Sludge organic fertilizer and preparation method thereof

A technology of organic fertilizer and sludge, applied in the field of fertilizers, can solve the problems of malodorous mosquitoes and flies, pollute the environment, etc., achieve the effects of improving yield and quality, solving environmental pollution problems, and high fertilizer utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

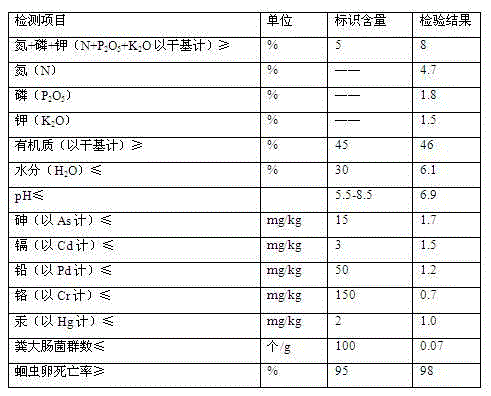

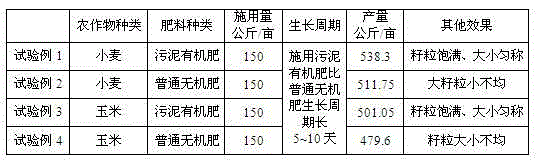

Image

Examples

Embodiment 1

[0023] A sludge organic fertilizer made of the following raw materials by weight: 100 parts of sludge, 2 parts of fly ash, 0.1 part of organic fertilizer starter, 0.5 part of quicklime, 20 parts of urea, 20 parts of monoammonium phosphate, chlorinated 15 parts of potassium, 20 parts of humic acid, 20 parts of clay.

[0024] The organic fertilizer starter comes from Kangyuan Oasis Biotechnology Co., Ltd. or Cangzhou Wang Biotechnology Research Institute Co., Ltd.

[0025] The humic acid comes from the lignite weathered coal humic acid organic matter provided by Zigong Huahao Industrial Co., Ltd.

[0026] The above-mentioned preparation method of sludge organic fertilizer includes the following steps:

[0027] (1) Mix 20kg of fly ash per ton of sludge, and then transport it to the sludge drying field for drying. When drying, use a turning and throwing machine for multiple times to reduce the moisture content of the sludge to 50%. When the rate is 50%, it is most suitable for the reprod...

Embodiment 2

[0032] A sludge organic fertilizer made of the following raw materials by weight: 90 parts of sludge, 2.5 parts of fly ash, 0.05 parts of organic fertilizer starter, 0.4 parts of quicklime, 10 parts of urea, 5 parts of monoammonium phosphate, chlorinated 4 parts of potassium, 40 parts of humic acid, 25 parts of clay.

[0033] The above-mentioned sludge organic fertilizer was prepared with reference to the method of Example 1, except that in step (2), forced ventilation was performed for 10 days for aerobic fermentation, and step (3) was for anaerobic fermentation for 12 days.

Embodiment 3

[0035] A sludge organic fertilizer, made of the following raw materials by weight: 110 parts of sludge, 1.5 parts of plant ash, 0.15 parts of organic fertilizer starter, 0.6 parts of quicklime, 30 parts of urea, 15 parts of monoammonium phosphate, and 10 parts of potassium chloride Parts, 30 parts of humic acid, 23 parts of clay.

[0036] The above-mentioned sludge organic fertilizer was prepared by referring to the method of Example 1, except that in step (2), forced ventilation was carried out for 12 days for aerobic fermentation, and in step (3), anaerobic fermentation was carried out for 8 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com