV

An intelligent warehousing based on increasing the amount of goods handled by robots and shortening the waiting time

The invention discloses an intelligent warehousing based on increasing the handling volume of robots and shortening the waiting time. The structure includes a storage rack, a frame structure, and an intelligent robot. The storage rack is installed on the frame structure. The double-row design increases the storage capacity of the robot. When moving, according to whether there is a robot on the side, it can flexibly move the storage spare frame left and right, so as to realize the smooth running of the robot on the side; when the robot in front stops for a short time , the robots at the back and the back side do not need to stop and wait. After driving, they are spliced with the front robot through the protruding frame and the frame connector. When driving again, the robots at the back and the back side play the role of pushing the front robot; and then optimize the Intelligent warehousing improves the efficiency of logistics and distribution and saves the driving energy consumption of robots.

Owner:深圳市兄弟仓储设备有限公司

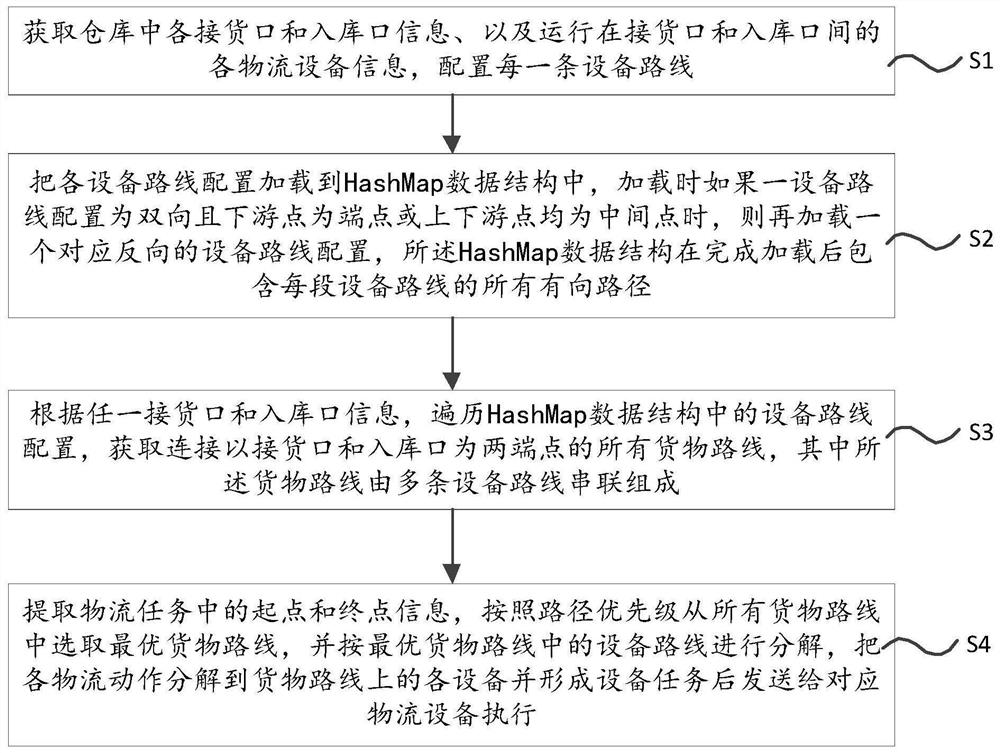

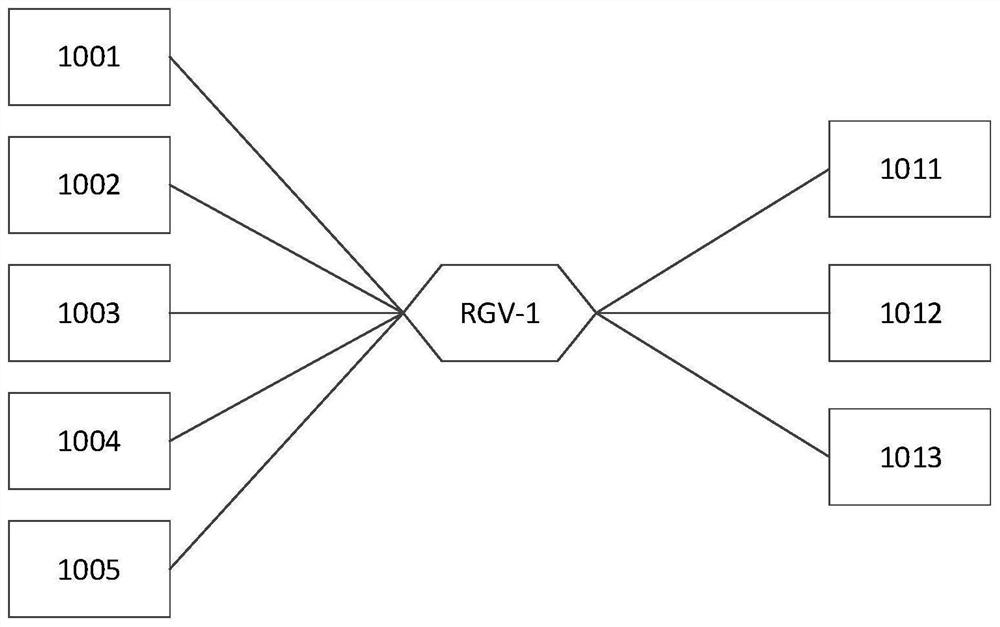

A device path management method, system and server for intelligent warehousing

ActiveCN112434875BReduce configuration workloadDoes not affect the transportation processForecastingLogisticsPathPingLogistics management

The invention discloses a device path management method and system for intelligent warehousing. By loading the route configuration of each device into the HashMap data structure, the devices in the HashMap data structure are traversed according to the information of any receiving port and storage port. Route configuration, obtain all cargo routes connecting the receiving port and storage port as two endpoints, extract the starting point and end point information in the logistics task, select the optimal cargo route from all cargo routes according to the route priority, and press the optimal The equipment route in the cargo route is decomposed, and each logistics action is decomposed into each device on the cargo route, and the equipment task is formed and sent to the corresponding logistics equipment for execution. Through the scheduling management method and system, equipment route configuration is simplified and the workload of equipment route configuration is reduced under the premise of satisfying the WCS system to control logistics equipment.

