Negative pressure strengthened multi-stage laminated disc type solar energy distillation system for desalination

A technology of distillation and desalination and solar energy, which is applied in the field of solar distillation and brackish water desalination, can solve the problems of large power consumption, high cost, and the membrane is easily affected by pollution and scaling, so as to reduce the cost of water production, save costs, The effect of excellent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

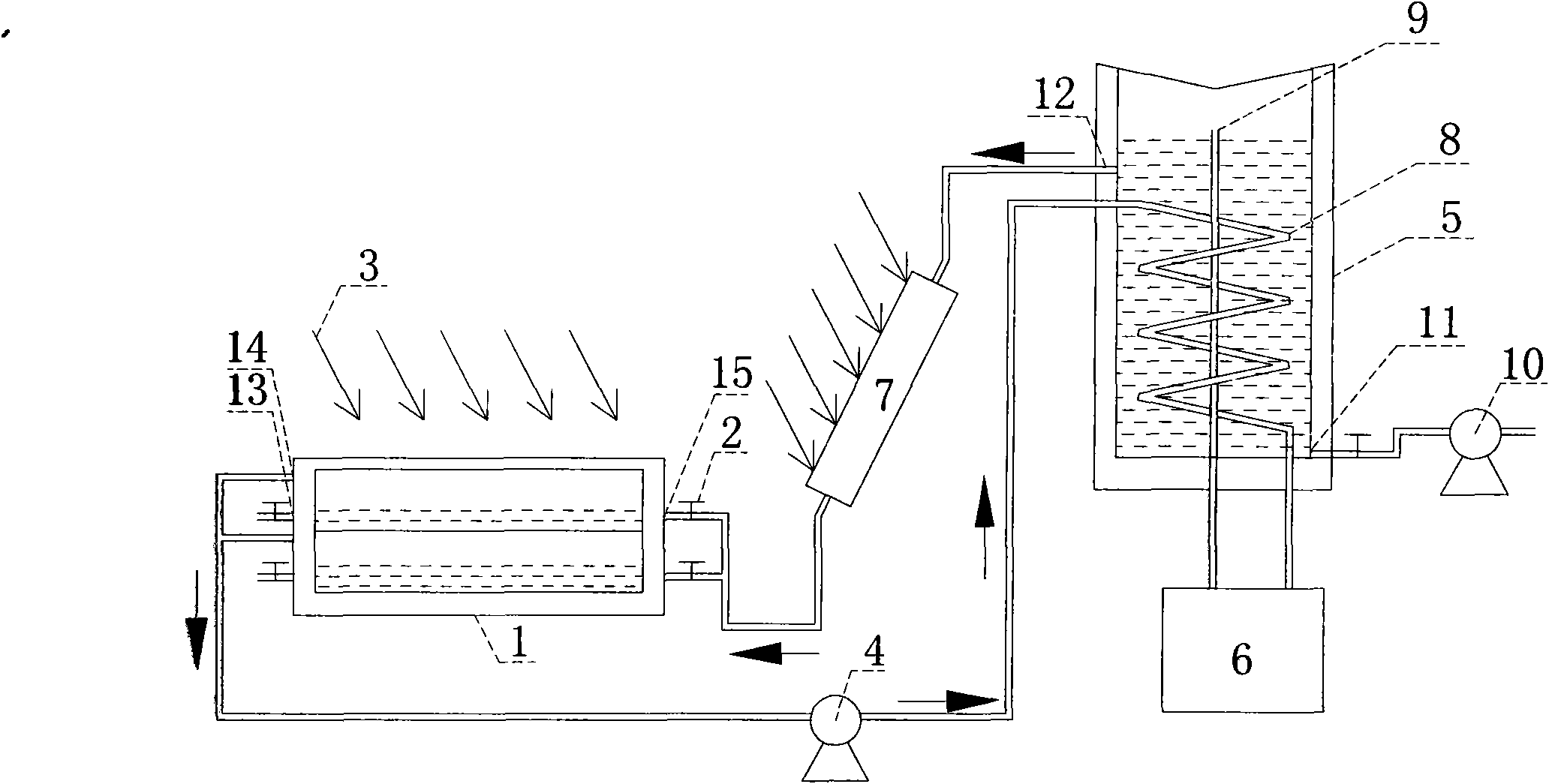

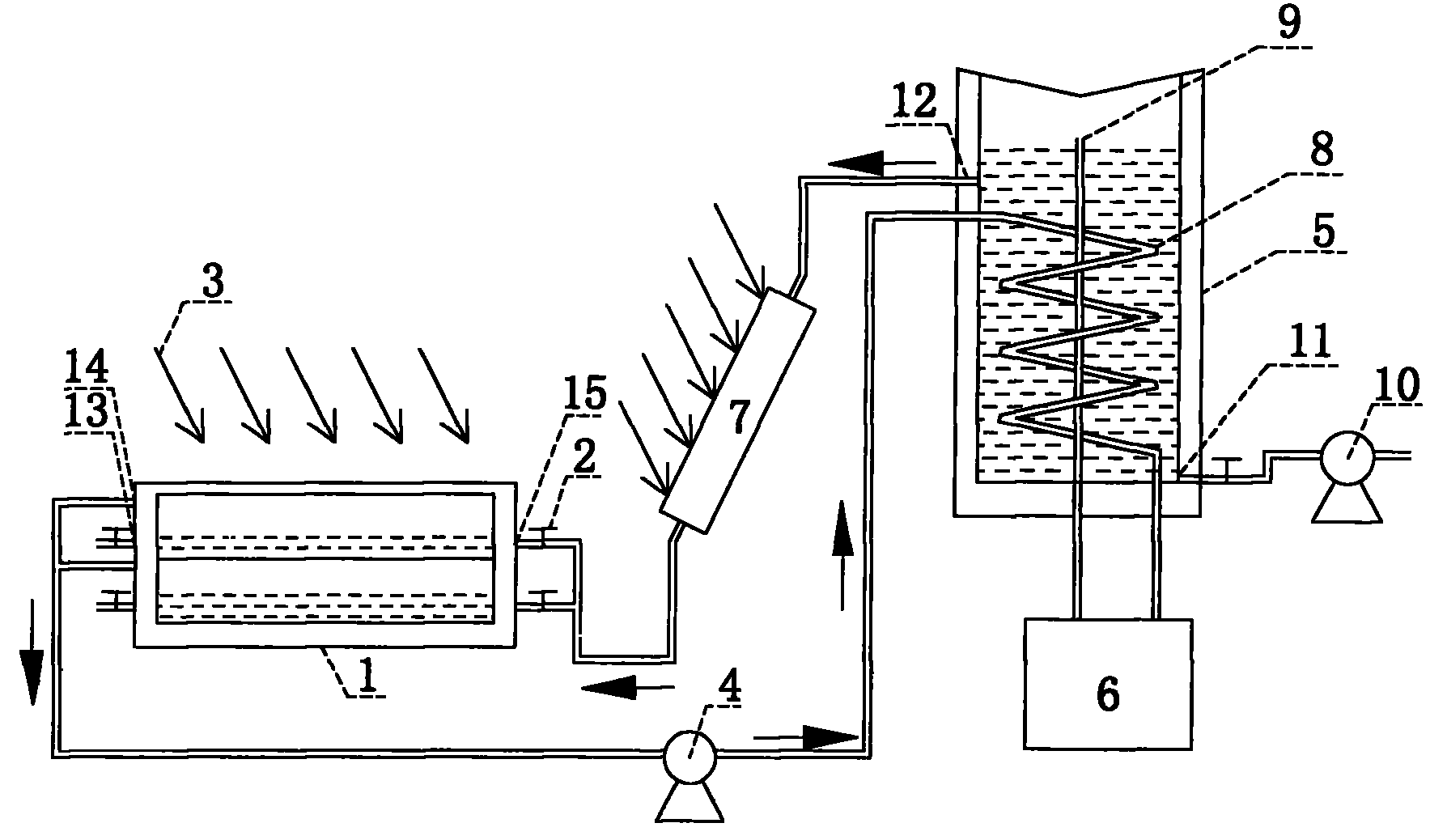

[0017] Example 1: Water production test of a single-stage stacked disc system at different temperatures.

[0018] The distillation stack adopts a single-stage form, and the constant temperature brine (salt content is 10g / L) with a water temperature of 45°C, 50°C, 55°C, 60°C, and 65°C is successively passed through to test the dynamic water production rate, and the test suction pressure Both are 0.045Mpa. It is measured above 60°C and run for 20 hours a day. The water production rate can reach 241L / d, and the conductivity of the effluent water is 85μs / cm.

example 2

[0019] Example 2: Water production test of the two-stage stacked disc system at different temperatures.

[0020] The distillation stack adopts the two-level form of the upper and lower stacked plates, which are sequentially fed with constant temperature brine (salt content: 10g / L) with water temperatures of 45°C, 50°C, 55°C, 60°C, and 65°C for dynamic distillation. For the water production test, the experimental suction pressure is 0.045Mpa. It is measured that the water production rate can reach 368L / d and the conductivity of the effluent water is 72μs / cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com