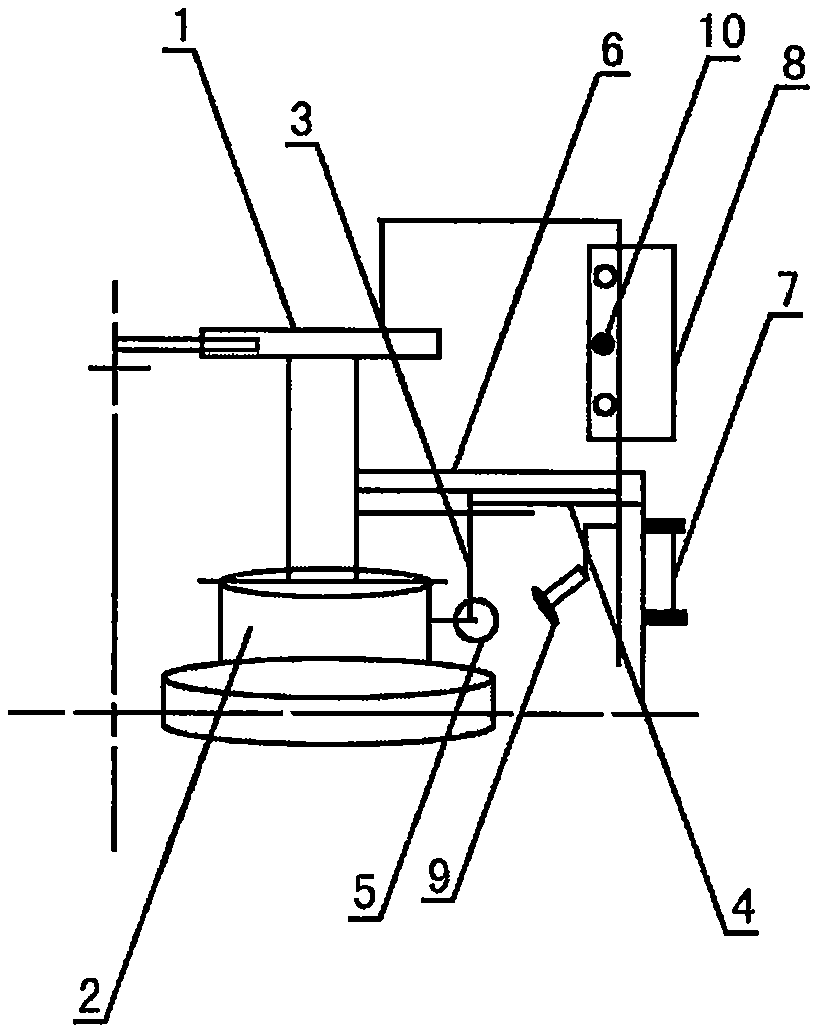

Visual assembly for externally positioned paper cutter tool sharpener

A knife sharpener and paper cutter technology, applied in grinding/polishing equipment, grinding/polishing safety devices, other manufacturing equipment/tools, etc., can solve the problems of inconvenient inspection and observation, inability to intuitively judge the grinding angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] Embodiment: as shown in the accompanying drawing. The visual assembly of the external positioning type paper cutter grinder includes a knife grinder grinding disc knife seat (1), and an angle adjustment disc (2) is arranged above the grinding disc to connect with the clamping beam (4) through a guide rod (3). The middle part is provided with an indicator plate device (5), the outer end of the tool holder (1) is provided with a positioning bracket structure (6), a manual push handle (7), an independent display (8), and a video device (9) is located under the frame body. Adjust the pitch of the manual push handle (7) for the degree of inclination of the grinding surface of the paper cutter. At the same time, the video device (9) transmits the moving path data to the display (8) for intuitive expression and indicates the inclination.

[0013] The visual component of the external positioning type paper cutter sharpener is provided with a plurality of prompting devices (10) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com