Coal ash resource treating method

A treatment method and resource recovery technology, applied in the field of coal ash resource recovery, can solve problems such as inconvenience, lack of appropriateness, unstable quality of coal ash, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

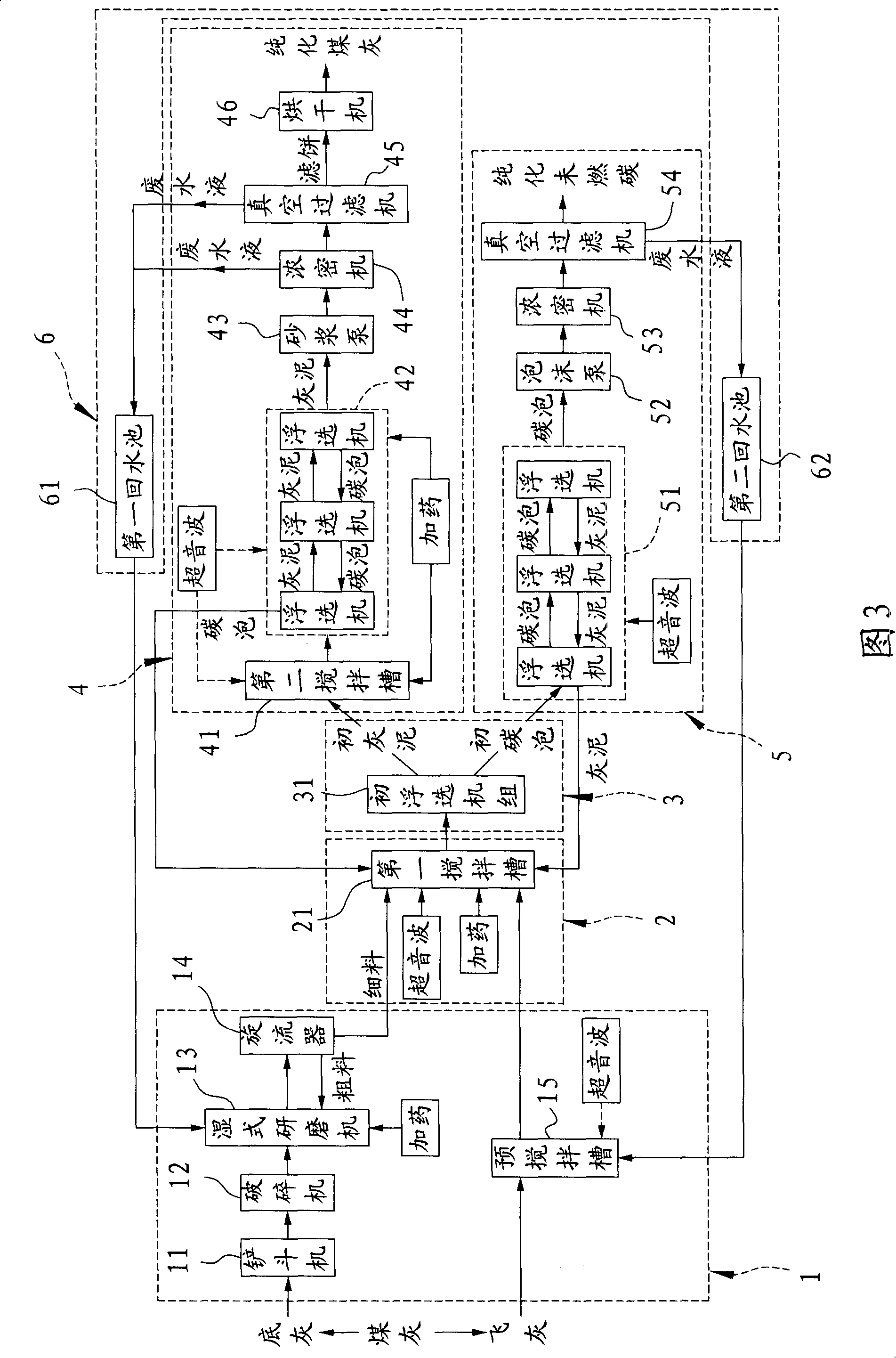

[0028] In order to further explain the technical means and effects that the present invention adopts to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation methods, methods, steps, Features and their functions are described in detail below.

