Patents

Literature

38 results about "Position paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A position paper is an essay that presents an arguable opinion about an issue – typically that of the author or some specified entity. Position papers are published in academia, in politics, in law and other domains. The goal of a position paper is to convince the audience that the opinion presented is valid and worth listening to. Ideas for position papers that one is considering need to be carefully examined when choosing a topic, developing an argument, and organizing the paper.

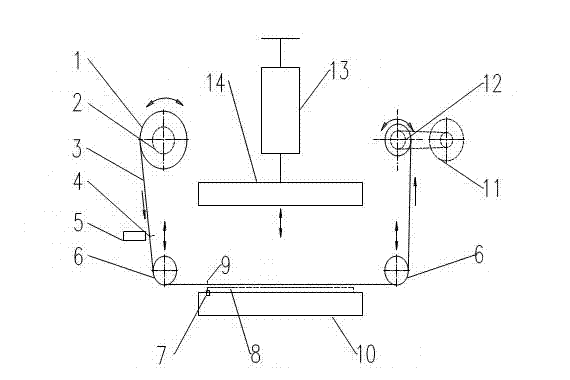

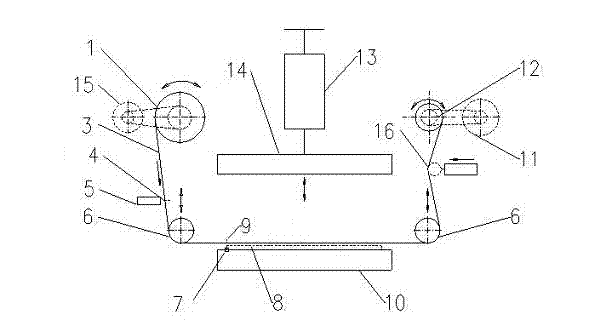

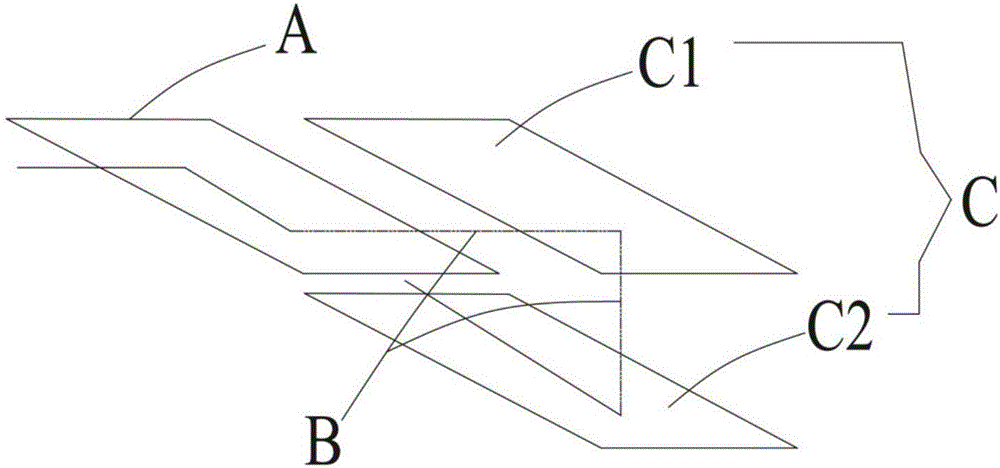

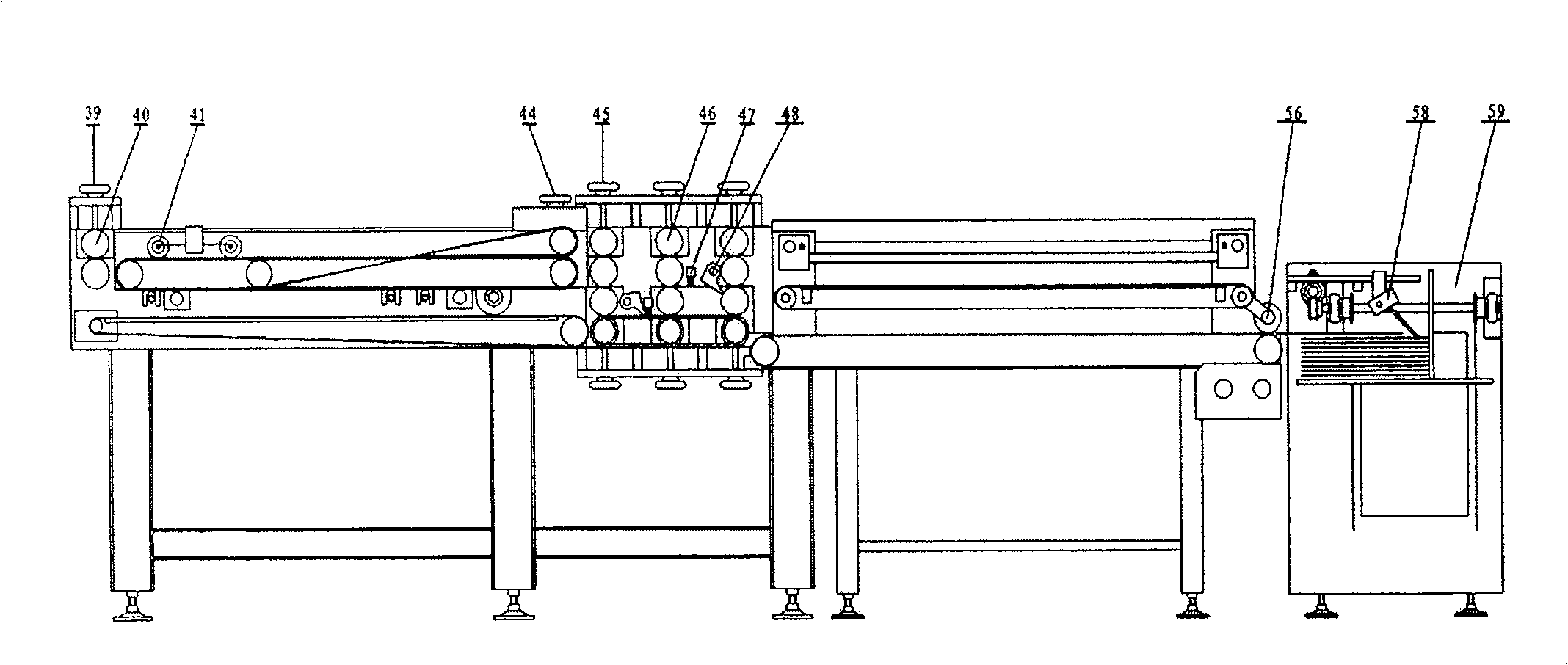

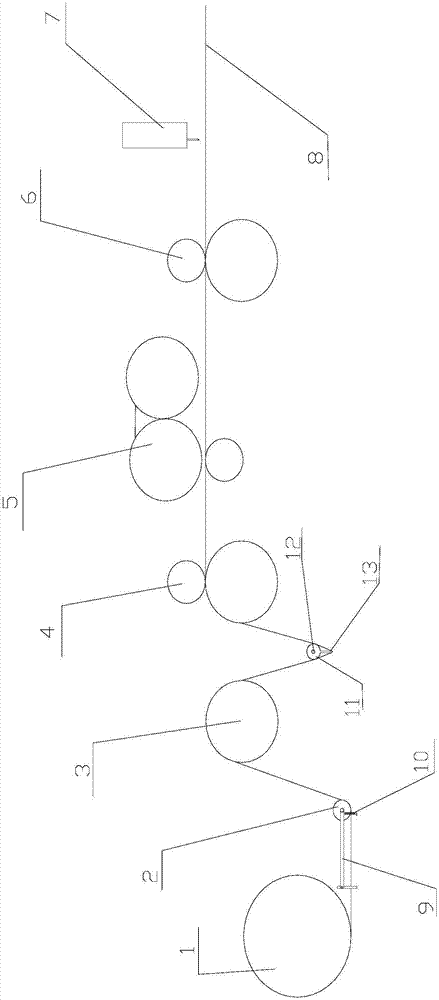

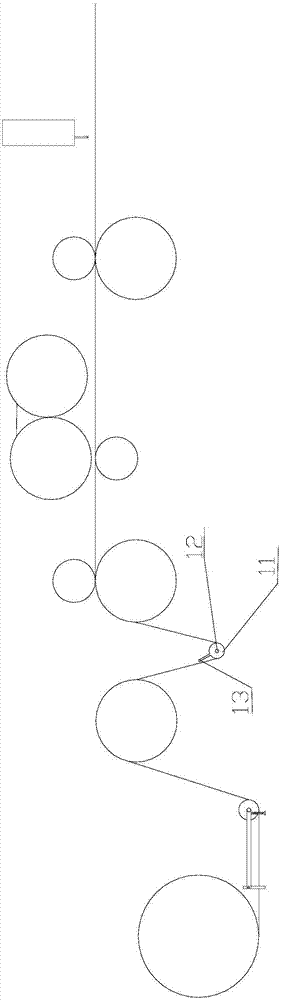

Automatically positioning paper feeding system and method for sheet material transfer printing machine

InactiveCN102785805AReduce processReduce waiting timeLabelling machinesWebs handlingControl systemPulp and paper industry

The invention relates to an automatically positioning paper feeding system and a method for a sheet material transfer printing machine, which is capable of effectively changing a sheet-cut printing paper delivery system of the sheet material transfer printing machine in the textile, printing and dyeing industry into a continuous drum material delivery, characterized in that the unreeling of the printing paper is driven by a magnetic particle brake or a motor plus a floating tension roller, the reeling of the printing paper is mainly driven by the motor, when a position sensor detects a signal, the position signal is delivered to a paper delivery system, a control system delivers the printing paper to a specified position to stop, the specified position is provided with the position sensor for detecting the position of the paper, and the tension force is kept by the magnetic powder brake or a pneumatic floating lever.

Owner:任继平

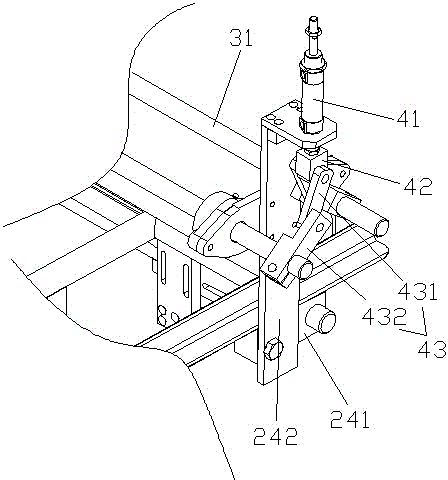

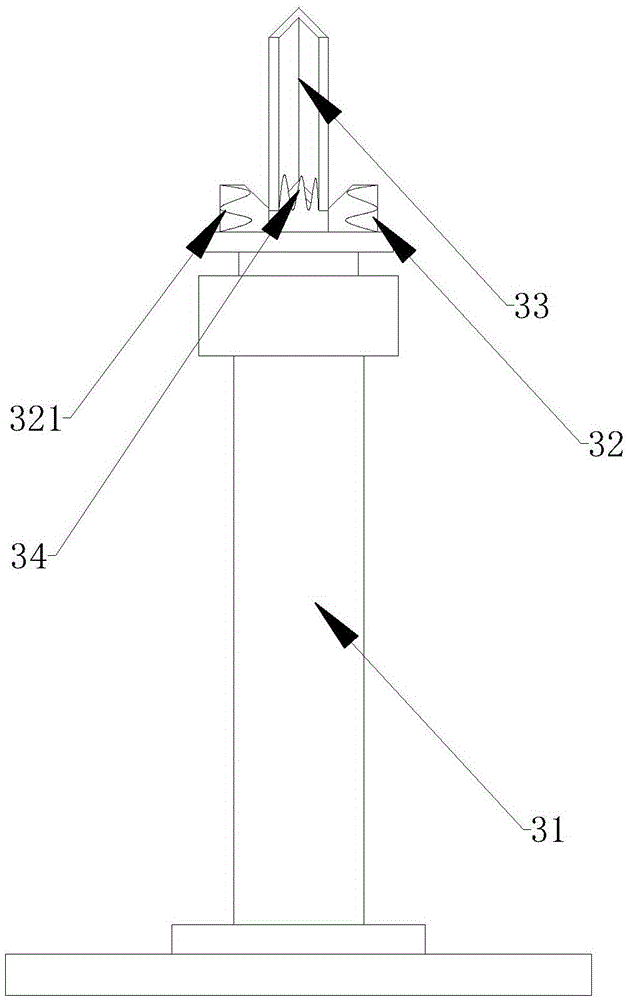

Positioning device for code spraying equipment and working method thereof

InactiveCN102602163AMachining accuracy is easy to guaranteeHigh initial positioning accuracyTypewritersOther printing apparatusMature technologyPulp and paper industry

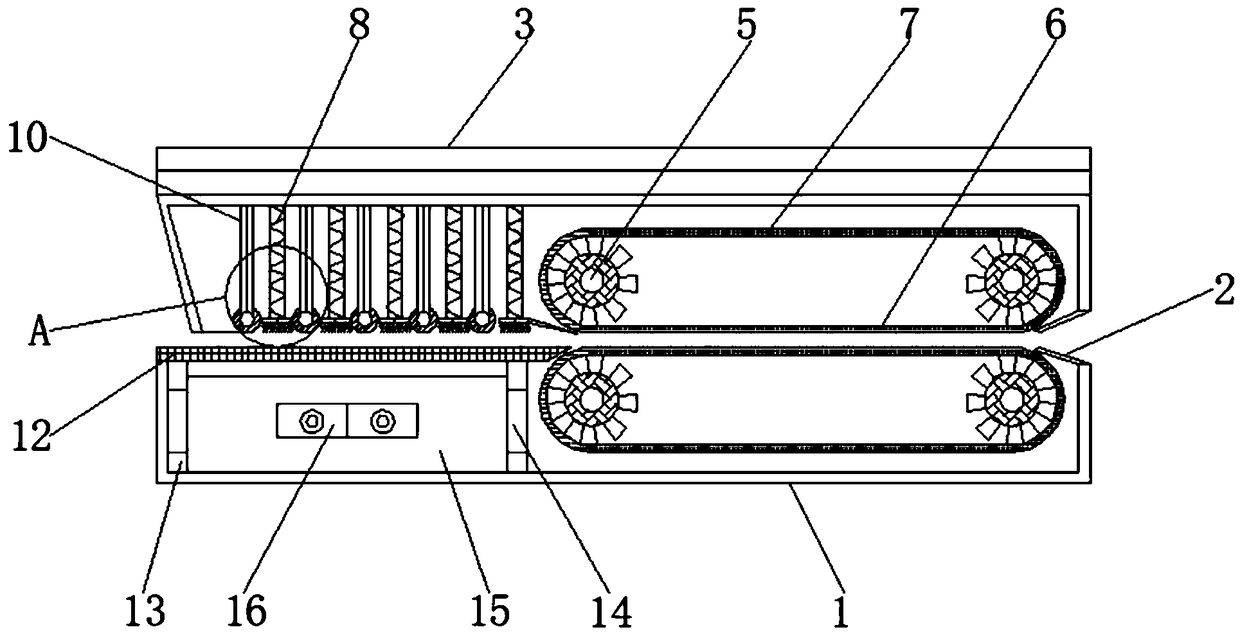

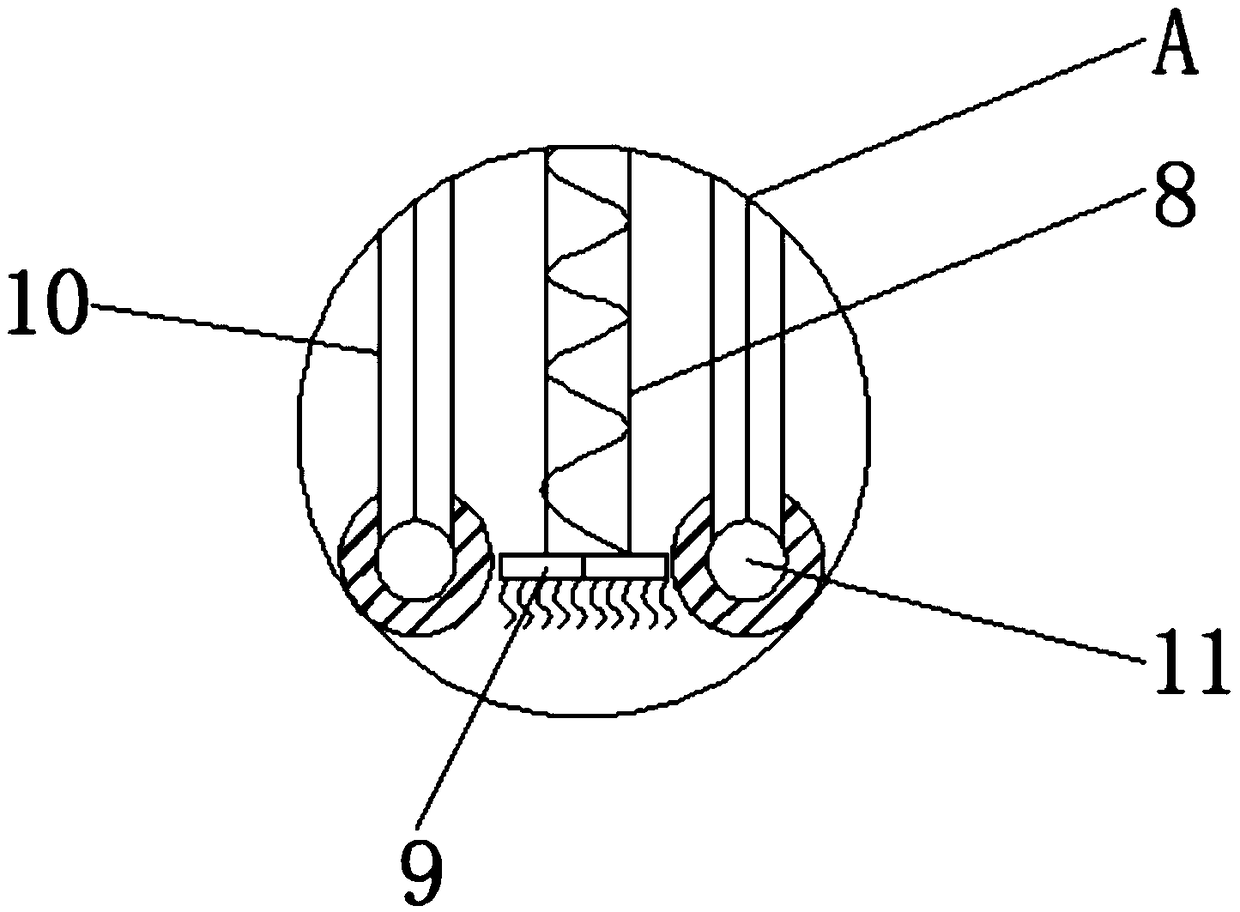

The invention relates to a positioning device for code spraying equipment. The invention is characterized in that the positioning device for the code spraying equipment comprises a paper conveying belt, a side gauge, a paper receiving wheel and a front gauge; paper is placed on the paper conveying belt; the back part of the paper conveying belt is provided with the side gauge; the back part of the side gauge is provided with the front gauge; and the paper receiving wheel is installed between the side gauge and the front gauge. The working method comprises the following steps that: (1) the paper is conveyed to the position of the side gauge by the paper conveying belt; (2) the paper edge of one side of the paper is pulled by the side gauge so as to be aligned with the rule of the side gauge in the conveying process of the paper; (3) the paper is continuously conveyed forwards, and the front paper edge of the paper is aligned with the rule of the front gauge; (4) after being positioned, the paper is conveyed out in the rotating process of the paper receiving wheel; and (5) the working processes of (1) to (4) are circulated so as to finish the work of initial positioning of each piece of paper at a paper conveying part. The invention has the following advantages that: 1, the accuracy of initial positioning is high; 2, a mature technology is reasonably utilized, and the positioning accuracy is better ensured; 3, the positioning device for the code spraying equipment is suitable for positioning paper with large breadth; and 4, the processing accuracy of components is easy to ensure.

