Automatic production line from ferrite pressing to furnace feeding and implementation method of automatic production line

An automated production line and ferrite technology, applied in the manufacture of inductors/transformers/magnets, conveyors, electrical components, etc., can solve the problems of large storage areas, chaotic search and management, labor-intensive, etc., to reduce manual use Quantity, reduce product defect rate, reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

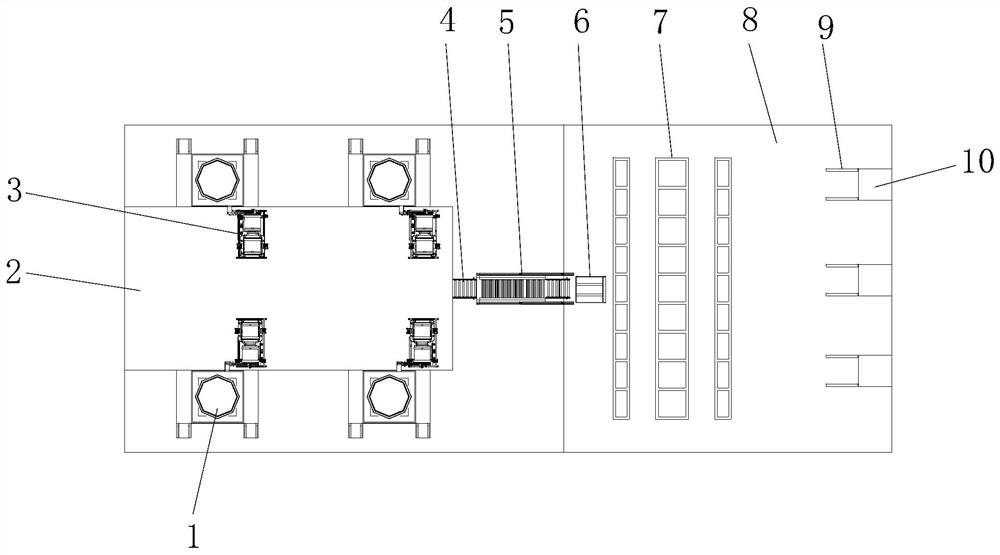

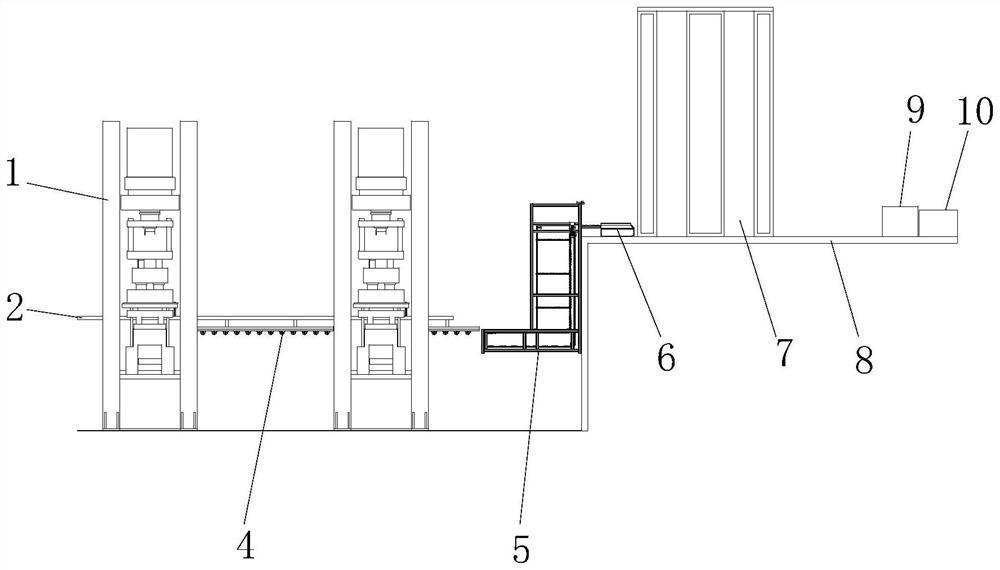

[0049] see Figure 1-14 , the present invention provides the following technical solutions: an automatic production line for pressing ferrite into the furnace, including an elevated platform 2 and a second-floor platform 8 arranged on one side of the elevated platform 2, and several A cartoning machine 3 corresponding to the press 1 is provided above the press 1 and the overhead platform 2, and a conveying line 4 corresponding to the cartoning machine 3 is connected to the bottom of the elevated platform 2, and one side of the output end of the conveying line 4 is provided with There is a continuous hoist 5, the output end of the continuous hoist 5 is located on the platform 8 on the second floor, an intelligent warehouse 7 is arranged above the platform 8 on the second floor, and several climbing AGVs 6 are arranged between the intelligent warehouse 7 and the continuous hoist 5, Above the platform 8 on the second floor is located on the side of the intelligent warehouse 7. Th...

