A kind of preparation method of high-purity water-insoluble xylan

A water-insoluble, xylan-based technology, applied in the field of food science, achieves the effects of saving use costs, avoiding flammable and explosive risks, and broad application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

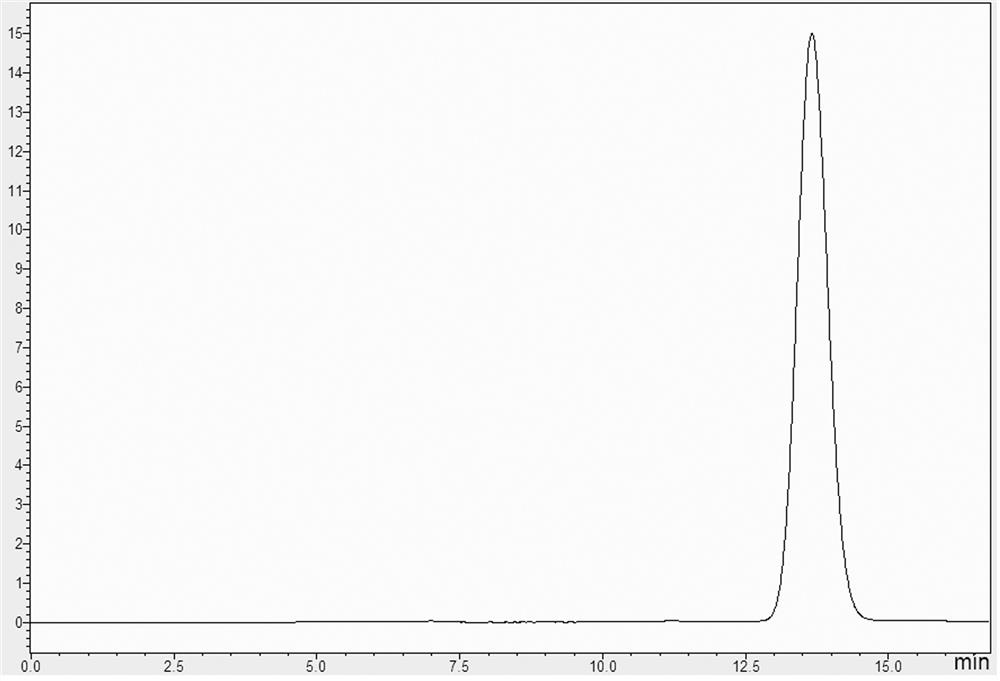

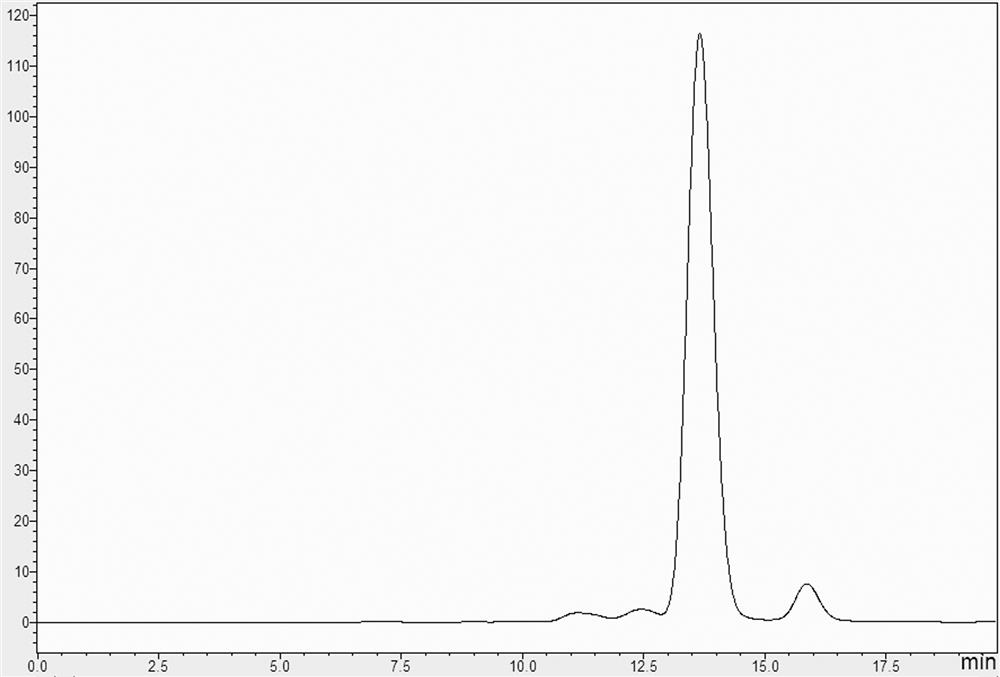

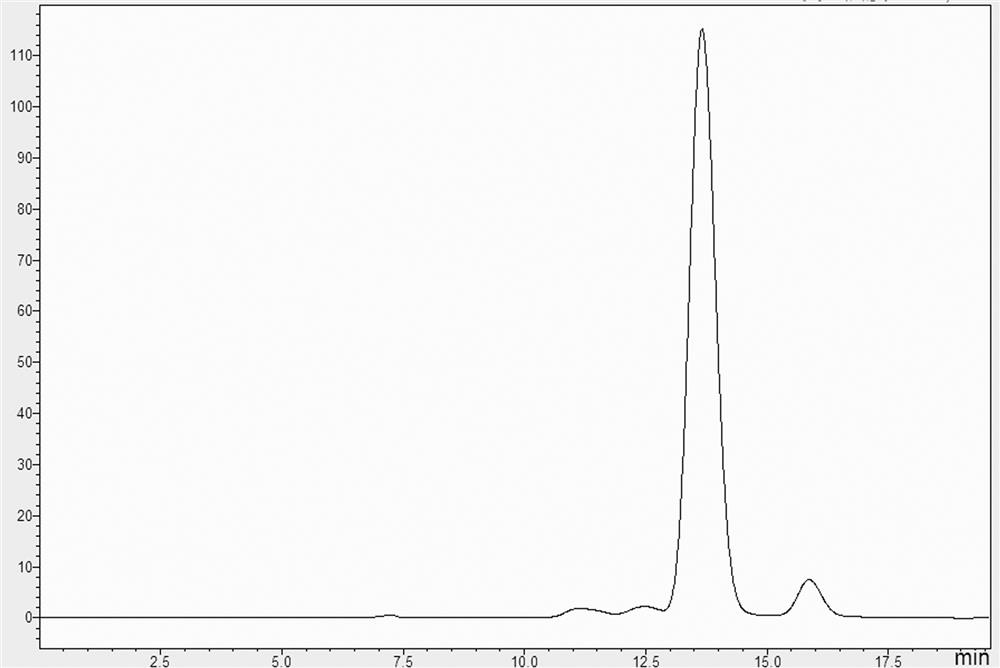

Image

Examples

Embodiment 1

[0028] A preparation method of high-purity water-insoluble xylan, comprising the following steps:

[0029] (1) Weigh 10kg of air-dried bagasse without mildew, wash it twice with clean water, and put it into the reaction kettle after centrifugal dehydration.

[0030] (2) Add 100kg of sodium hydroxide solution with a mass concentration of 14%, heat to 60°C for leaching for 3 hours, and perform solid-liquid separation after leaching.

[0031] (3) The residue after solid-liquid separation was repeatedly leached once with 50 kg of sodium hydroxide solution with a mass concentration of 8%, and solid-liquid separation was performed again.

[0032] (4) Combine two lye extracts, filter and clarify with plate and frame, then de-alkalize and concentrate with alkali-resistant ultrafiltration membrane, add water to the concentrated solution to replace ultra-filtration twice, until a small amount of xylan precipitates out, and obtain dealkalization leaching Extract the liquid and recover t...

Embodiment 2

[0038] A preparation method of high-purity water-insoluble xylan, comprising the following steps:

[0039] (1) Weigh 10kg of air-dried bagasse without mildew, wash it twice with clean water, and put it into the reaction kettle after centrifugal dehydration.

