Method for preparing vegetable oil-based plasticizer by micro-reaction continuous flow by using amido

A vegetable oil-based and amide-based technology, which is applied in the preparation of carboxylic acid amides, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problem that the miscibility of pure epoxy soybean oil and epoxy resin cannot exert plasticizing performance and instability Migration resistance and volatility of the three-membered ring, etc., to achieve the effects of avoiding intense heat release for a long time, optimizing the synthesis process, and improving mass and heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

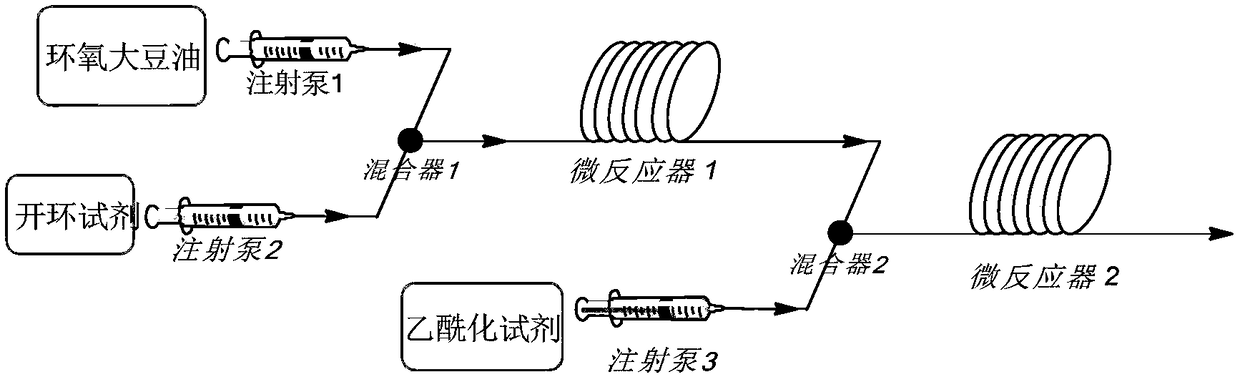

[0036] The preparation steps of the inventive method are:

[0037] Step 1: dissolving epoxidized soybean oil in an organic solvent to obtain a solution A, dissolving an amide ring-opening reagent and a ring-opening reaction catalyst in an organic solvent to obtain a solution B;

[0038] Step 2: The solution A and solution B obtained in step 1 are simultaneously pumped into the first mixer of the micro-reaction device to mix, and then enter the first micro-reactor of the micro-reaction device to react to obtain the ring-opened product of epoxidized soybean oil;

[0039] Step 3: Dissolve the acetylation reagent and acetylation reaction catalyst in an organic solvent to obtain solution C, and simultaneously pump the epoxidized soybean oil ring-opening product obtained in step 2 into the second mixer of the micro-reaction device for mixing, and then enter the micro-reaction The reaction is carried out in the second microreactor of the device, and the reaction product is obtained b...