Owner:MASTERWORK GROUP CO LTD

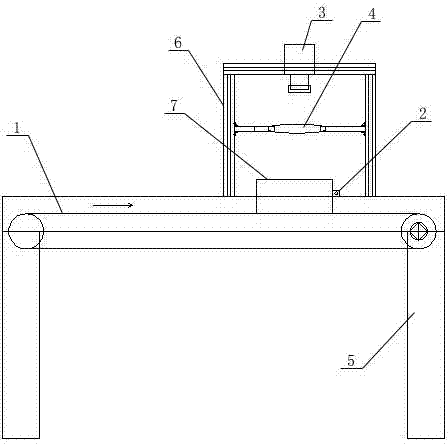

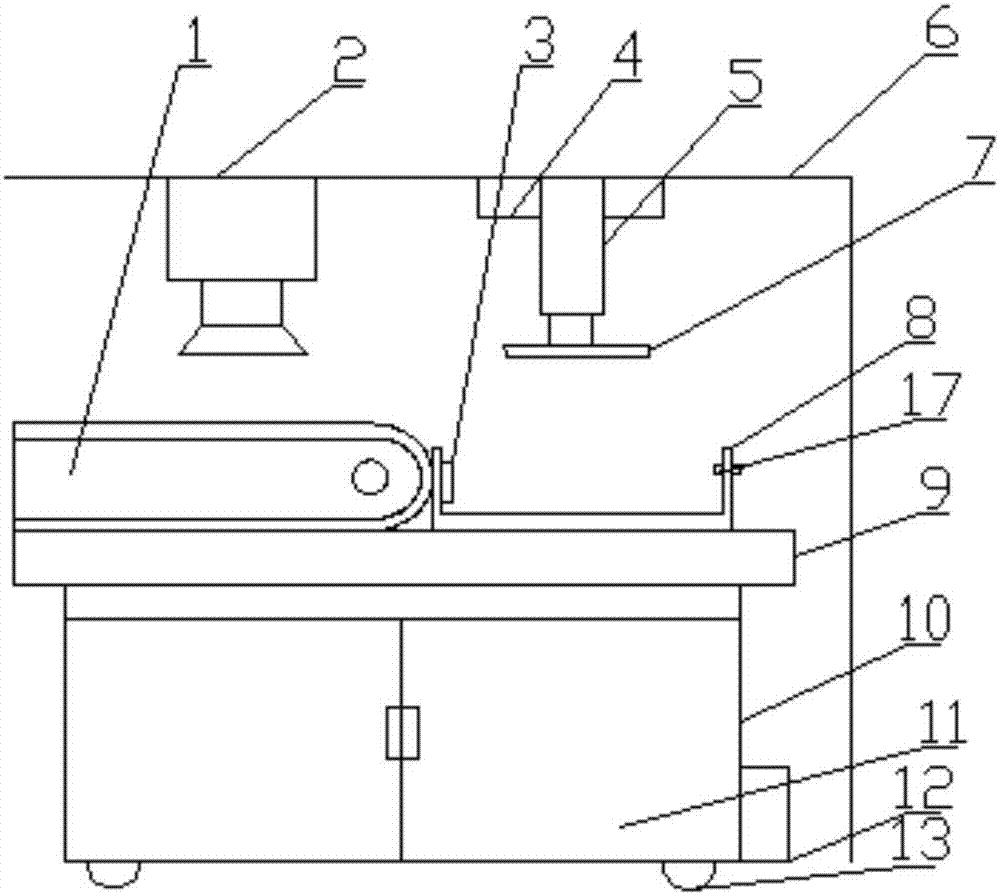

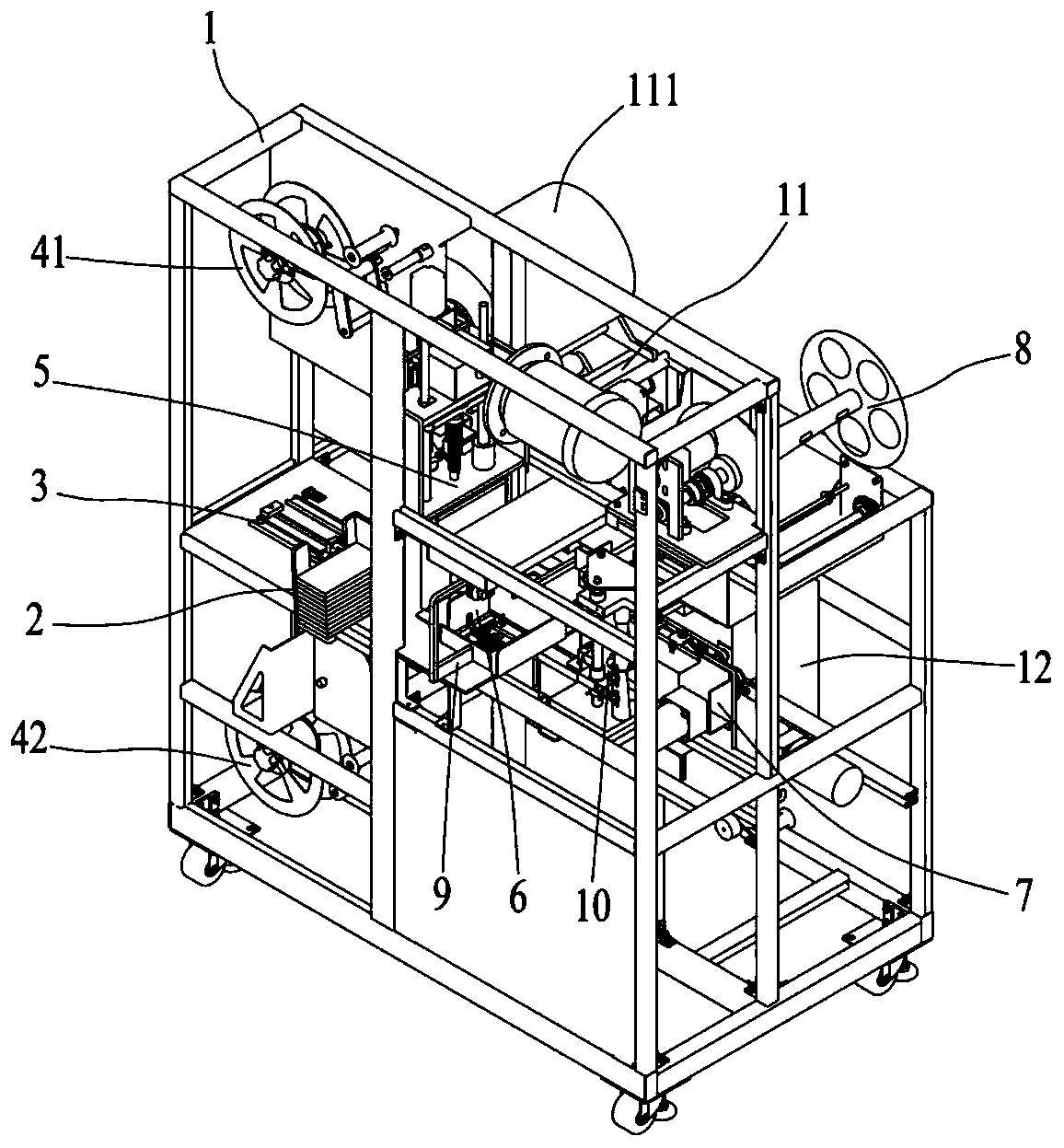

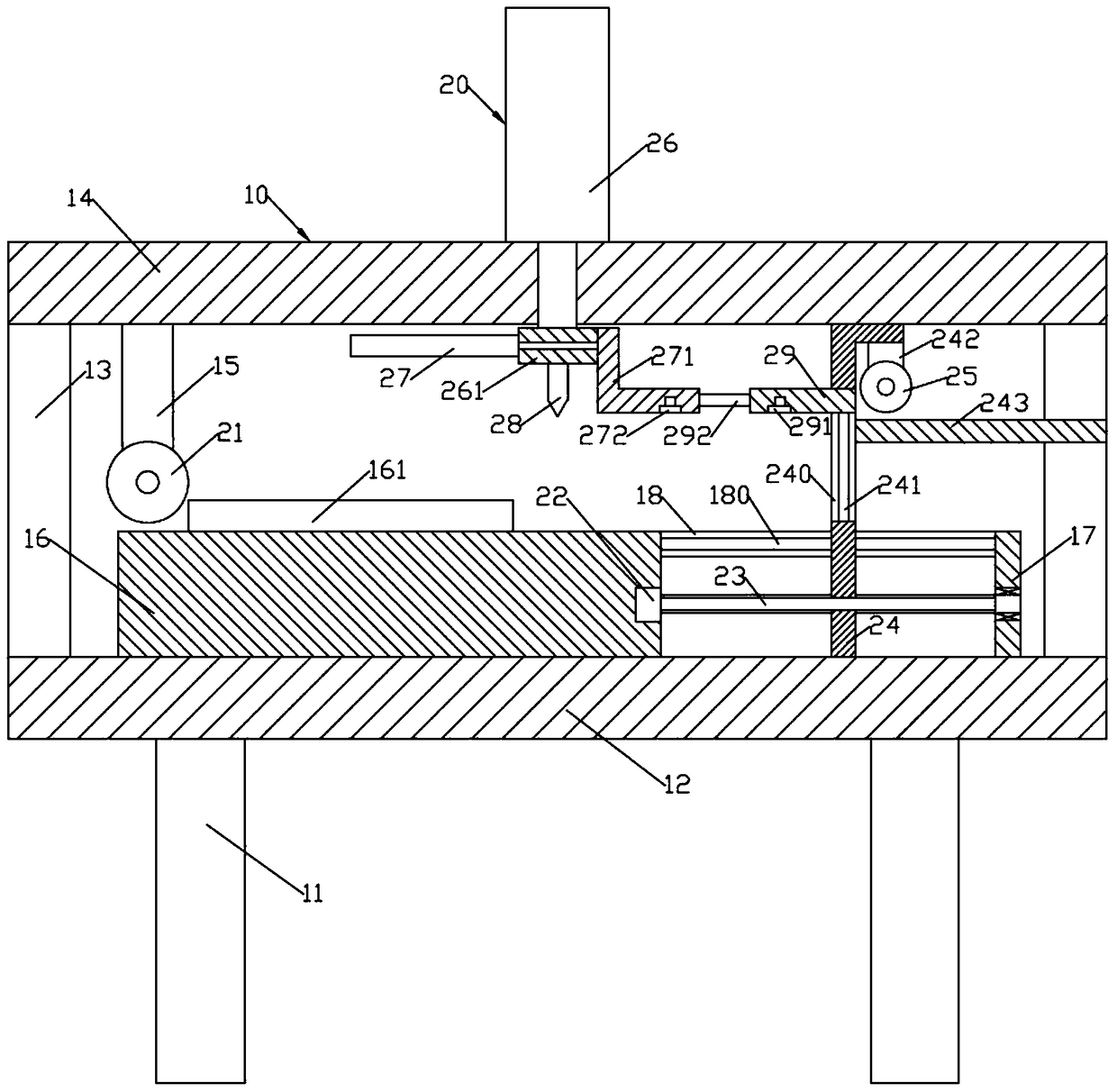

Precise counting device and method based on microimaging method

ActiveCN104268623ACounting objects on conveyorsCharacter and pattern recognitionControl systemPulp and paper industry

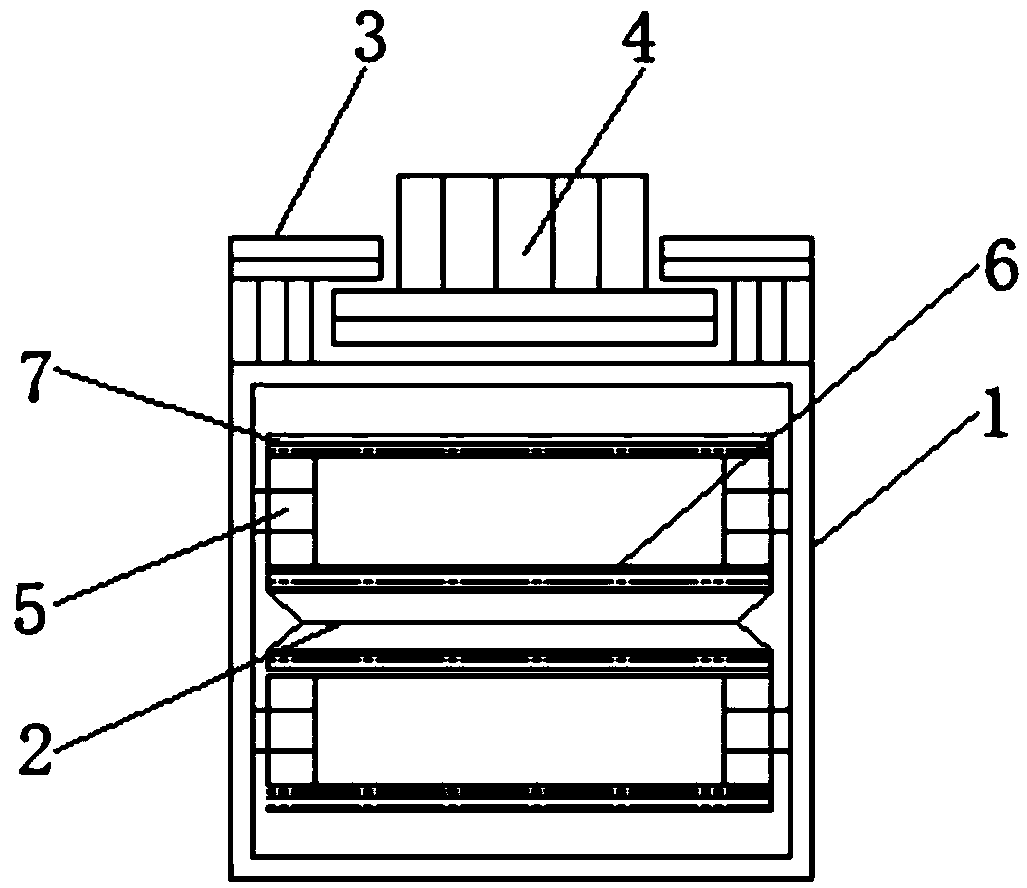

The invention discloses a precise counting device based on the microimaging method. The device comprises a paper money conveying system, a paper money positioning mechanism, an image acquisition system and a microimaging system, wherein the paper money conveying system is arranged on a machine frame, the image acquisition system is arrange above the paper money conveying system through a support, the microimaging system is connected with the support through a lifting adjusting mechanism and arranged between the image acquisition system and the paper money conveying system, the paper money positioning system is arranged on the paper money conveying system and used for positioning paper money conveyed by the paper money conveying system within the acquisition range of the image acquisition system, and the paper money conveying system, the paper money positioning mechanism and the image acquisition system are all connected with a control system. The device is mainly used for counting plastic-packaged thousand-based paper money products in different specifications, and effectively solves the problem that in the current paper money production process, paper money is counted in a large-sheet hundred-based mode, cut, bundled in a small-sheet thousand-based mode and plastic-packaged and then no other counting operation is conducted, and therefore potential number safety hazards exist.