Owner:MINGDU ZHIYUN (ZHEJIANG) TECH CO LTD

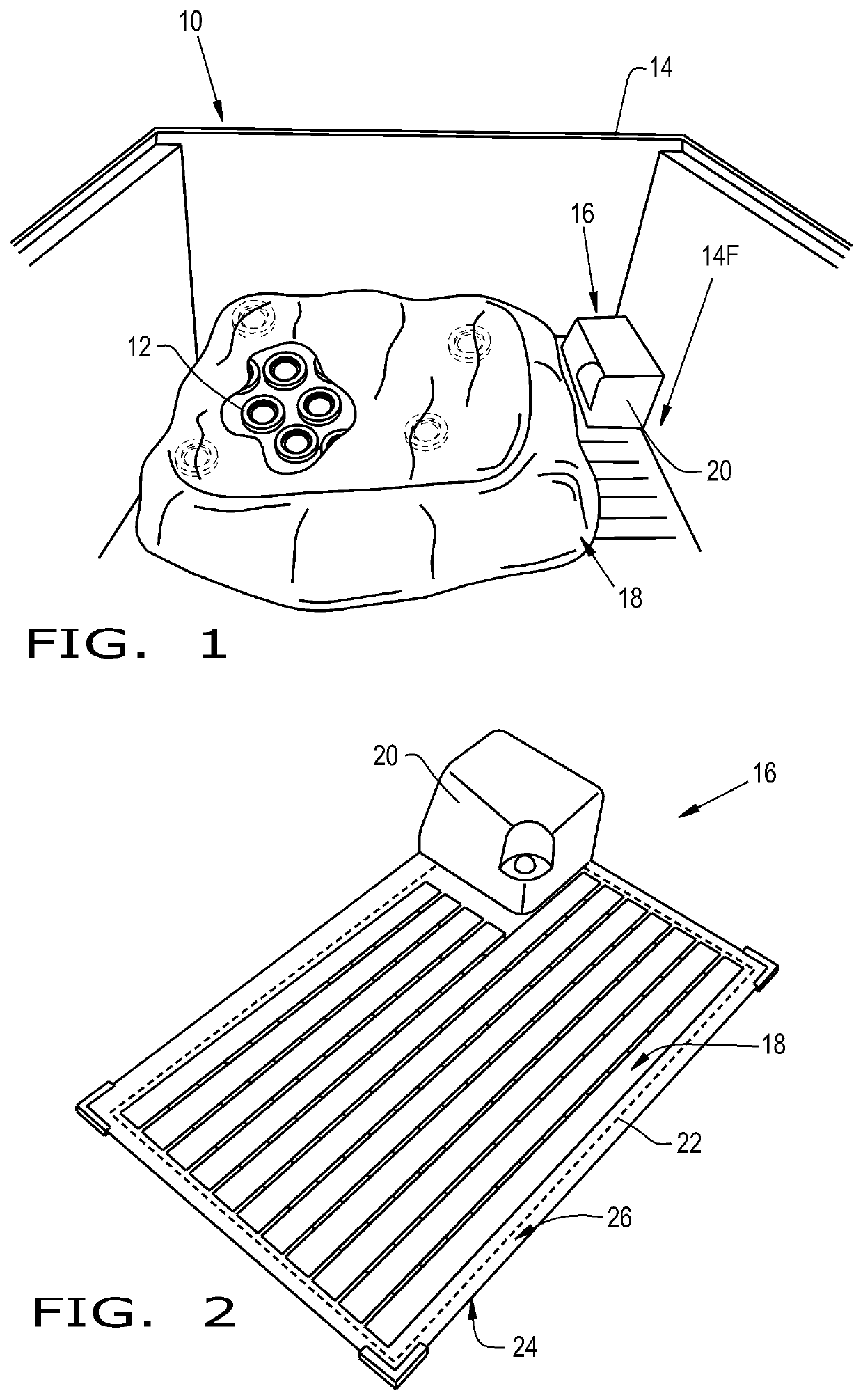

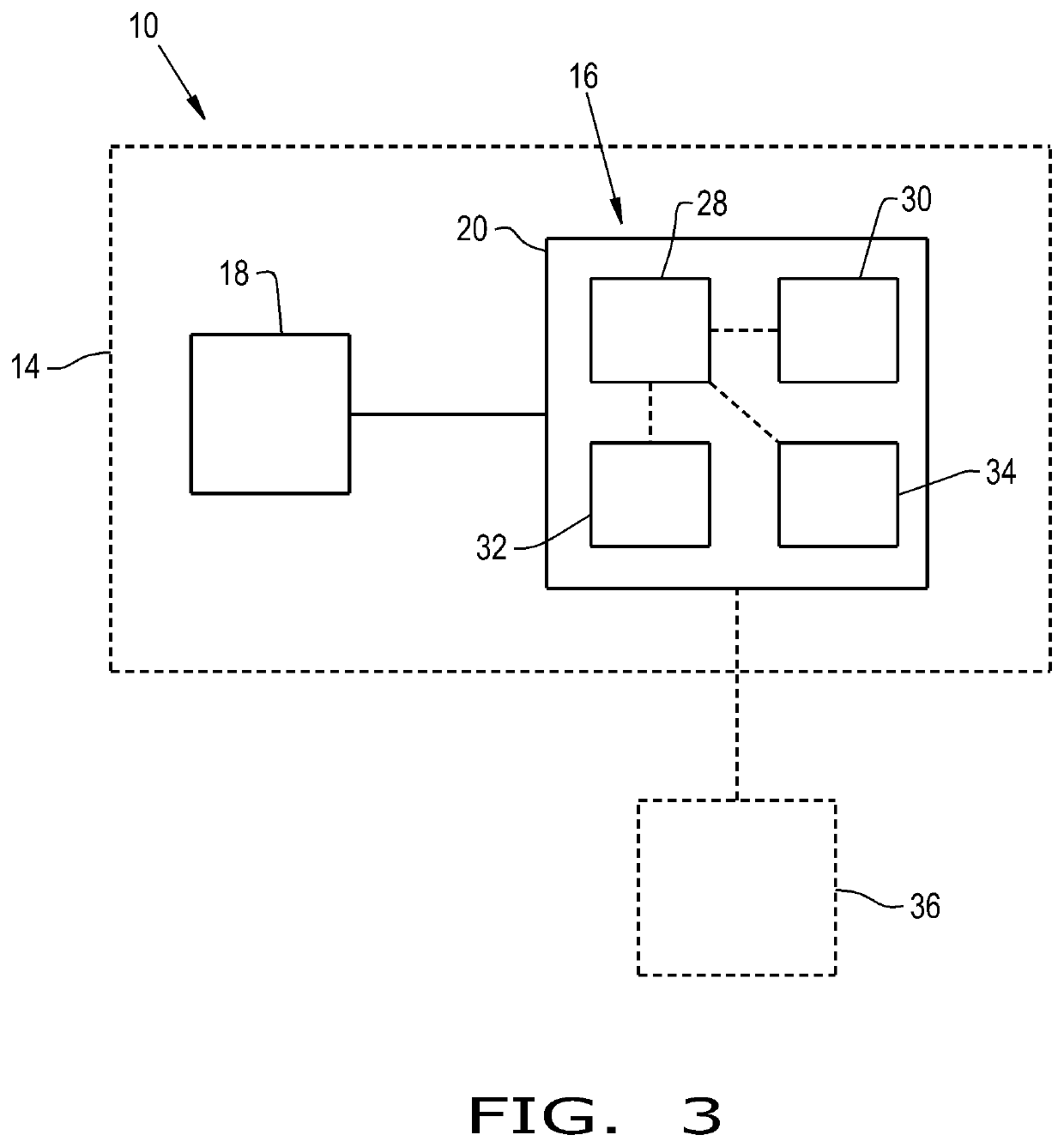

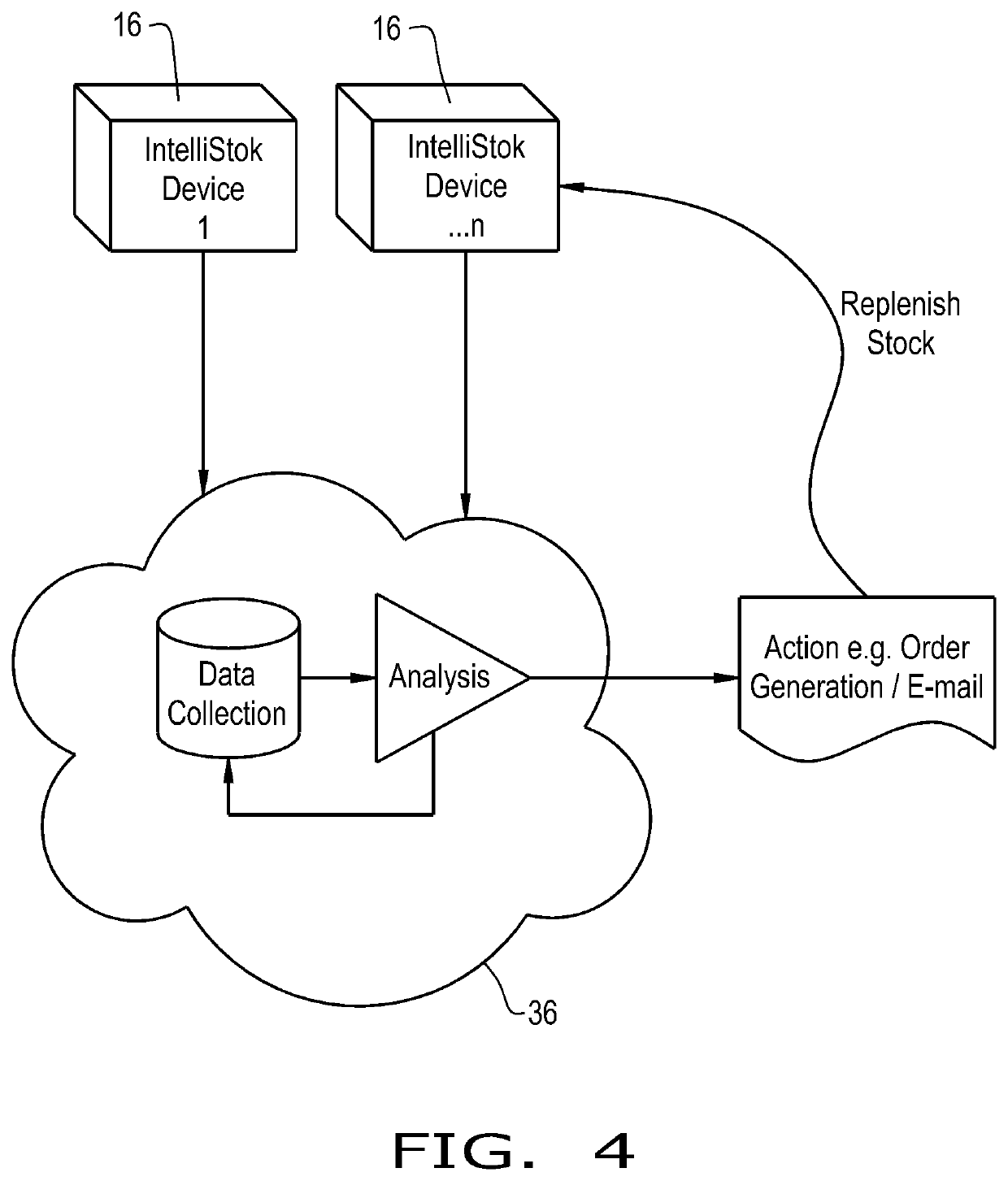

Smart bin system

A reordering system for automatically reordering one or more objects. The reordering system includes at least one storage bin configured for storing the one or more objects and at least one reorder device positioned within the at least one storage bin. The at least one reorder device including a pressure sensor and a control unit operably coupled to the pressure sensor.

