Cyclic preparation method for lithium battery positive electrode material

A technology for positive electrode materials and recycling preparation, which is applied in the direction of battery electrodes, positive electrodes, battery recycling, etc., can solve the problems that the extractant cannot be recycled and the performance of positive electrode materials is low, so as to facilitate efficient recycling, realize full utilization, and realize recycling The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

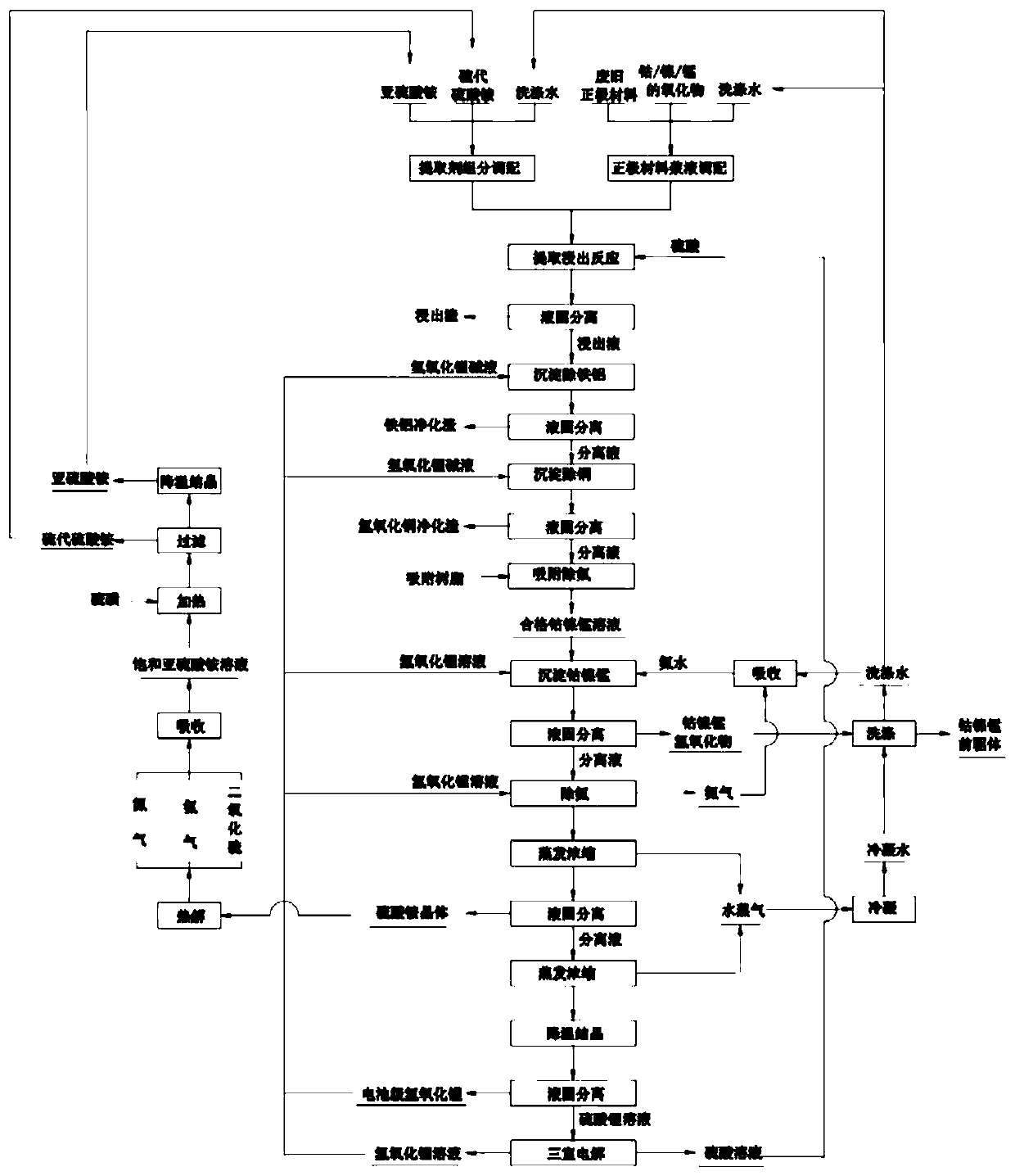

Method used

Image

Examples

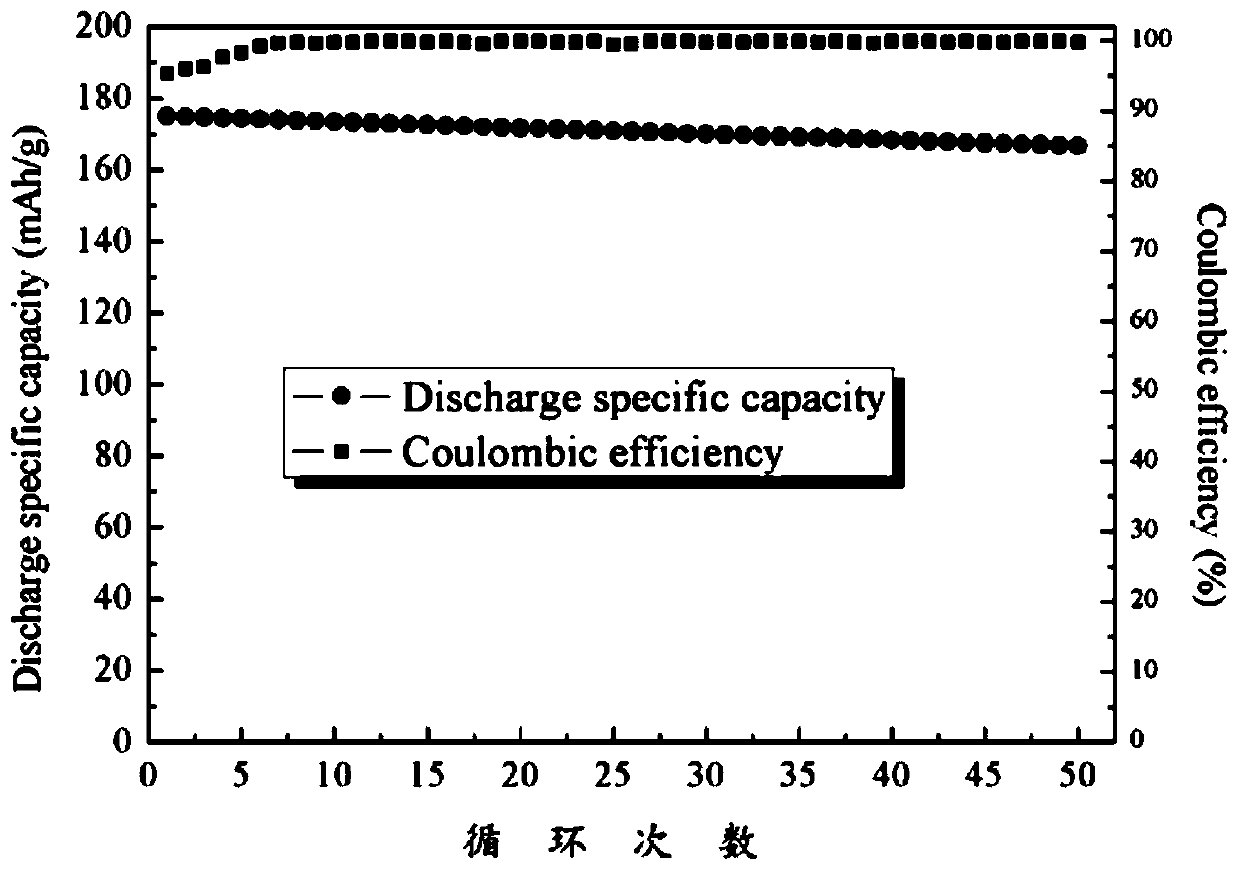

Embodiment 1

[0041] A cyclic preparation method for a lithium battery positive electrode material, comprising the following steps: wherein, the positive electrode material is a 523-type ternary positive electrode material;

[0042] (1) Crushing and sieving waste positive electrode materials to obtain granular materials with a particle size of 80 meshes, adding cobalt dioxide, nickel dioxide, manganese dioxide and washing water to the granular materials, and mixing to obtain positive electrode material slurry, the positive electrode The liquid-solid mass ratio in the slurry is 2:1; the molar ratio of nickel, cobalt and manganese in the positive electrode slurry is 5:2:3;

[0043] (2) Take ammonium sulfite and ammonium thiosulfate, mix them evenly, then add washing water to it and stir to obtain an extractant, wherein the molar ratio of ammonium sulfite to ammonium thiosulfate is 0.05:1, and sulfurous acid The ratio of the total moles of ammonium and ammonium thiosulfate to the total moles o...

