Rubbish penetrating fluid treatment method

A technology of waste permeate and treatment method, which is applied in the field of waste permeate treatment, which can solve the problems of high water production cost, complicated operation and complicated process, and achieve the effect of low water production cost, simple operation and high treatment degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

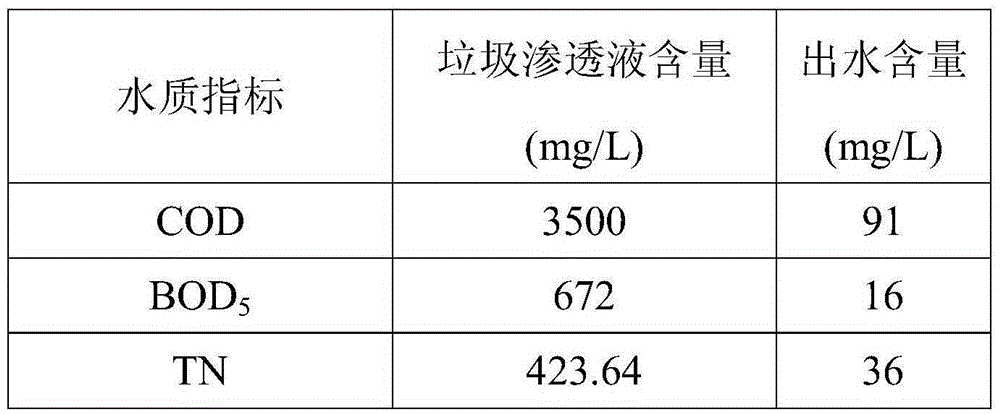

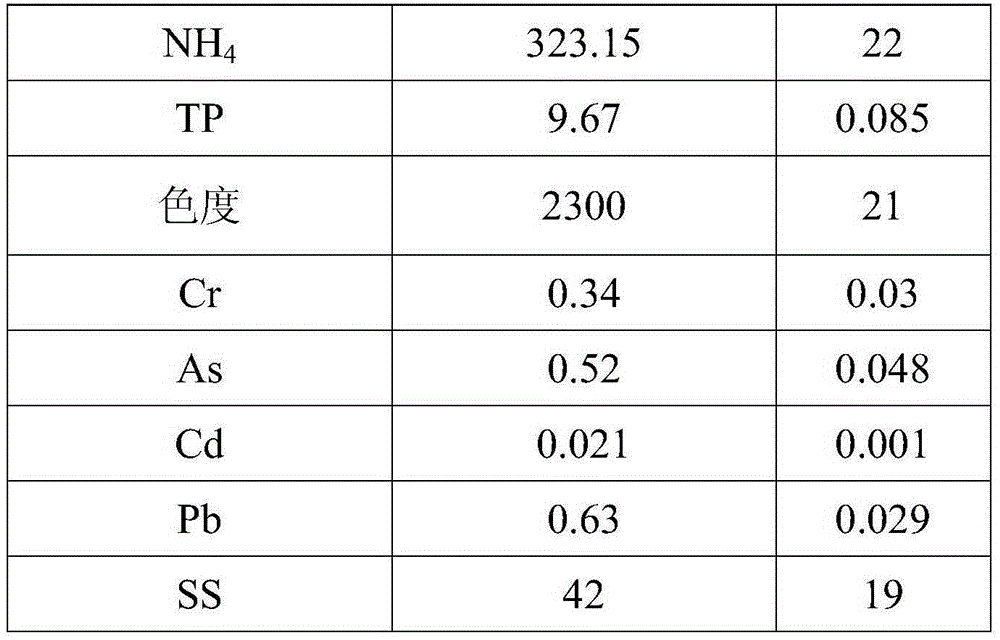

Embodiment 1

[0031] A treatment method for garbage permeate, comprising the following steps:

[0032] Step 1. Flocculation and sedimentation treatment: Send 1000L of garbage permeate into the flocculation sedimentation tank, which adopts a flat flow sedimentation tank, and controls the average flow rate in the sedimentation tank to be 25-50mm / s; then add 30L mass fraction of 2% quaternary ammonium cationic polymer compound solution as decolorizer, 20L concentration of 20g / L polyaluminum chloride solution and 10L mass fraction of 0.1% polyacrylamide solution, fully stirred and mixed, let stand 1 hour.

