Surface water desalting apparatus by-producing saline waste water treatment method

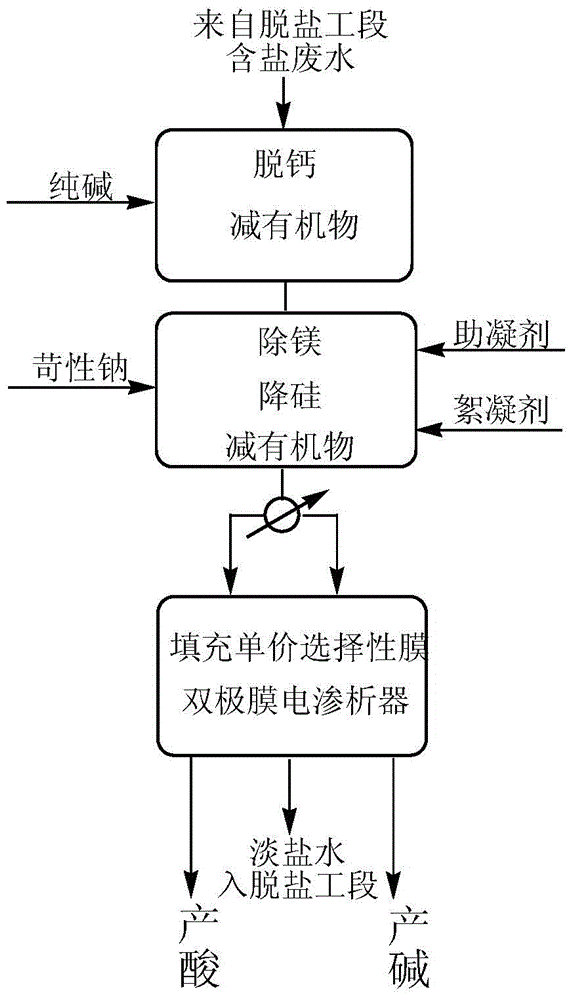

The technology of a desalination device and a treatment method is applied in the field of treatment of by-product salt-containing wastewater from desalination of surface water, which can solve the problems of high treatment cost and low treatment capacity, and achieve the effects of high treatment capacity, low treatment cost and pollution avoidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A company adopts ion exchange method to desalinate surface water to produce water for production. The content of heavy metal ions and suspended solids in the by-product saline wastewater is relatively small, and the typical main composition of the water sample is: Na + 158.48±50mmol / L, Ca 2+ 21.764±15mmol / L, Mg 2+ 7.83±5mmol / L, SO 4 2- 2.92±2mmol / L, NO 3 - 1.22±1mmol / L, Cl - 222.50±70mmol / L, silicon content (as SiO 2 meter) is 1.15±1mmol / L; alkalinity (HCO 3 - and CO 3 2- ) is 1.84±1.5mmol / L; UV 254 It is 1.857; the pH of the system is 7.10; the conductivity is 20±5ms / cm. The following methods are used to treat and recycle the saline wastewater:

[0022] The first step is preprocessing. For the water sample with the above average composition, firstly, the wastewater is pumped into the fluidized pellet reactor (the filler is garnet sand, the particle size is controlled to be 150 μm-200 μm, and the ratio of the filling height to the reactor under no flow con...

Embodiment 2

[0026] A company uses reverse osmosis to desalinate surface water to produce water for production. The content of heavy metal ions and suspended solids in the by-product saline wastewater is relatively small, and the typical main composition of the water sample is: Na + 65±15mmol / L, Ca 2+ 2.4±1mmol / L, Mg 2+ 0.5±0.3mmol / L, SO 4 2- 3.3±2mmol / L, NO 3 - 2.9±1mmol / L, Cl - 72.7±20mmol / L, silicon content (as SiO 2 meter) is 1.5±0.5mmol / L; alkalinity (HCO 3 - and CO 3 2- ) is 4.5±1.5mmol / L; UV 254 It is 1.729; the pH of the system is 7.10; the conductivity is 10.5±2ms / cm. The following methods are used to treat and recycle the saline wastewater:

[0027] The first step is preprocessing. For the water sample with the above average composition, firstly, the waste water is pumped into the fluidized pellet reactor (the filler is garnet sand, the particle size is controlled to be 220μm-260μm, and the ratio of the filling height to the reactor in the case of no flow is 1:4 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy consumption | aaaaa | aaaaa |

| Energy consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com