High-precision detection instrument and method for measuring perpendicularity of large mechanical element

A mechanical part and high-precision technology, applied in the field of detectors, can solve the problems of insufficient precision and digitization of monitors, limitations of the use environment and the space of the instrument itself, and complicated operation of CCD measurement methods, achieving simple structure, low maintenance costs, Measuring the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

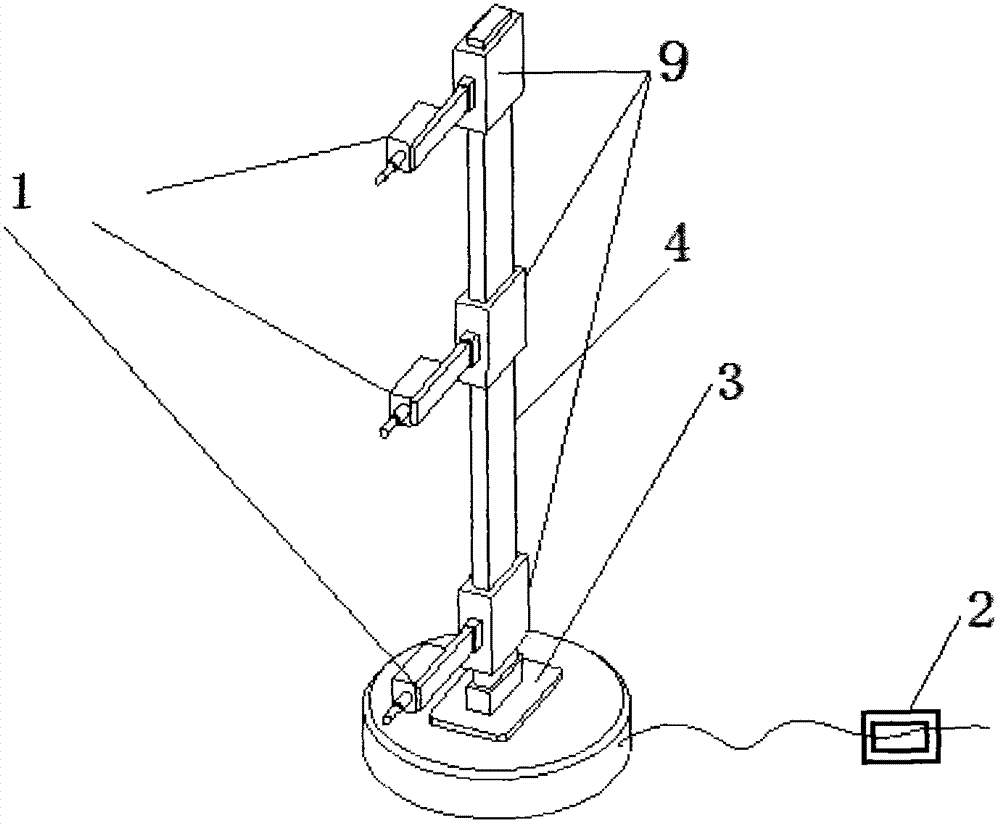

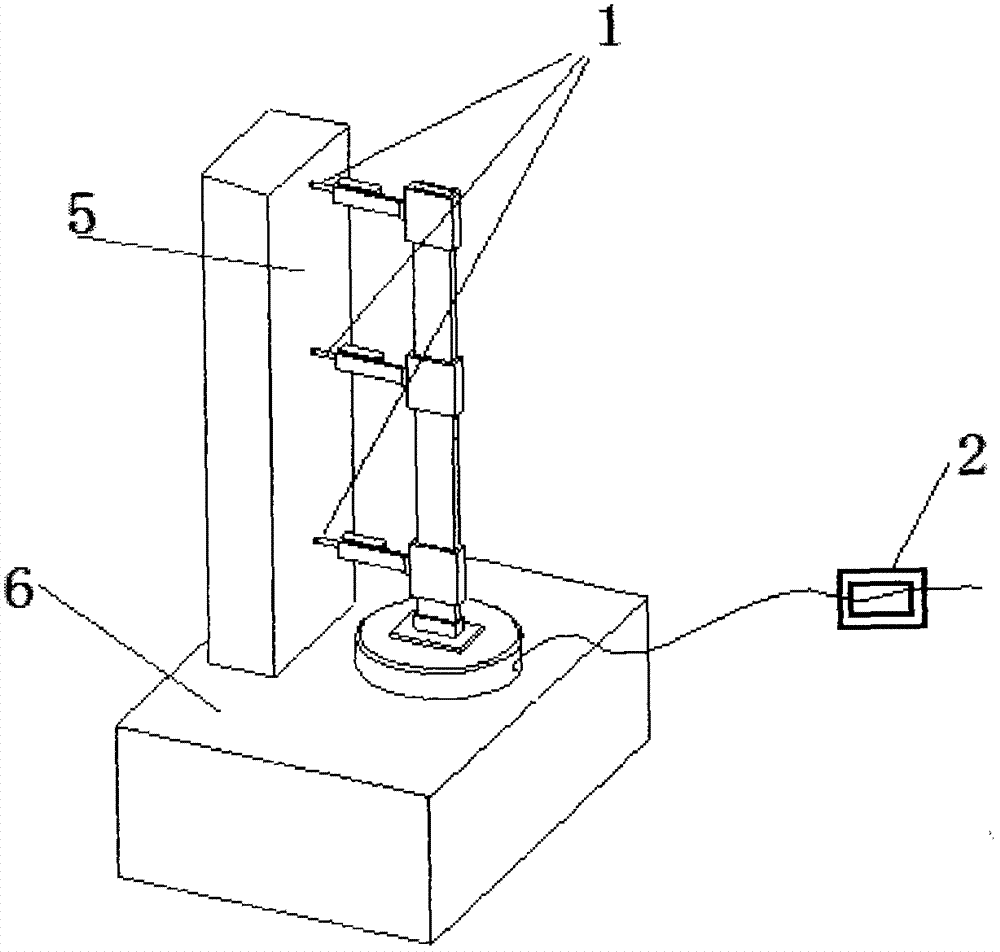

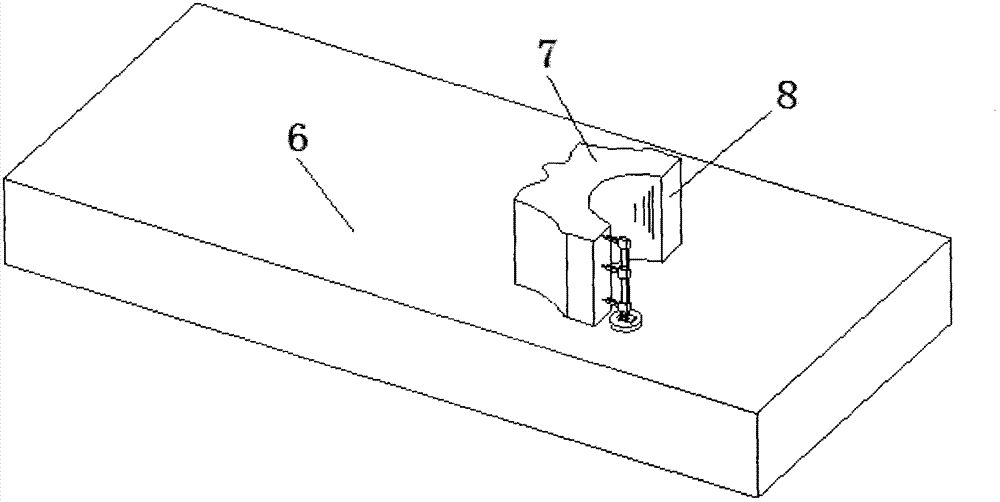

[0019] like figure 1 As shown, the measuring instrument is mainly composed of three parts: a displacement sensor device, an information communication and processing module 2 and an instrument seat.

[0020] The instrument seat is made up of base 3 (disk part) and support 4, and support is installed on the base. It plays the role of fixing and supporting the displacement sensor, and the material is ordinary metal structural steel. The displacement sensor device is composed of a high-precision displacement sensor 1 and an information communication and processing module 2 . Two or more high-precision displacement sensors 1 are arranged in parallel up and down; the high-precision displacement sensors are set on the bracket 4 through the sliding seat 9 and form an adjustable connection with the bracket.

[0021] The main function of the displacement sensor device is to accept the instructions of the information communication and processing module to realize self-tuning, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com