Owner:CHENGDU BANKNOTE PRINTING +1

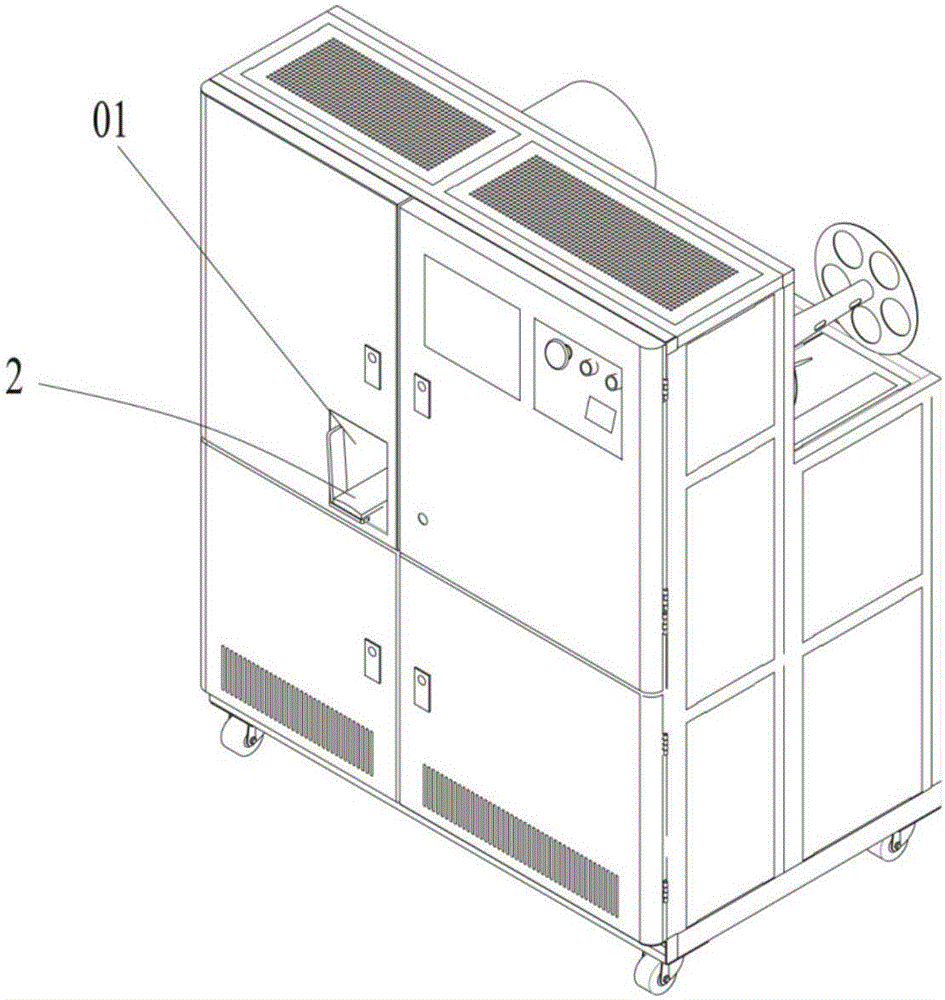

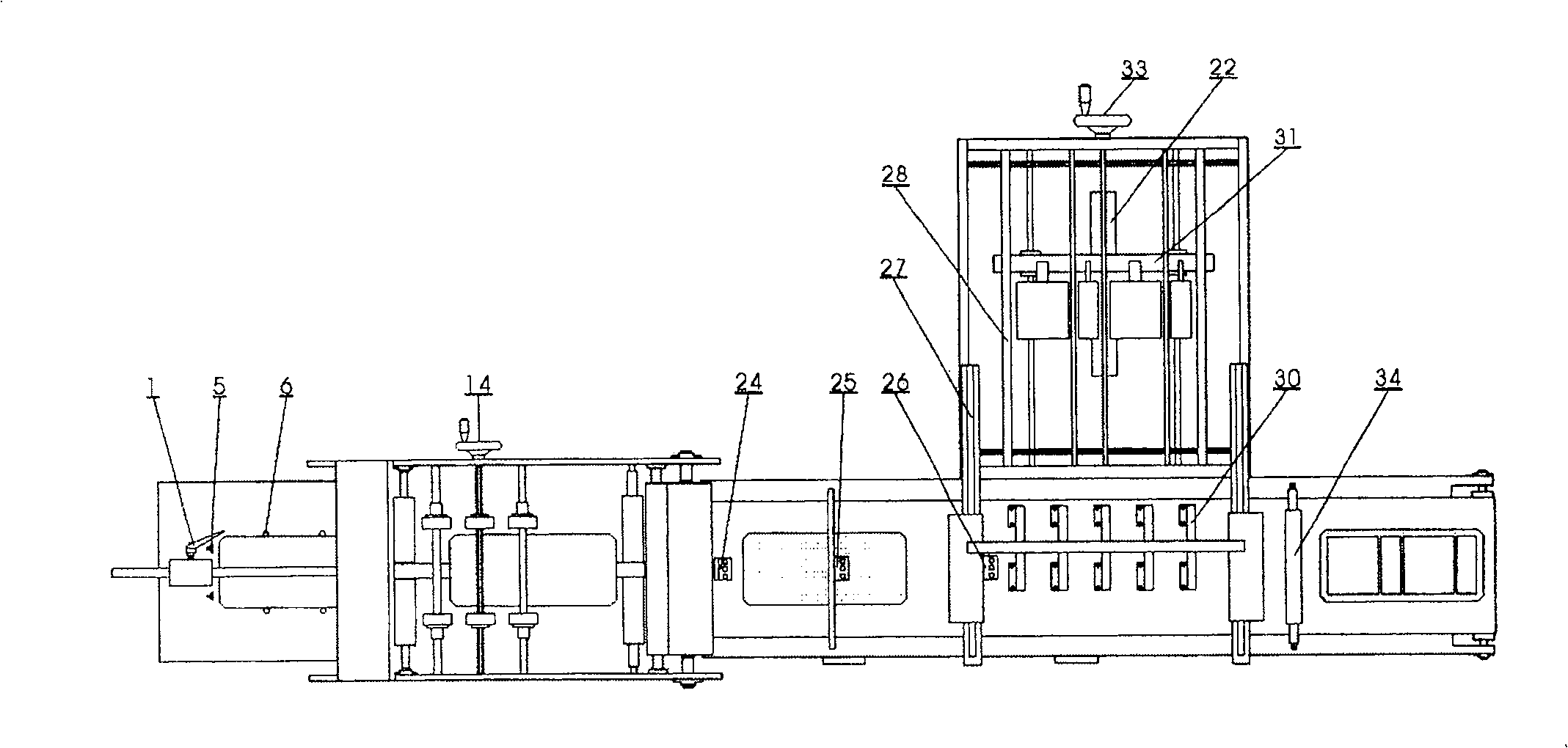

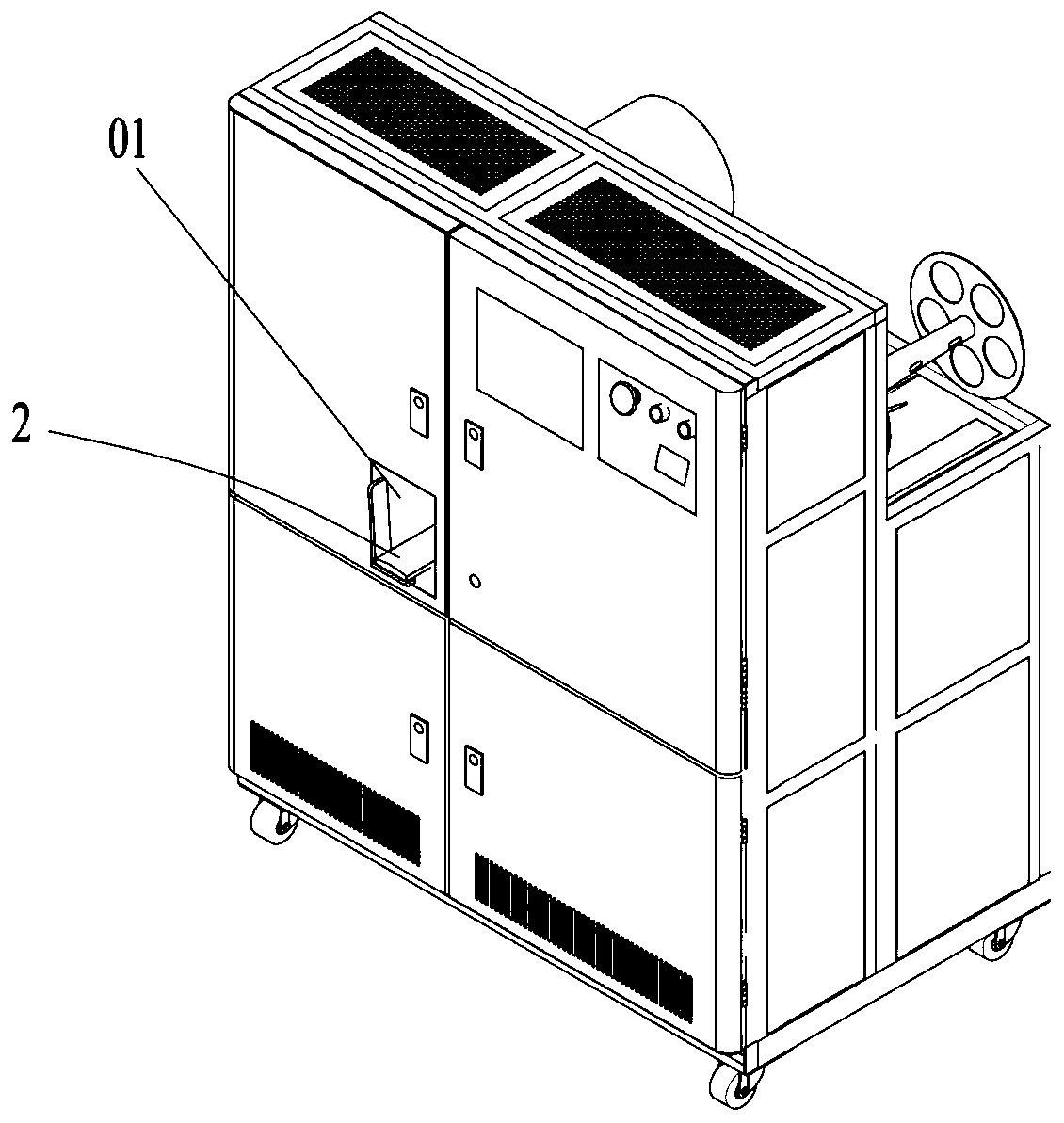

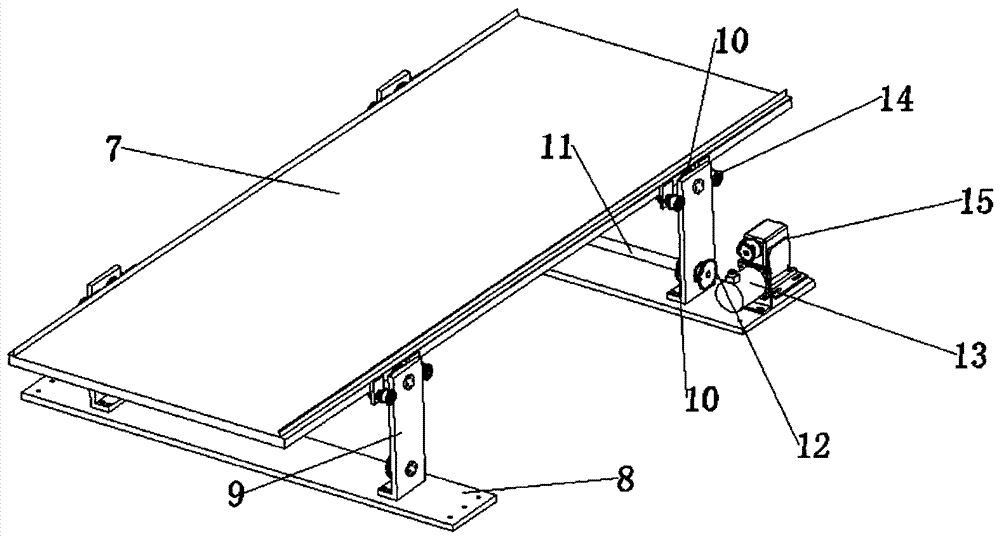

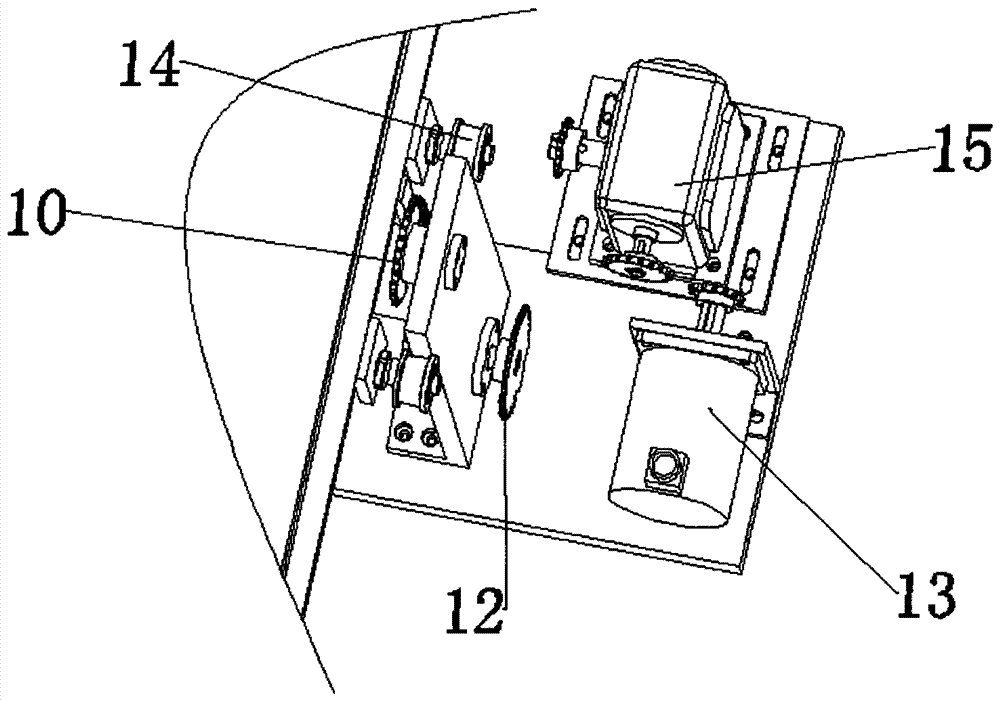

Paper currency plastic enveloping machine

ActiveCN106672295AReduce processImprove the efficiency of sending moneyPaper article packagingWrappingPulp and paper industryPosition paper

The invention relates to the field of financial equipment, and discloses a paper currency plastic enveloping machine. The machine comprises a pre-binding part, a transition part and a plastic-enveloping thermal shrinking part, wherein the pre-binding part is connected with a paper currency receiving device; a positioning window is arranged in one sidewall of the plastic-enveloping machine; the paper currency receiving device comprises a first base plate, a paper currency receiving part for positioning paper currency, a guide assembly and a driving assembly; the guide assembly and the driving assembly are arranged on the first base plate; the paper currency receiving part is arranged on the guide assembly; one end of the guide assembly is arranged at the positioning window, and the other end of the guide assembly extends into the plastic-enveloping machine; the driving assembly can drive the paper currency receiving part to reciprocate on the guide assembly. According to the paper currency plastic enveloping machine, the paper currency can be manually positioned on the paper currency receiving part from the positioning window, and then the driving assembly can be operated to drive the paper currency receiving part to reciprocate along the guide assembly so as to finish the processes of automatically conveying the paper currency and returning to a start point. Therefore, that the paper currency is manually conveyed to a specified position in the paper currency plastic enveloping machine can be avoided, and as a result, the paper currency conveying process is saved, and the paper currency conveying efficiency is improved.

Owner:GUANGZHOU INTELLICASH FINANCIAL TECH

Feeding device of paper tube edge grinding machine

InactiveCN104924205AEfficient deliveryPrecise positioningEdge grinding machinesGrinding feedersPulp and paper industryPosition paper

The invention relates to a feeding device of a paper tube edge grinding machine. The feeding device comprises a rack and a feeding area arranged on the rack. The feeding area comprises two parallel bottom feeding plates with one ends fixed to the rack, material frame adjusting rods vertically fixed to the bottom feeding plates, and two feeding rods which are transversely installed on the material frame adjusting rods of the bottom feeding plates respectively and are parallel to the bottom feeding plates, and paper tubes are arranged on the two feeding rods. The feeding device efficiently conveys the paper tubes, the accurately-positioned paper tubes are provided for subsequent edge grinding, and the edge grinding efficiency is ensured.

Owner:ZHEJIANG HUANLONG MACHINERY CO LTD

Transfer platinum cat eye positioning paper and preparation process thereof

PendingCN109440534ASolve the sticky problemStrong lusterSpecial visual effect coatingsFlexible coversWater basedPlatinum

The invention provides and particularly relates to transfer platinum cat eye positioning paper and a preparation process thereof, and relates to the technical field of printing. The preparation process of the transfer platinum cat eye positioning paper comprises the following work procedures of a UV coating molding pressing work procedure, an aluminum plating work procedure, back glue and cuttingwork procedure, a compounding work procedure, a connecting line peeling and surface coating work procedure and a transverse cutting work procedure. The transfer platinum cat eye positioning paper comprises a bottom paper layer, a transfer glue water layer, a water-based back glue layer, a platinum cat eye aluminum plating layer and a water-based surface coating layer, wherein the transfer glue water layer, the water-based back glue layer, the platinum cat eye aluminum plating layer and the water-based surface coating layer are sequentially compounded onto the bottom paper layer. The aluminum layer of the paper prepared by the preparation process realizes the firm combination with the paper; the positioning precision is high; the problem of poor combination firmness of a UV layer and an aluminum layer of a conventional transfer process is solved; the process of only transferring the platinum cat eye aluminum layer and not transferring the UV coating is realized; in addition, the platinum luster is better than that of a film coating card; the efficiency is higher; the production cost is reduced; the application is not limited; the application of the platinum positioning paper in thepackaging industry can be greatly promoted.

