Automatic positioning paper feeding mechanism

An automatic positioning and paper feeding technology, applied in the direction of object supply, object separation, pile separation, etc., can solve the problems of rising demand for creasing die-cutting machines, inability to take care of corrugated cardboard, complex structure, etc., to achieve increased left and right positioning functions, The effect of simple structure and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

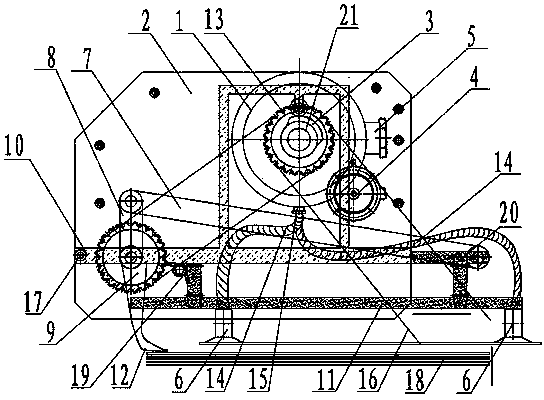

[0015] Such as figure 1 As shown, the automatic positioning paper feeding mechanism includes suction distribution valve 1, frame 2, guide rail lifting cam 3, left and right positioning motor 4, vacuum pump connection seat 5, paper suction nozzle 6, connecting rod 7, crank 8, crank sprocket 9. Guide rail 10 of paper-absorbing nozzle frame, paper-absorbing nozzle frame 11, paper presser foot 12, main sprocket 13, suction pipe 14, main drive chain 16 and main sprocket shaft 21, and main sprocket shaft 21 is rotatably installed on the frame 2, the suction distribution valve 1, the guide rail lifting cam 3 and the main sprocket 13 are respectively installed on the main sprocket shaft 21, the left and right positioning motors 4 are installed on the frame 2, and the vacuum pump connection seat 5 is installed on the suction distribution valve 1 , the paper-absorbing frame 11 is two layers up and down, movably connected by pivot pin 20, the paper-absorbing nozzle 6 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com