Flexible bin allocation method for electric power materials

A distribution method and technology of power materials, applied in the field of warehouse management, can solve problems such as lack of physical strength, uncontrollable personnel, whether vehicles enter, difficulty in ensuring loading and unloading efficiency, etc., to achieve the effect of standardized storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

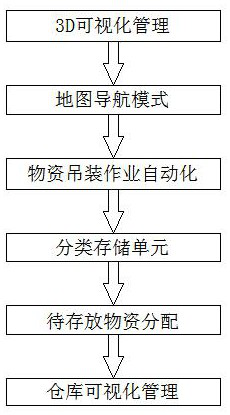

[0022] A method for flexible position allocation of electric power materials, specifically comprising the following steps:

[0023] Step 1, through 3D visualization management, count the current material storage situation and build a 3D model.

[0024] The 3D visualization management system visually displays the actual storage location of the materials in the warehouse in the form of an isometric model, and at the same time, establishes a spatial coordinate axis to achieve precise positioning of the warehouse materials and provide a basis for the space utilization of the warehouse. , Space planning provides data support to realize real-time management of the entire warehouse.

[0025] According to the type, quantity, size of the goods received and the actual utilization of the current warehouse, intelligently pre-allocate the coordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com