Owner:绍兴虎彩激光材料科技有限公司

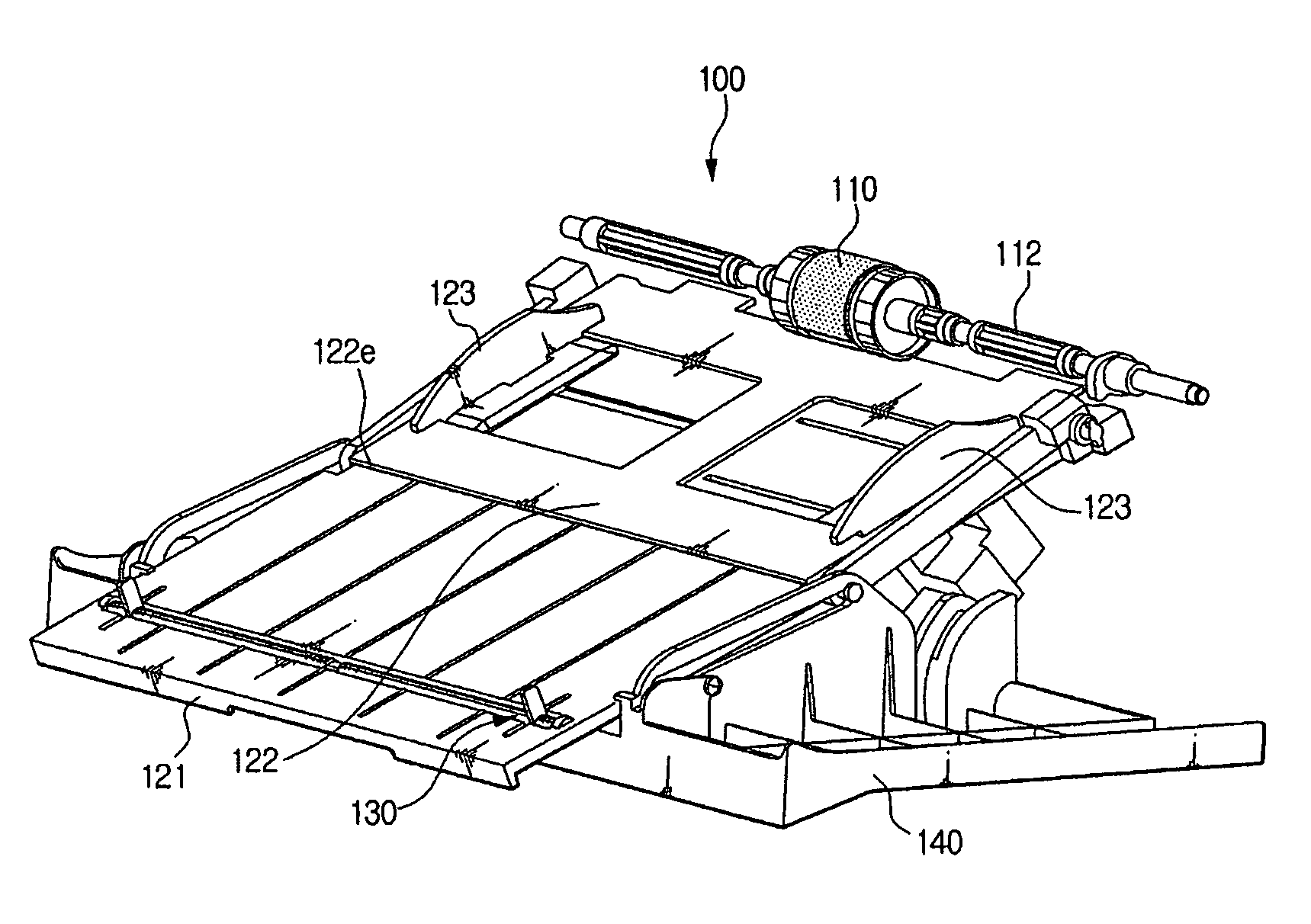

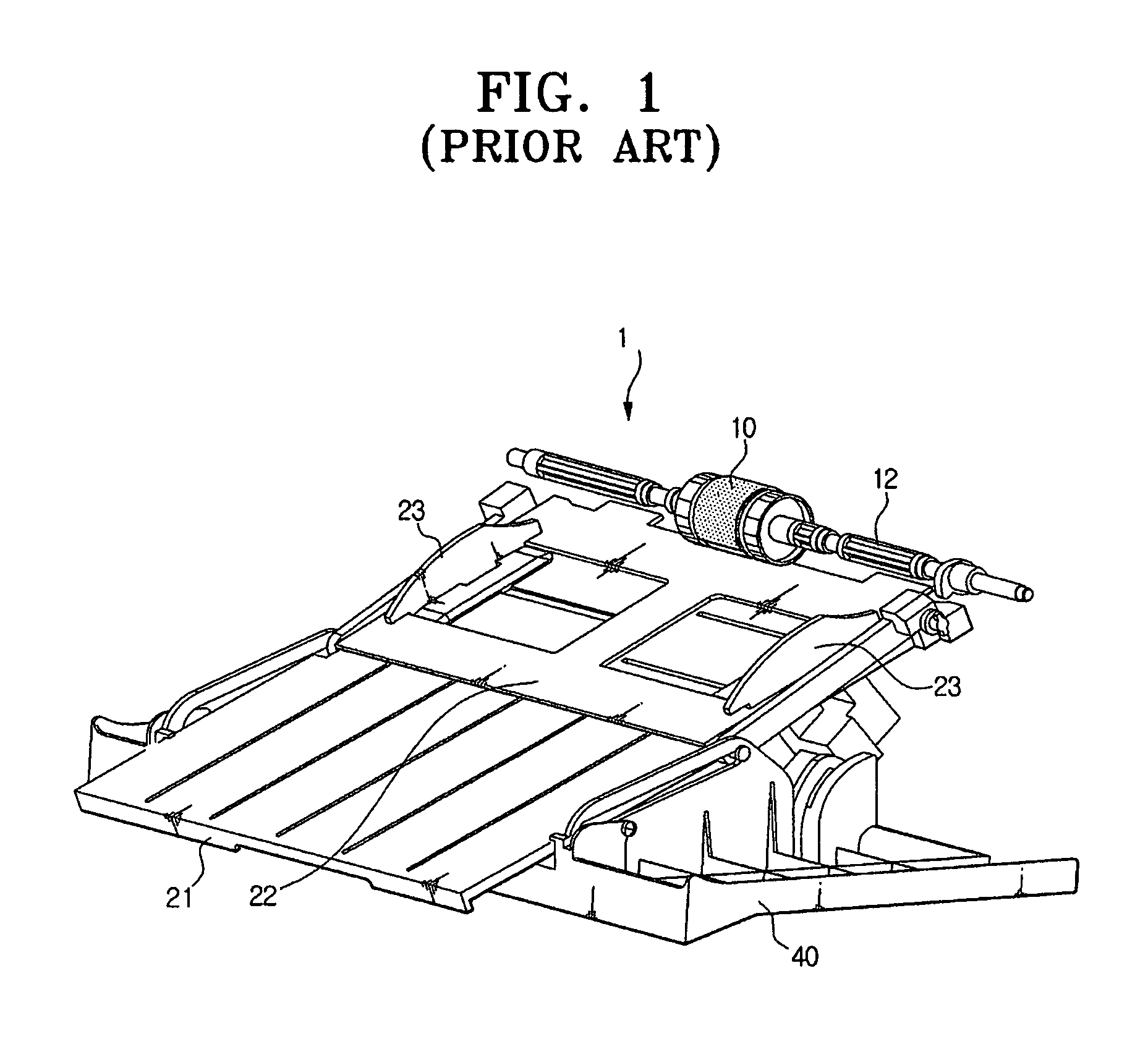

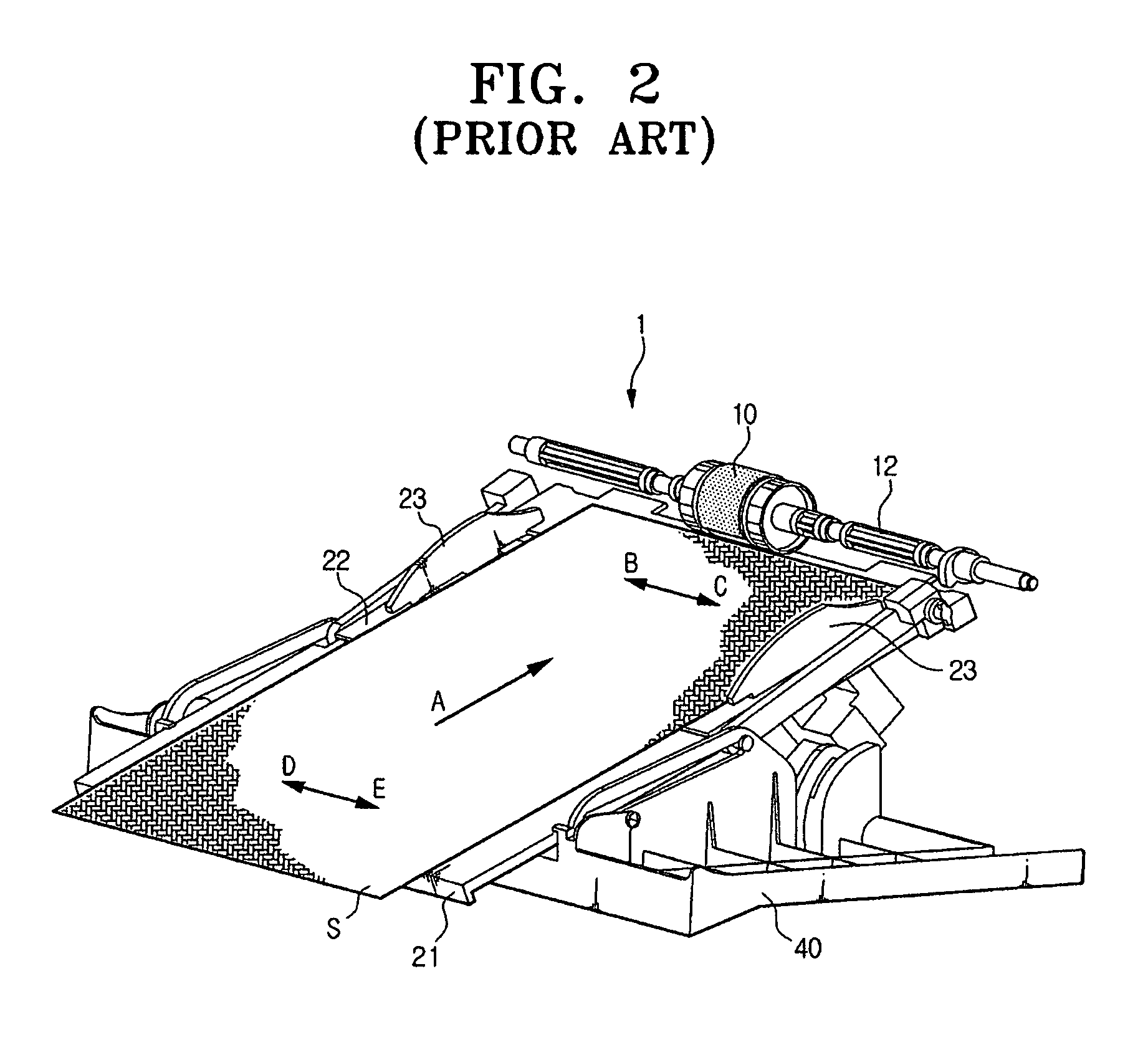

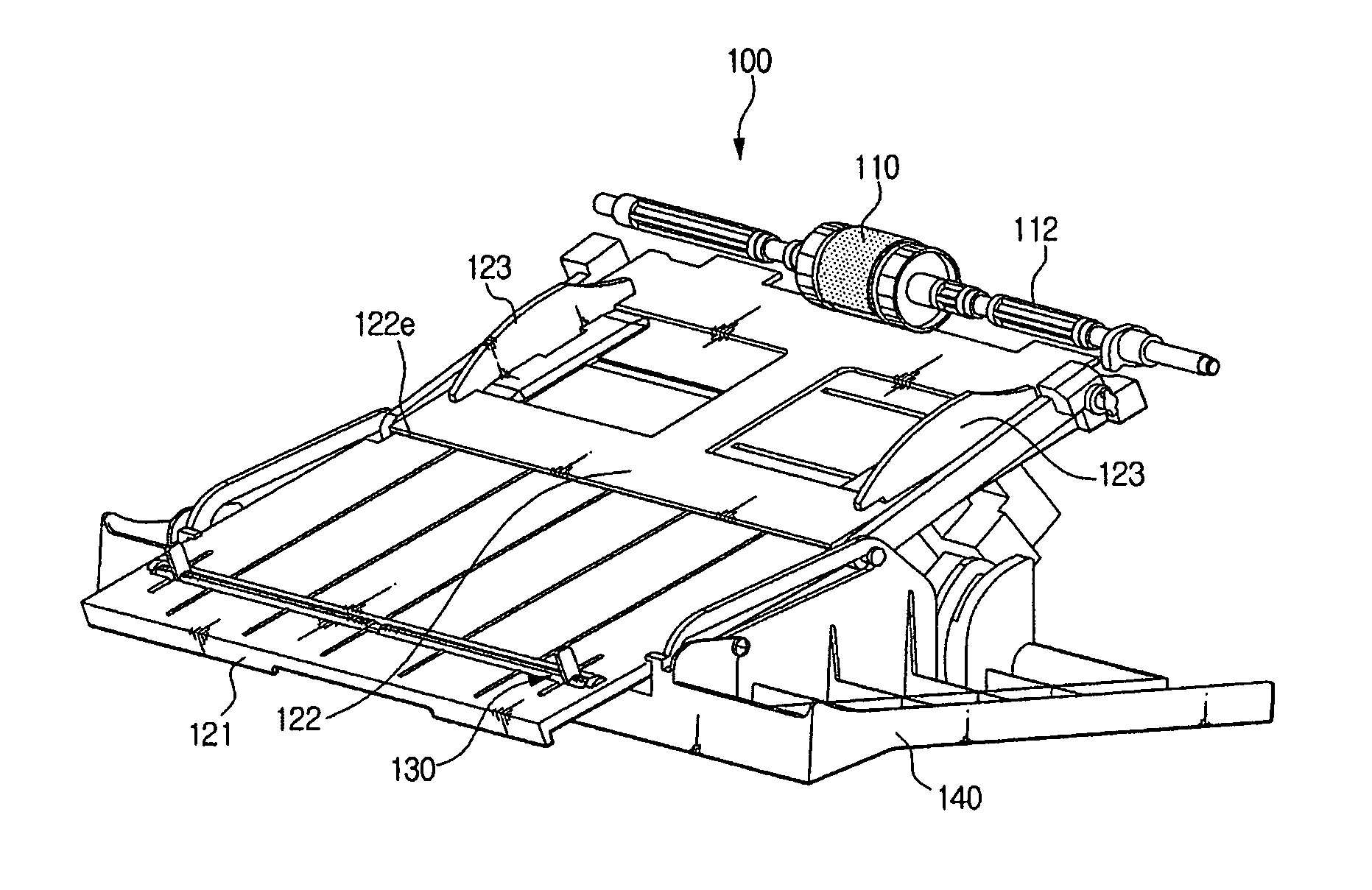

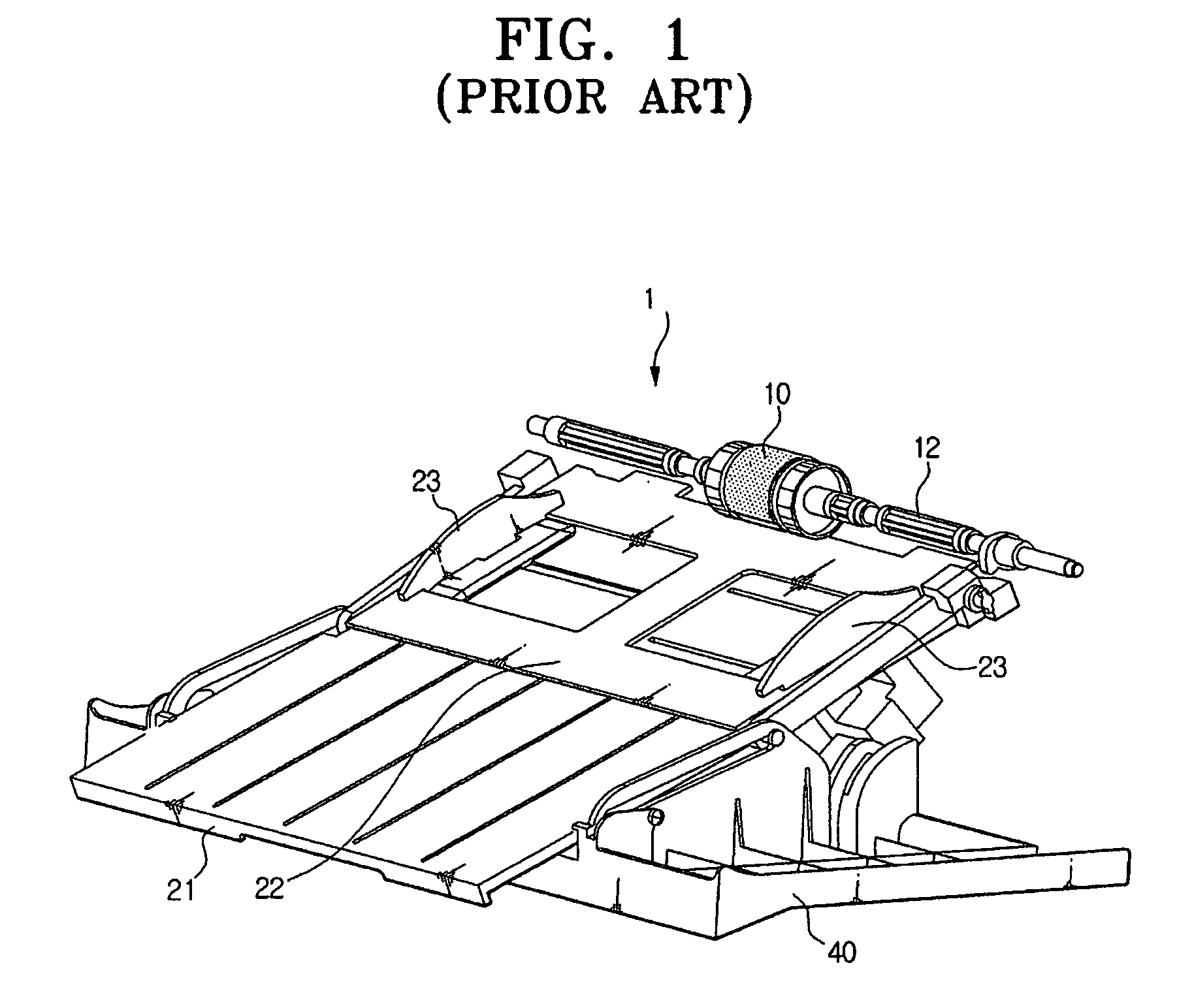

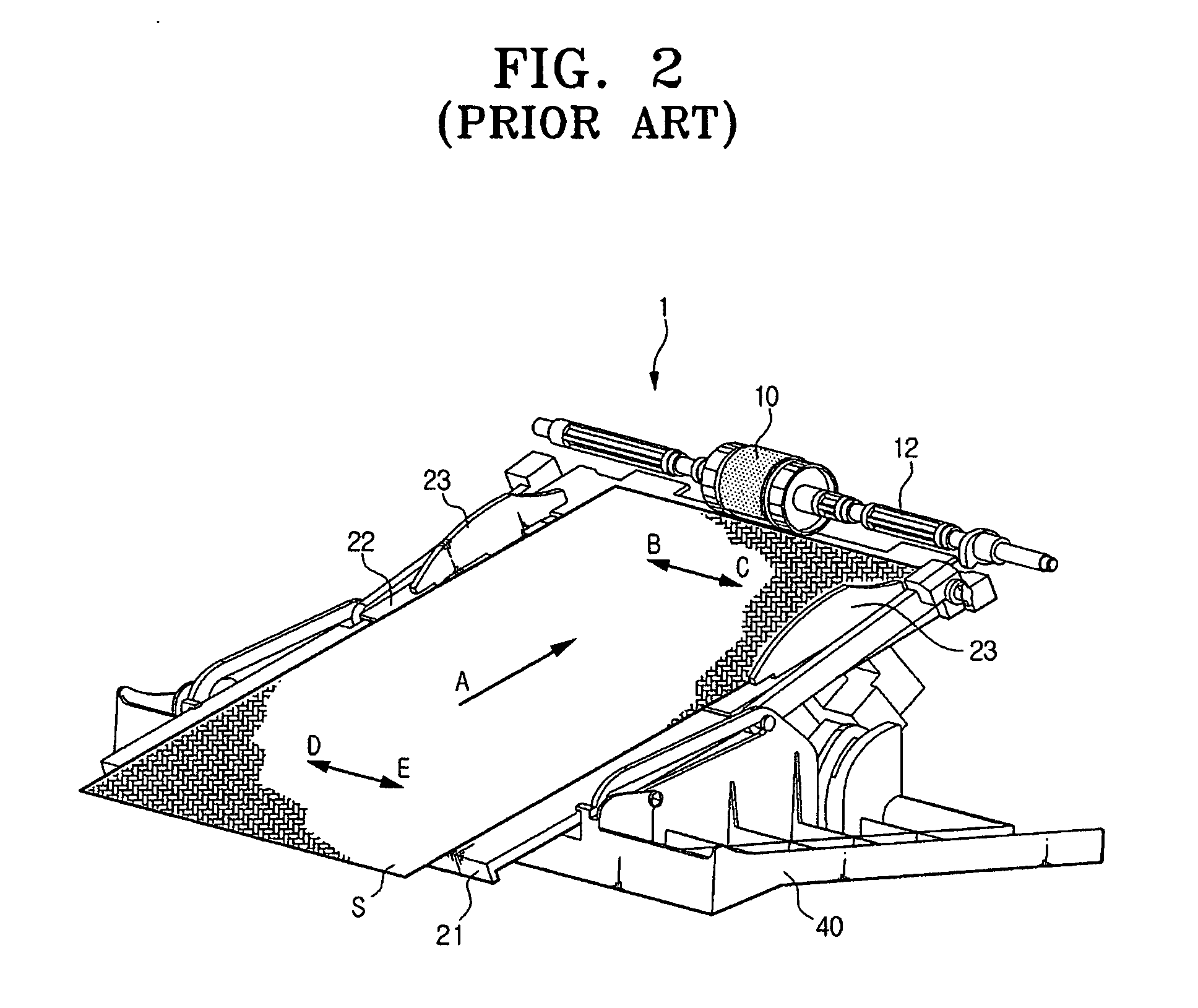

Versatile paper feeding device of image forming apparatus

InactiveUS7434801B2Improve printing qualityRegistering devicesFunction indicatorsImage formationPulp and paper industry

A versatile paper feeding device of an image forming apparatus includes a pick-up roller, a paper support tray under the pick-up roller to stack paper on, a paper support expansion tray to be able to freely slide toward or away from the paper support tray to support the trailing edge of the paper, a forward positioned paper alignment guide on the paper support tray to align a leading end portion of the paper, and a second paper alignment member formed on the paper support expansion tray to align a following end portion of the paper. When the versatile paper feeding device is used to print images on paper of various sizes, the paper can be properly positioned and straightly fed without skewing.

Owner:S PRINTING SOLUTION CO LTD

Preparation method of heat transferable mold silica gel transfer label

InactiveCN109263330AAvoid problemsIncrease productivityStampsDuplicating/marking methodsSilica gelPosition paper

The invention discloses a preparation method of a heat transferable mold silica gel transfer label. The method comprises the following steps: 1, preparing a transfer adhesive film; 2, making a mold; 3, preparing silica gel; 4, filling the mold, obtained in the step 2, with the silica gel obtained in the step 3, and vacuumizing; 5, sticking the side of the transfer adhesive film, which is obtainedby the step 1 and is coated with a bridging agent, with the side of the mold filled with the silica gel; 6, molding the product, obtained in the step 5, by using a press labeling machine under the condition of heating, retaining a silica gel label in a knife edge, placing the silica gel label in a positioning mold, laying a piece of positioning paper on the positioning mold, sticking out the silica gel label, and attaching a protective film on the silica gel label so as to obtain heat transferable silica gel transfer label. The heat transferable silica gel transfer labels prepared by the method at a time can be printed on dozens or hundreds of products, so that the production efficiency is increased; the cost is lowered for consumers; the quality is guaranteed by 100%, and high quality andstable quality are escorted.

Owner:东莞市林知海新材料科技有限公司

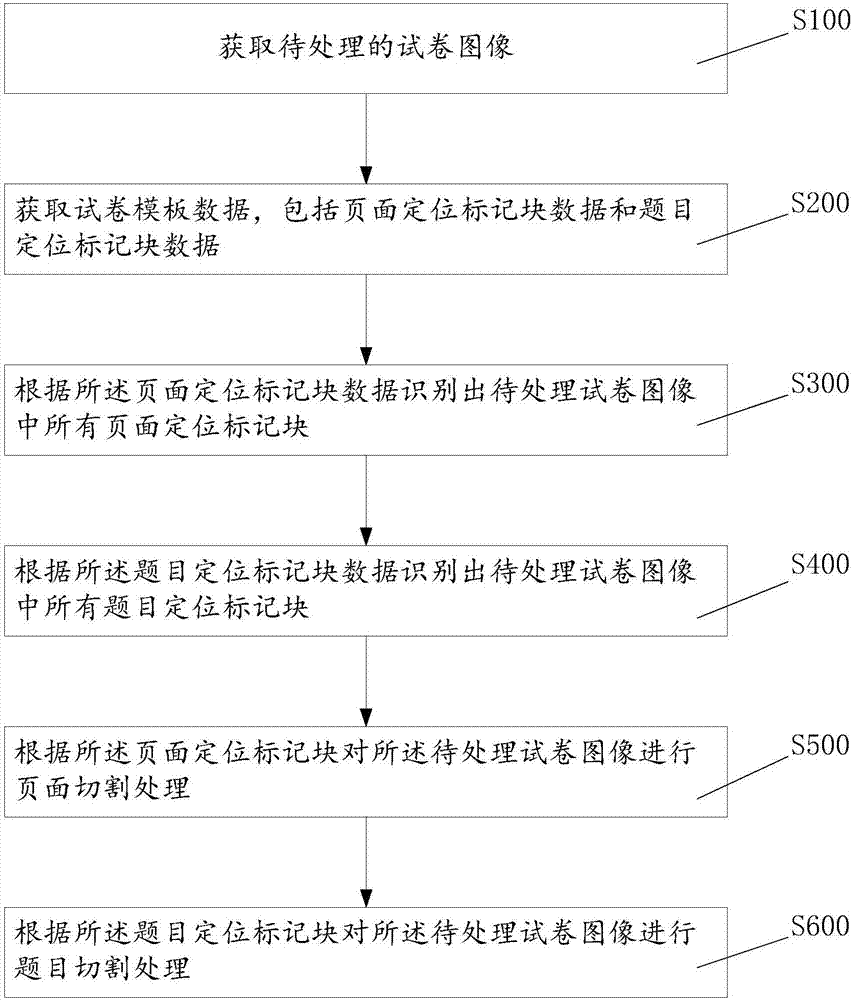

Test paper segmentation processing method of scoring online system

InactiveCN107066939AEasy to classify and saveEasy to storeCharacter and pattern recognitionData acquisitionPosition paper

The invention provides a test paper segmentation processing method of a scoring online system. The test paper segmentation processing method of a scoring online system includes the following steps: acquiring a test paper image to be processed; acquiring the test paper template data, including the data of page positioning tag blocks and the data of question positioning tag blocks; according to the data of page positioning tag blocks, identifying all the page positioning tag blocks in the test paper to be processed; according to the data of question positioning tag blocks, identifying all the question positioning tag blocks in the test paper to be processed; according to the page positioning tag blocks, performing page segmentation processing on the test paper to be processed; and according to the question positioning tag blocks, performing question segmentation processing on the test paper to be processed. The test paper segmentation processing method of a scoring online system can accurately segment and page the test image and further segment, classify and save each question, and the segmented question is convenient for display and checking, especially on a mobile device.

Owner:HANGZHOU STRONG NETWORK TECH

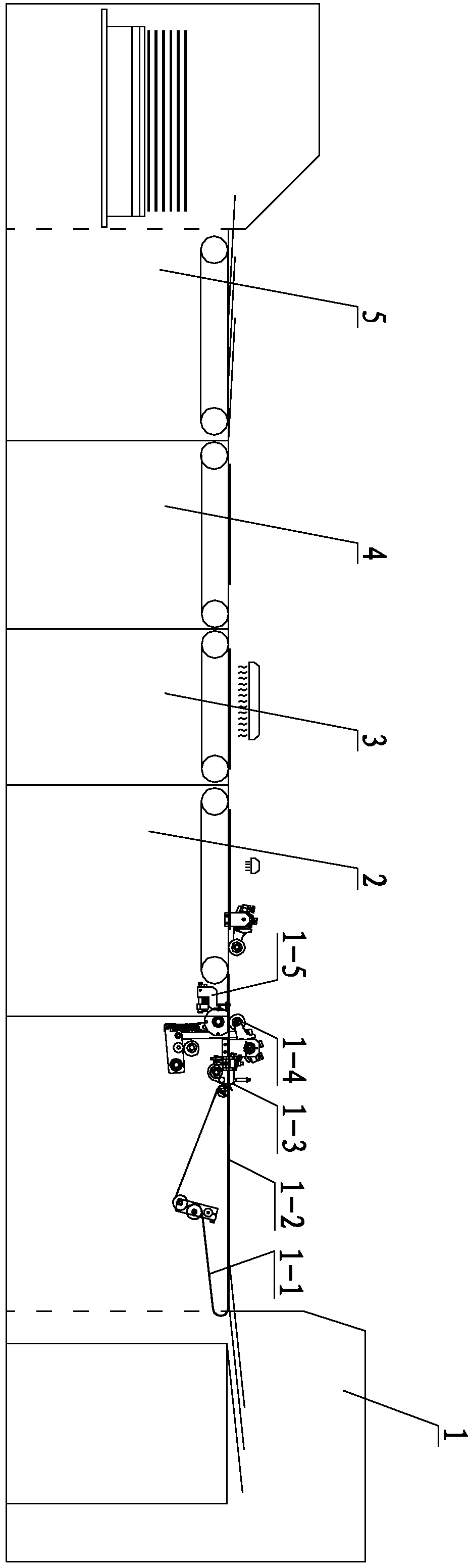

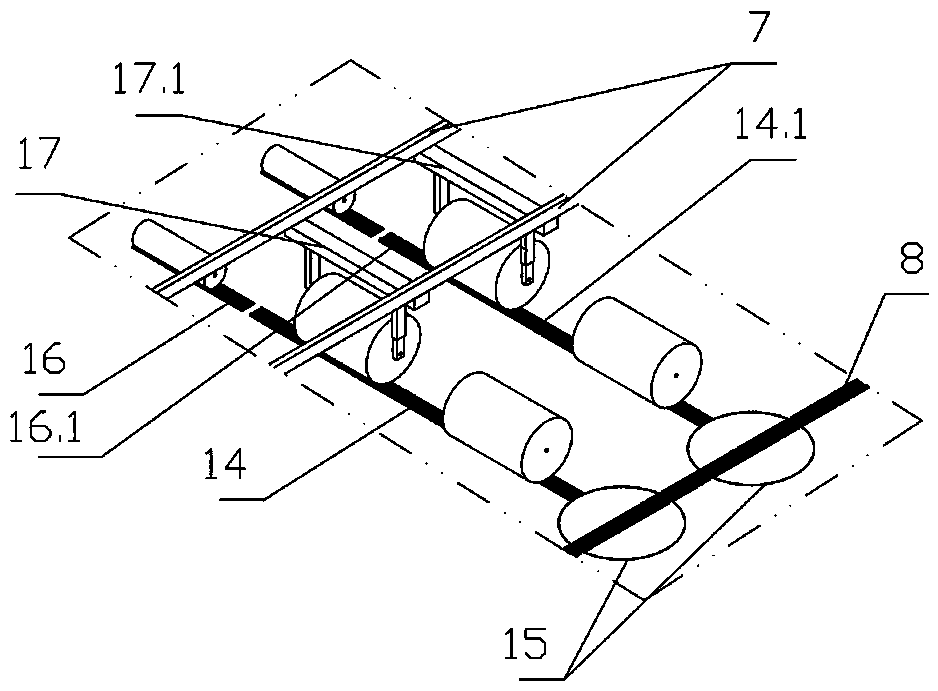

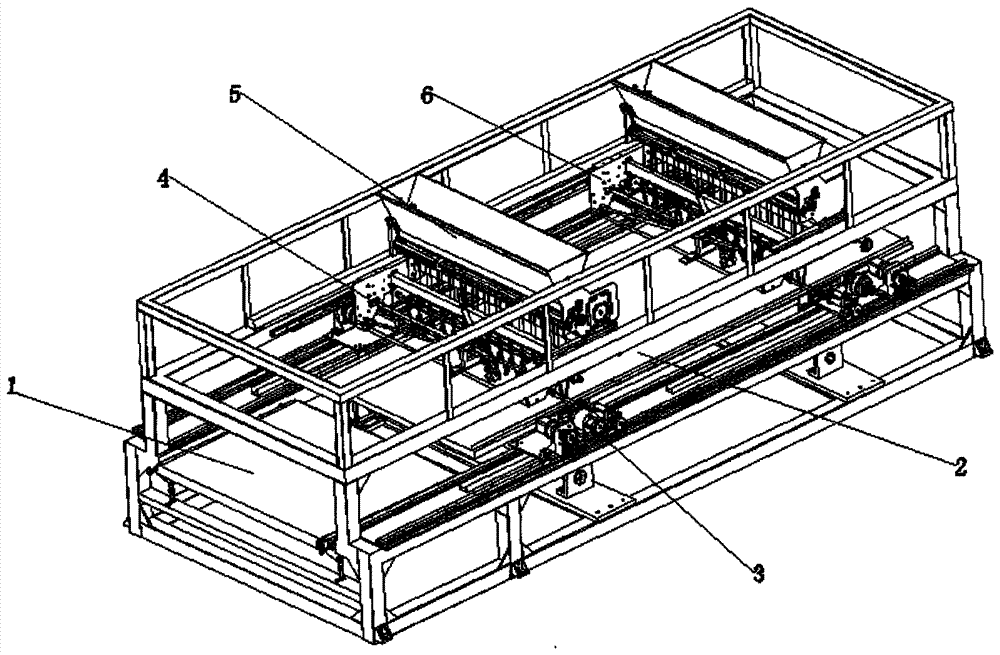

Full-automatic paper supply system of corrugated paper board production line

InactiveCN108608682ARealize unmanned operationSave work spaceMechanical working/deformationMechanical conveyorsProduction lineButt joint

The invention discloses a full-automatic paper supply system of a corrugated paper board production line. The full-automatic paper supply system comprises a paper supplementation area arranged at thefront end of the corrugated paper board production line and connected with a body paper warehouse in a butt joint manner, and multiple paper supplementation position paper roll conveying passageways are arranged in the paper supplementation area. A body paper roll conveying passageway is arranged on one side of an overbridge frame of the corrugated paper board production line in the longitudinal direction. Paper feed conveying passageways are arranged at positions corresponding to all paper supply positions of the corrugated paper board production line correspondingly. The paper feed end of each paper feed conveying passageway is connected with the body paper roll conveying passageway through a logistics turning plate. Suspension type body paper frames of the same structure are perpendicularly arranged at the positions, corresponding to the paper feed conveying passageways, on the overbridge frame of the corrugated paper board production line correspondingly. The full-automatic paper supply system has the beneficial effects that unmanned operation is achieved for all the paper supply positions of the corrugated paper board production line, body paper rolls only need to be placed inplace in a body paper bin according to numbers, and technical support is provided for industrial 4.0 mode production of the corrugated paper board production line; and meanwhile a large quantity of operation places, manpower and material resources are saved, and the operation environment is improved.

