PLC programming method used in material carrying among grid arrays

A grid array and grid technology, which is applied in the field of PLC program design in which materials are transported between grid arrays, can solve problems such as increased costs, more storage space, and full PLC storage space, and achieve lower skill requirements and simple operation Fast, low-memory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

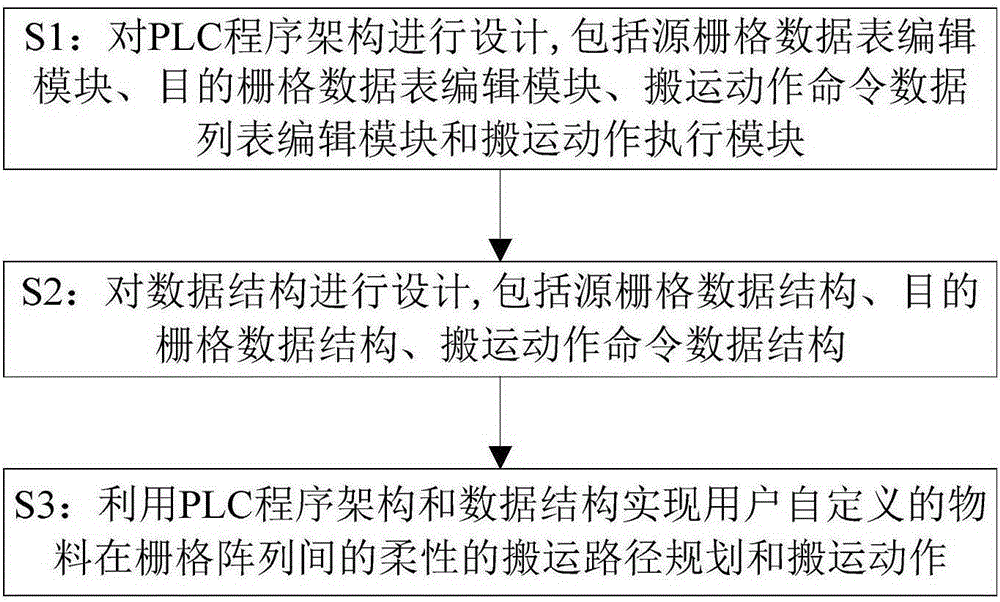

[0029] Such as figure 1 Shown, a kind of design method of the PLC program that is used for material handling between grid arrays of the present invention comprises the following steps:

