Ex-situ catalytic pyrolysis liquefaction system for biomass

A technology of catalytic pyrolysis and liquefaction system, applied in the field of biomass ex-situ catalytic pyrolysis and liquefaction system, can solve the problems of difficult separation of fluidized medium and catalyst, not being widely used and popularized, and high operating cost against gravity field, Achieve the effect of reducing coking inactivation, saving economic costs and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

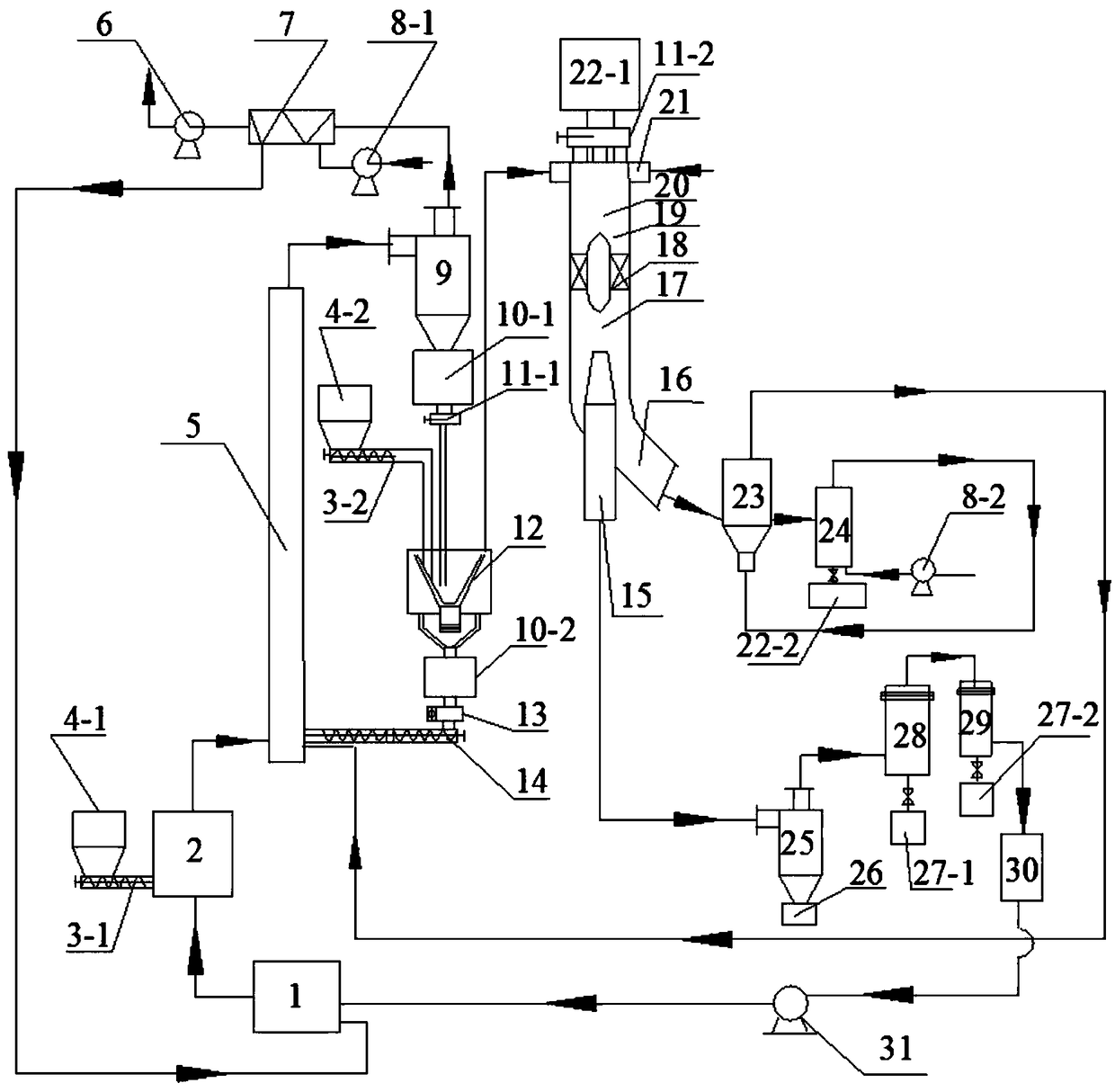

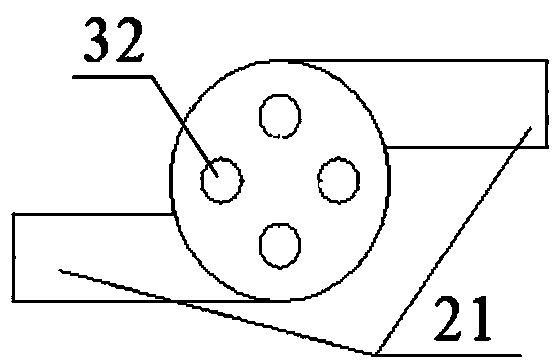

[0028] Such as figure 1 , figure 2 As shown, a biomass ex-situ catalytic pyrolysis liquefaction system includes a gasifier 2, a riser heater 5, a rotating cone reactor 12, a diversion cyclone reactor 19, a catalyst regeneration system, and a gas-solid separator 25 and condensing system.

[0029] The bottom of the gasifier 2 is connected to the first biomass feeder 3-1, the first biomass feeder 3-1 is connected to the first biomass hopper 4-1, the upper part of the gasifier 2 is connected to the riser heater The lower part of 5 is connected by a gas phase pipeline, the quartz sand feeder 14 is connected with the lower part of the riser heater 5, and the quartz sand feeder 14 is a screw feeder. The upper part of the riser heater 5 is connected to the inlet of the quartz sand separator 9, the lower part of the quartz sand separator 9 is connected to the heated sandbox 10-1, and the lower part of the heated sandbox 10-1 is connected to the inlet of the rotary cone reactor 12. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com