Method for preparing nano aluminum/porous copper oxide nano thermite through P4VP self-assembly

A copper oxide and nano-aluminum technology, applied in copper oxide/copper hydroxide, non-explosive/non-thermal agent components, offensive equipment, etc., can solve the problems of poor product consistency, shortened mass transfer distance of reactants, and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

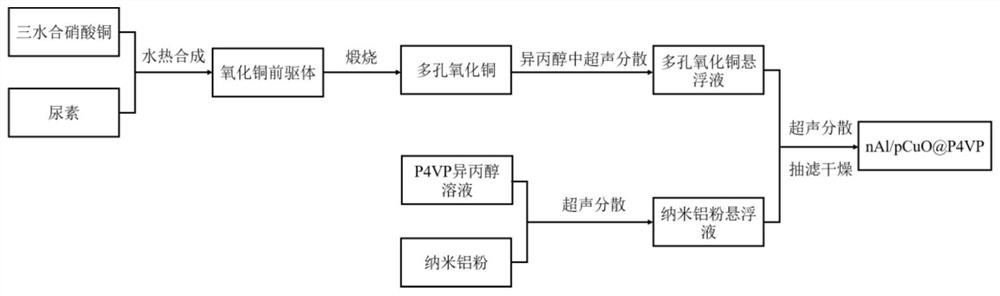

Method used

Image

Examples

Embodiment 1

[0025] Step 1: 12.08 g of three hydrolyzate copper and 3.003 g of urea were dissolved in 500 mL of deionized water, stirred for 30 min.

[0026] Step 2: Pour the solution in step 1 in a high pressure hydraulic kettle for hydrothermal synthesis, the reaction temperature is 130 ° C, the reaction time is 4 h.

[0027] Step 3: Wash the product by filtration, deionized water, water absolute ethanol, and dried to obtain a porous oxide precursor.

[0028] Step 4: The precursor is calcined using a muffer furnace, and the calcination temperature is 500 ° C, the calcination time is 4 h.

[0029] Step 5: Dissolve 0.1 g of P4VP in 100 mL of isopropyl alcohol, then 0.346 g of nano-aluminum powder, ultrasonic dispersed 1 h.

[0030] Step 6: 1 g of sheet-shaped porous calcium oxide was added to 100 ml of isopropanol, and the ultrasonic dispersion was dispersed, and the time was 1 h.

[0031] Step 7: Using magnetic stirring dispersed the nano-aluminum powder suspension in step 5, then poured into...

Embodiment 2

[0035] Step 1: 12.08 g of three hydrolyzate copper and 3.003 g of urea were dissolved in 500 mL of deionized water, stirred for 30 min.

[0036] Step 2: Pour the solution in step 1 in a high pressure hydraulic kettle for hydrothermal synthesis, the reaction temperature is 130 ° C, the reaction time is 4 h.

[0037] Step 3: Wash the product by filtration, deionized water, water absolute ethanol, and dried to obtain a porous oxide precursor.

[0038] Step 4: The precursor is calcined using a muffer furnace, and the calcination temperature is 500 ° C, the calcination time is 4 h.

[0039] Step 5: Dissolve 0.2 g of P4VP in 100 mL of isopropyl alcohol, then 0.346 g of nano-aluminum powder, ultrasonic dispersed 1 h.

[0040] Step 6: 1 g of sheet-shaped porous calcium oxide was added to 100 ml of isopropanol, and the ultrasonic dispersion was dispersed, and the time was 1 h.

[0041] Step 7: Using magnetic stirring dispersed the nano-aluminum powder suspension in step 5, then poured into...

Embodiment 3

[0044] Step 1: 12.08 g of three hydrolyzate copper and 3.003 g of urea were dissolved in 500 mL of deionized water, stirred for 30 min.

[0045] Step 2: Pour the solution in step 1 in a high pressure hydraulic kettle for hydrothermal synthesis, the reaction temperature is 130 ° C, the reaction time is 4 h.

[0046] Step 3: Wash the product by filtration, deionized water, water absolute ethanol, and dried to obtain a porous oxide precursor.

[0047] Step 4: The precursor is calcined using a muffer furnace, and the calcination temperature is 500 ° C, the calcination time is 4 h.

[0048] Step 5: Dissolve 0.2 g of P4VP in 100 mL of isopropyl alcohol, then 0.484 g of nano-aluminum powder, ultrasonic dispersed 1 h.

[0049] Step 6: 1 g of sheet-shaped porous calcium oxide was added to 100 ml of isopropanol, and the ultrasonic dispersion was dispersed, and the time was 1 h.

[0050]Step 7: Using magnetic stirring dispersed the nano-aluminum flour suspension in step 5, then poured into a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com