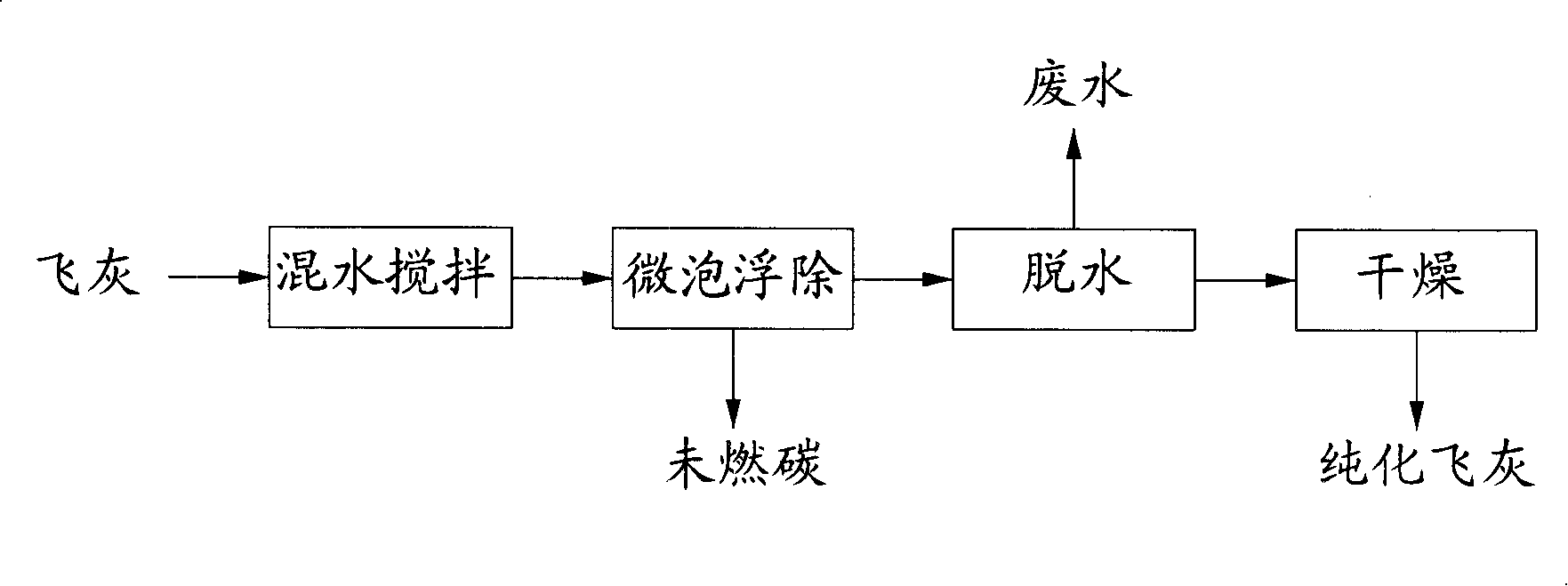

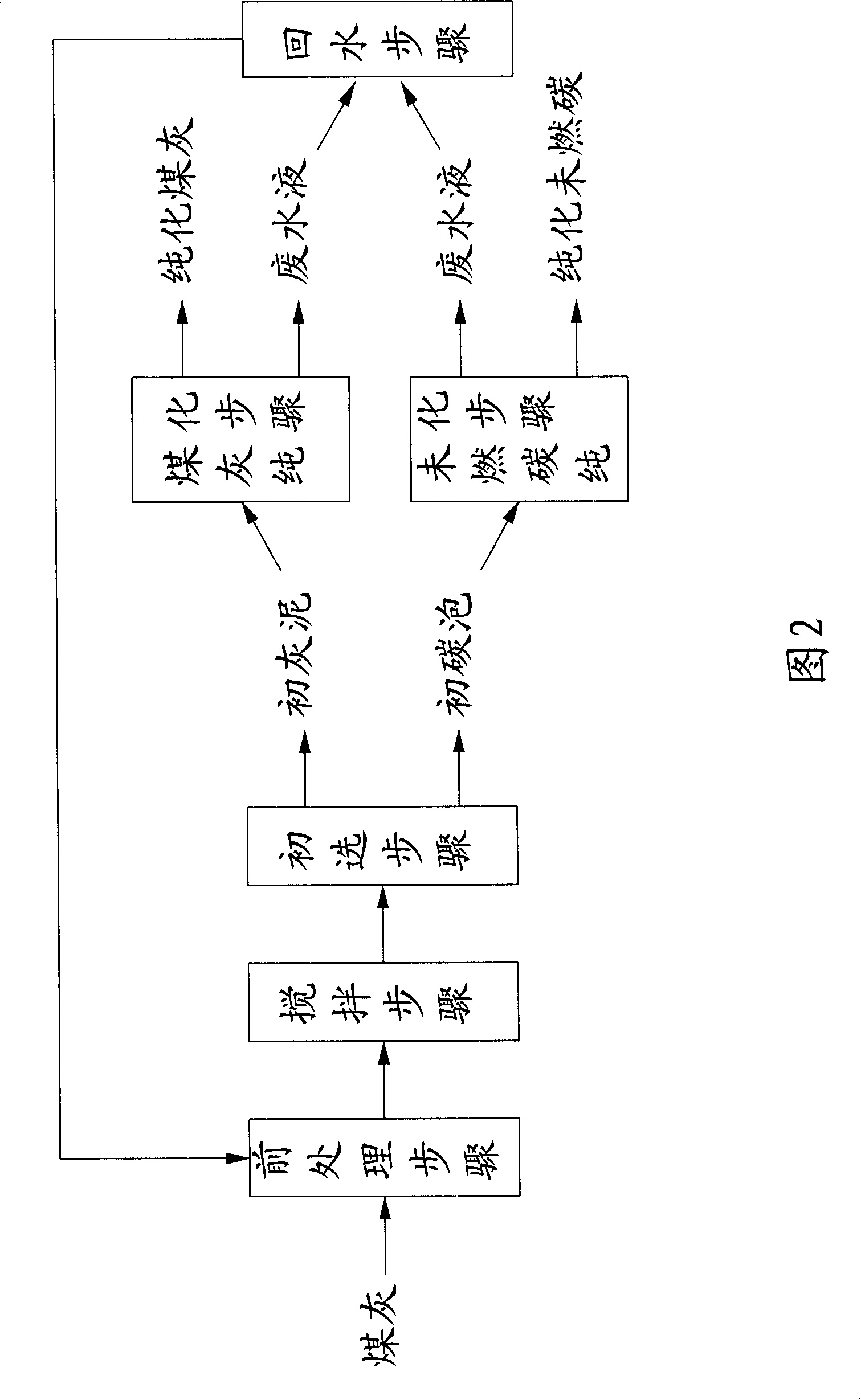

[0029] Please refer to Fig. 2 and Fig. 3 first, the coal ash recycling treatment method of the preferred embodiment of the present invention is used to recover high-purity coal ash and unburned carbon, and includes a pretreatment step 1 and a stirring step 2. A primary selection step 3, a coal ash purification step 4, an unburned carbon purification step 5, and a return water step 6.

[0030] In the pretreatment step 1, firstly, the coal ash is inspected and screened to obtain fly ash and bottom ash. As for the bottom ash part, a bucket machine 11 is used to shovel it into a crusher 12 for crushing, and then feed it into a wet grinder 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com