Owner:HENAN XINDOUCAI PRINTING

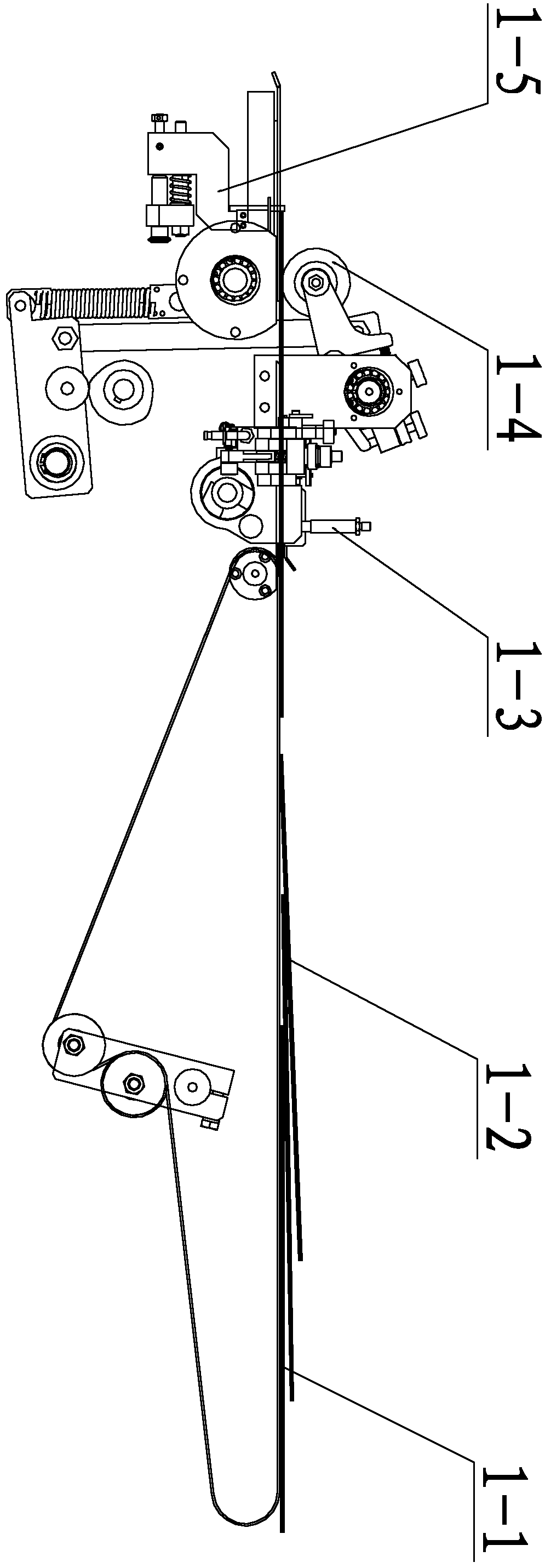

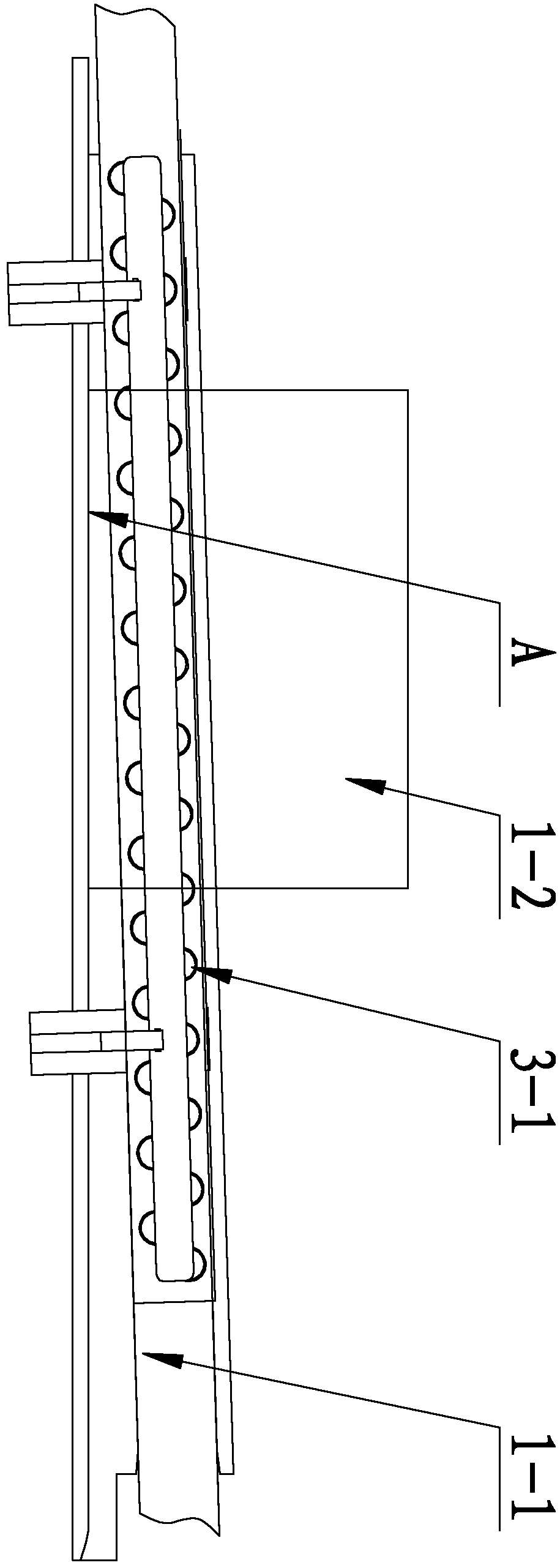

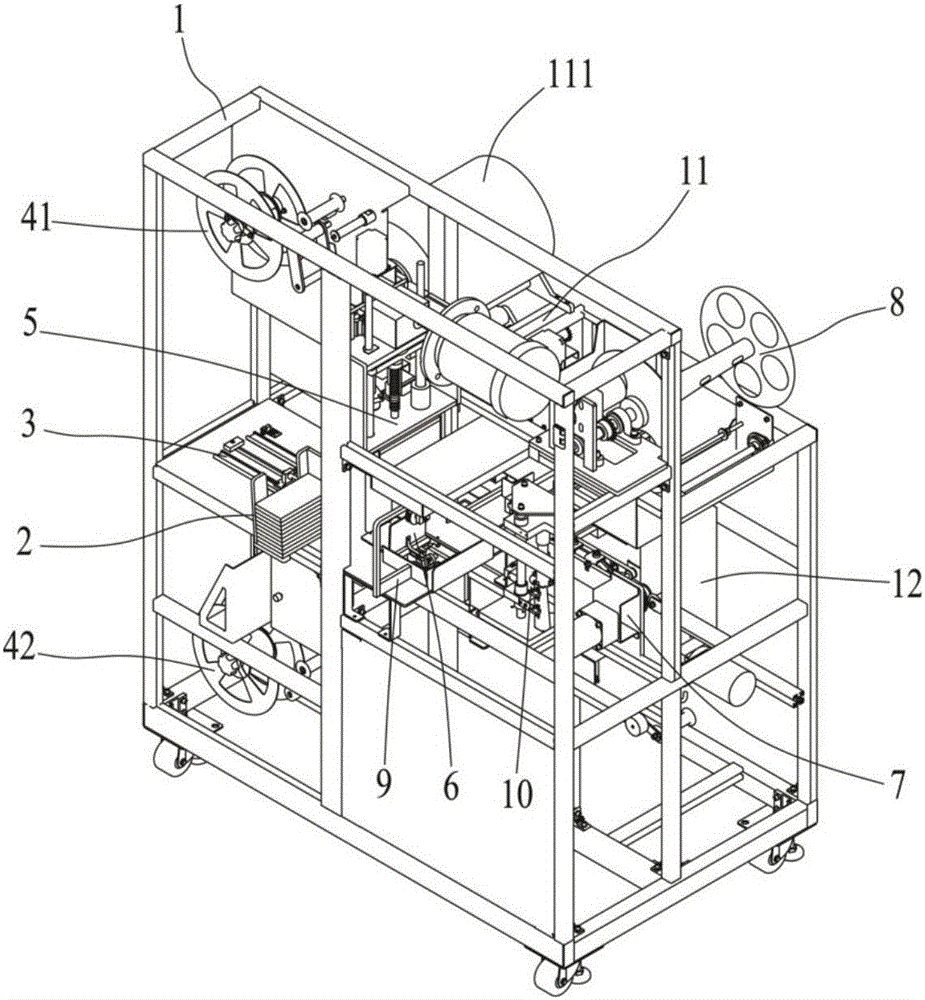

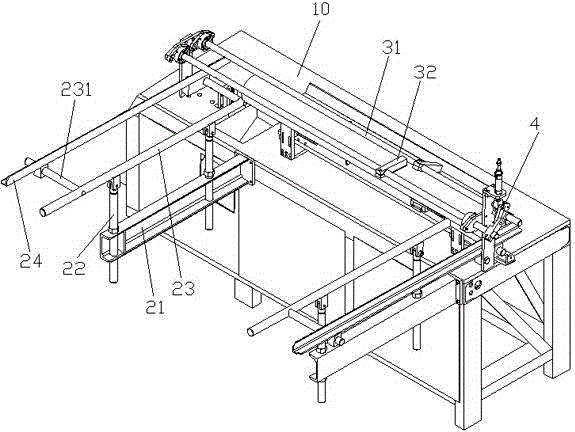

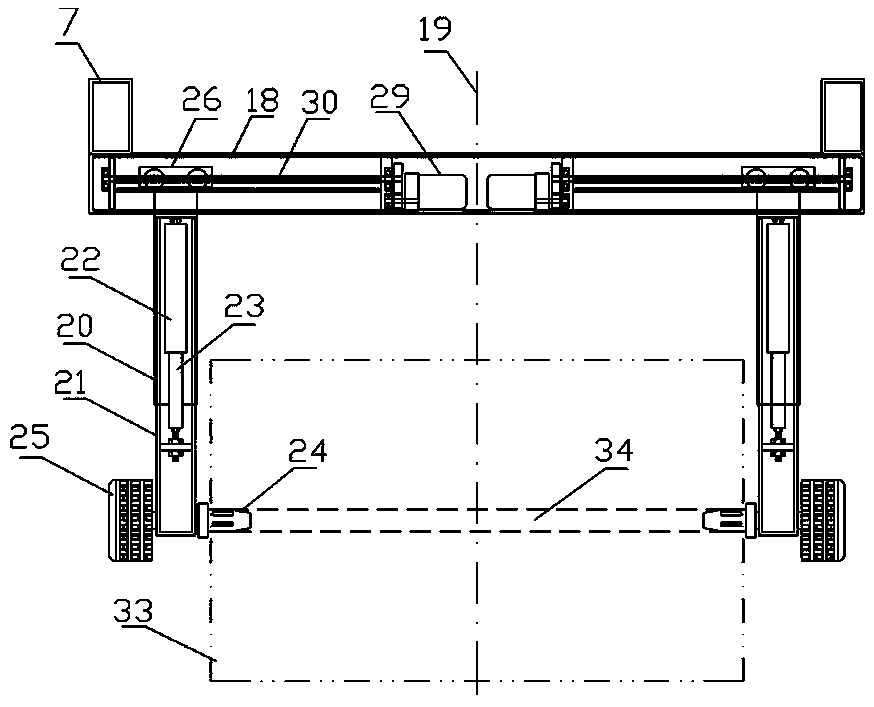

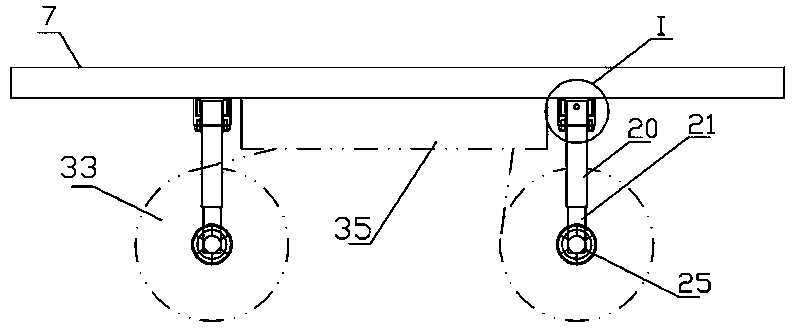

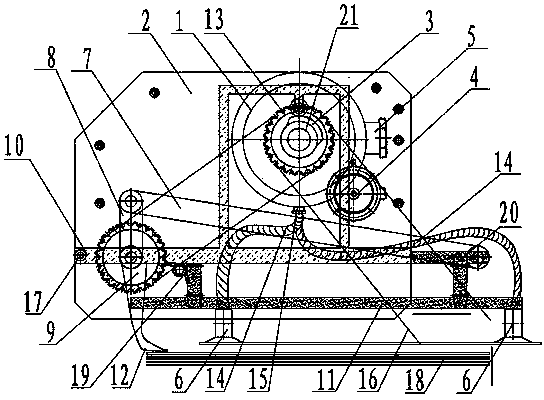

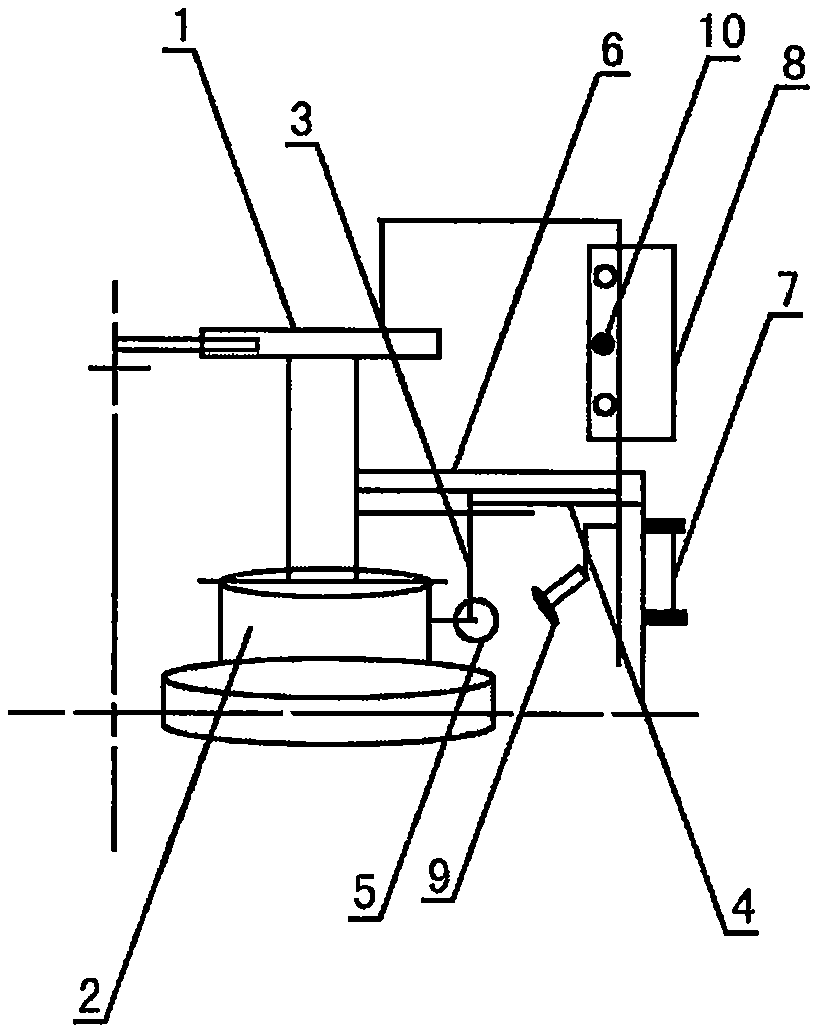

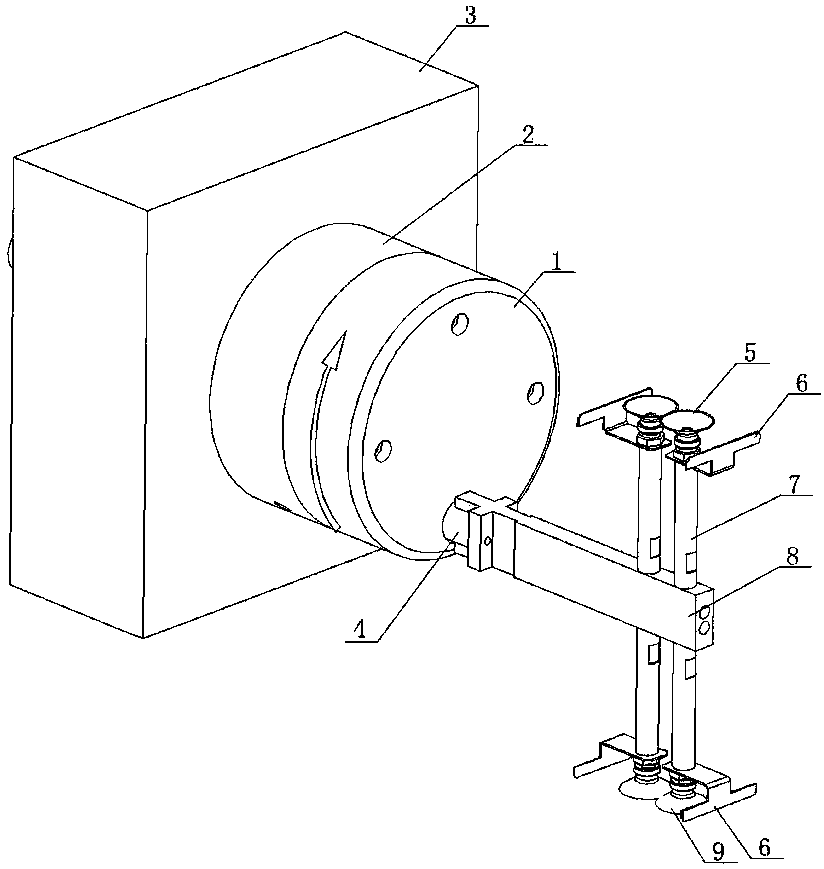

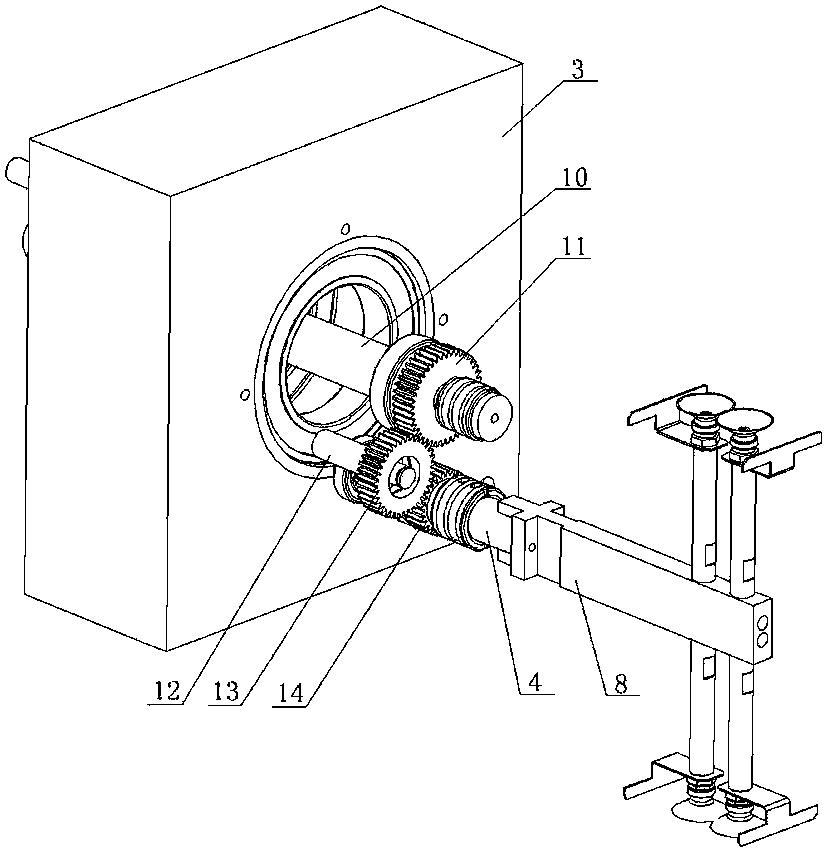

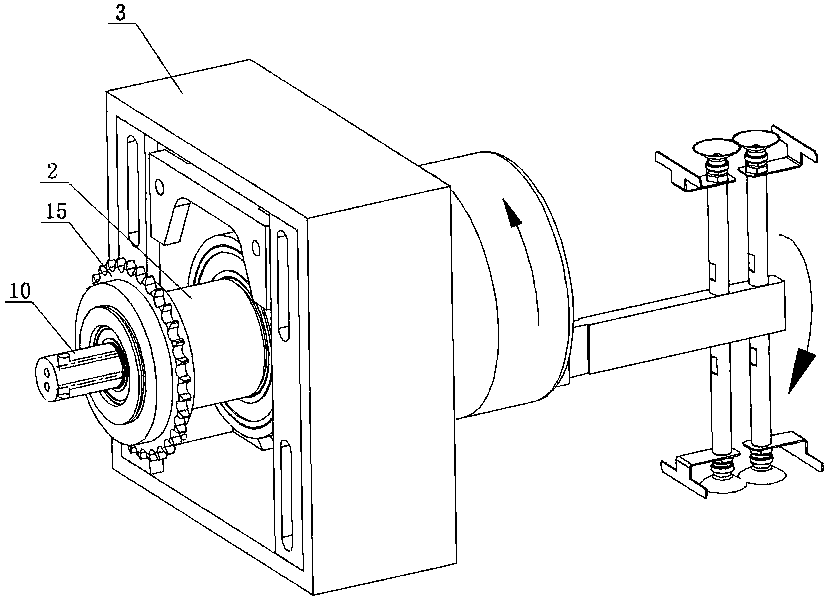

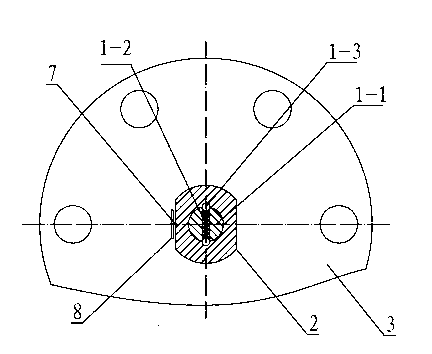

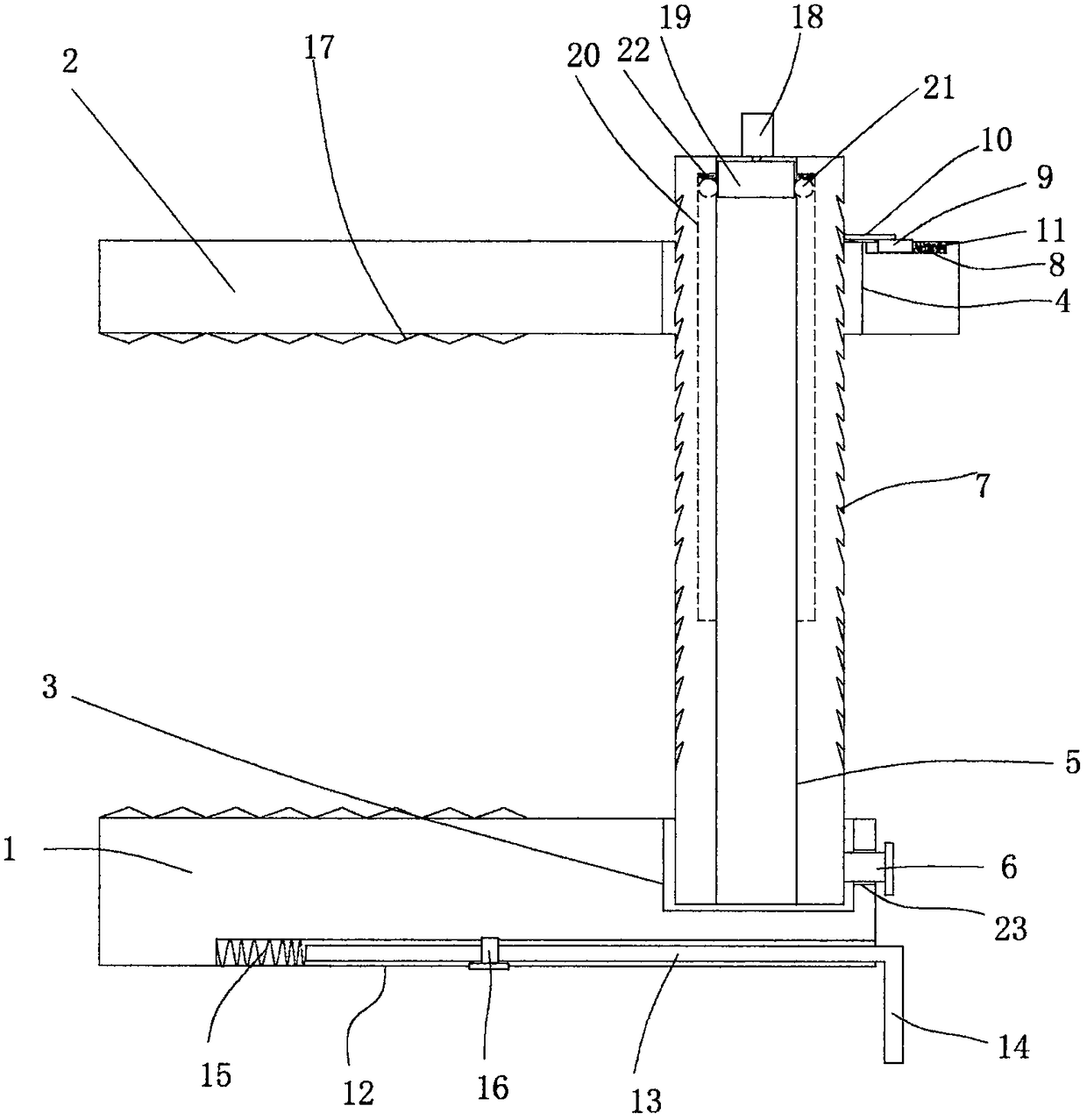

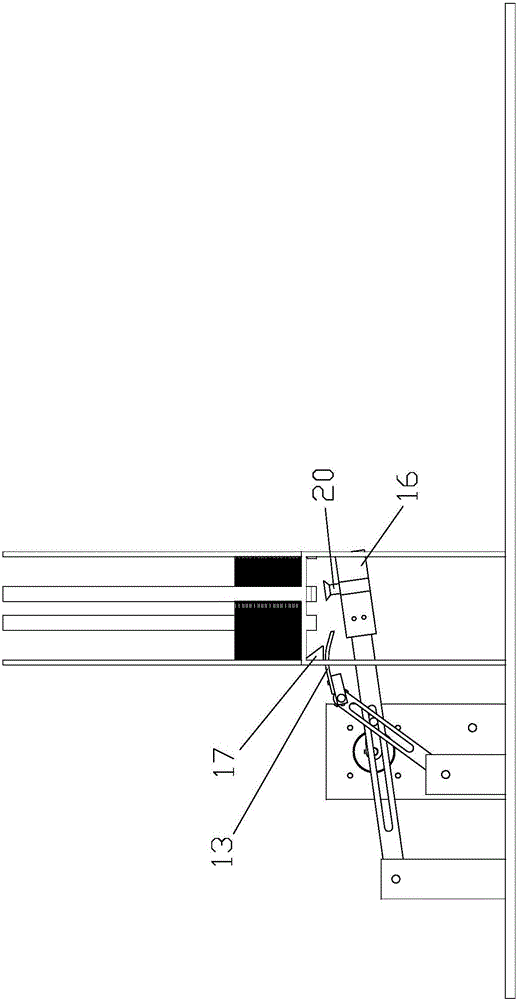

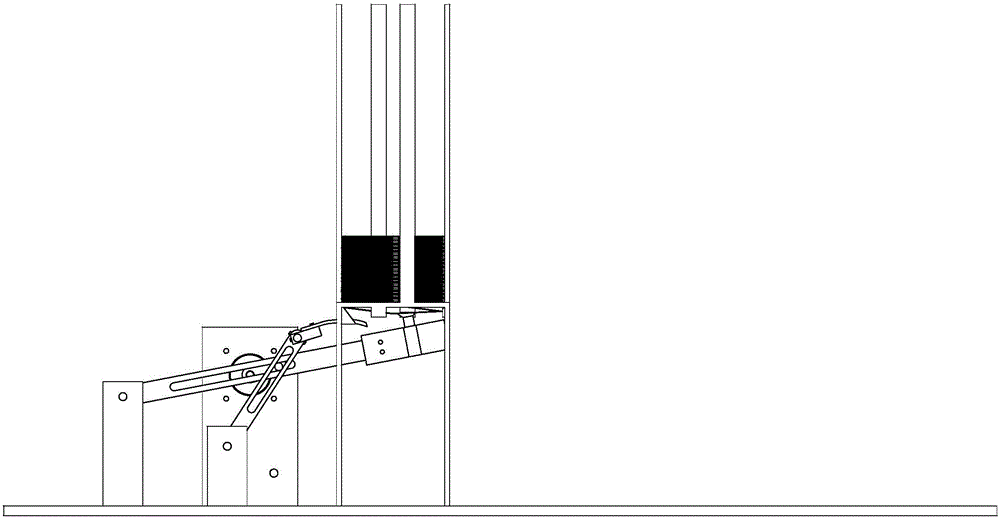

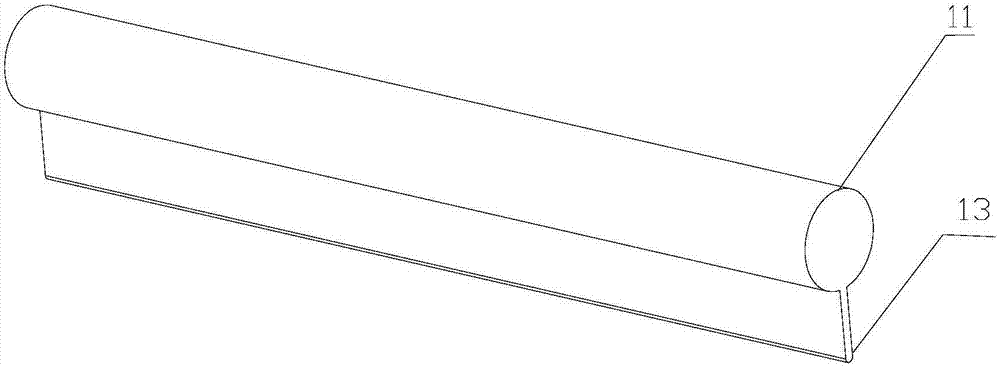

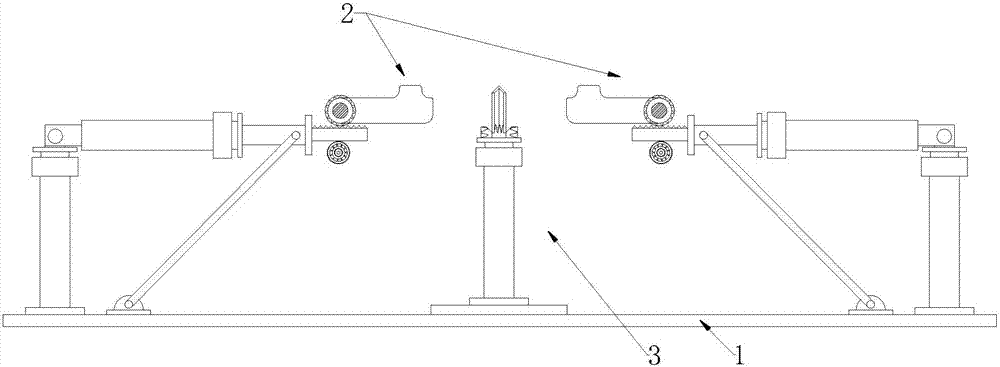

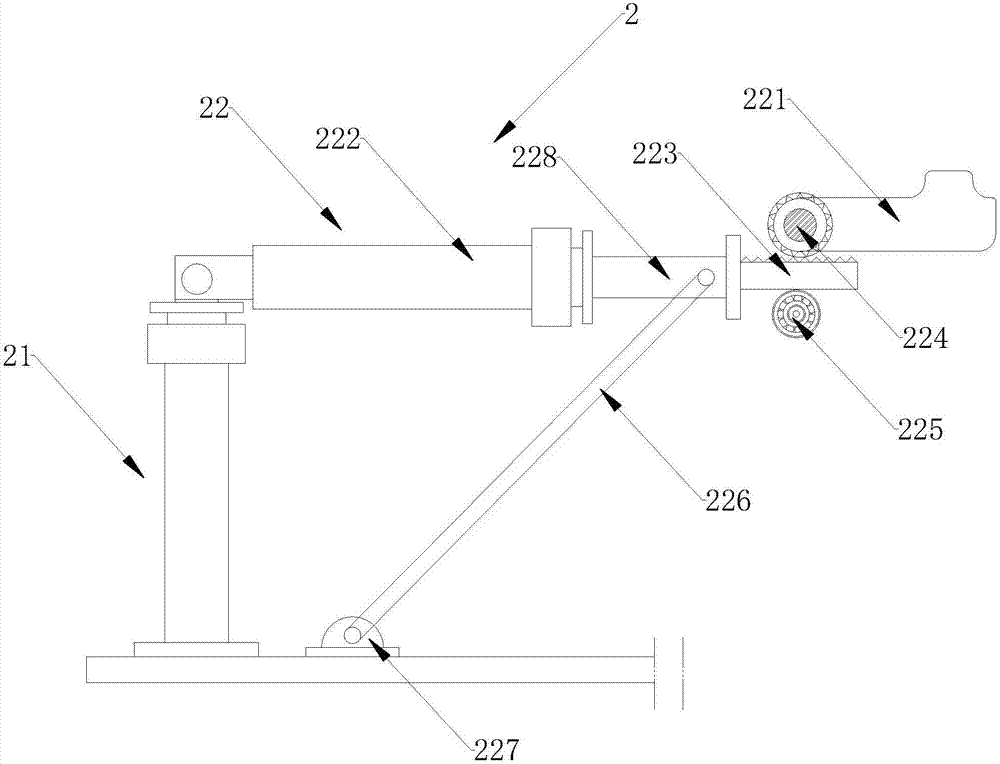

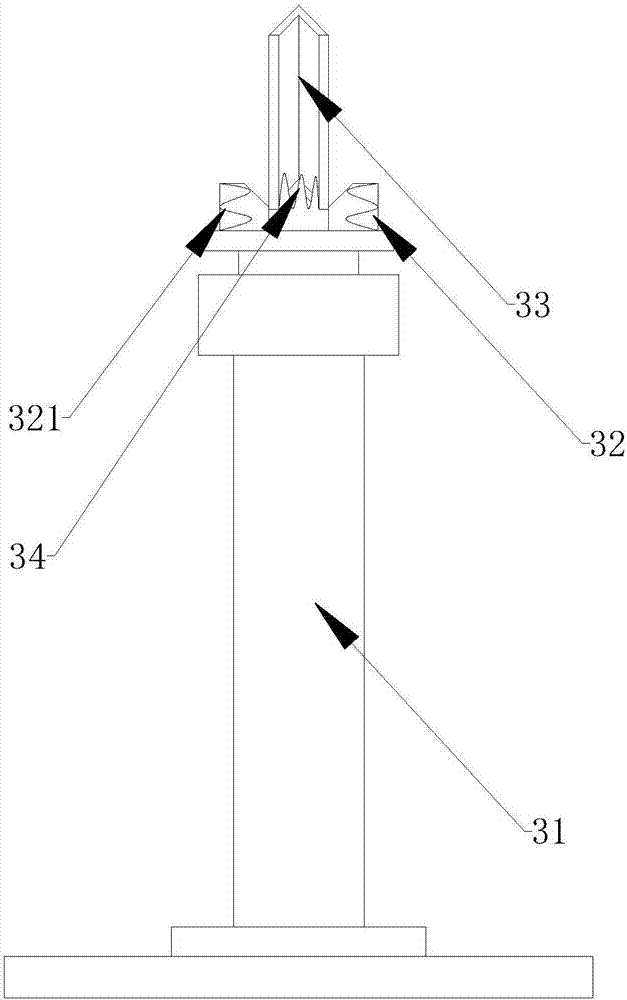

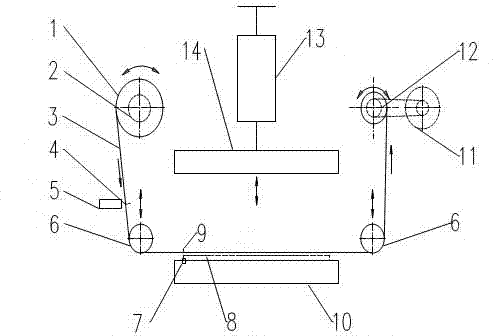

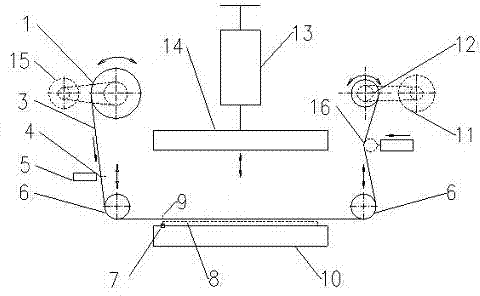

Automatic positioning paper feeding mechanism

InactiveCN103896086AReduce manufacturing costPrecise positioningArticle feedersArticle separationPaperboardPulp and paper industry

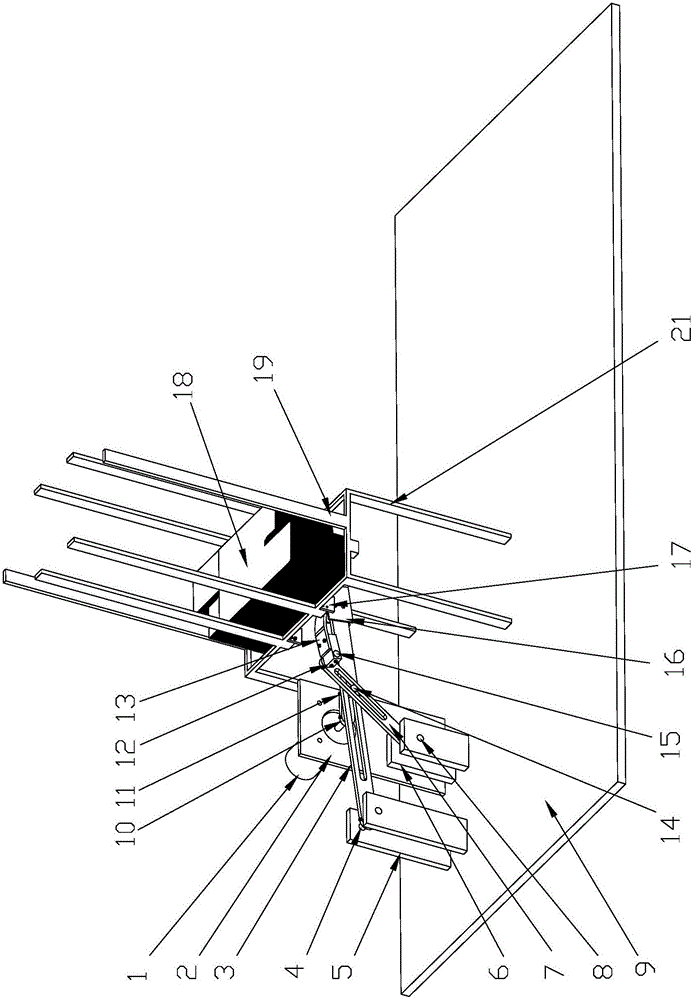

The invention discloses an automatic positioning paper feeding mechanism which comprises an air suction distribution valve (1), a machine frame (2), a guide rail lifting cam (3), a horizontal positioning motor (4), a vacuum pump connecting base (5), a paper suction nozzle (6), a connecting rod (7), a crank (8), a crank chain wheel (9), a paper suction nozzle frame guide rail (10), a paper suction nozzle frame (11), a paper pressing foot (12), a main chain wheel (13), an air suction pipe (14), a main driving chain (16) and a main chain wheel shaft (21). According to the automatic positioning paper feeding mechanism, a gap bridge track between an existing automatic paper feeding mechanism and a die-cutting machine is omitted, pre-localization and horizontal positioning functions are added, more than fifty percent of production cost of the automatic paper feeding mechanism is reduced, more than half of the size is reduced, performance is doubled, and the automatic positioning paper feeding mechanism has the advantages of being simple in structure, easy to assemble and debug, wide in paperboard application range, capable of achieving automatic positioning and paper feeding for paperboards and corrugated boards and capable of reducing labor cost to a great extent.

Owner:张香宏

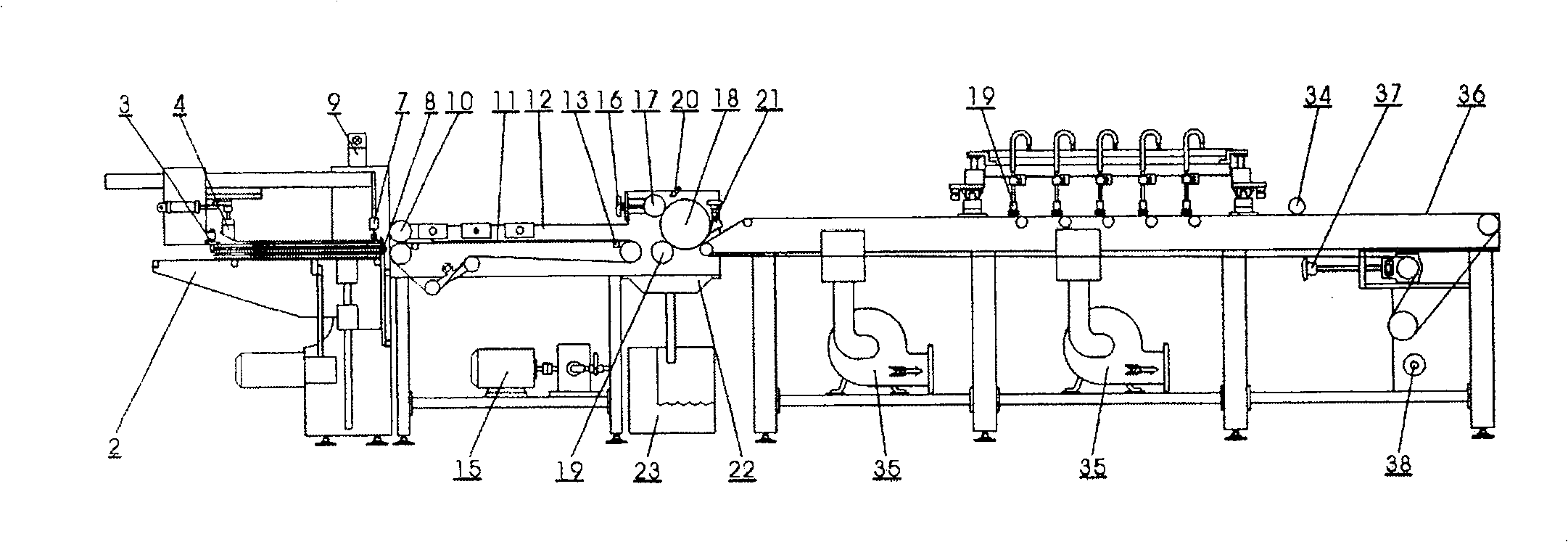

Full-automatic cover making machine

ActiveCN100528599CFast and stable transmissionFacilitates error-free operationBookbinding casesCardboardPulp and paper industry