Owner:TRELLEBORG SEALING SOLUTIONS GERMANY

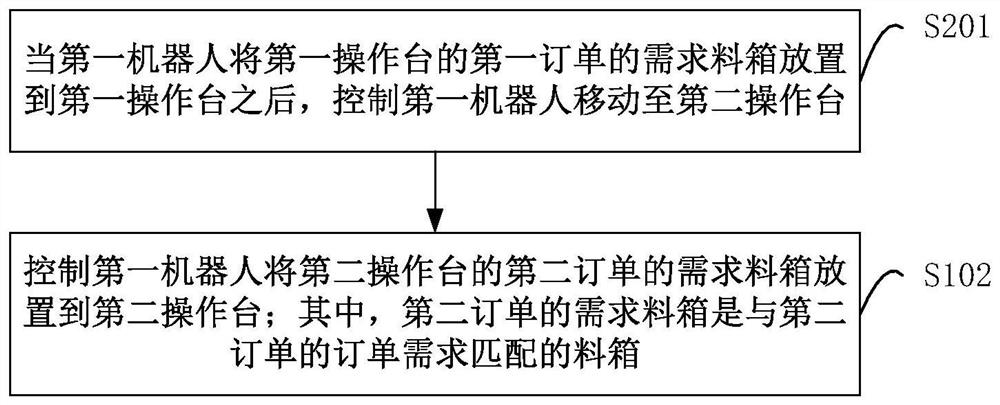

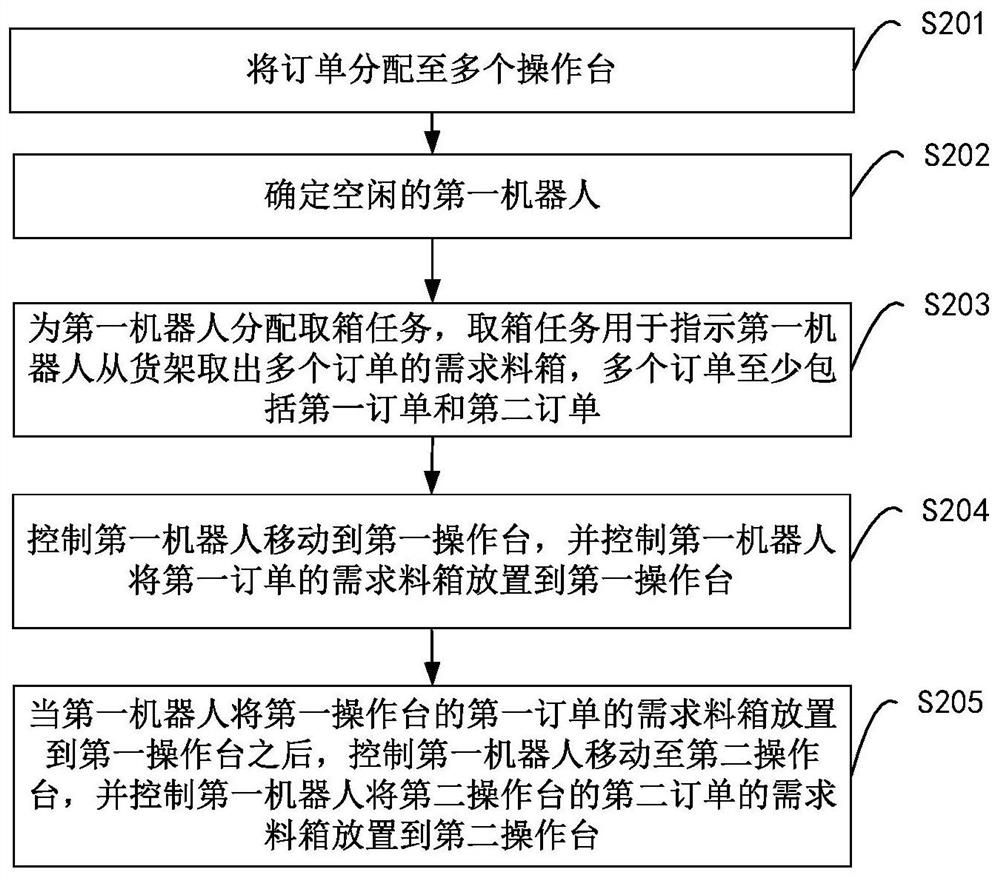

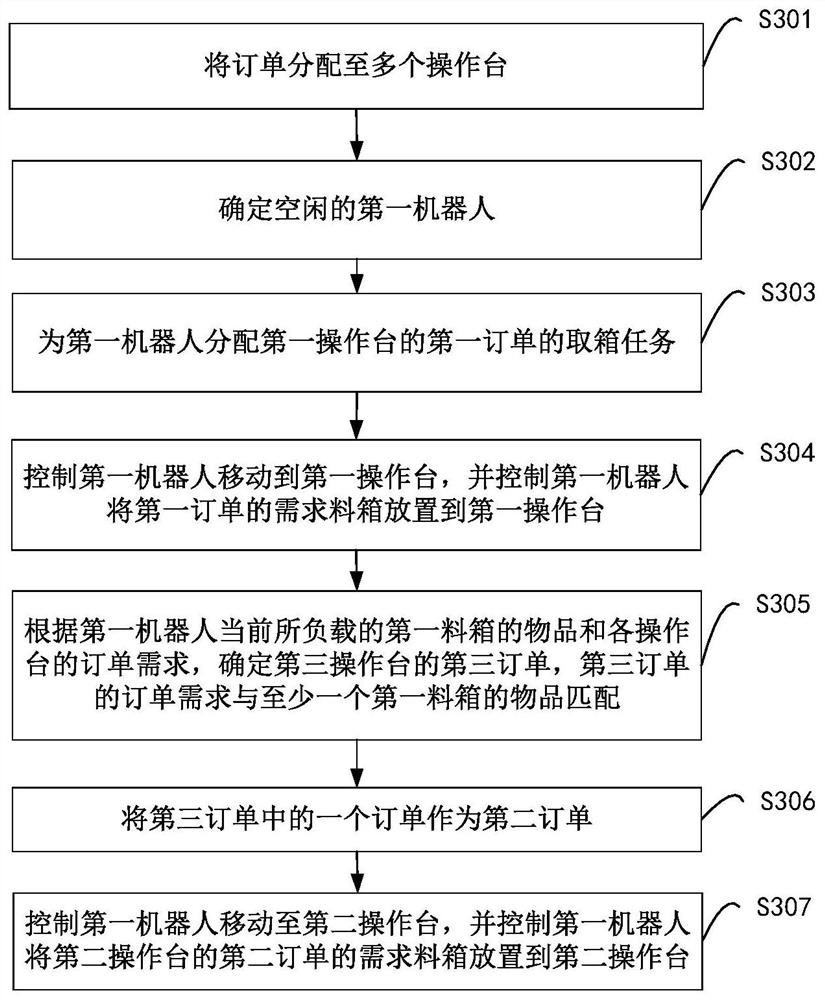

Robot scheduling method, device, system, storage medium and program product

ActiveCN113044462BImprove efficiencyImprove performanceStorage devicesLogisticsSmart binOperating system

The present application provides a robot scheduling method, device, system, storage medium and program product. The method of the present application controls the first robot to move to the second operation platform after the first robot places the demand bin of the first order of the first operation platform on the first operation platform, and controls the first robot to place the second The required material box of the second order of the operation platform is placed on the second operation platform, so that the first robot can perform box unloading operations across the operation platform during the process of performing a material box handling task, so that it can use as much as possible in a material box handling task. As many material boxes as possible are placed on the operation table, which reduces the number of picking / returning boxes, realizes a more flexible and efficient pick-and-place strategy, and can improve the overall efficiency and performance of the intelligent storage system.

