Liquid crystal screen defect on-line detection system for intelligent factory

A detection system and liquid crystal screen technology, applied in the direction of comprehensive factory control, comprehensive factory control, general control system, etc., can solve the problems of inability to realize intelligent assembly line online detection, fail to meet the requirements of intelligent factories, low detection efficiency, etc., and achieve novel structure , It is convenient for online detection and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

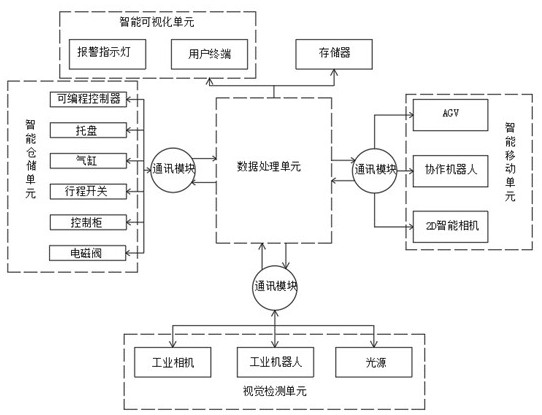

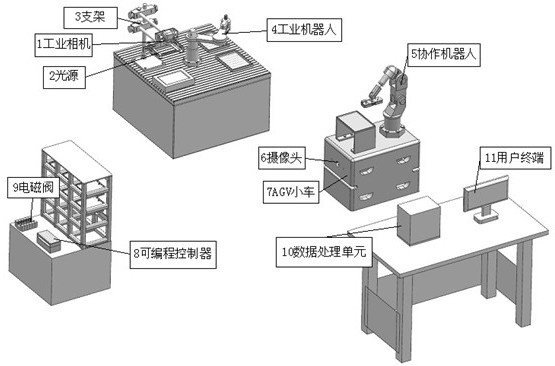

[0021] Attached below Figure 1-2 The specific implementation manner of the present invention will be described in further detail.

[0022] Example, by Figure 1-2 Given, the present invention provides a smart factory-oriented liquid crystal screen defect online detection system, including a data processing unit, an intelligent mobile unit, a visual inspection unit, an intelligent storage unit and an intelligent visualization unit, the data processing unit: including a central processing unit , memory, user terminal and communication module, the central processor is connected to the memory, user terminal and communication module respectively, and placed in the equipment control cabinet uniformly;

[0023] Intelligent mobile unit: including AGV mobile car, collaborative robot, 2D smart camera, mechanical suction cup, control cabinet and mechanical connection structure, in which the collaborative robot is installed on the AGV mobile car and moves together with the AGV mobile ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com