The invention relates to an equipment for gluing paper products, positioning paper boards and folding edges, which is applicable for producing covers for hardcovered books, calendars, wall calendars, book-shape boxes, and file folders, etc. A fully automatic covering machine comprises a back-push type paper feeding structure, a gluing part, an edge-folding part and a collecting table; the gluing part comprises a paper stacking platform, a paper delivering platform, a gluing mechanism and a paper board feeding table; and the edge-folding part comprises an edge-folding mechanism and a conveyance mechanism. The invention has simple and reasonable design, and the open structure makes convenient for the error free operation of operators; the paper board conveyance is quick and stable, the positioning is accurate and reliable, and the reject rate of the finished products is greatly reduced.

Owner:WENZHOU ZHENGRUN MACHINERY

Versatile paper feeding device of image forming apparatus

InactiveUS20070090587A1Improve printing qualityRegistering devicesFunction indicatorsPulp and paper industryTrailing edge

Owner:S PRINTING SOLUTION CO LTD

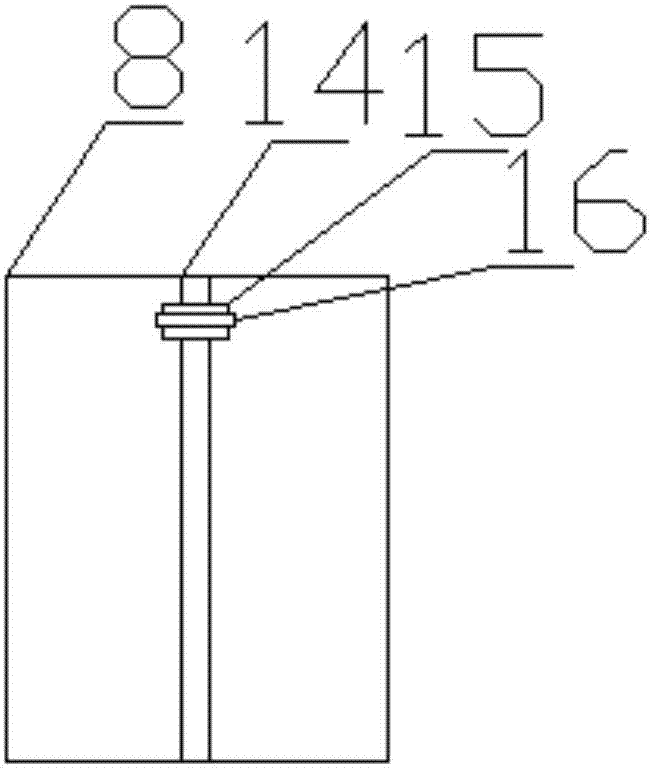

Visual assembly for externally positioned paper cutter tool sharpener

InactiveCN107866703AQuality improvementIntuitive understanding of dynamic changesOther manufacturing equipments/toolsGrinding/polishing safety devicesDisplay deviceEngineering

The visual assembly of the external positioning type paper cutter sharpener includes a knife grinder grinding disc knife seat (1), and an angle adjustment disc (2) is set above the grinding disc to connect with the clamping beam (4) through the guide rod (3). The middle part is provided with an indicator plate device (5), the outer end of the tool holder (1) is provided with a positioning bracket structure (6), a manual push handle (7), an independent display (8), and a video device (9) is located under the frame body. The degree of inclination of the grinding surface of the paper cutter is adjusted by adjusting the distance between the manual push handles (7). At the same time, the video device (9) transmits the moving path data to the display (8) for intuitive expression and indicates the inclination; multiple prompting devices are set (10) Provide corresponding prompts for the operating status of different sensing parts; adopt linkage mode design, not only can intuitively understand the dynamic changes in the deployment process, provide convenience for managers, but also ensure stable quality of the grinding section, simple operation, economical and practical .