Owner:SHENZHEN KUBO SOFTWARE CO LTD

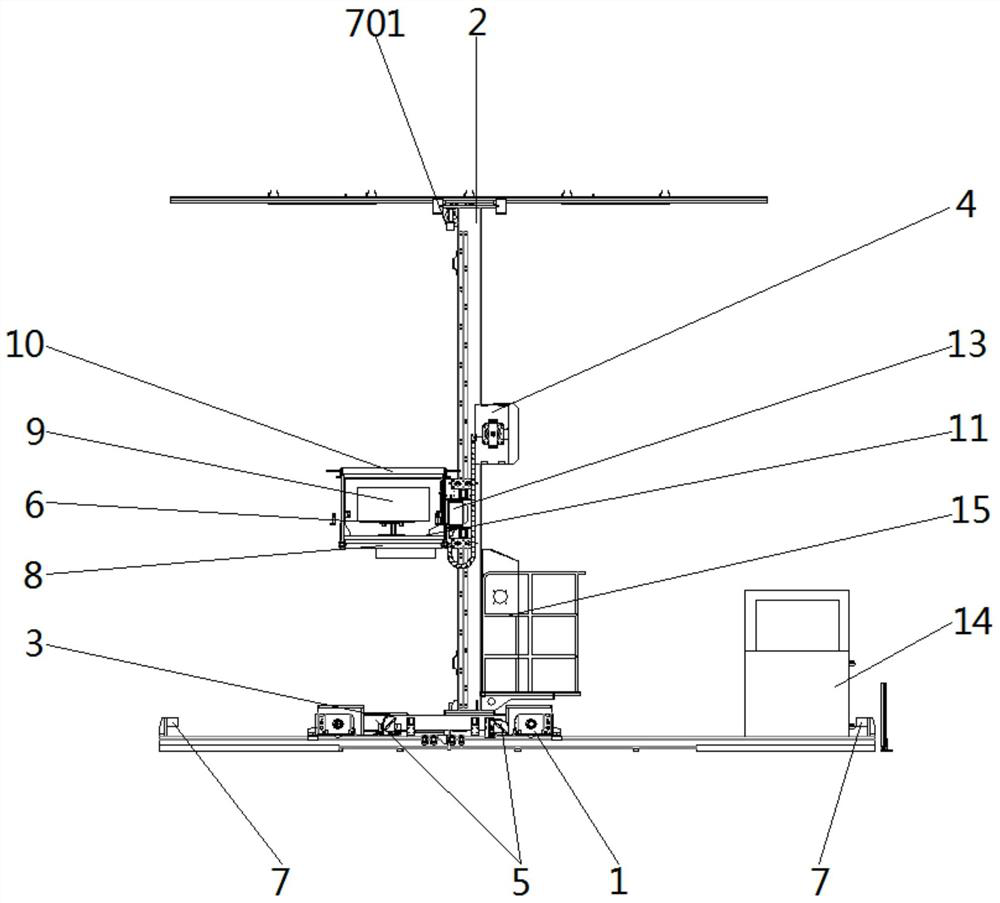

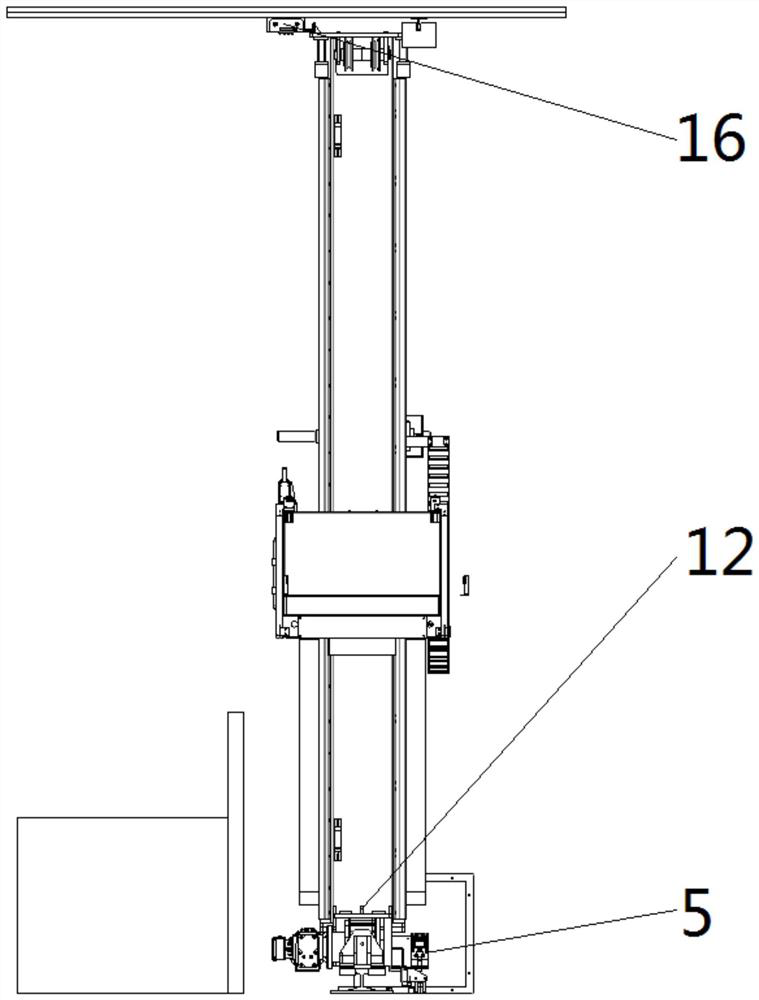

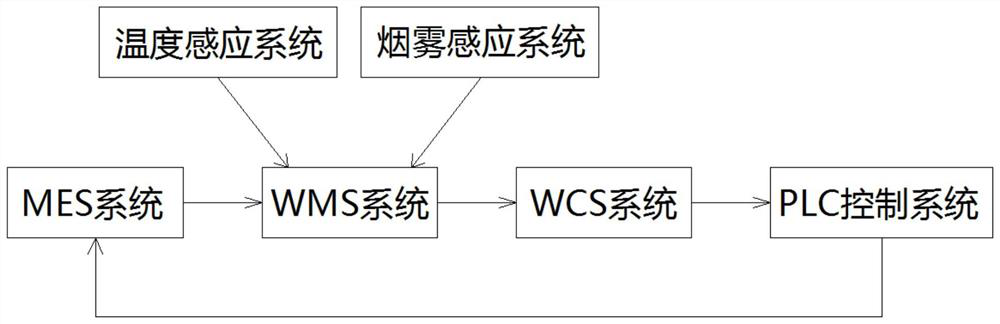

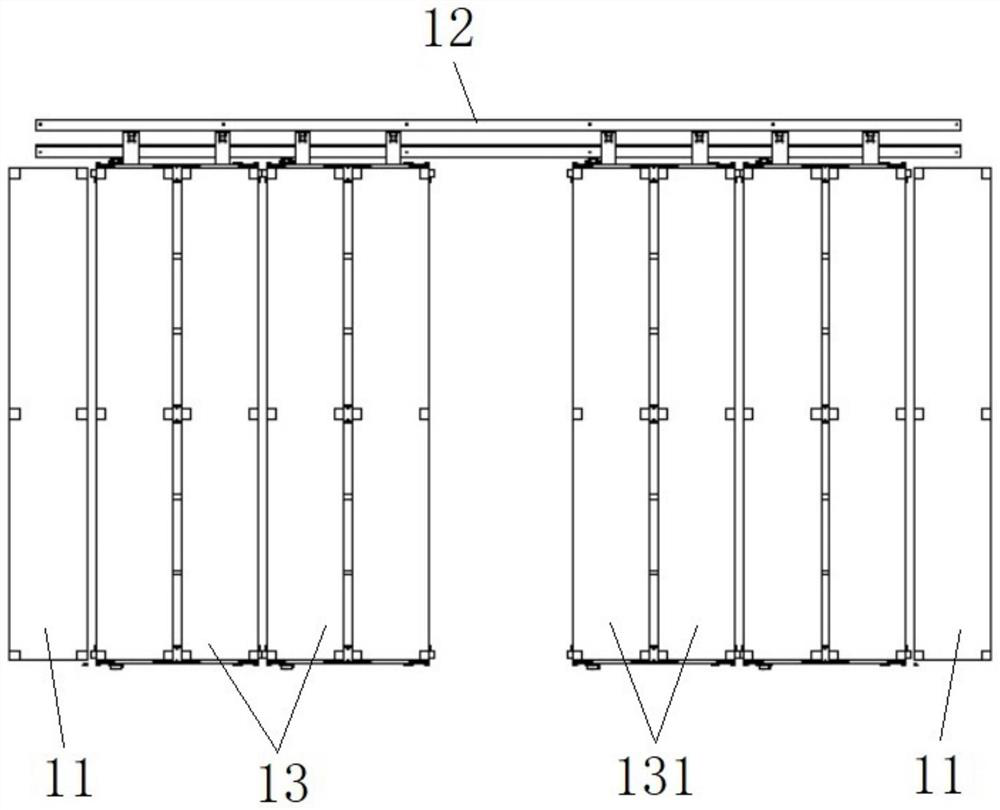

An automated warehousing logistics system

ActiveCN109205162BWalk accuratelySafe, efficient and reliable operationStorage devicesVia deviceMachine

The invention discloses an automated storage and logistics system, which includes a stacker device, a workshop management system MES, an intelligent warehouse management software WMS and an equipment control software WCS. The stacker is used as the main equipment, and the stacker is mainly controlled by the intelligent warehouse. The management software WMS, and through the equipment control software WCS to contact the PLC control system of the machine to complete the task, so that the stacker can automatically complete the task of entering and leaving the warehouse according to the task allocation of the system, without the need for personnel to participate in the operation; and the information of the company's shipment is only through The customer's ERP system, linked to the WMS system, can automatically complete the delivery task through the stacker, and the completion of the production task is controlled by the MES production management system. The WMS intelligent storage system is controlled by the WCS to complete the task; the invention is completely Intelligent and efficient work without manual operation ensures the accuracy of the work.

Owner:深圳市捷创自动化设备有限公司

Intelligent robot movable material rack for improving storage space utilization rate

The invention belongs to intelligent storage equipment, and relates to an intelligent robot movable material rack for improving the storage space utilization rate. The intelligent robot movable material rack comprises two fixed material racks arranged in parallel in the X direction, a Y-direction slide rail arranged between the two fixed material racks and a plurality of movable material racks arranged side by side between the two fixed material racks and capable of sliding in the Y-direction slide rail, and the distance between the fixed material frames is larger than the total width of all the movable material racks by one channel width allowing an intelligent robot to enter and exit. According to the intelligent robot movable material rack, different channels for the intelligent robot to enter and exit can be provided through transposition of the movable material racks, and storage space waste caused by the multiple channels is avoided.

