Automatically positioning paper feeding system and method for sheet material transfer printing machine

A technology of transfer printing and automatic positioning, which is applied to labeling machines, thin material processing, labels, etc., can solve the problems of increasing equipment, increasing energy consumption, packaging and transportation costs, waste, etc., and achieves the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

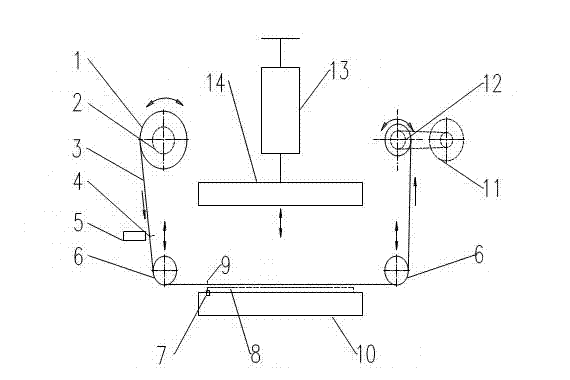

[0013] Embodiment 1: with reference to attached figure 1 . An automatic positioning paper feeding system for a sheet material transfer printing machine, including a control system 17, two synchronous floating rollers 6 are distributed above the outer sides of the printing pressure plate 10, and a feeding mechanism is respectively arranged above the two synchronous floating rollers 6 1 and the receiving mechanism 12, the printing paper 3 on the discharging roller in the discharging mechanism 1 is wound on the receiving roller in the receiving mechanism 12 through two synchronous floating rollers 6 and is located between the two synchronous floating rollers 6 The printing paper 3 is tensioned horizontally, the printing platen 14 is located in the space between the two synchronous floating rollers 6, the pressurizing device 13 is located on the printing platen 14 and drives the printing platen 14 to press down or move up, and the position sensor 7 is set on the printing pressure ...

Embodiment 1-1

[0014] Embodiment 1-1: On the basis of Embodiment 1, an automatic positioning and paper feeding system of a sheet transfer printing machine, when the printed sheet fabric 8 is placed on the printing pressure plate 10, the position sensor 7 detects its actual position The signal is sent to the control system 17, and the output instruction is given to the receiving drive motor 11 to make the decal paper 3 run. When the actual pattern position 9 reaches the designated position, the virtual pattern position 4 reaches the position of the position sensor 5, and the position sensor 5 sends a signal to the control system 17. The control system 17 sends a stop signal to the receiving drive motor 11, the receiving mechanism 12 stops rotating and receiving, the pressurizing device 13 pressurizes, and the printing platen 14 (heat transfer printing must be heated to the specified temperature at the same time) goes down to the printing sheet. The fabric 8, the printing paper 3, and the print...

Embodiment 2

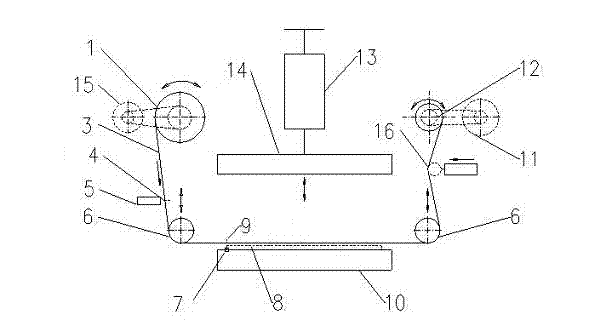

[0015] Embodiment 2: with reference to attached figure 2 . An automatic positioning paper feeding system for a sheet material transfer printing machine, including a control system 17, two synchronous floating rollers 6 are distributed above the outer sides of the printing pressure plate 10, and a feeding mechanism is respectively arranged above the two synchronous floating rollers 6 1 and the receiving mechanism 12, the printing paper 3 on the discharging roller in the discharging mechanism 1 is wound on the receiving roller in the receiving mechanism 12 through two synchronous floating rollers 6 and is located between the two synchronous floating rollers 6 The printing paper 3 is tensioned horizontally, the printing platen 14 is located in the space between the two synchronous floating rollers 6, the pressurizing device 13 is located on the printing platen 14 and drives the printing platen 14 to press down or move up, and the position sensor 7 is set on the printing pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com