Owner:XINCHANG COUNTY DONGMING TOWNSHIP DECHUANG MACHINERY PLANT

Double-position paper box suction forming mechanism

The invention discloses a double-position paper box suction forming mechanism. The mechanism comprises a rotating disc and a ventilation fixed shaft, wherein a sun gear is fixedly mounted at the shaftend of the ventilation fixed shaft; the sun gear drives a planet gear through an intermediate idle gear; intermediate idle gear shafts and planet gear shafts are mounted on the rotating disc; the front shaft end of the planet gear shaft is connected with a gas distribution block; and a suction nozzle is mounted on the gas distribution block. The mechanism is characterized that only one set of planet gear shafts and gas distribution blocks is provided; a ventilation rod is connected with the front end of the gas distribution block; the suction nozzles are mounted at the upper and lower rod ends of the ventilation rod; the suction nozzle at the upper rod end and the suction nozzle at the lower rod end are symmetrical to the rotating center of the planet gear shaft; the ratio of number of teeth of the planet gear to the sun gear is 1: 1.5, so that motion trails of the suction nozzle at the upper rod end and the suction nozzle at the lower rod end are regular triangles with the same shapes during the process of 360-degree rotation of the rotating disc, the mechanism has the advantages that single gas distribution block design is adopted, the structure is simplified, the boundary dimension is small, the box suction speed is increased, the automatic opening forming of a paper box can be further realized during the process of paper box suction, and the paper box quality is guaranteed.

Owner:浙江佳德包装机械有限公司

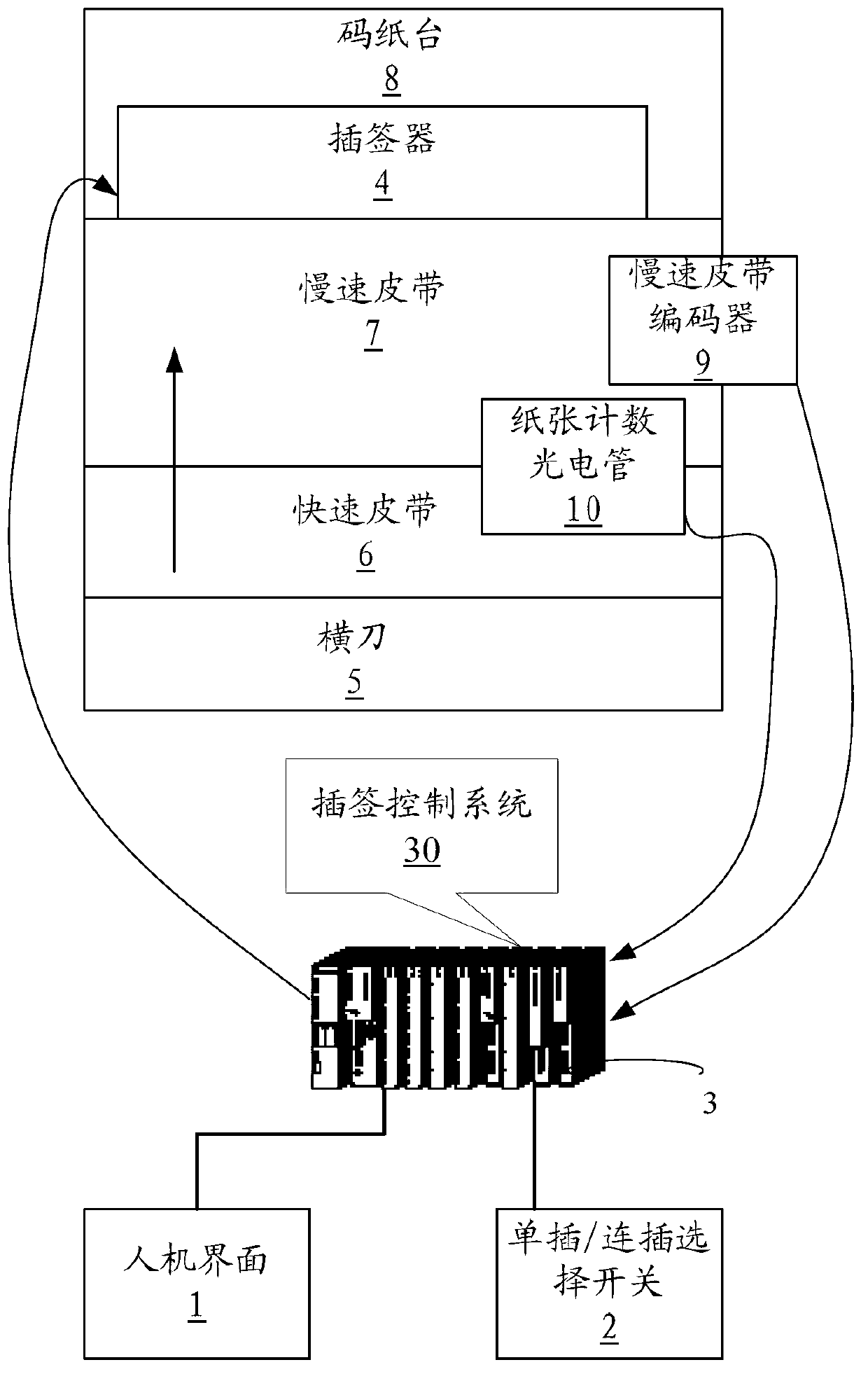

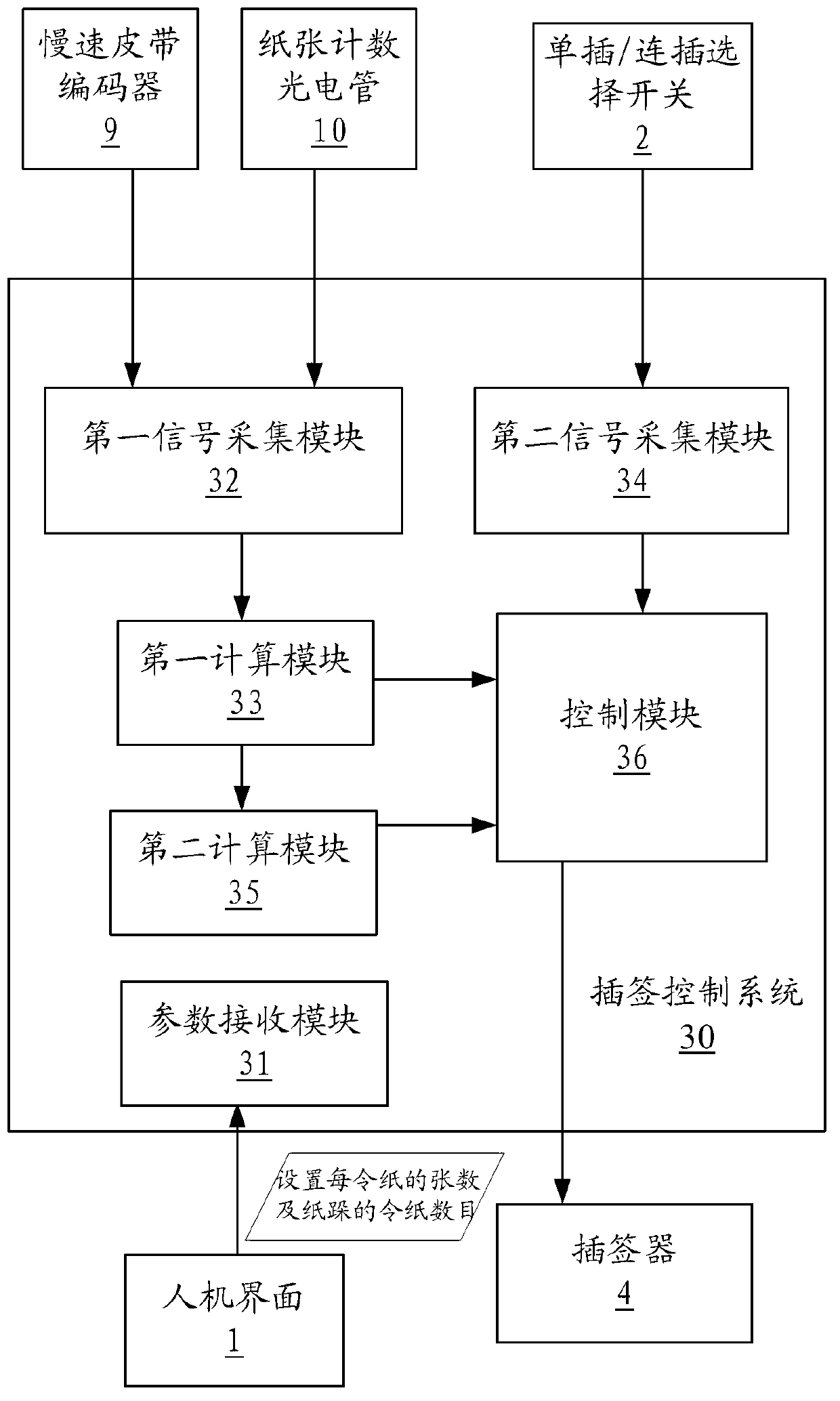

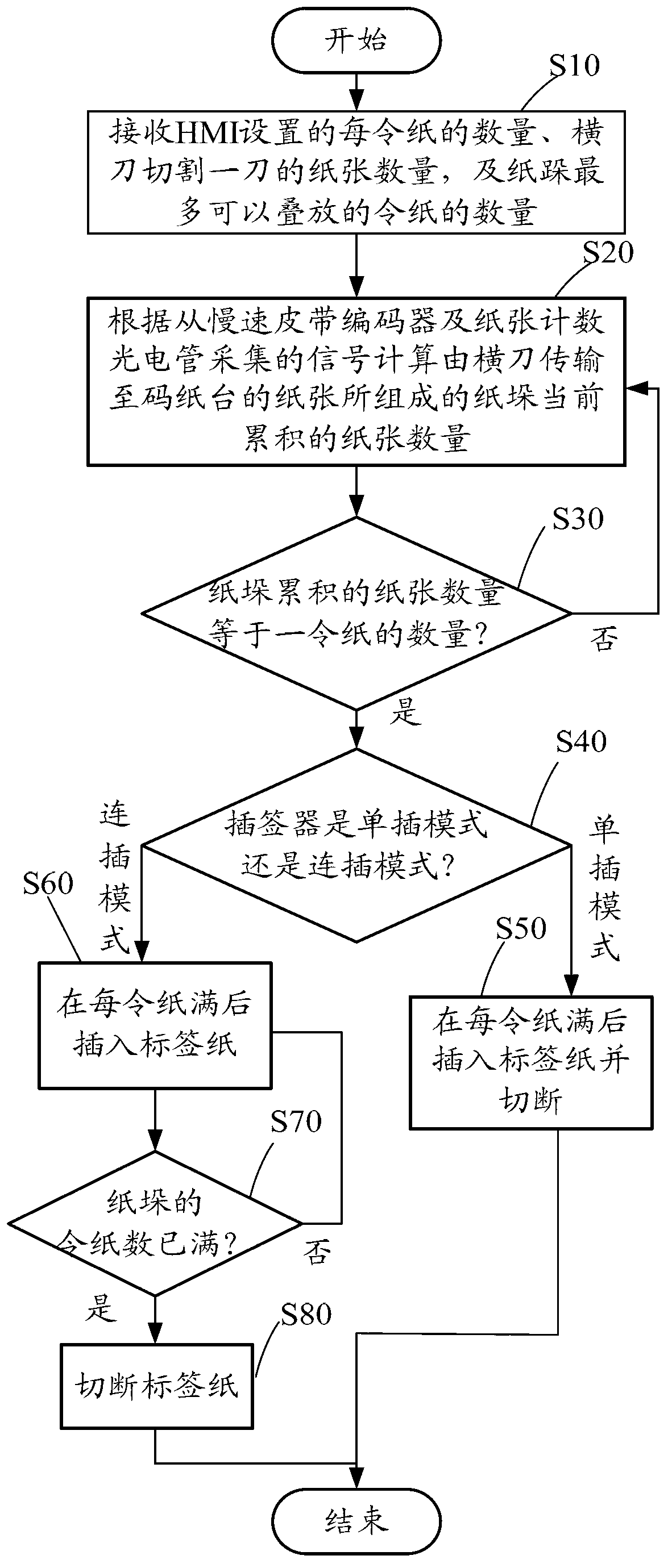

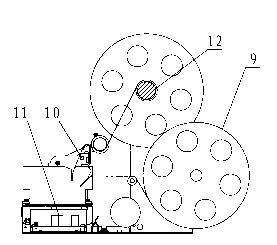

Label inserting control system and method

ActiveCN103345202AControl Continuous InsertionExtended service lifeNumerical controlLow speedProgrammable logic controller

The invention provides a label inserting control system which is applied to a programmable logic controller (PLC). The PLC is connected with a single-inserting / continuous-inserting selection switch and a label inserting device. The PLC acquires signals output by a low-speed belt encoder and a paper counting photoelectric tube, counts and positions paper transmitted to a paper coding table and acquires a selection signal of the single-inserting / continuous-inserting selection switch so as to judge that the label inserting device is set to be in a single-inserting mode or a continuous-inserting mode. If the label inserting device is set to be in the single-inserting mode, the PLC controls each ream of paper of the label inserting device on the paper coding table, inserts a labeled paper and then performs cutting off. If the label inserting device is set to be in the continuous-inserting mode, the PLC controls each ream of paper of the label inserting device on the paper coding table, inserts the labeled paper but does not perform cutting off until the ream number of the paper coding table reaches to the maximum stackable ream number. The invention further provides label inserting control method.

Owner:GOLD EAST PAPER JIANGSU

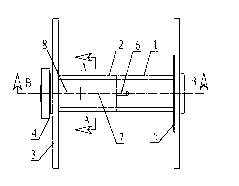

Automatic positioning paper-delivery shaft structure of journal printer

Disclosed is an automatic positioning paper-delivery shaft structure of a journal printer. The technical problem that the printing paper of a prior paper-delivery shaft structure is inconvenient to replace is solved. The technical scheme includes that the structure comprises a paper-delivery shaft assembly, a right paper-delivery baffle, a left paper-delivery baffle and a paper-delivery shaft gear, wherein the right paper-delivery baffle, the left paper-delivery baffle and the paper-delivery shaft gear are installed on the paper-delivery shaft assembly, the paper-delivery shaft assembly consists of a right paper-delivery half shaft and a left paper-delivery half shaft, one end of the left paper-delivery half shaft is fixedly connected to the left paper-delivery baffle and the paper-delivery shaft gear, the other end of the right paper-delivery half shaft is provided with a stair shat, a positioning bumping ball which is controlled by a spring is arranged on the stair shaft radially, one end of the right paper-delivery half shaft is fixedly connected to the right paper-delivery baffle, the other end of the left paper-delivery half shaft is provided with a shaft hole which is matched with the stair shaft, an annular axial positioning slot which is matched with the positioning bumping ball is arranged in the shaft hole, and an axial positioning pin which is used for preventing relative rotation is arranged on the combined end face of the right paper-delivery half shaft and the left paper-delivery half shaft. The device has the advantages of being simple in structure and quick and convenient for replacement of printing scroll s.

Owner:NDT SCI & TECH

Unpacking positioning mechanism of full-automatic packing machine

The invention discloses an unpacking positioning mechanism of a full-automatic packing machine, which is used for positioning paper boxes in a folding state before. The unpacking positioning mechanism comprises a rectangular support, a left-right positioning device, an opposite angle positioning device, and a paper box unfolding device, wherein the rectangular support is provided with a base, the left-right positioning device is provided with two first positioning components symmetrically arranged at the left and right sides of the base, the opposite angle positioning device is provided with two second positioning components symmetrically arranged at the front and rear sides of the base, and the paper box unfolding device comprises a first unfolding component connected to the first positioning components and a second unfolding component connected to the second positioning components. According to the unpacking positioning structure provided by the invention, the first positioning components of the left-right positioning device are used for positioning and unfolding the left and right sides of a folded paper box, the two second positioning components of the opposite angle positioning device enable an included angle between any two adjacent sides of the paper box to be a right angle, and thus the section of the unpacked paper box is rectangular or square.

Owner:SHANGHAI LONGTENG TECH

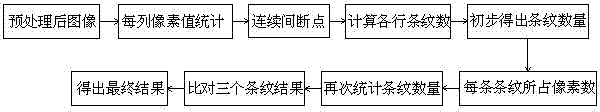

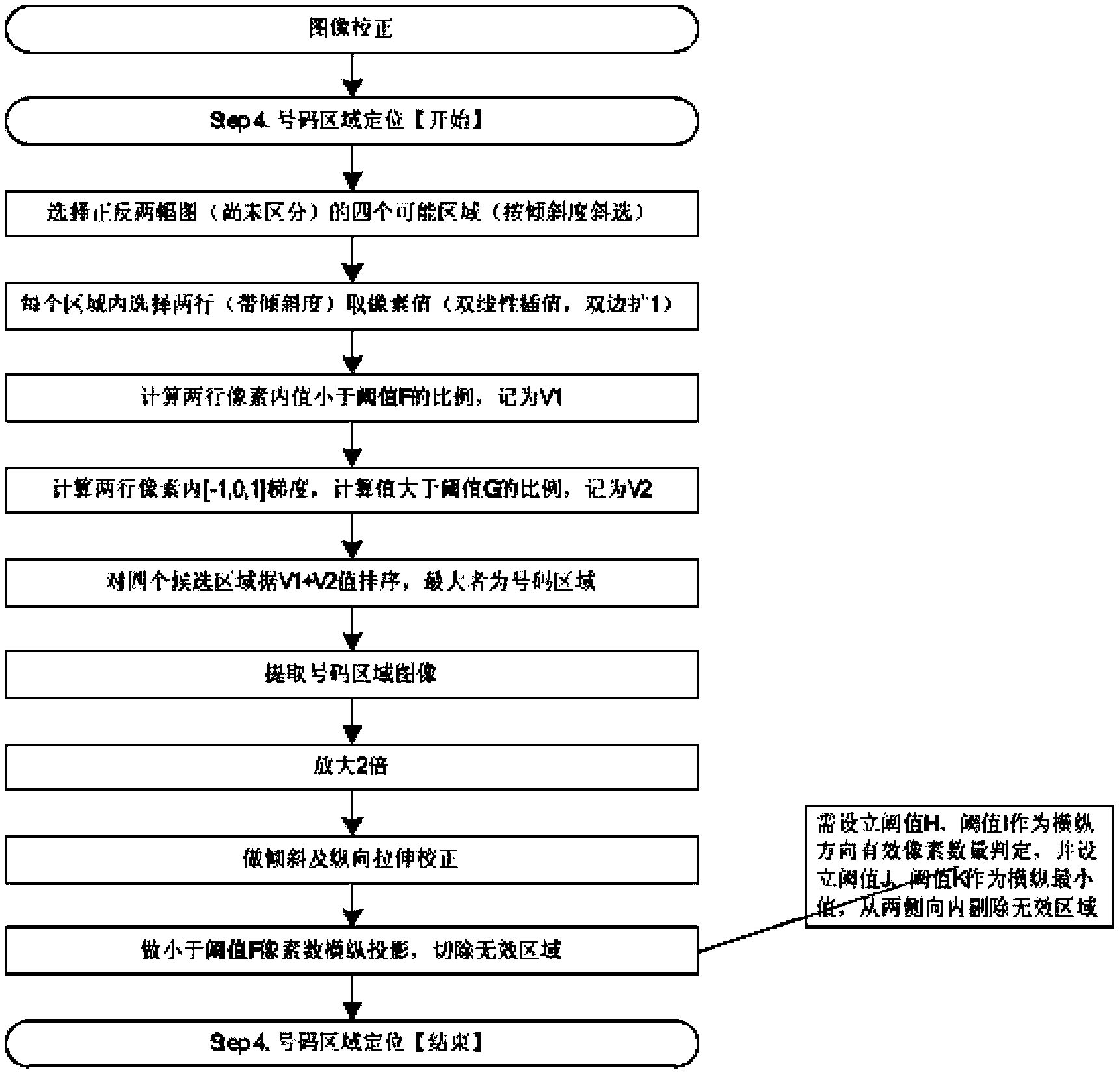

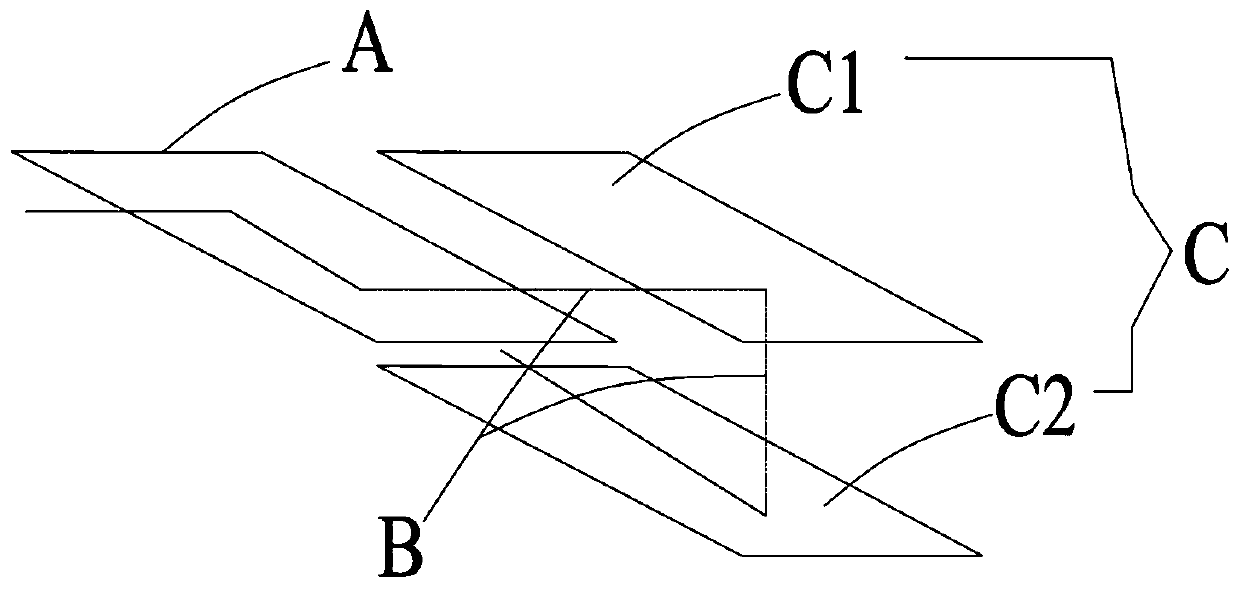

Method for positioning paper money number image region

ActiveCN102750773BAccurate identificationEnsure identificationPaper-money testing devicesCharacter and pattern recognitionComputer visionPosition paper

The invention relates to a method for positioning a paper money number image region. The method comprises the following steps: acquiring a horizontally arranged single paper money image; acquiring the appearing region of the number of the current paper money image, respectively selecting two rows in each region, and acquiring the proportion of the quantity of pixels with the pixel values less than an upper threshold F accounting for the total quantity of the pixels; carrying out [-1, 0, 1] Sobel gradient calculation respectively on the pixels of each row in each region, and acquiring the proportion of the quantity of the pixels with the gradient calculated values larger than a lower threshold G accounting for the total quantity of the pixels; respectively calculating the sums of V1 and V2 of the sampling rows in the four regions, searching for the maximum value of the sums of V1 and V2, and taking the region corresponding to the maximum value as a number region; and amplifying the image of the number region, carrying out slant and longitudinal draw correction on the amplified image, removing the blank region of the image of the number region, and identifying characters of the image of the number region. The method disclosed by the invention has the advantages that the paper money number region can be accurately positioned and the reliability is high.