Owner:友上智能科技(苏州)有限公司

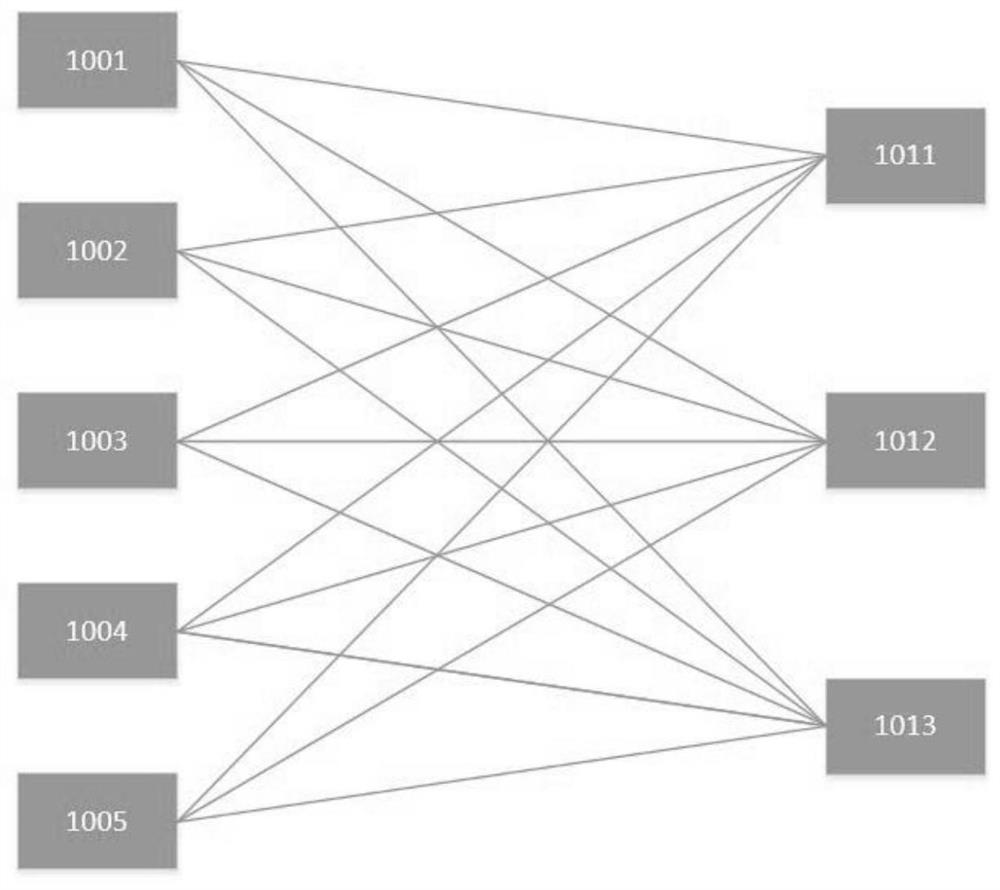

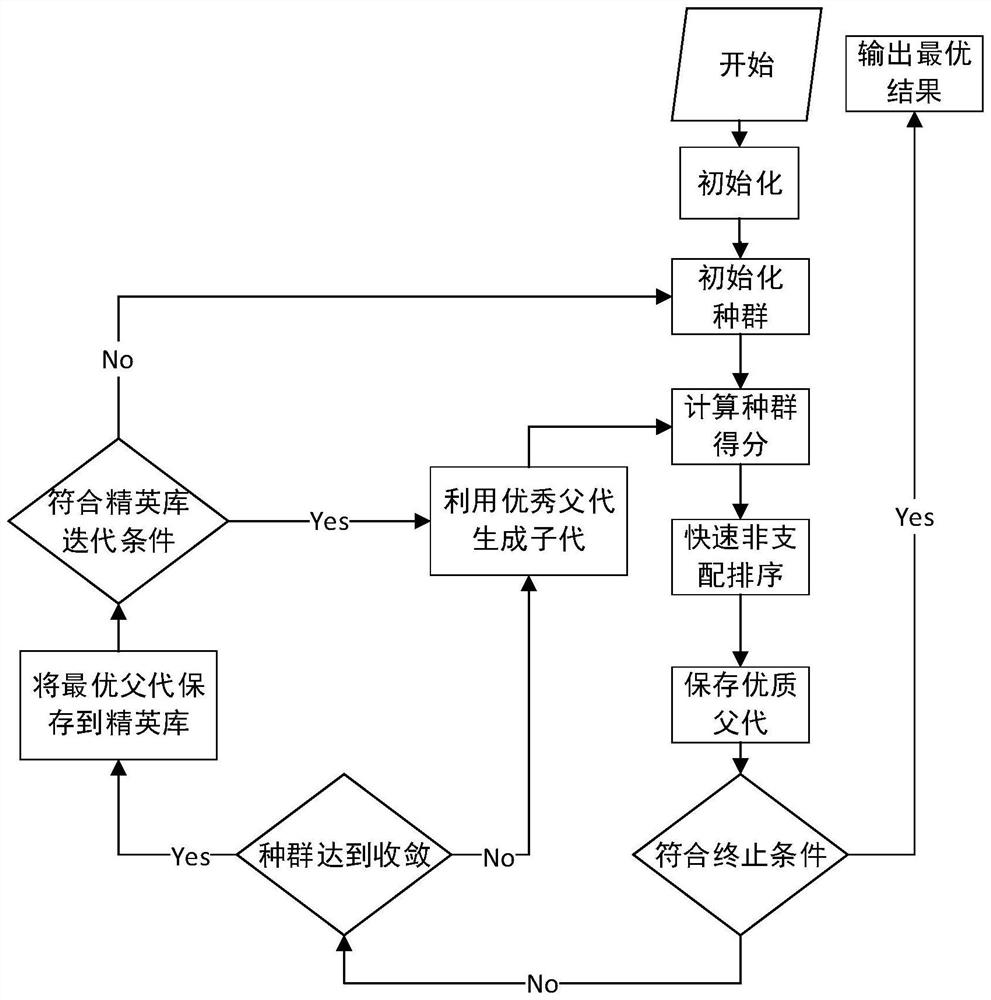

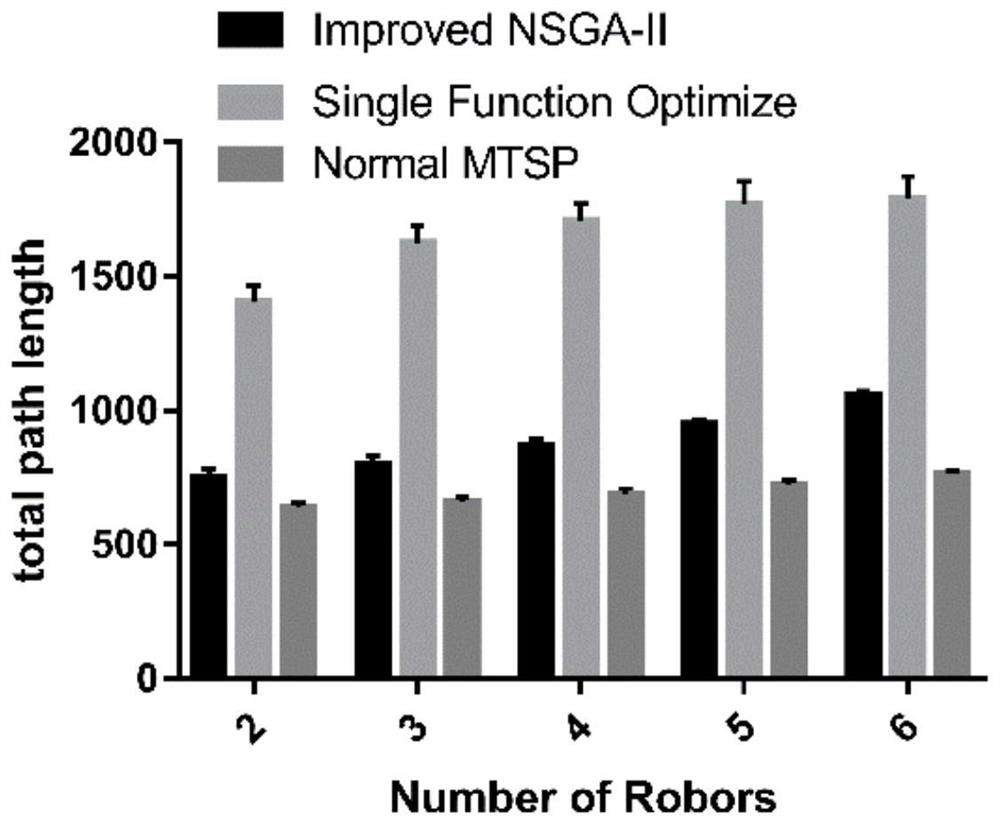

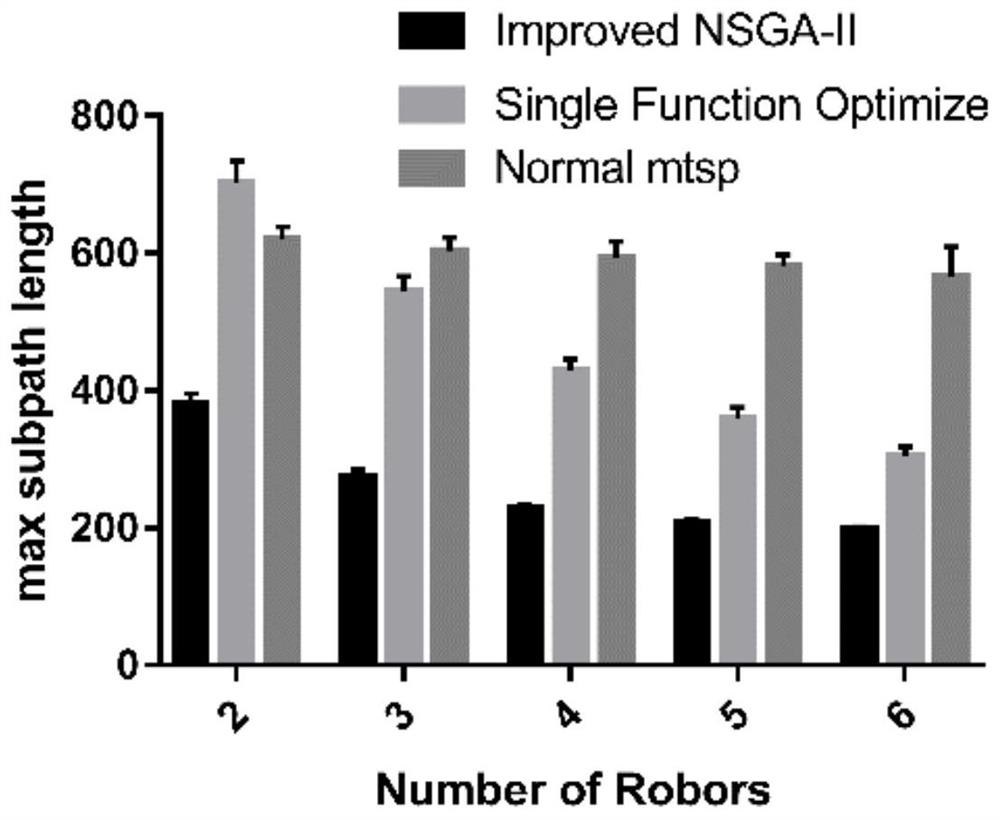

A multi-robot task assignment method for intelligent storage system

ActiveCN110084512BSolve task assignment problemsImprove scienceForecastingResourcesMultirobot systemsDistribution method