Embodiment 2

[0067] Further, the realization method of the automatic production line of pressing ferrite into the furnace according to the present invention comprises the following steps:

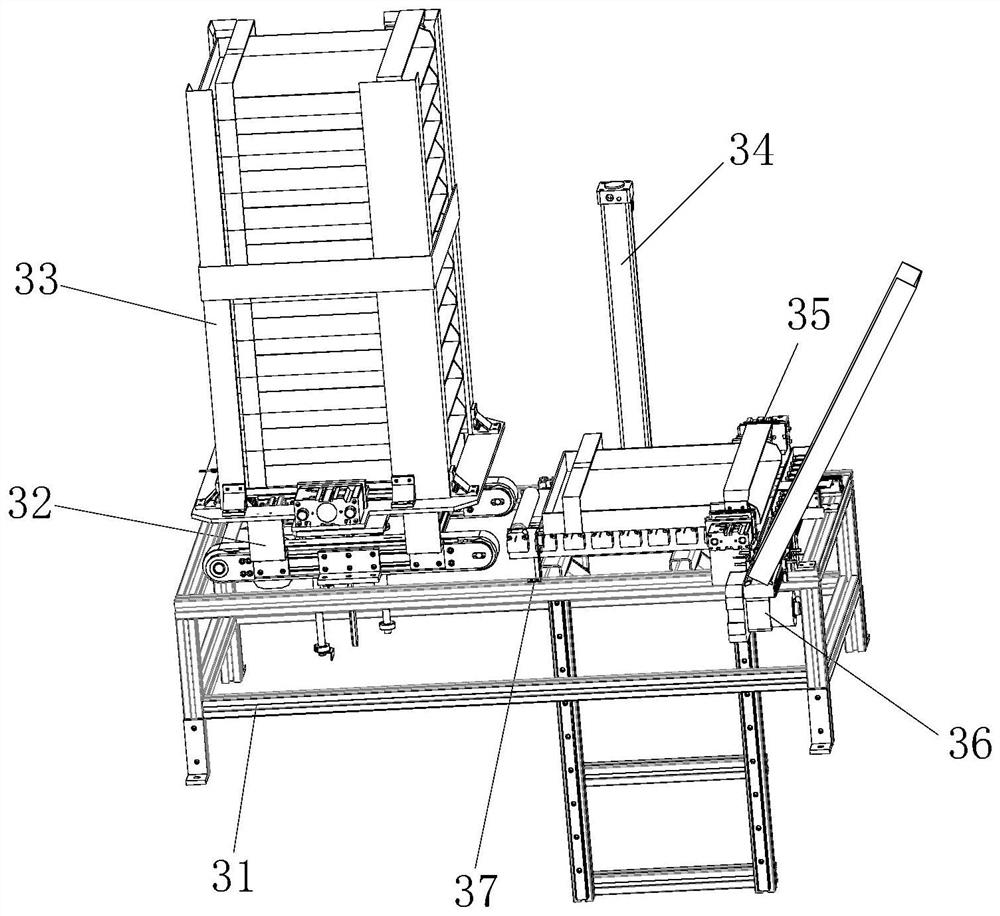

[0068] (1) Manually stack and place the empty turnover boxes 335 in the empty box bin 33 after scanning the two-dimensional code. The empty turnover boxes 335 are separated by the separation and conveying mechanism 32 and transported to the electric roller table 345 of the box loading and lowering assembly 34 superior;

[0069] (2), then position the positioning hole 3356 and the rotation hole 3358 on the turnover box 335 of the positioning closing assembly 35, the feeding assembly 36 arranges the products and packs them in the turnover box 335, and the positioning closing assembly 35 on the turnover box 335 after filling up The movable plate 3351 rotates 90 degrees so that the movable plate 3351 blocks the product and prevents the product from falling, and then the positioning cylinder 352 of the door ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com