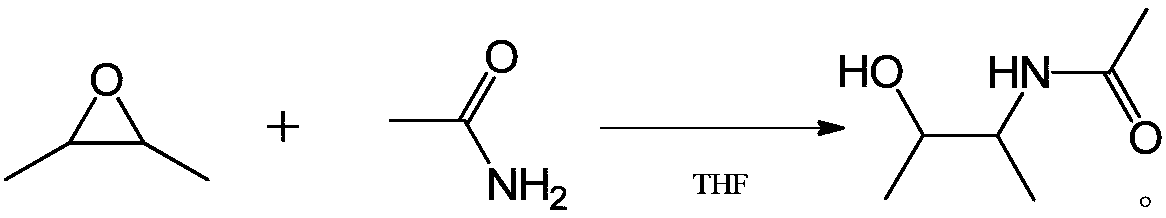

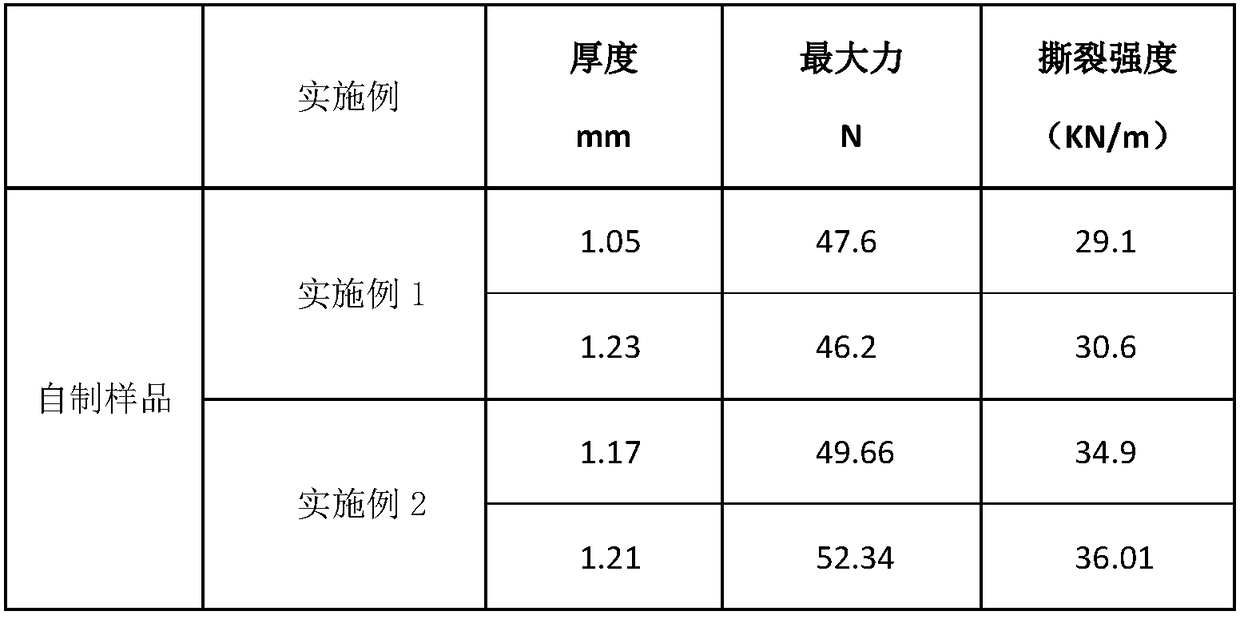

Embodiment 1

[0043] Dilute epoxidized soybean oil with THF as one phase into the syringe pump, dissolve acetamide in THF, add sodium ethoxide as the other phase into the syringe pump, inject the two phases into the microreactor at the same time, and react at 50°C 15min, wherein the mol ratio of epoxy compound and acetamide in epoxy soybean oil is 1:5, two-phase flow velocity is respectively 0.146,0.054, and the mol ratio of the epoxy compound in catalyst sodium ethylate and epoxy soybean oil is 0.01: 1. The obtained epoxy soybean oil ring-opening product continues to pass into another section of microreactor, mixed with acetic anhydride and catalyst perchloric acid as another phase, passes through the microreactor, and reacts at 10°C for 15min, wherein the epoxy large The molar ratio of soybean oil ring-opening products to acetic anhydride was 1:5, and the molar ratio of perchloric acid to epoxidized soybean oil ring-opening products was 0.2:1. The pH of the product is adjusted to about 7 ...

Embodiment 2

[0045] Dilute epoxidized soybean oil with THF as one phase into the syringe pump, dissolve acetamide in THF, add sodium ethoxide as the other phase into the syringe pump, inject the two phases into the microreactor at the same time, and react at 100°C 10min, wherein the mol ratio of epoxy compound and acetamide in epoxy soybean oil is 1:10, two-phase flow velocity is respectively 0.176,0.074, the mol ratio of the epoxy compound in catalyst sodium ethylate and epoxy soybean oil is 0.08: 1. The obtained epoxy soybean oil ring-opening product continues to pass into another section of micro-reactor, mixed with acetic anhydride and catalyst perchloric acid as another phase, passes through the micro-reactor, and reacts at 25°C for 10 minutes, wherein the epoxy large The molar ratio of soybean oil ring-opening product to acetic anhydride was 1:10, and the molar ratio of perchloric acid to epoxidized soybean oil ring-opening product was 0.08:1. The pH of the product is adjusted to abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com