Intelligent robot movable material rack for improving storage space utilization rate

A utilization rate and robot technology, applied in tool storage devices, manufacturing tools, etc., can solve problems such as increasing storage costs and space waste, and achieve the effect of avoiding storage space waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

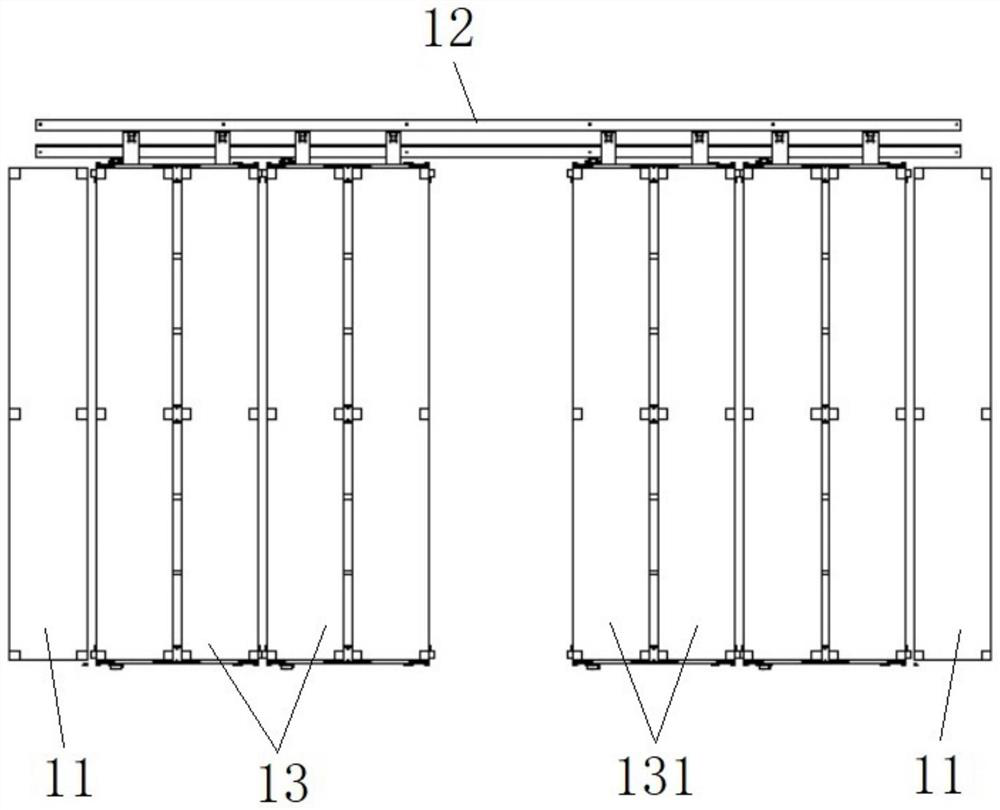

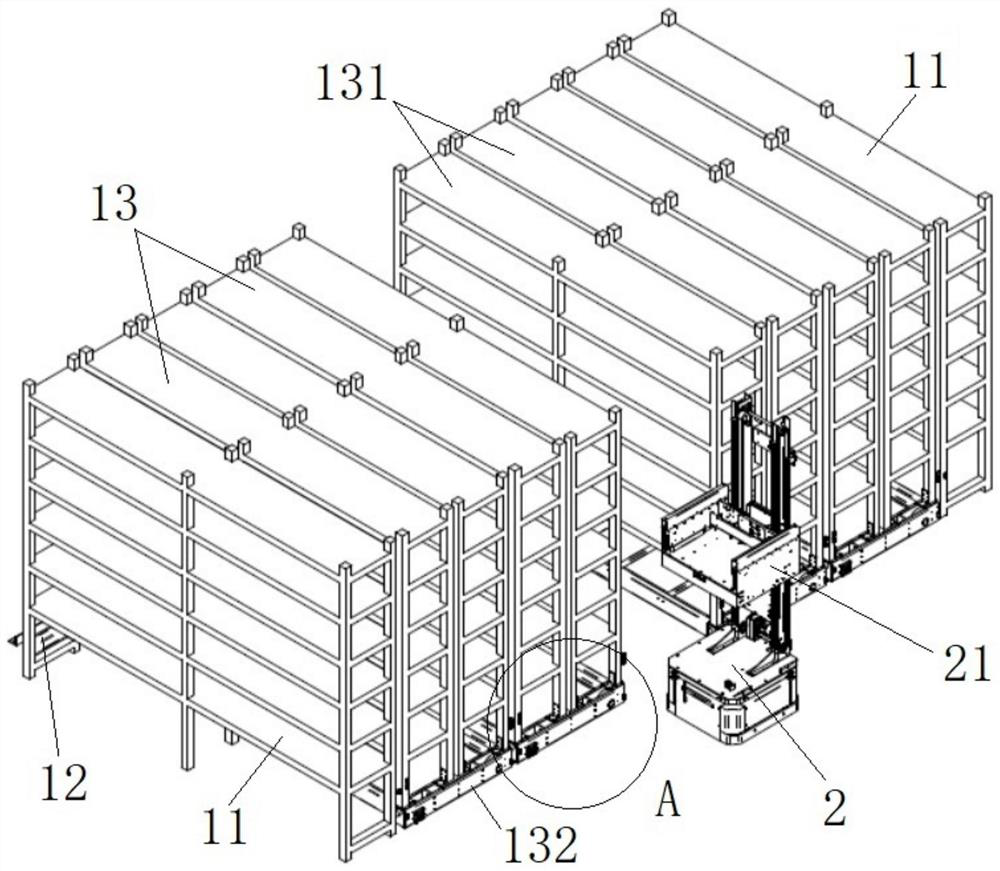

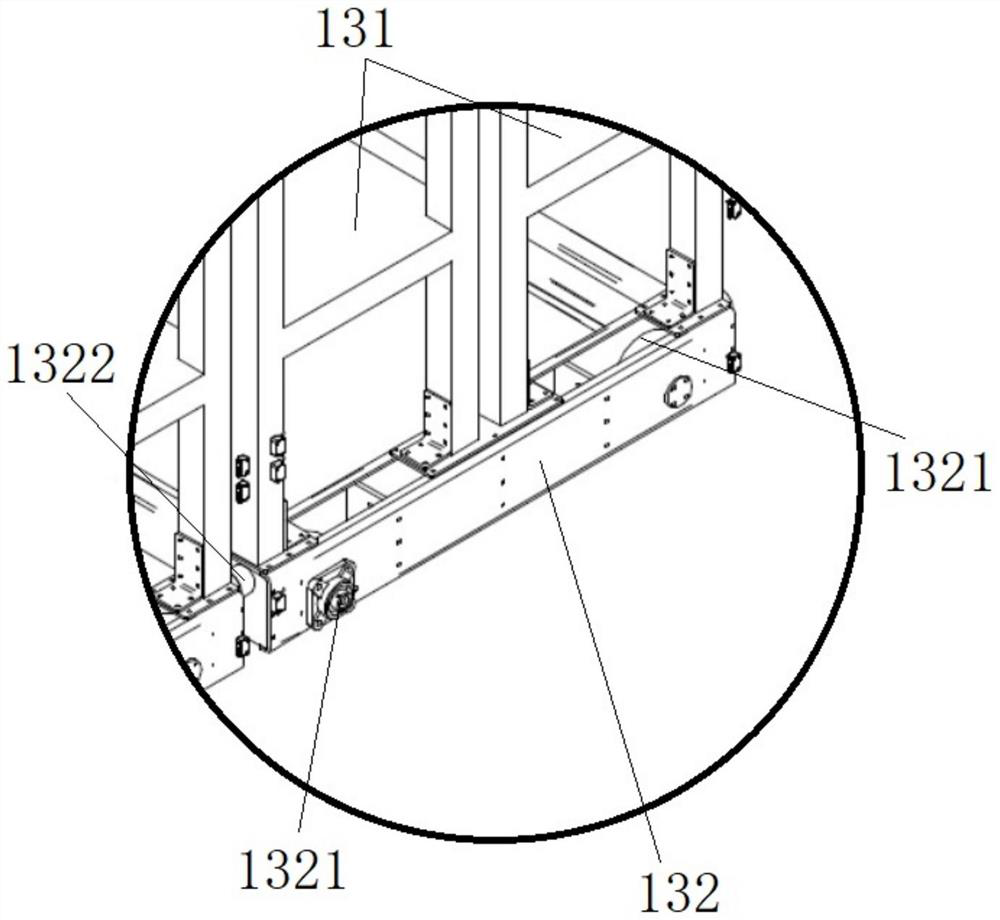

[0022] Such as Figure 1 to Figure 3 As shown, an intelligent movable material rack for a robot that improves storage space utilization of the present invention includes two fixed material racks 11 arranged in parallel along the X direction, and a Y-direction slide between the two fixed material racks 11. Rail 12 and four moving material racks 13 that are arranged side by side between two fixed material racks 11 and can slide along the Y direction slide rail 12, the spacing between the fixed material racks 11 is more than the total width of all moving material racks 13 A channel width that can be used by the intelligent robot 2 to enter and exit. Both the fixed material rack 11 and the mobile material rack 13 can be used to place goods. The fixed material rack 11 can be placed against the wall without moving. There is only one channel width between all the mobile material racks 13, so when the pick-and-place position is in the middle position , the mobile material racks 13 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com