Method for continuously synthesizing hydroquinone dihydroxyethyl ether

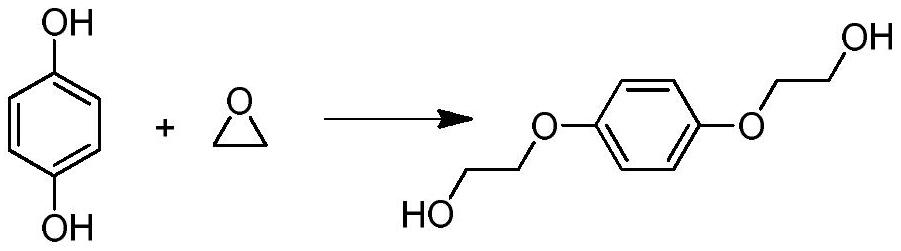

A technology for hydroquinone dihydroxyethyl ether and hydroquinone, which is applied in the field of continuous synthesis of hydroquinone dihydroxyethyl ether in a microchannel reactor, and can solve the problems of low reaction rate, long time consumption, complicated operation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

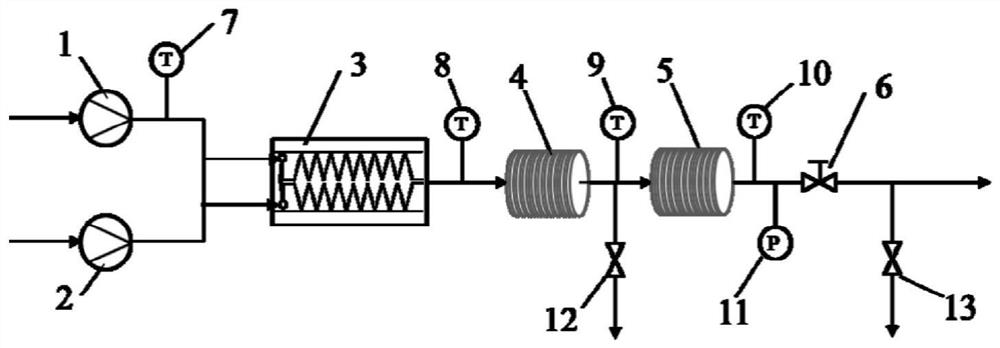

[0035] Such as figure 1 visible:

[0036] (1) Preparation of hydroquinone and ethylene oxide aqueous solution: adding 80g of hydroquinone to 950mL of water for dilution, obtaining a mass concentration of 8% aqueous solution of hydroquinone, adding sodium hydroxide to aqueous solution of hydroquinone In, wherein, the addition amount of sodium hydroxide is 2% of hydroquinone quality, heats to dissolve; Ethylene oxide is added into 500mL water and dilutes, obtains mass concentration and is 12% ethylene oxide aqueous solution, cryopreservation, to The molar ratio of hydroquinone and ethylene oxide is 1:2.1;×

[0037] (2) Adjust the pressure of the back pressure valve to 1.2MPa, raise the temperature to 80°C, preheat the pipeline and the feed pump, and then pass the hydroquinone and ethylene oxide aqueous solutions through the first and second metering advection pumps respectively Input into the microchannel reactor, the hydroquinone aqueous solution flow rate is 19mL / min, the et...

Embodiment 2

[0039] (1) Preparation of hydroquinone and ethylene oxide aqueous solution: 80g of hydroquinone is added into 550mL of water and diluted to obtain a mass concentration of 13% aqueous solution of hydroquinone, sodium hydroxide is added to aqueous solution of hydroquinone In, wherein, the addition amount of sodium hydroxide is 2% of hydroquinone quality, heats to dissolve; Ethylene oxide is added into 450mL water and dilutes, obtains mass concentration and is 14% ethylene oxide aqueous solution, cryopreservation, to The molar ratio of hydroquinone and ethylene oxide is 1:2.3;

[0040] (2) Adjust the pressure of the back pressure valve to 1.5MPa, raise the temperature to 100°C, preheat the pipeline and the feed pump, and then input hydroquinone and ethylene oxide aqueous solution into the microchannel reactor synchronously, and the hydroquinone The flow rate of the phenol aqueous solution is 18mL / min, the flow rate of the ethylene oxide aqueous solution is 15mL / min, and the react...

Embodiment 3

[0042] (1) Prepare hydroquinone and ethylene oxide aqueous solution: 80g hydroquinone is added 1300mL water and dilutes, obtains the hydroquinone aqueous solution that mass concentration is 6%, sodium hydroxide is added hydroquinone aqueous solution In, wherein, the addition amount of sodium hydroxide is 2% of hydroquinone quality, heats to dissolve; Add ethylene oxide to 600mL water and dilute, obtain mass concentration and be 10% aqueous solution of ethylene oxide, cryopreservation, to The molar ratio of hydroquinone and ethylene oxide is 1:2.2;

[0043] (2) Adjust the pressure of the back pressure valve to 1.8MPa, raise the temperature to 120°C, preheat the pipeline and the feed pump, and then input hydroquinone and ethylene oxide aqueous solution into the microchannel reactor synchronously, and the hydroquinone The flow rate of phenol aqueous solution is 17mL / min, the flow rate of ethylene oxide aqueous solution is 13mL / min, and the reaction residence time is 4min. After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com