Improved method and improved equipment for dense phase fluidized bed and equipment

A fluidized bed and equipment technology, used in petrochemical and fluidization fields, can solve the problems of not forming a complete system, and achieve the effects of improving mass transfer and heat transfer efficiency, improving efficiency, and improving gas utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

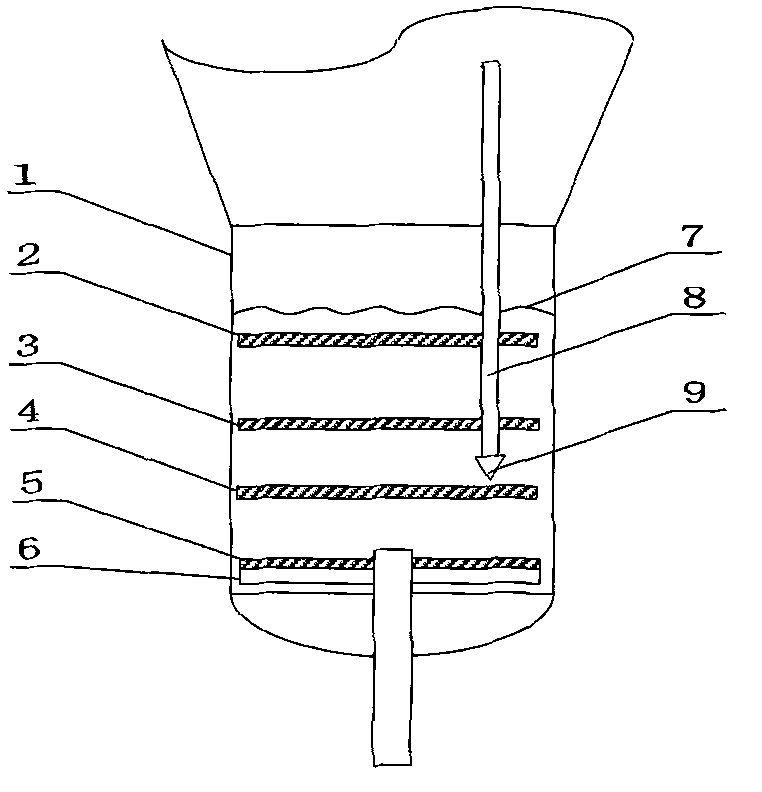

[0014] See figure 1 , the upper surface of the fluidized bed is the material surface 7, the material leg 7 and the wing valve or inverted cone 9 are placed in it, the bottom of the fluidized bed has a distribution pipe 6, and the 4-layer grid is the grid 2 below the material surface from top to bottom. , Grille 3 in the middle of the fluidized bed, Grille 4 below the wing valve or inverted cone, Grille 5 above the distributor.

[0015] see figure 1 , the gas enters the fluidized bed from the distribution pipe 6, and first redistributes the gas through the grid 5 above the distributor, so that the gas is more evenly distributed at the bottom of the fluidized bed. Then the air bubbles rise to the vicinity of the wing valve or the inverted cone, and the large air bubbles are broken through the grid 4 under the wing valve or the inverted cone to make the diameter smaller, so as to improve the stability of the fluidized bed. Then the bubbles continue to rise to the middle of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com