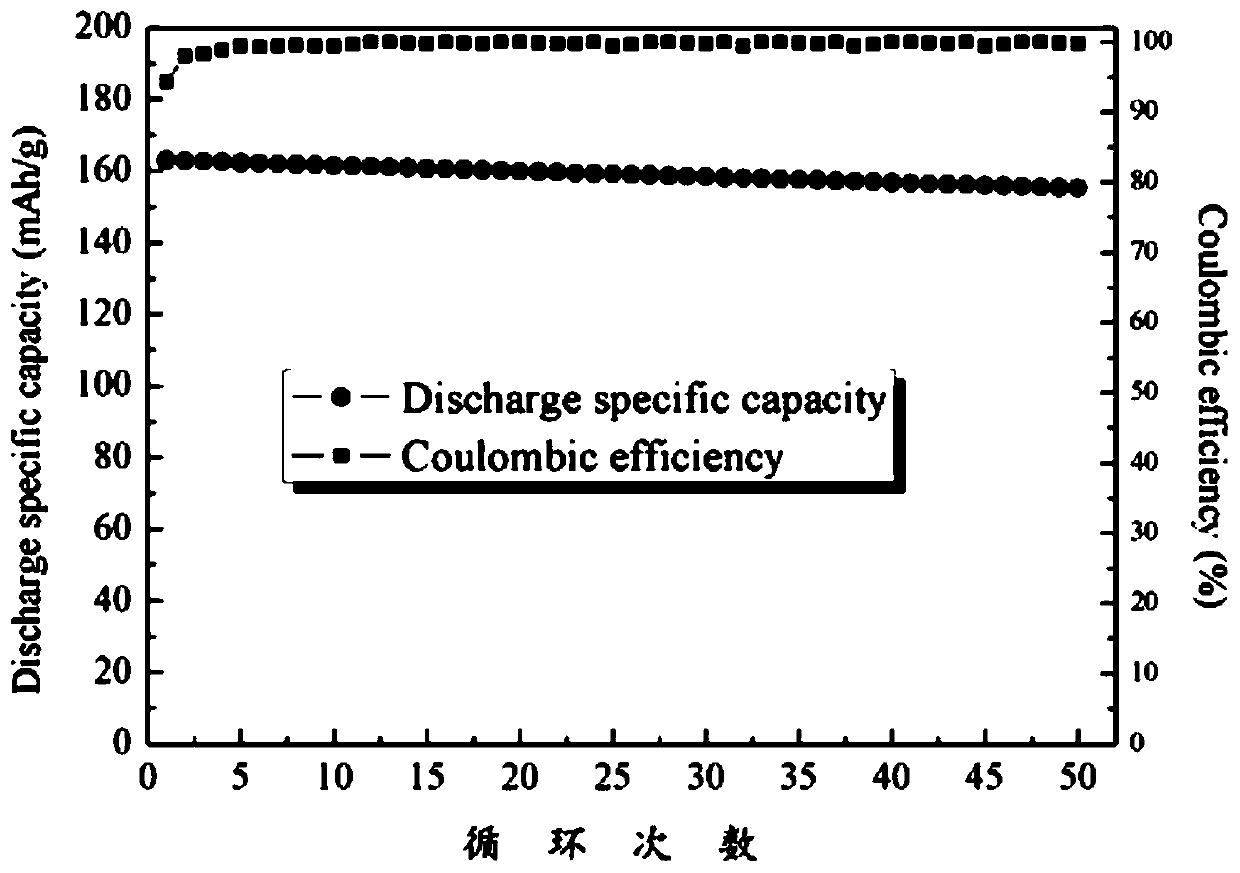

Embodiment 2

[0054] A method for cyclic preparation of a lithium battery positive electrode material, comprising the following steps: wherein, the positive electrode material is a 111-type ternary positive electrode material;

[0055] (1) Crushing and sieving waste positive electrode materials to obtain granular materials with a particle size of 200 mesh, adding tricobalt tetroxide, nickel dioxide, trimanganese tetraoxide and washing water to the granular materials, and mixing to obtain positive electrode material slurry, the positive electrode material The liquid-solid mass ratio in the slurry is 15:1; the molar ratio of nickel, cobalt and manganese in the positive electrode slurry is 1:1:1;

[0056] (2) Take ammonium sulfite and ammonium thiosulfate, mix them evenly, then add washing water to it and stir to obtain an extractant, wherein the molar ratio of ammonium sulfite to ammonium thiosulfate is 1:1, and sulfurous acid The ratio of the total moles of ammonium and ammonium thiosulfate ...

Embodiment 3

[0067] A method for cyclic preparation of a lithium battery positive electrode material, comprising the following steps: wherein, the positive electrode material is a 622-type ternary positive electrode material;

[0068] (1) Crushing and sieving waste positive electrode materials to obtain granular materials with a particle size of 160 mesh, adding tricobalt tetroxide, nickel dioxide, manganese dioxide and washing water to the granular materials, and mixing to obtain a positive electrode material slurry, the positive electrode material slurry The liquid-solid mass ratio in the positive electrode slurry is 3:1; the molar ratio of nickel, cobalt and manganese in the positive electrode slurry is 6:2:2;

[0069] (2) Take ammonium sulfite and ammonium thiosulfate, mix them evenly, then add washing water to it and stir to obtain an extractant, wherein the molar ratio of ammonium sulfite to ammonium thiosulfate is 0.2:1, and sulfurous acid The ratio of the total moles of ammonium an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com