Internal high-pressure forming production line for pipes in intelligent factory

A technology of internal high pressure forming and internal high pressure, which is applied in the field of pipe fittings processing, can solve the problems of shortening service life, reducing work efficiency, and long time consumption, and achieves the effect of improving work efficiency and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

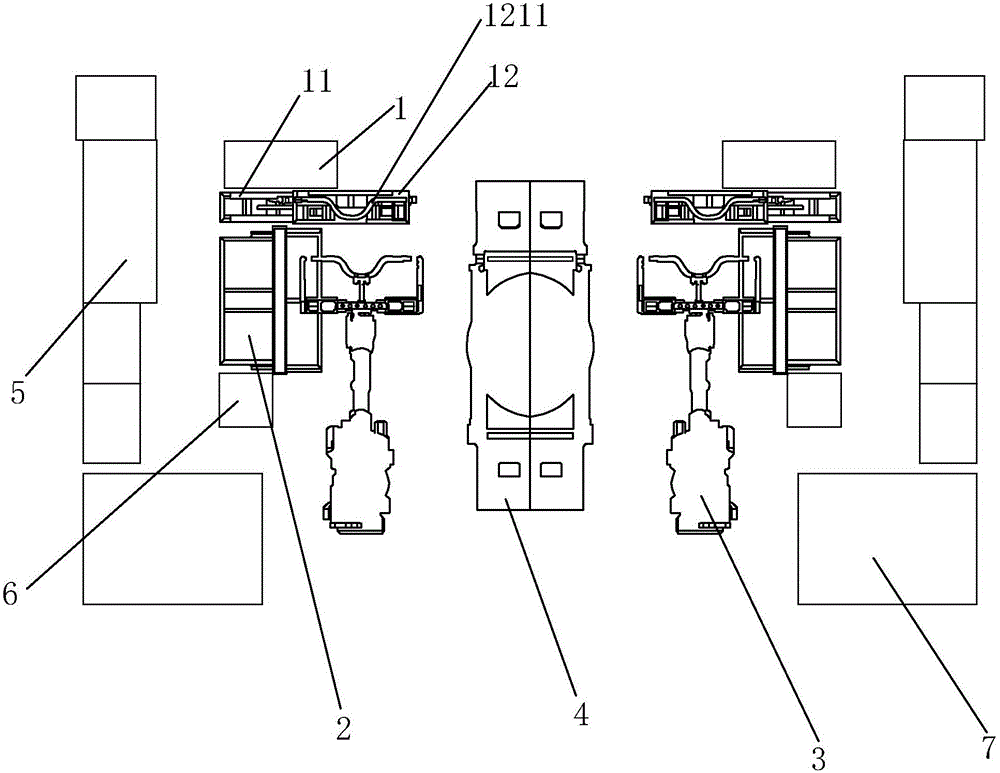

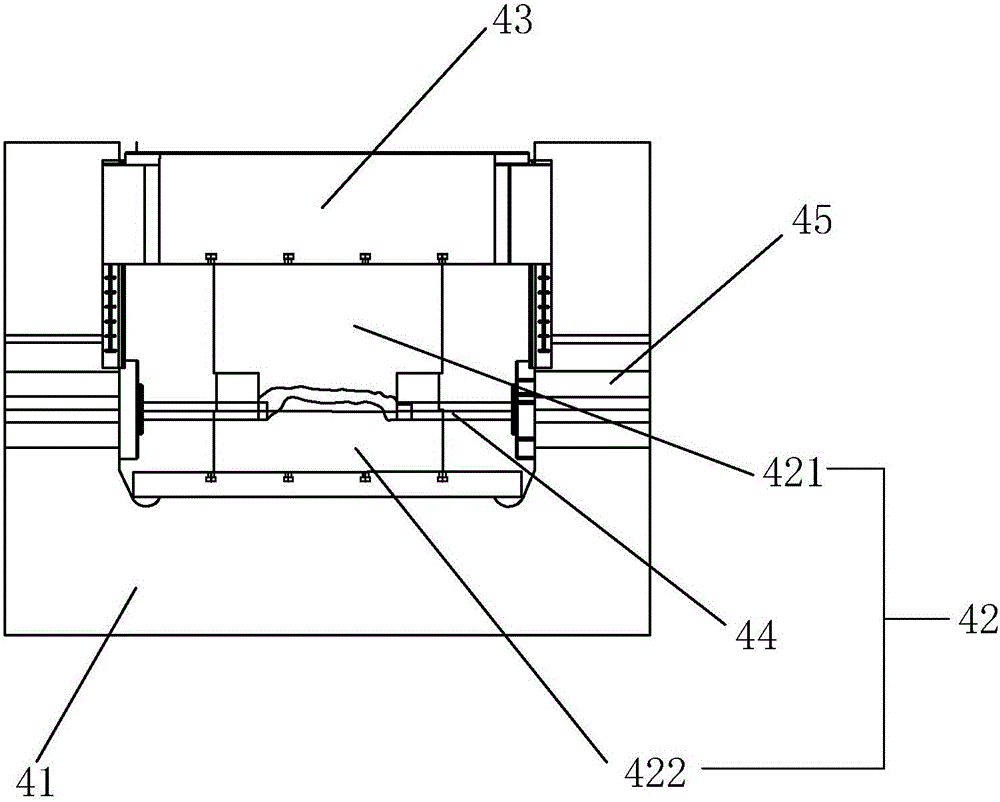

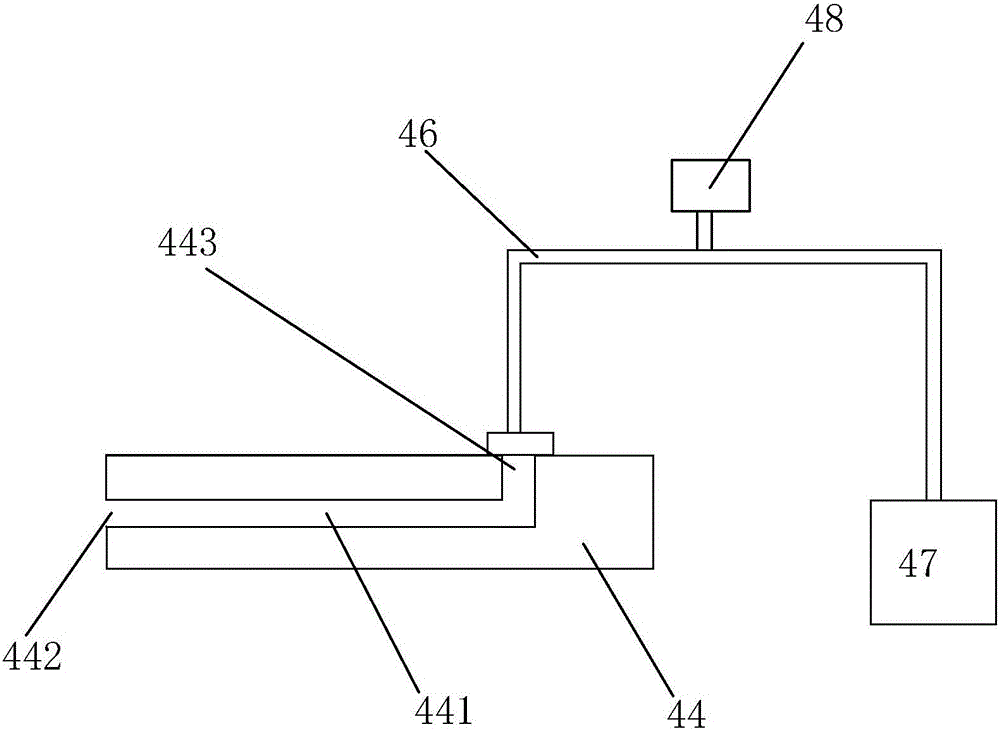

[0037] Such as Figure 1-Figure 3 As shown, this embodiment is an internal high-pressure forming production line for pipe fittings in an intelligent factory, including a loading rack 1, a surface treatment table 2, a mechanical reclaiming mechanism 3, an internal high-pressure forming machine 4, a cutting machine 5, and a marking machine. The machine 6 and the cleaning station 7 are connected with signal lines between the above-mentioned various devices, through which the data exchange between the various devices can be realized, and the overall control can be realized through the central control system of the assembly. The specific layout of the production line is as follows:

[0038] Internal high pressure forming machine 4 is placed in the central position of the whole production line, and described internal high pressure forming machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com