[0033] Step 2, Fenton oxidation treatment: Send the supernatant I obtained after step 1 to stand still into the Fenton pool, then add sulfuric acid to the supernatant I, and adjust the pH value of the supernatant I to 3; Add 10L mass fraction of 30% hydrogen peroxide solution and 10L concentration of 50g / L FeSO 4 ·7H 2 O aqueous solution, stirred thoroughly to mix the reaction, and then s...

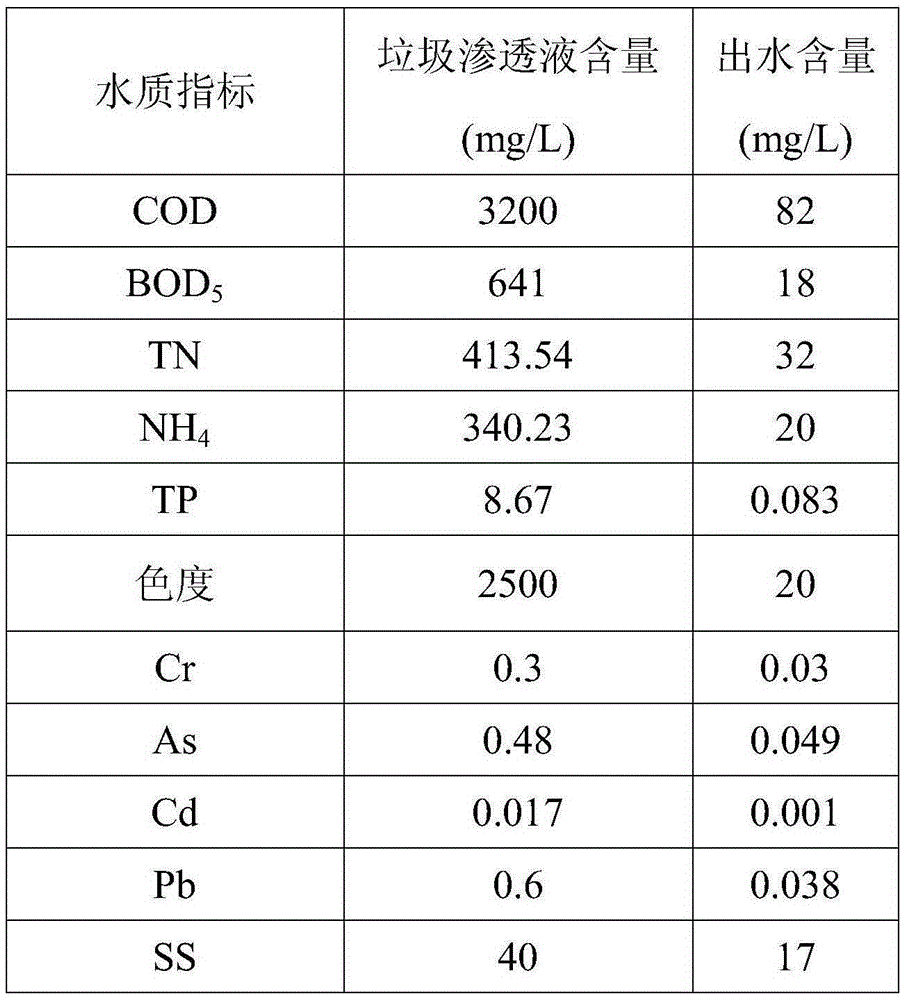

Embodiment 2

[0041] A treatment method for garbage permeate, comprising the following steps:

[0042] Step 1. Flocculation and sedimentation treatment: Send 2000L of garbage permeate into the flocculation sedimentation tank, which adopts a flat flow sedimentation tank, and controls the average flow rate in the sedimentation tank to be 10-25mm / s; then add 60L mass fraction is 2% quaternary ammonium type cationic macromolecular compound solution as decolorizer, 40L concentration is 40g / L polyaluminum chloride solution and 20L mass fraction is 0.1% polyacrylamide solution, fully stir and mix, let stand 1 hour.

[0043]Step 2, Fenton oxidation treatment: send the supernatant I obtained after standing in step 1 into the Fenton pool, then add sulfuric acid to the supernatant I, and adjust the pH value of the supernatant I to 3; Add 20L mass fraction of 30% hydrogen peroxide solution and 20L concentration of 50g / L FeSO 4 ·7H 2 O aqueous solution, stirred thoroughly to mix the reaction, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com