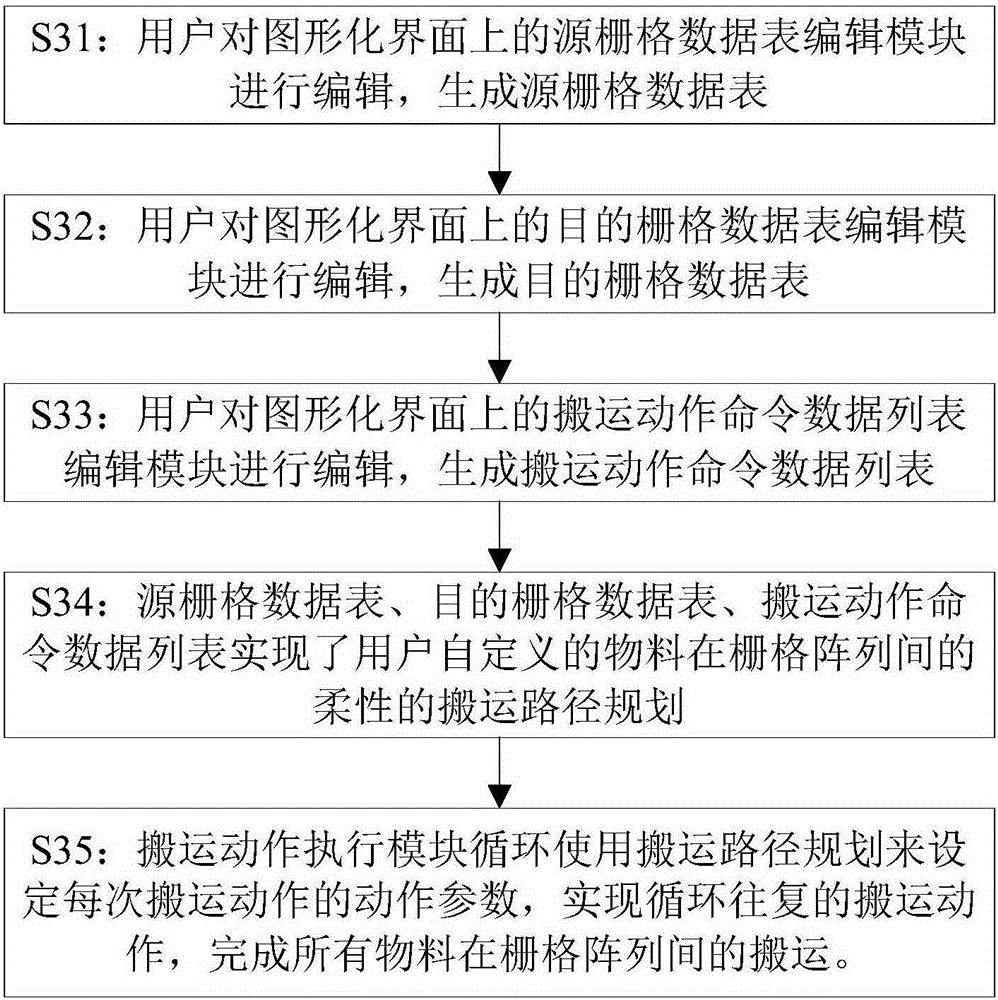

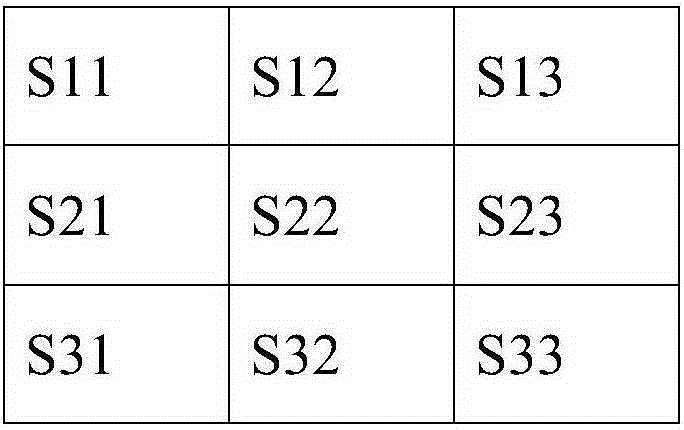

[0030] S1: Design the PLC program architecture, the PLC program architecture includes a source grid data table editing module, a destination grid data table editing module, a moving action command data list editing module, and a moving action execution module; the source grid data The table editing module, the target raster data table editing module, and the moving action command data list editing module are presented as a graphical interface for human-computer interaction, and the user operates the graphical interface to generate a source raster data table, a destination raster data table, etc. grid data table and moving action command data list; the moving action execution module is used to complete the moving action according to the data in the source grid data table, target grid data table...

Embodiment 2

[0137] This embodiment provides a method for designing a PLC program for material transfer between grid arrays, including a method for designing a PLC program architecture and data structure, and using this program architecture and data structure to realize user-defined flexible handling In the method of path planning, the PLC program architecture refers to that the PLC program includes a source and destination grid structure data table editing module, a moving action command data editing module and a moving action execution module, a grid data editing module and a moving action command data The editing module is presented as a graphical man-machine interface, and the operator can realize data editing tasks through human-computer interaction. The moving action execution module completes the moving action by using the data of the source and destination grids and the moving action command data. The data structure refers to the source grid data structure, the target grid data stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com