Feeding device of paper tube edge grinding machine

A technology of feeding device and edging machine, which is applied to the parts of the grinding machine tool, the machine tool suitable for grinding the edge of the workpiece, and the grinding feed movement, etc., which can solve the problems affecting the edging effect and edging speed, etc. To achieve the effect of ensuring the efficiency of edging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

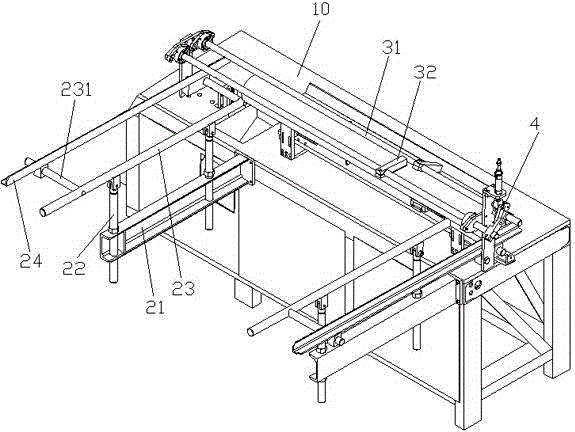

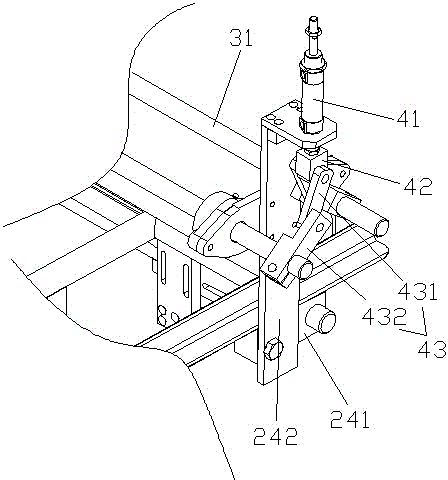

[0017] A feeding structure of a paper tube edging machine, as attached figure 1 , 2 As shown, it includes a frame 10 and a feeding area erected on the frame 10 . The feeding area includes two mutually parallel feeding base plates 21 fixed on the frame 10 at one end and a material rack adjusting rod 22 vertically fixed on the feeding base plate 21, and each feeding base plate 21 is provided with two material racks Adjusting rod 22, between the two material rack adjusting rods 22 on the same feeding base plate 21, there are feeding rods 23 parallel to the feeding base plate 21, and the paper tube enters from the two feeding rods 23 on both sides, and is sent To the feeding area, and then transported from the feeding area to the edging place for edging. In order to prevent the paper tube from sliding to both sides when being transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com