[0040] (2) Add 100kg of sodium hydroxide solution with a mass concentration of 14%, heat to 60°C for leaching for 3 hours, and perform solid-liquid separation after leaching.

[0041] (3) The residue after solid-liquid separation was repeatedly leached once with 50 kg of sodium hydroxide solution with a mass concentration of 8%, and solid-liquid separation was performed again.

[0042] (4) Combine two lye extracts, filter and clarify with plate and frame, then de-alkalize and concentrate with alkali-resistant ultrafiltration membrane, add water to the concentrated solution to replace ultra-filtration twice, until a small amount of xylan precipitates out, and obtain dealkalization leaching Extract the liquid and recover t...

Embodiment 3

[0048] A preparation method of high-purity water-insoluble xylan, comprising the following steps:

[0049] (1) Weigh 10kg of air-dried corn cob without mildew, wash it twice with clean water, dehydrate it with a vibrating screen, and then shred it twice with a double-shaft shredder to obtain small corn cob particles, and put the small corn cob particles into the reaction kettle Inside.

[0050] (2) Add 100kg of sodium hydroxide solution with a mass concentration of 14%, heat to 60°C for leaching for 3 hours, and perform solid-liquid separation after leaching.

[0051] (3) The residue after solid-liquid separation was repeatedly leached once with 50 kg of sodium hydroxide solution with a mass concentration of 8%, and solid-liquid separation was performed again.

[0052] (4) Combine two lye extracts, filter and clarify with plate and frame, then de-alkalize and concentrate with alkali-resistant ultrafiltration membrane, add water to the concentrated solution to replace ultra-fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com