Recycling treatment method for salt-containing wastewater

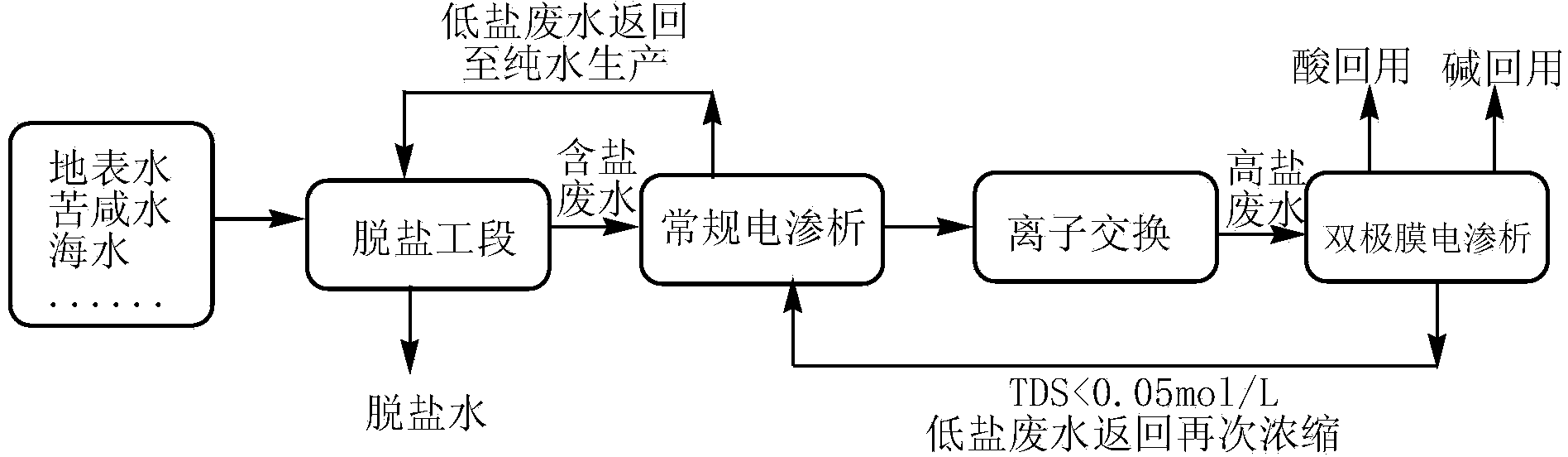

A technology for saline wastewater and treatment methods, which is applied in the field of resource treatment of saline wastewater, can solve the problems of wasting production capacity of bipolar membrane electrodialysis equipment and the complexity of control process, and achieve convenient operation control process and pretreatment work High efficiency and reduction of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A chemical company in Shanghai used ion exchange to desalinate surface water to produce water for production. According to long-term observation, the content of heavy metal ions and suspended solids in the by-product saline wastewater is relatively small, and the typical composition of the water sample is: Na + 158.48±50 mmol / L, Ca 2+ 21.764±15 mmol / L, Mg 2+ 7.83±5 mmol / L, SO 4 2- 2.92±2 mmol / L, NO 3 - 1.22±1 mmol / L, Cl - 222.50±70 mmol / L, silicon content (as SiO 2 meter) is 1.15±1 mmol / L; alkalinity (HCO 3 - and CO 3 2- ) is 1.84±1.5 mmol / L; UV 254 is 1.857; the pH of the system is 7.10; the conductivity is 20±5 ms / cm.

[0020] The first step is preprocessing. The saline wastewater from the plant's neutralization tank is directly pumped into a conventional electrodialyzer filled with monovalent selective separation membranes (Japan, SELEMION membrane, monovalent selective positive membrane CSO and monovalent selective negative membrane ASV) . Each elect...

Embodiment 2

[0024] A chemical company in Sichuan used reverse osmosis to desalinate surface water to produce water for production. According to long-term observation, the content of heavy metal ions and suspended solids in the by-product saline wastewater is relatively small, and the typical composition of the water sample is: Na + 65±15 mmol / L, Ca 2+ 2.4±1 mmol / L, Mg 2+ 0.5±0.3 mmol / L, SO 4 2- 3.3±2 mmol / L, NO 3 - 2.9±1 mmol / L, Cl - 72.7±20 mmol / L, silicon content (as SiO 2 meter) is 1.5±0.5 mmol / L; alkalinity (HCO 3 - and CO 3 2- ) is 4.5±1.5 mmol / L; UV 254 is 1.729; the pH of the system is 7.10; the conductivity is 10.5±2 ms / cm.

[0025] The first step is preprocessing. The waste water produced by the pure water production process is directly pumped into a conventional electrodialyzer filled with monovalent selective separation membranes (Japan, SELEMION membrane, monovalent selective positive membrane CSO and monovalent selective negative membrane ASV). Each electrodialy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com