Paper cutting device for high-position paper discharge of printing machine

A paper cutting device and high-level technology, applied in metal processing and other directions, can solve the problems of low adjustment ability, poor product quality, and low work efficiency, and achieve the effects of high precision, controllable cutting length, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

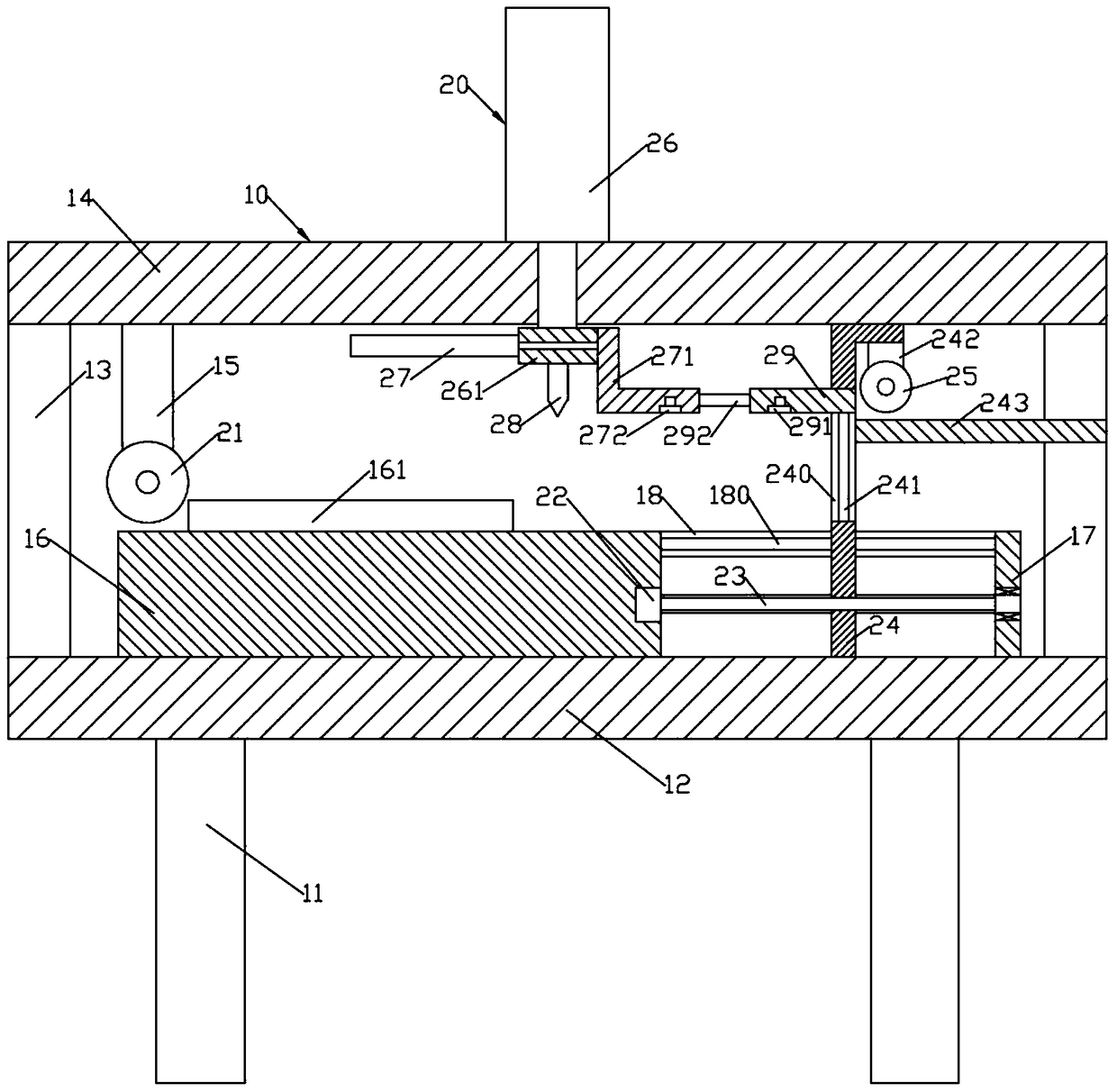

[0014] like figure 1 As shown, a paper cutting device for high-position paper output of a printing machine includes a support 10 and a paper cutting device 20; the support 10 includes a lower support plate 12 and an upper support plate 14; the lower support plate 12 is located below the upper support plate 14 and The two are connected into one body by several evenly distributed vertical support rods 13; the bottom surface of the lower support plate 12 is provided with several evenly distributed support feet 11; the left upper end surface of the lower support plate 12 is provided with a left support plate 16 The paper cutting device 20 includes a lift support base 261 and an inverted L-shaped mobile adjustment support plate 24; the lift support base 261 is set on the bottom surface center of the upper support plate 14 and the lower end surface is detachably equipped with a cutter 28; lift The right end surface of the support seat 261 is provided with an L-shaped left adsorption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com