The invention discloses a multi-robot task assignment method for an intelligent storage system. According to the intelligent storage task assignment problem, a multi-objective task assignment model is established, and a time cost function and an energy consumption cost function are designed; A multi-objective genetic algorithm for non-dominated sorting; and a new iterative process is added to the framework of the above-mentioned genetic algorithm to ensure that it can further converge to a better non-dominated solution. The invention obtains a better non-dominated solution by sorting the dominance levels of each optimization component, and improves the probability that the algorithm converges to a better non-dominated solution through population restart and an elite pool mechanism. And at the same time, the present invention takes into account the time cost and energy consumption cost of the multi-robot system in the task allocation problem of the multi-robot system, can solve the task allocation problem in the multi-robot system more systematically, and improve the scientificity and rationality of the task allocation results.

Owner:HOHAI UNIV CHANGZHOU

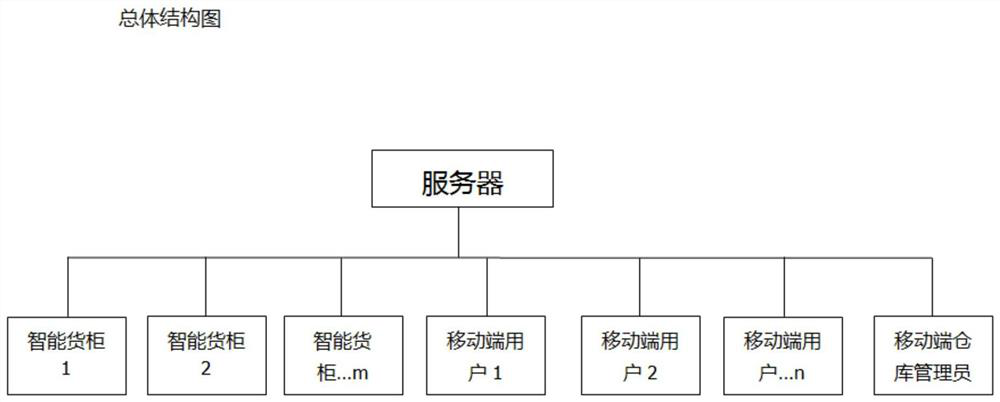

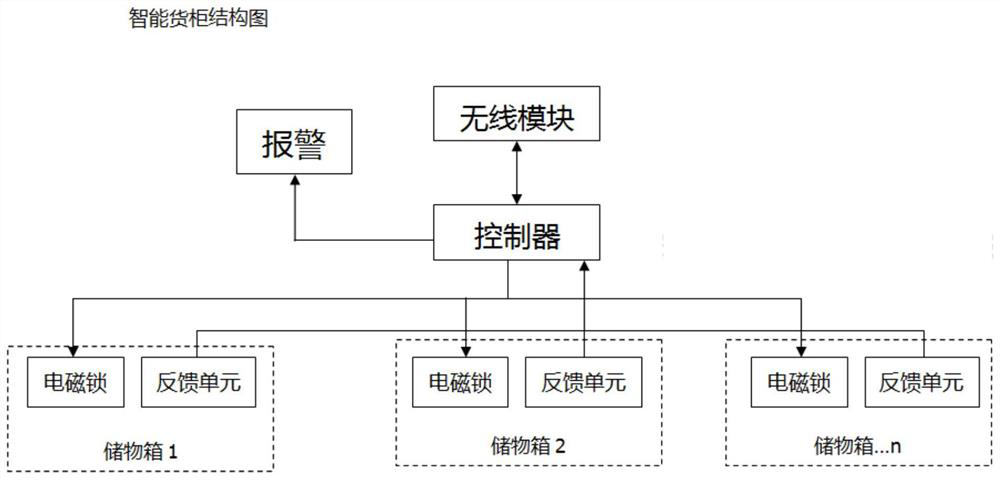

Intelligent warehousing system

The invention discloses an intelligent warehousing system which comprises an electromagnetic lock, a server, an intelligent warehousing hardware system and an intelligent warehousing software system, and relates to the technical field of warehousing equipment. When the materials are taken, the number of the materials is selected at the mobile client, the intelligent warehousing software system transmits instructions to the server and the intelligent warehousing hardware system in sequence, and the hardware system controls the cabinet door to be opened to take out the materials. And the cabinet door is closed to generate a goods taking success instruction, the intelligent warehousing hardware system transmits the instruction to the server and the intelligent warehousing software system in sequence, and the intelligent warehousing software system deducts the number of the materials. When the materials are stored and the quantity of the materials in the containers is lower than the standard quantity, the intelligent warehousing software system pushes a prompt to the warehouse administrator mobile terminal, and the warehouse administrator uploads the information of the stored materials through the mobile terminal, checks the quantity of the supplemented materials and then opens the corresponding intelligent containers through the mobile terminal to store the materials. And the warehouse administrator inputs the quantity of the supplemented materials into the intelligent warehousing software system through the mobile terminal to complete material storage.

Owner:山东人人智能科技有限公司

A Smart Warehouse Based on the Internet of Things

Owner:中钧科技有限公司

Interactive method and interactive device of logistics system

PendingCN107857044AFewer conversion stepsReduced transit timeStorage devicesLogistics managementComputer science

The invention relates to an intelligent logistics system and belongs to the field of logistics. An interactive device of a logistics system comprises first equipment in the logistics system and is characterized by also comprising second equipment at an article destination, wherein the first equipment is used for taking a to-be-transferred article out; the article needs to be transferred to the destination of a multi-layer storage structure; and after the article is taken out and transferred to a designated position of an interactive platform by the first equipment, the second equipment can directly reach the upward side of the article on the interactive platform, directly takes the article out and transfers the article to the destination of the multi-layer storage structure through a through guide rail. Through the interactive platform and the guide rail, the second equipment can get the article directly from the first equipment, so that the efficiency is increased, the article transferring step is reduced and the article transferring time is shortened; and the requirements on the first equipment and the second equipment are not high through the interactive mode, so that the follow-up expansion and improvement of the whole intelligent storage system are benefitted, the efficiency is higher and the cost is lower.