Owner:杭州九聚科技有限公司

Compression device for paper product processing

InactiveCN107140270AIncrease productivityImprove practicalityPackagingPaper productionCompression device

The invention discloses a compression device for paper product processing, which includes a workbench, a cabinet body, a conveyor belt, an electric hydraulic cylinder, a compression plate and a paper product compression groove. One side of the cabinet body is provided with an electric storage box. The top of the body is provided with a workbench, and the top of the workbench is provided with a conveyor belt, and one end of the conveyor belt is provided with a paper product compression groove, and one side of the paper product compression groove is provided with a reserved slide hole, and the reserved slide hole is A fixing plate is provided, and a fixing bolt is arranged on the fixing plate, and a paper product fixing block is arranged at the other end of the fixing bolt, and the paper product fixing block is located in the paper product compression groove, and on the inner wall of the paper product compression groove An electronic dehumidifier is provided, and an electric hydraulic cylinder is provided at the upper end of the paper compression tank. The present invention compresses first in the production and transportation of paper products, which can greatly reduce the occupied space of paper products, and under the same volume transportation condition, the transportation efficiency of paper products can be greatly improved.

Owner:BEITANG JUNZHI PRINTING PAPER PROCESSING FACTORY

Hot riveting paper transferring device with positioning structure

InactiveCN108297168AEffective and fast clamping positioningReasonable structureMetal working apparatusEngineeringPosition paper

The invention discloses a hot riveting paper transferring device with a positioning structure. The hot riveting paper transferring device with the positioning structure comprises a bearing bottom board; a compressing panel is arranged on the top face of the bearing bottom board; a clamping cavity with an opening in the top face is formed in the bearing bottom board; an I-shaped hole through up anddown is formed in the compressing panel; an I-shaped insertion rod is arranged inside the I-shaped hole; a locking position hole communicating with the clamping cavity is formed in the side face of the bearing bottom board; a locking position pin rod is arranged inside the locking position hole; inverted-V-shaped clamping grooves are evenly formed in the I-shaped insertion rod; an adjusting groove is formed in the compressing panel; an adjusting slide block is arranged inside the adjusting groove; an insertion card positioning board is fixedly arranged on the adjusting slide block; and an abutting spring is fixedly arranged between the adjusting slide block and the outer wall of the adjusting groove. The hot riveting paper transferring device with the positioning structure is reasonable in structure and convenient and rapid to operate, can effectively and rapidly clamp and position paper, can avoid looseness or falling off in the transferring process, advantageously improves the machining efficiency and precision, and is good in use stability and high in practicability.

Owner:王恒标

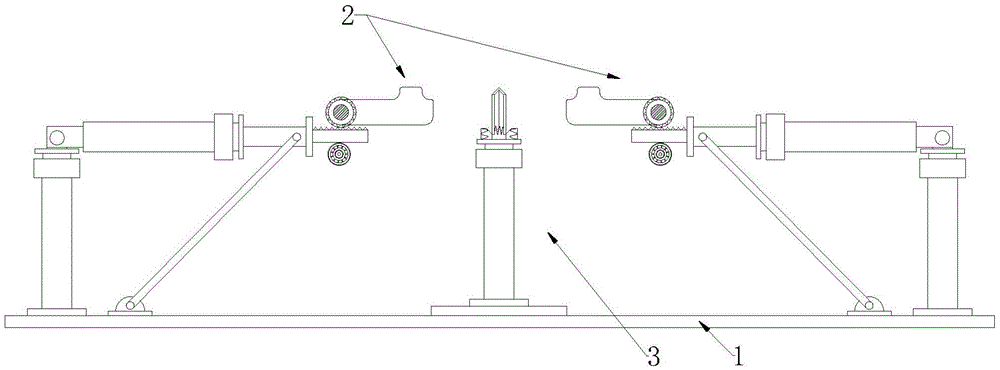

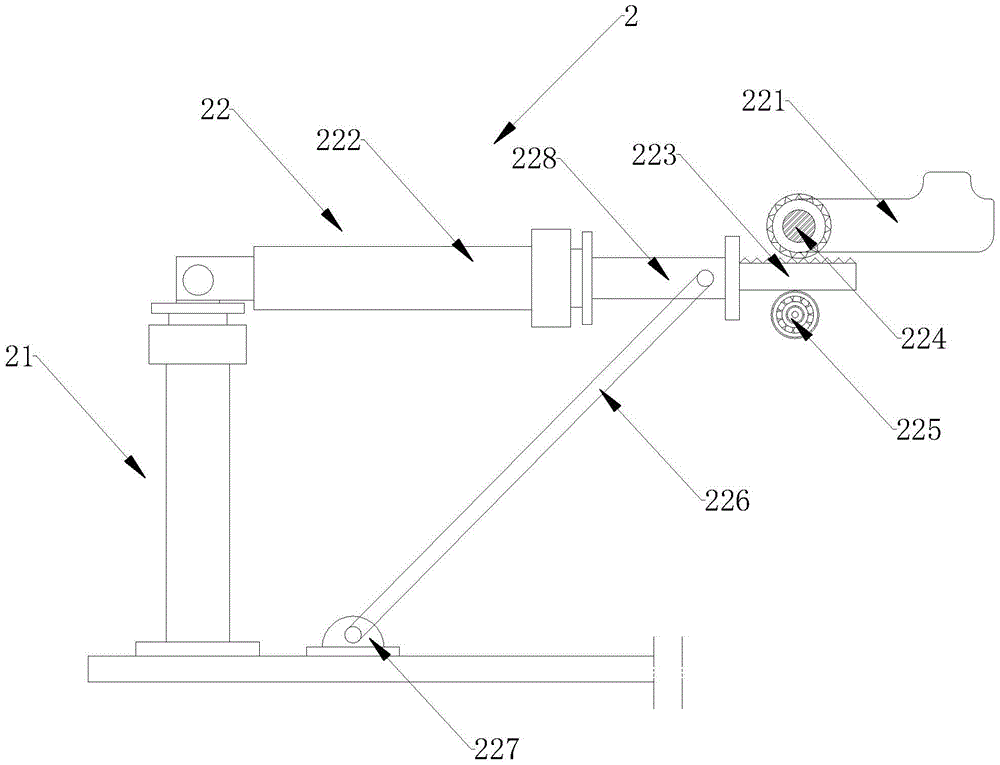

Banknote Laminating Machine

ActiveCN106672295BReduce processImprove the efficiency of sending moneyPaper article packagingWrappingPulp and paper industryPosition paper

The invention relates to the field of financial equipment, and discloses a paper currency plastic enveloping machine. The machine comprises a pre-binding part, a transition part and a plastic-enveloping thermal shrinking part, wherein the pre-binding part is connected with a paper currency receiving device; a positioning window is arranged in one sidewall of the plastic-enveloping machine; the paper currency receiving device comprises a first base plate, a paper currency receiving part for positioning paper currency, a guide assembly and a driving assembly; the guide assembly and the driving assembly are arranged on the first base plate; the paper currency receiving part is arranged on the guide assembly; one end of the guide assembly is arranged at the positioning window, and the other end of the guide assembly extends into the plastic-enveloping machine; the driving assembly can drive the paper currency receiving part to reciprocate on the guide assembly. According to the paper currency plastic enveloping machine, the paper currency can be manually positioned on the paper currency receiving part from the positioning window, and then the driving assembly can be operated to drive the paper currency receiving part to reciprocate along the guide assembly so as to finish the processes of automatically conveying the paper currency and returning to a start point. Therefore, that the paper currency is manually conveyed to a specified position in the paper currency plastic enveloping machine can be avoided, and as a result, the paper currency conveying process is saved, and the paper currency conveying efficiency is improved.

Owner:广电运通集团股份有限公司 +1

Cloud printing terminal equipment inlet position paper flattening device

InactiveCN108724975AAvoid cumbersomeSolve the problem of aestheticsOther printing apparatusTerminal equipmentPulp and paper industry

The invention discloses a cloud printing terminal equipment inlet position paper flattening device. The cloud printing terminal equipment inlet position paper flattening device comprises a shell, a motor and rotation shafts. A paper inlet is formed in the right side of the shell. The motor is arranged in the shell. A conveying belt is arranged on the outer surface of the motor. A soft film is arranged above the conveying belt. The rotation shafts are arranged in the shell. Brushes are arranged below the rotation shafts. Connecting rods are arranged on the left sides of the rotation shafts. Wheels are arranged below the connecting rods. The cloud printing terminal equipment inlet position paper flattening device is provided with the soft film, the soft film on the conveying belt can downwards press paper to a certain degree, the paper is more flatly printed, and the phenomenon of printer paper clamping due to placement of wrinkled paper into a printer is avoided.

Owner:ANHUI TIANSINU INFORMATION TECH

Double-connecting-rod type medical adhesive tape boxing machine box suction mechanism

The invention relates to a double-connecting-rod type medical adhesive tape boxing machine box suction mechanism. The mechanism aims at achieving the purposes that the structure is simple and reasonable, working efficiency is high, and the defects of an existing medical packaging machine box suction mechanism are overcome. According to the technical scheme, the double-connecting-rod type medical adhesive tape boxing machine box suction mechanism is characterized by comprising a base; box supports for positioning paper boxes to be folded and a folding mechanism for extracting and folding the paper boxes to be folded one by one are fixed to the base.

Owner:ZHEJIANG SCI-TECH UNIV

Tube coiling machine for quick-dry firework paper tube

ActiveCN106940157AGuaranteed sealing effectDry fastPaper/cardboard wound articlesFireworksPulp and paper industryState switching

Owner:LIUYANG HAILONG FIREWORKS MFG

An unpacking positioning mechanism of a fully automatic box packing machine

The invention discloses an unpacking positioning mechanism of a full-automatic packing machine, which is used for positioning paper boxes in a folding state before. The unpacking positioning mechanism comprises a rectangular support, a left-right positioning device, an opposite angle positioning device, and a paper box unfolding device, wherein the rectangular support is provided with a base, the left-right positioning device is provided with two first positioning components symmetrically arranged at the left and right sides of the base, the opposite angle positioning device is provided with two second positioning components symmetrically arranged at the front and rear sides of the base, and the paper box unfolding device comprises a first unfolding component connected to the first positioning components and a second unfolding component connected to the second positioning components. According to the unpacking positioning structure provided by the invention, the first positioning components of the left-right positioning device are used for positioning and unfolding the left and right sides of a folded paper box, the two second positioning components of the opposite angle positioning device enable an included angle between any two adjacent sides of the paper box to be a right angle, and thus the section of the unpacked paper box is rectangular or square.

Owner:SHANGHAI LONGTENG TECH

A fully automatic hanging picture rolling packaging machine

ActiveCN104589901BRealize mechanized productionIncrease productivityPaperhangingPackagingEngineeringAssembly line

The invention discloses a fully automatic scrolling and packaging machine for hanging pictures, which is composed of a machine body and a finished product conveyor belt fixed on the machine body, a lifting platform, a rolling device, a gluing device, and a lower scroll device. The above body preferably adopts upper and lower frames The lower frame is larger than the upper frame. The finished product conveyor belt, lifting platform and rolling device are all fixed on the top surface of the lower frame. The finished product conveyor belt and the lifting platform are arranged horizontally, and the rolling device is vertical to both. The gluing device and the falling picture scroll device are fixed by a fixed plate, and the fixed plate is fixed on the upper frame. When in use, the drawing paper is placed on the lifting platform, the scroll is placed in the falling scroll device, and the gluing device is applied on the corresponding position of the drawing paper. Good glue, move on the lifting platform to make the drawing paper stick to the scroll, the rolling device clamps the scroll and transports it to the finished product conveyor belt. After adopting the above structure, the upper shaft and rolling can be completed by mechanical assembly line, which improves the Production efficiency, reducing production costs.

Owner:JINHUA SHENGCHANG MACHINERY

Paper cutting device for high-position paper discharge of printing machine

The invention discloses a paper cutting device for high-position paper discharge of a printing machine. The paper cutting device comprises a bracket and a paper cutting device body; a left support plate is arranged on the upper end surface of a lower support plate; a lifting support seat is arranged at the center of the bottom surface of the upper support plate in a lifting manner; a cutter is detachably arranged on the lower end surface of the lifting support seat; a left suction plate is arranged on the right end surface of the lifting support seat in left-right movement manner; a pluralityof left suction nozzles which are evenly distributed front and back are formed in the bottom surface of the left suction plate; a movement adjusting support plate is arranged on the right side of theleft support plate in a left-right movement manner; a right suction plate is arranged on the vertical part of the movement adjusting support plate in a lifting manner; a plurality of right suction nozzles which are evenly distributed front and back are formed in the bottom surface of the right suction plate; a pair of connecting insertion rods symmetrically arranged front and back are formed on the left end surface of the right suction plate; the left ends of the connecting insertion rods penetrate through the horizontal part of the left suction plate in a left and right horizontal manner; anda paper discharge support plate is formed on the upper part of the right end surface of the vertical part of the movement adjusting support plate. The paper cutting device is simple in structure andhigh in precision and a paper cutting length can be controlled.

Owner:嘉兴市华丽印刷有限公司

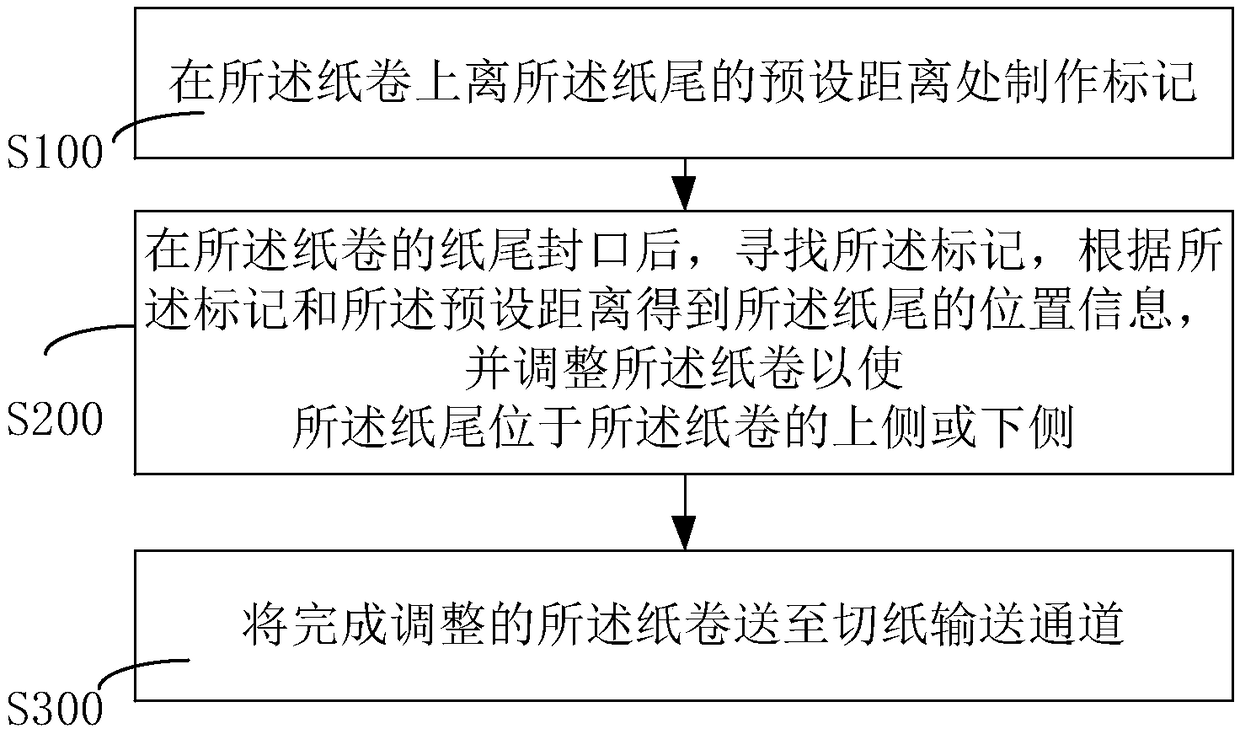

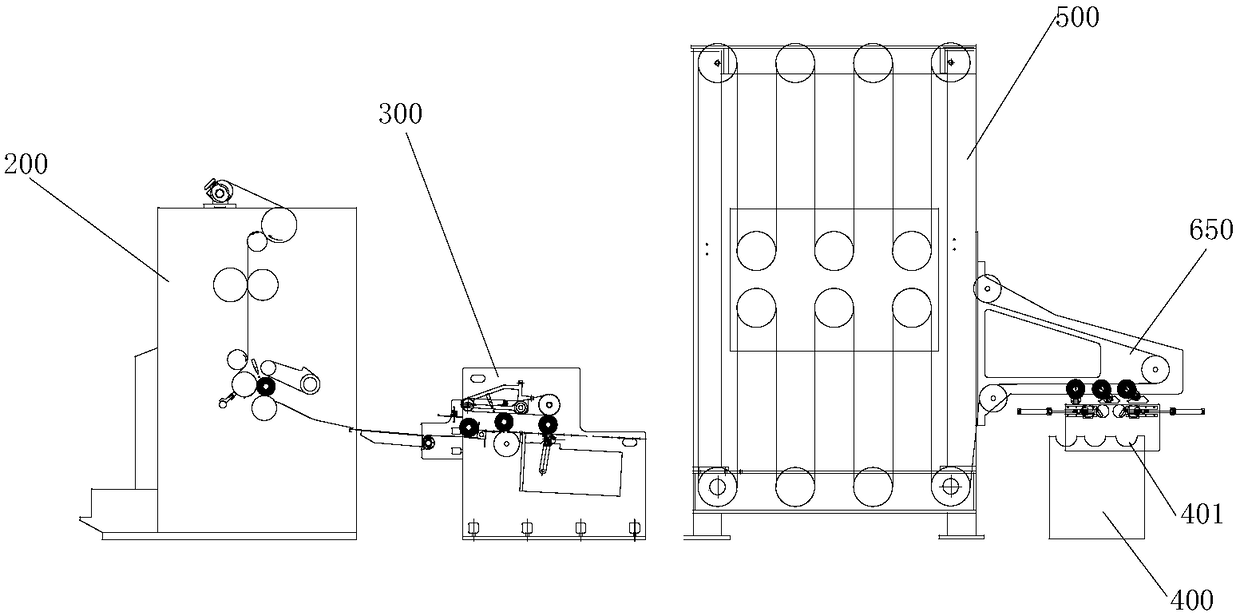

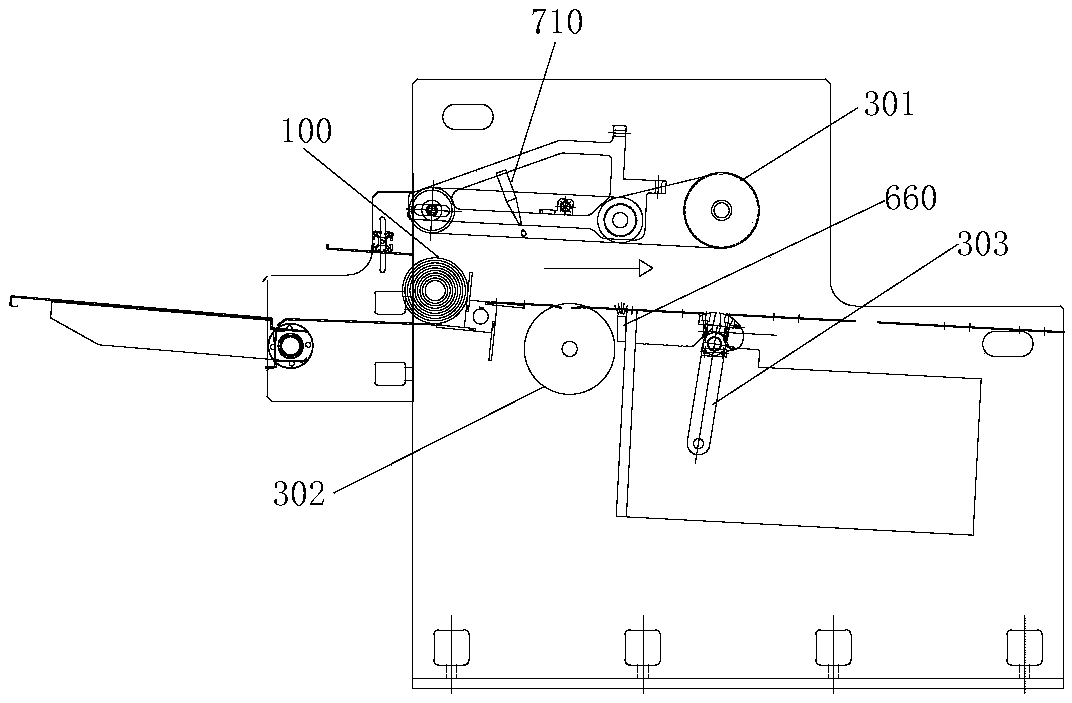

Method and device for positioning paper tail of paper roll before paper cutting

ActiveCN108688904AAvoid the phenomenon that the seal falls offPackagingPulp and paper industryPosition paper

The invention relates to a method and device for positioning the paper tail of a paper roll before paper cutting. The method comprises the following steps that a mark is made on the paper roll at a preset distance from the paper tail; after the paper tail of the paper roll is sealed, the mark is searched, the position information of the paper tail is obtained according to the mark and the preset distance, and the paper roll is adjusted so that the paper tail is positioned on the upper side or the lower side of the paper roll; and the adjusted paper roll is fed to a paper cutting conveying channel. In the traditional paper cutting process, a pressing plate presses the upper side of the paper roll tightly to stabilize the paper roll for cutter cutting, if the paper tail at the sealing part of the paper roll is located on the left and right sides of the paper roll, the sealing position can burst open and fall off due to the sealing part of the paper tail being stressed. The method for positioning the paper tail of the paper roll before paper cutting positions the paper tail before the paper roll enters the paper cutting conveying channel, so that the paper tail is prevented from beingpositioned on the two sides, where the paper roll are extruded and lengthened, of the paper roll, and the phenomenon of seal falling off is avoided.

Owner:FOSHAN BAOSUO PAPER MASCH MFG CO LTD

Automatically positioning paper feeding system for sheet material transfer printing machine

InactiveCN102785805BReduce processReduce waiting timeTransfer printingLabelling machinesMaterial transferDelivery system

The invention relates to an automatically positioning paper feeding system and a method for a sheet material transfer printing machine, which is capable of effectively changing a sheet-cut printing paper delivery system of the sheet material transfer printing machine in the textile, printing and dyeing industry into a continuous drum material delivery, characterized in that the unreeling of the printing paper is driven by a magnetic particle brake or a motor plus a floating tension roller, the reeling of the printing paper is mainly driven by the motor, when a position sensor detects a signal, the position signal is delivered to a paper delivery system, a control system delivers the printing paper to a specified position to stop, the specified position is provided with the position sensor for detecting the position of the paper, and the tension force is kept by the magnetic powder brake or a pneumatic floating lever.

Owner:任继平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com