Planetary gear spherical surface measuring device

A technology for planetary gears and measuring devices, applied in measuring devices, mechanical measuring devices, mechanical devices, etc., can solve problems such as not suitable for online detection, achieve objective measurement results, simple detection structure, and easy detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to accompanying drawing.

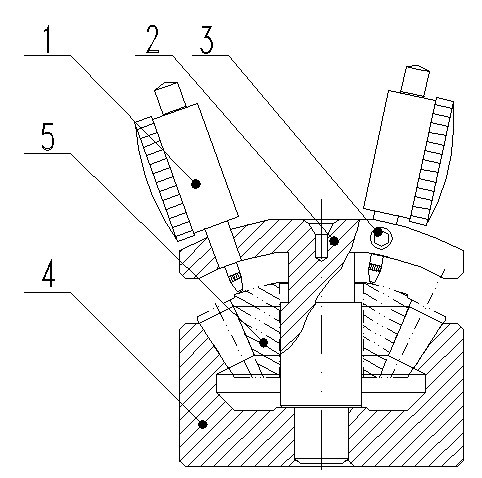

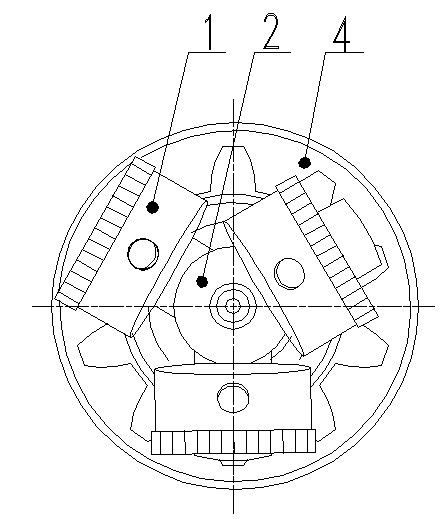

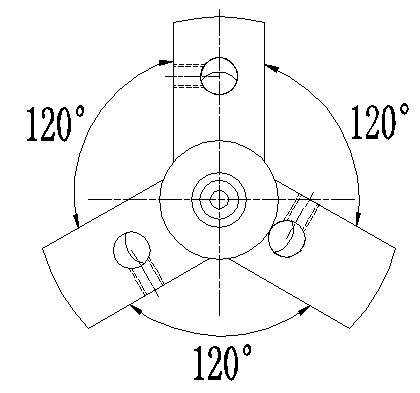

[0017] figure 1 The planetary gear spherical surface measuring device shown includes a dial indicator 1, a table frame 2, a screw 3 and a tooth mold 4. The tooth mold base 4 is a bevel gear positioning member inside, and the bevel gear gear placed flat on the top is positioned to install the planetary gear 5 to be inspected with the spherical surface facing upwards. round hole. figure 1 , image 3 The table frame 2 shown is an umbrella-shaped frame member, the top is a spherical trifurcated strip, and the bottom is connected by a vertical shaft. 5 inner hole clearance fit. figure 2 , Figure 4 The spherical surface at the top of the shown table frame 2 is concentric with the spherical surface of the planetary gear 5 to be checked on the tooth mold base 4, and each fork bar is provided with a through hole for installing a dial gauge 1. figure 1 , image 3 The through-holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com