Owner:上海海丰智能科技有限公司

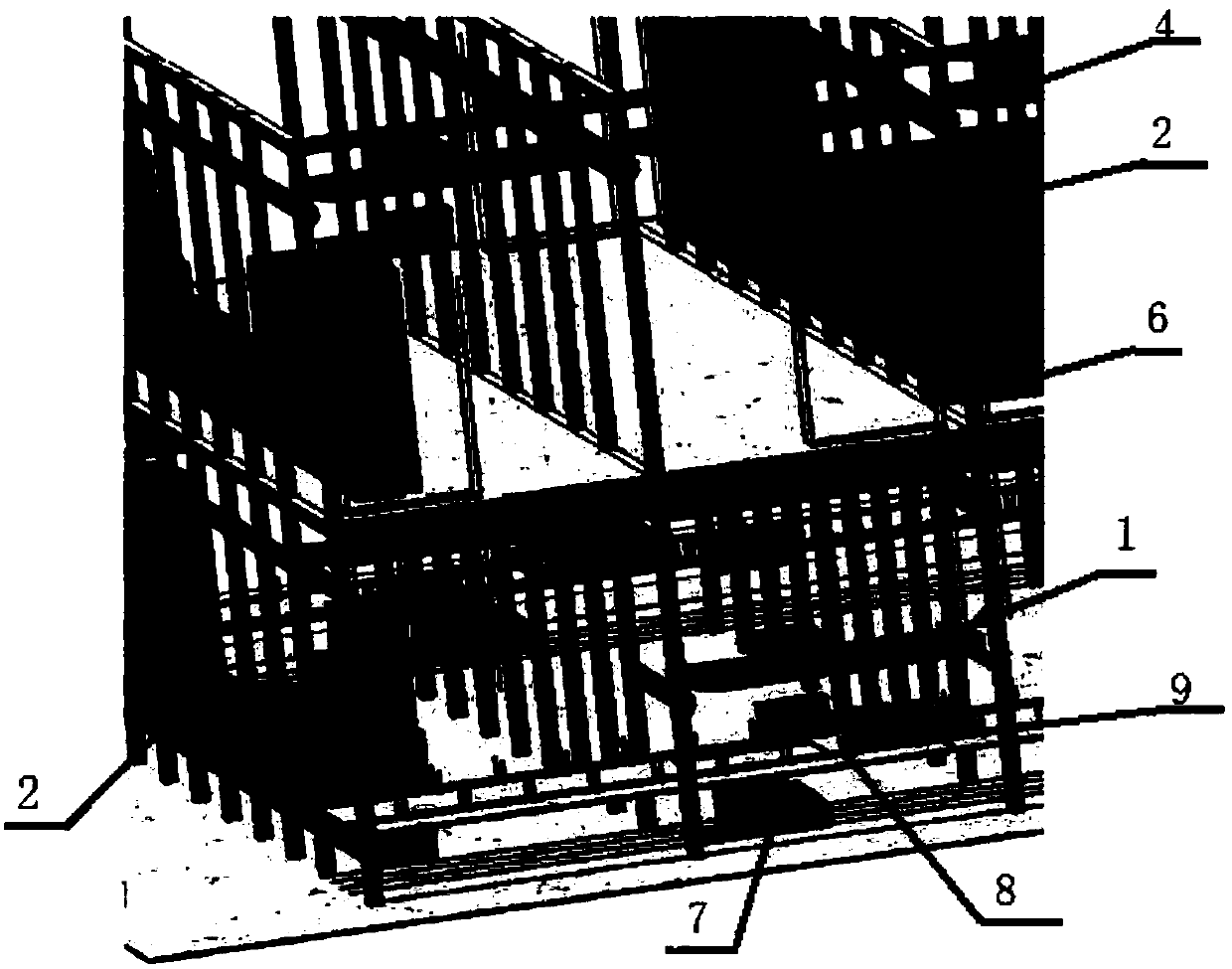

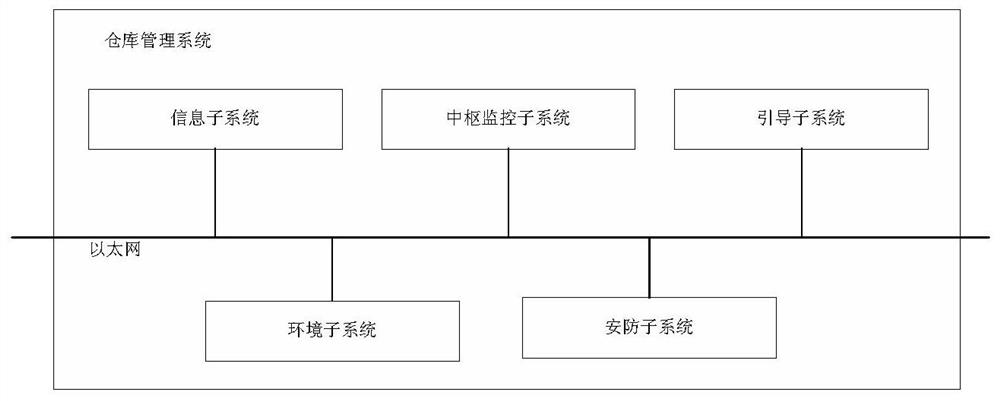

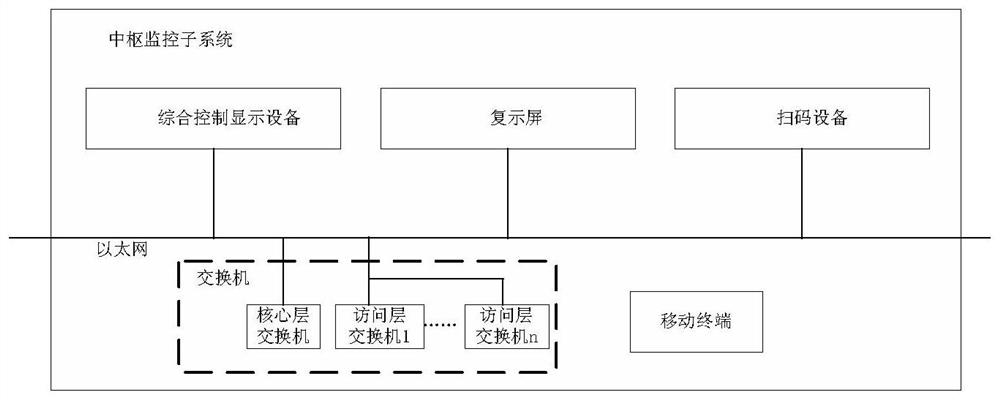

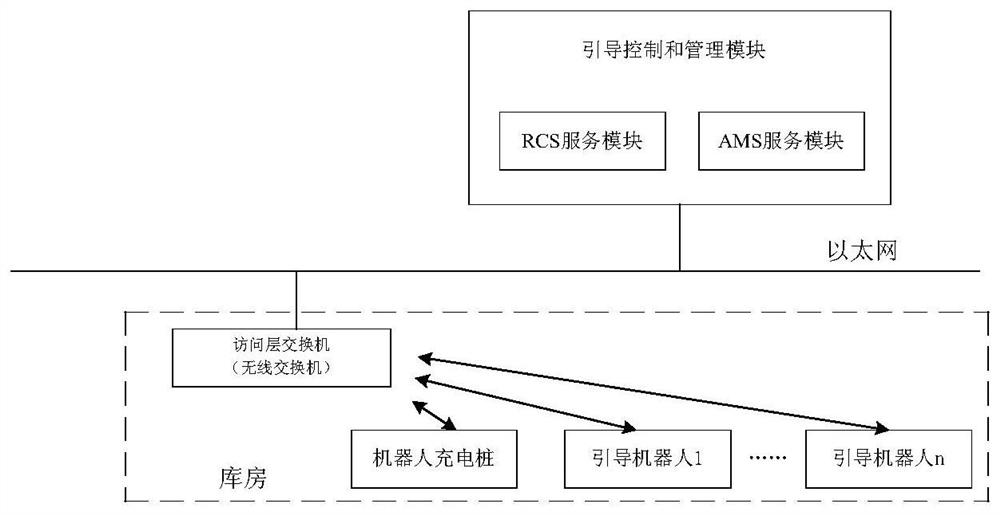

An Intelligent Warehouse Management Method Based on Central Monitoring

ActiveCN107705058BIntelligent linkage in and out of storageIntelligent linkage security monitoringDatabase management systemsCo-operative working arrangementsMonitoring systemEnvironment surveillance

The invention relates to a central monitoring-based intelligent warehouse management method. According to user requests, the central monitoring system of the intelligent warehouse uses a guiding robot to assist the operator to complete the tasks of warehouse-out, warehouse-in and inventory. The intelligent warehouse management method informatizes the equipment management of the warehouse, and can intelligently link equipment in and out of the warehouse, environment monitoring, and security monitoring; introduce intelligent guidance robots, transform them according to warehouse needs, and realize integrated linkage with the equipment management system; introduce mobile terminals , interoperate with the robot, and the equipment can be put in and out of the warehouse in real time; in view of the shortage of warehouse personnel, the replacement of old and new warehouse managers, and the unfamiliarity of the business, it assists the warehouse manager to achieve rapid warehouse entry and exit. After field testing, the personnel requirements are the original warehouse One-third of the time, the time is shortened by nearly 50%.

Owner:CSSC ELECTRONICS TECH

An intelligent storage shelf based on the Internet of Things

ActiveCN112249586BWith rotational characteristicsHas a rotating characteristicStorage devicesShow shelvesControl systemThe Internet

The invention relates to an intelligent storage shelf based on the Internet of Things, and relates to the technical field of intelligent storage shelves. The rear part of the shelf is raised by means of a jacking action, which solves the problem that the goods in the rear area are not easy to take when the shelf is used against the wall. Including a shelf, the bottom of the shelf is welded with a front loading plate, the rear of the front loading plate is hingedly connected with a rear loading plate, and the rear of the shelf is welded with a The rear horizontally supported drop board, the middle part of the shelf is welded with a top loading board, and a display screen is installed on the front side of the top loading board, and the display screen is remotely connected with the external Internet of Things control system, thereby forcing the items stored on the rear loading board to be lifted The height is convenient for picking up the items in the rear area. The setting of the pull seat mechanism is easy to use. After pulling forward, the lifted goods can fall with the wire rope and return to the original shape. At this time, it can be adapted to the rear items. In occasions that do not need to be taken separately, the flexibility and practicality have been improved.

Owner:江西金虎保险设备集团有限公司

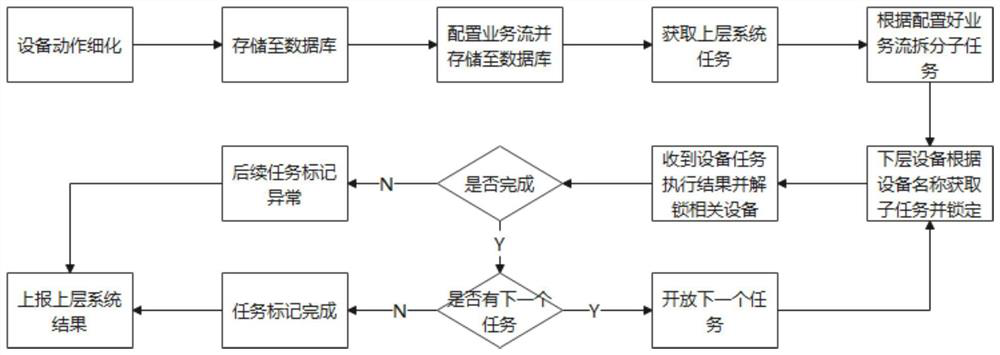

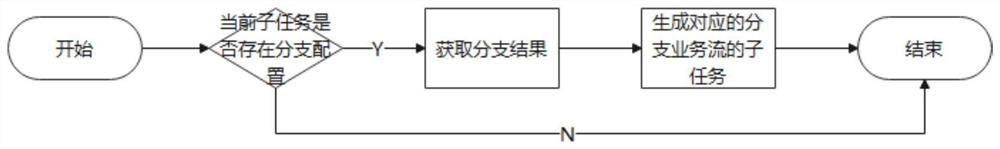

Scheduling method for collaborative operation of multiple intelligent devices in intelligent warehouse

PendingCN114254952ARealize the effect of "drag and drop"Reduce development costsResourcesLogisticsService flowControl system

The invention relates to a scheduling method for collaborative operation of multiple intelligent devices in an intelligent warehouse, which comprises the following steps of: disassembling and numbering executable actions of each intelligent device, and combining the executable actions according to an actual service flow; after an upper-layer task is obtained, calling a corresponding configured service flow, and splitting the service flow into device sub-tasks according to a device to which the action number belongs; the control system continuously sends a task request to the scheduling layer according to the name of the controlled equipment, obtains sub-tasks and distributes the sub-tasks to the equipment; and after the device executes the subtask, feeding back a subtask execution result to the scheduling layer, if the subtask is executed, judging whether a next task exists and opening the next subtask or marking the subtask to complete operation, otherwise, marking that a subsequent task is abnormal, and reporting the subtask execution result. According to the method, equipment actions are disassembled for sub-task scheduling, and the control system requests whether a task needs to be done or not according to the equipment name, so that task loss can be reduced, and abnormity positioning is facilitated.

