Remote monitoring method and system for industrial production

A remote monitoring system, industrial production technology, applied in general control systems, control/regulation systems, transmission systems, etc., can solve problems such as incompatibility, and achieve the effect of high degree of digitalization, efficient production management, and convenient production management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

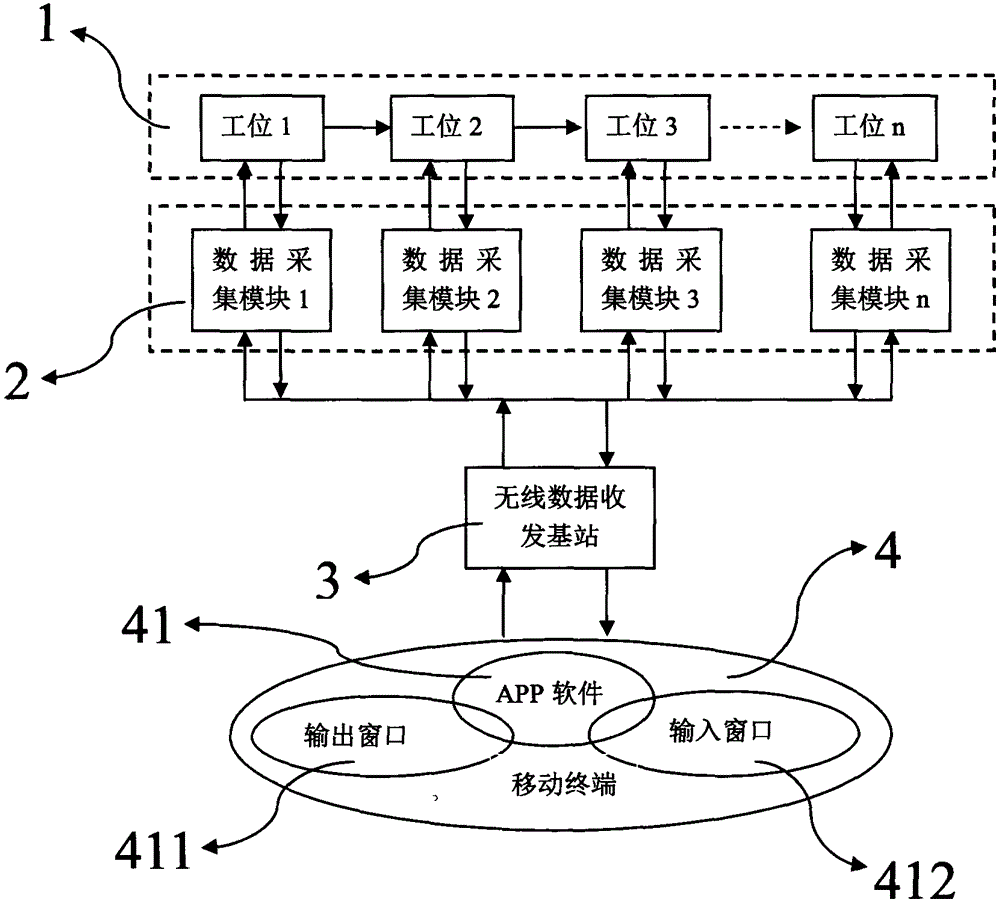

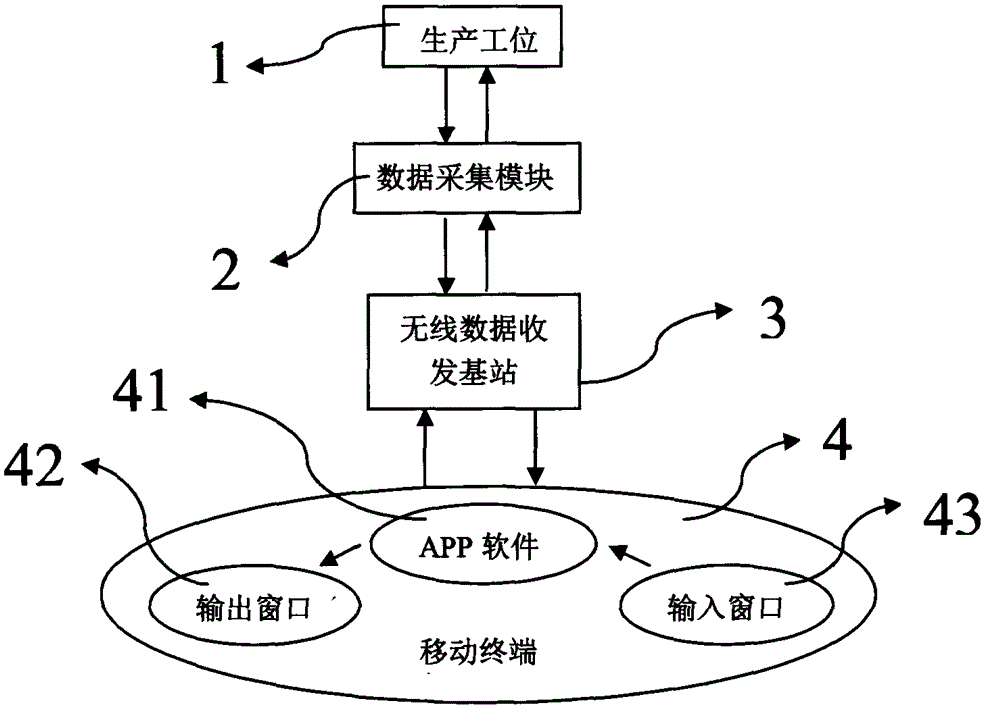

[0040] Such as figure 1 As shown, in order to realize the four remote monitoring operation modes described above, the industrial production remote monitoring system constructed is mainly composed of the following parts: the data collection for collecting, receiving, sorting and transmitting the data generated by the production station 1 Module 2, a wireless data transceiver base station 3 for wireless transmission of data, a mobile terminal 4 with functions of wirelessly receiving data and wirelessly sending data, and an APP software 41 installed on the mobile terminal; wherein, the data acquisition module 2, wireless data transceiver base station 3 abide by a specific data transmission protocol; the wireless data transceiver base station 3 and the mobile terminal 4 abide by a specific wireless data transmission protocol, and transmit data through the wireless network to realize data transmission; the mobile terminal 4 is installed with a dedicated APP software 41 ; The APP so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com