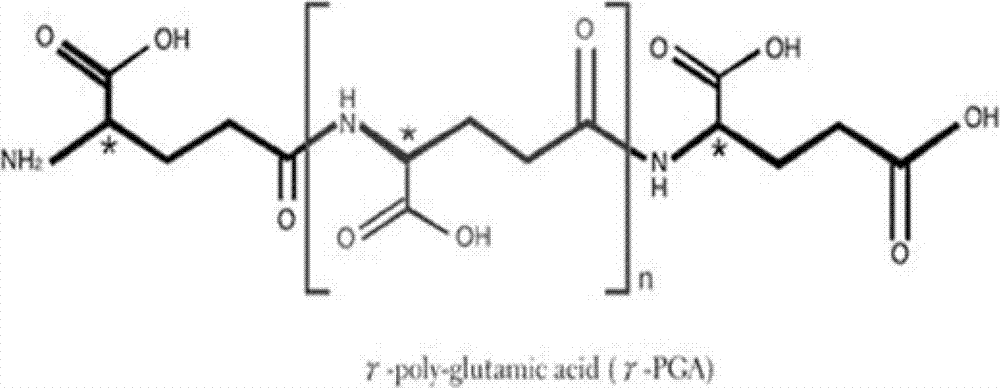

Liquid compound microbial fertilizer containing polyglutamic acid, and preparation method and application thereof

A technology of compound microorganisms and polyglutamic acid, which is applied in the direction of application, fertilizer mixture, fertilization device, etc., can solve the problems that have not yet appeared in the invention of combining polyglutamic acid and compound microbial bacterial fertilizer, and achieve the purpose of improving crop production stimulating substances, inhibiting Vitality, effect of increasing plant height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]Put the seed liquids of Bacillus megaterium, Bacillus thuringiensis, and Bacillus amyloliquefaciens into the fermentation medium respectively, ferment for 20 hours at 37°C, with a rotation speed of 300rpm, and a ventilation ratio of 1:1 to obtain a fermentation liquid, which is fixed with diatomaceous earth, and three The seed solution is mixed at a mass ratio of 1:1:1; the fermentation medium is composed of: by mass percentage, 1% glucose, 0.6% dipotassium hydrogen phosphate, 0.3% potassium dihydrogen phosphate, 0.15% urea, 0.5% Yeast powder, 0.41‰ magnesium sulfate, the rest is water, pH 7.0-7.2;

[0043] The parts by weight of each component of the compound nutrient are: 8 parts of urea, 4 parts of monoammonium phosphate, 4 parts of potassium sulfate, 15 parts of chelated calcium, 7.5 parts of magnesium sulfate, 7.5 parts of chelated magnesium, 3 parts of sodium silicate, sulfuric acid 4 parts of zinc, 4 parts of chelated zinc, 2 parts of manganese sulfate, 2 parts of...

Embodiment 2

[0048] The fermentation preparation of microbial bacterial liquid is basically the same as embodiment 1;

[0049] The parts by weight of each component of the compound nutrient are: 8 parts of urea, 4 parts of monoammonium phosphate, 4 parts of potassium sulfate, 80 parts of potassium dihydrogen phosphate, 15 parts of chelated calcium, 7.5 parts of magnesium sulfate, 7.5 parts of chelated magnesium, silicon 3 parts of sodium sulfate, 4 parts of zinc sulfate, 4 parts of chelated zinc, 2 parts of manganese sulfate, 2 parts of chelated manganese, 8 parts of boric acid, 8 parts of chelated iron, 4 parts of chelated copper, 0.5 parts of humic acid, soybean peptone 5 parts, 3 parts of compound amino acid, 5 parts of wheatgrass powder;

[0050] The parts by weight of each component of the compound amino acid are: 5 parts of alanine, 10 parts of arginine, 5 parts of aspartic acid, 3 parts of cystine, 2 parts of glutamic acid, 2 parts of glycine, histamine 3 parts of acid, 10 parts of...

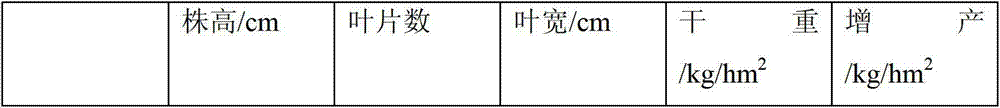

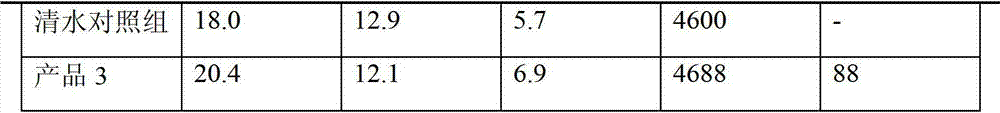

Embodiment 3

[0053] The fermentation preparation of microbial bacterial liquid is basically the same as embodiment 1;

[0054] The parts by weight of each component of the compound nutrient are: 88 parts of urea, 4 parts of monoammonium phosphate, 4 parts of potassium sulfate, 15 parts of chelated calcium, 7.5 parts of magnesium sulfate, 7.5 parts of chelated magnesium, 3 parts of sodium silicate, 4 parts of zinc, 4 parts of chelated zinc, 2 parts of manganese sulfate, 2 parts of chelated manganese, 8 parts of boric acid, 8 parts of chelated iron, 4 parts of chelated copper, 0.5 parts of humic acid, 5 parts of soybean peptone, 3 parts of compound amino acids parts, 10 parts of wheatgrass powder;

[0055] The parts by weight of each component of the compound amino acid are: 5 parts of alanine, 10 parts of arginine, 5 parts of aspartic acid, 3 parts of cystine, 2 parts of glutamic acid, 2 parts of glycine, histamine 3 parts of acid, 10 parts of lysine, 3 parts of methionine, 5 parts of phen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com