Transfer platinum cat eye positioning paper and preparation process thereof

A preparation process and cat's eye technology, which is applied in the field of transfer platinum cat's eye positioning paper and its preparation, can solve the problems of insufficient bonding fastness between the UV layer and the aluminum layer, use restrictions, and the impossibility of transferring platinum positioning paper, etc., and achieve high anti-counterfeiting performance, High positioning accuracy and strong platinum luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

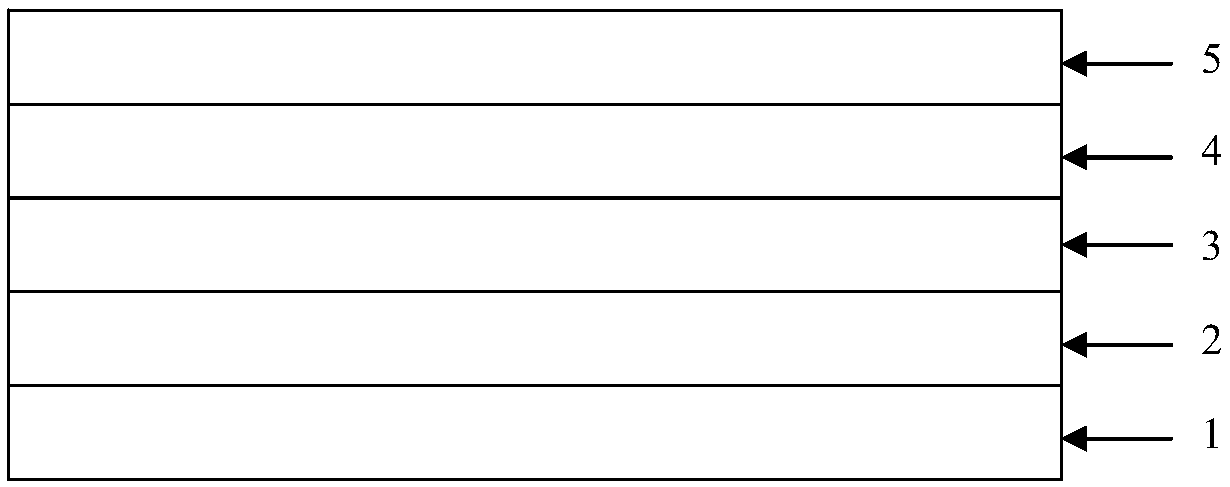

Image

Examples

Embodiment 1

[0037] A kind of preparation technology of transferring platinum cat's eye positioning paper of the present embodiment comprises the following steps:

[0038] (1) UV coating molding process: UV varnish is coated on the PET pretreatment film, and the mother film is obtained by molding and UV curing; the platinum cat's eye pattern can be photo-etched according to the design requirements; Difficulties such as overflow glue, sticky material, and top damage are the guarantee for making high-quality platinum cat-eye mother film; UV varnish is a special varnish that has been specially treated. UV varnish is composed of oligomers, photoinitiators, and reactive diluents. , additives, etc., wherein the oligomer is a low-molecular resin containing C=C unsaturated double bonds, such as acrylic resin, polyurethane acrylic resin and polyester acrylic resin, etc., with a functionality of 2~3. It is required that the bonding fastness between the varnish layer and the pre-coating film is good ...

Embodiment 2

[0045] A kind of preparation technology of transferring platinum cat's eye positioning paper of the present embodiment comprises the following steps:

[0046] (1) UV coating molding process: UV varnish is coated on the PET pretreatment film, and the mother film is obtained by molding and UV curing; the platinum cat's eye pattern can be photo-etched according to the design requirements; Difficulties such as overflow glue, sticky material, and top damage are the guarantee for making high-quality platinum cat's eye mother film; UV varnish is a special varnish after special treatment, which requires good bonding fastness and folding resistance between the varnish layer and the pre-coated film , The bonding fastness with the aluminum layer is poor. The UV coating molding process is realized on the coating molding machine. The specific implementation method is: photolithography platinum cat's eye master plate → imposition → reprint → plate cutting → overlay → plate seam treatment → ...

Embodiment 3

[0053] A kind of preparation technology of transferring platinum cat's eye positioning paper of the present embodiment comprises the following steps:

[0054] (1) UV coating molding process: UV varnish is coated on the PET pretreatment film, and the mother film is obtained by molding and UV curing; the platinum cat's eye pattern can be photo-etched according to the design requirements; Difficulties such as overflow glue, sticky material, and top damage are the guarantee for making high-quality platinum cat's eye mother film; UV varnish is a special varnish after special treatment, which requires good bonding fastness and folding resistance between the varnish layer and the pre-coated film , The bonding fastness with the aluminum layer is poor. The UV coating molding process is realized on the coating molding machine. The specific implementation method is: photolithography platinum cat's eye master plate → imposition → reprint → plate cutting → overlay → plate seam treatment → ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com