Owner:江苏智库智能科技有限公司

An intelligent cold storage with partition management

ActiveCN111351297BRealize regulationRealize automatic independent controlLighting and heating apparatusStationary refrigeration devicesControl systemControl engineering

The invention discloses an intelligent cold storage with partition management, which includes a storage body and a control system. The storage body includes several cold storage areas, and the control system includes an intelligent storage unit and several first cold storage control units. The unit is set corresponding to the cold storage area, and the first cold storage control unit includes a temperature sensor, an RFID card reading module and a control module. After adopting the above technical solution, the present invention is an intelligent cold storage with zoned management. The temperature monitoring and temperature adjustment of each cold storage area can realize automatic independent control, realize local cooling, etc., so as to achieve the purpose of energy saving and consumption reduction. Compared with the traditional technology, there is no need to manually go to the warehouse to measure the temperature, etc. When the temperature in the warehouse is to be lowered, there is no need to manually control the opening and closing of the manual valve in the machine room. The invention only needs remote control.

Owner:石狮市洋鸿新能源科技有限公司

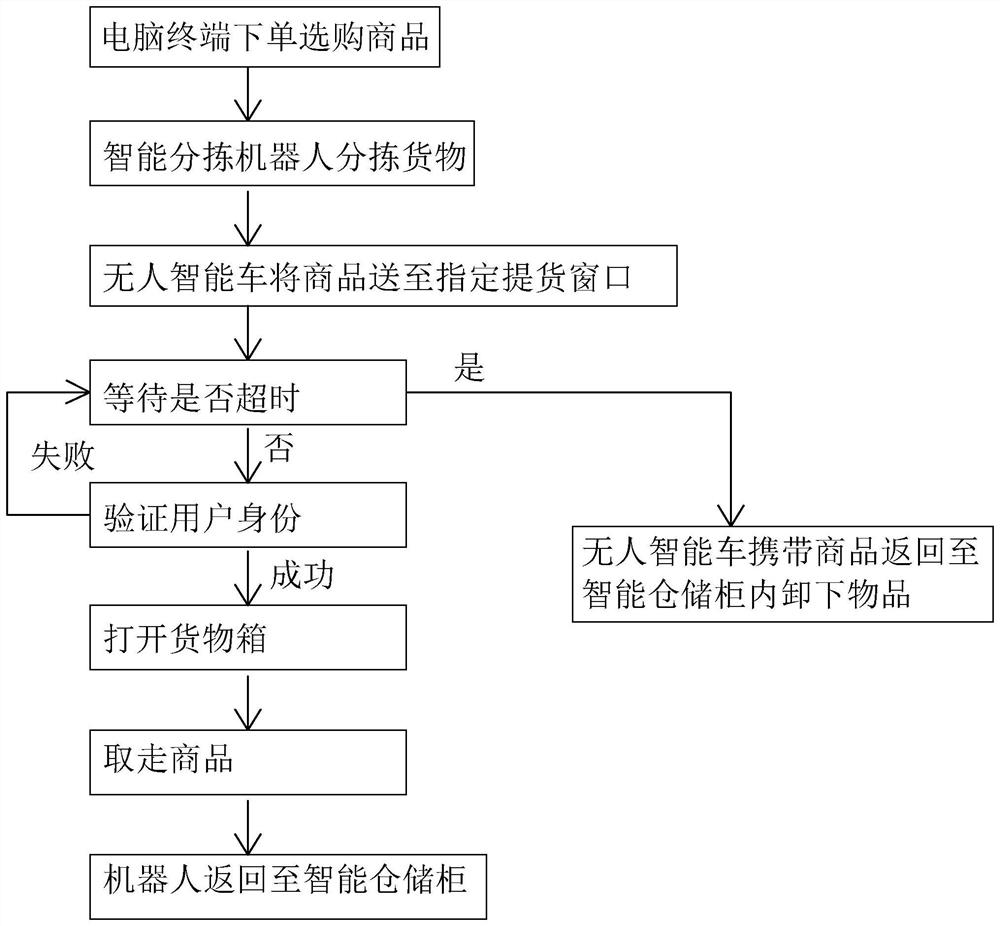

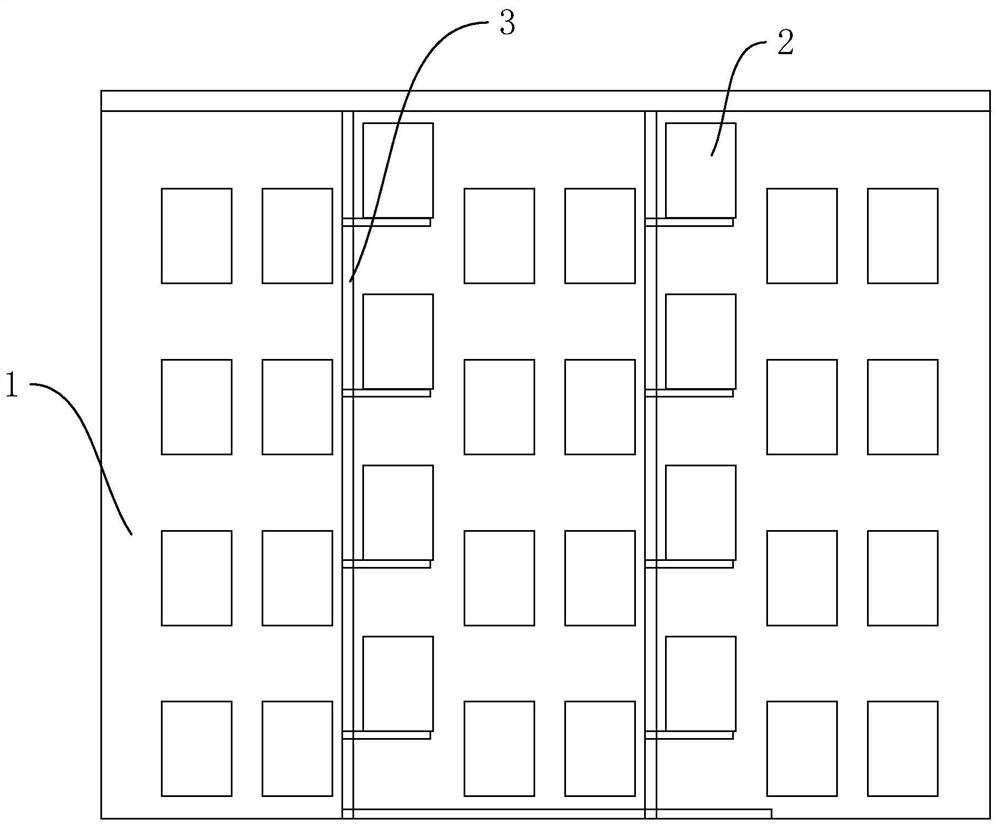

Method and system for real-time to-the-home logistics consumption serving people in building

InactiveCN113627842ASolve the logistics business of sending and receiving express mail without leaving homeProtect private informationControl devices for conveyorsFranking apparatusLogistics managementComputer terminal

The invention discloses a method and system for real-time to-the-home logistics consumption serving people in building, and the method comprises the following steps: S1, placing an order: a user selects and purchases a commodity on a computer terminal, and gives an instruction to a server; s2, sorting goods: the server issues an instruction to the system, and an intelligent sorting robot in an intelligent storage cabinet extracts goods and commodities and loads the goods and commodities into an unmanned intelligent vehicle; s3, transferring goods: the unmanned intelligent vehicle advances to the corresponding building outer wall track according to the delivery address and runs to a designated goods picking window; s4, delivering the goods: the computer terminal notifies the user to go to the window to pick up the goods within the specified time in advance according to the real-time operation information of the unmanned intelligent vehicle, and after the user completes goods pick-up, the goods pick-up window is closed. According to the invention, real-time to-home logistics and consumption services can be provided for the user, the intelligent sorting robot and the unmanned intelligent vehicle cooperate for operation, the user can autonomously arrange the delivery and pickup time in all weather, no person participates in delivery in the process, and the system is safer and more convenient.

Owner:嘉兴市齐创环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com