Energy-saving white spirit distillation device and distillation method

A technology of distillation device and distillation method, which is applied to the preparation of alcoholic beverages, etc., can solve the problems of difficult use of hot water, low-grade hot water, and power consumption, and achieve the effects of reducing consumption, reducing power consumption, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

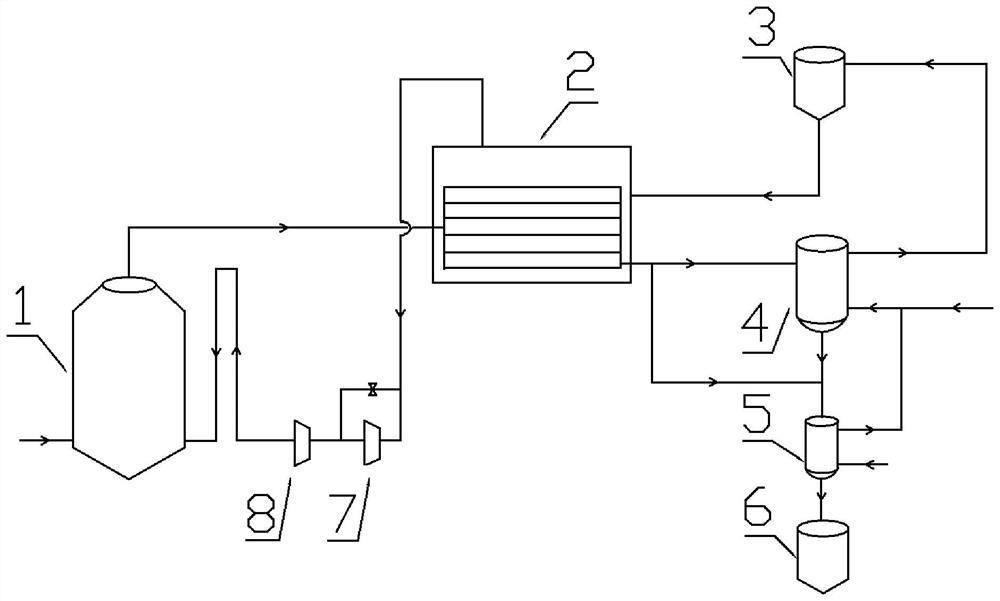

[0041] White wine distillation device, structural and composition figure 1 As shown, including distillation 1, evaporator 2, cooler 5, condenser 4, alcohol 6, cooling water storage tank 3 and steam compressor (7 and 8);

[0042] The material of the distillation 1 is heated and then produced alcohol, and the evaporator 2 and the cooling water heat exchange heat, most of which are condensed, and the condensate enters the cooler 5 to normal temperature, not being condensed within the evaporator 2 The wine vapor passes through the condenser 4, and then entering the cooler 5 is cooled to a normal temperature liquid, and finally the wine tank 6 is finally

[0043] The evaporator uses a sleeper evaporator (manufacturer to Foshan Fengchuan Energy Saving Technology Co., Ltd., model is IED10000-75 / 108), cooling water is immersed in the sleeper, alcoholic tube, alcohol passes and cooling water Change tube.

[0044] The cooler 5 and the condenser 4 are provided with a cooling water outlet, ...

Embodiment 2

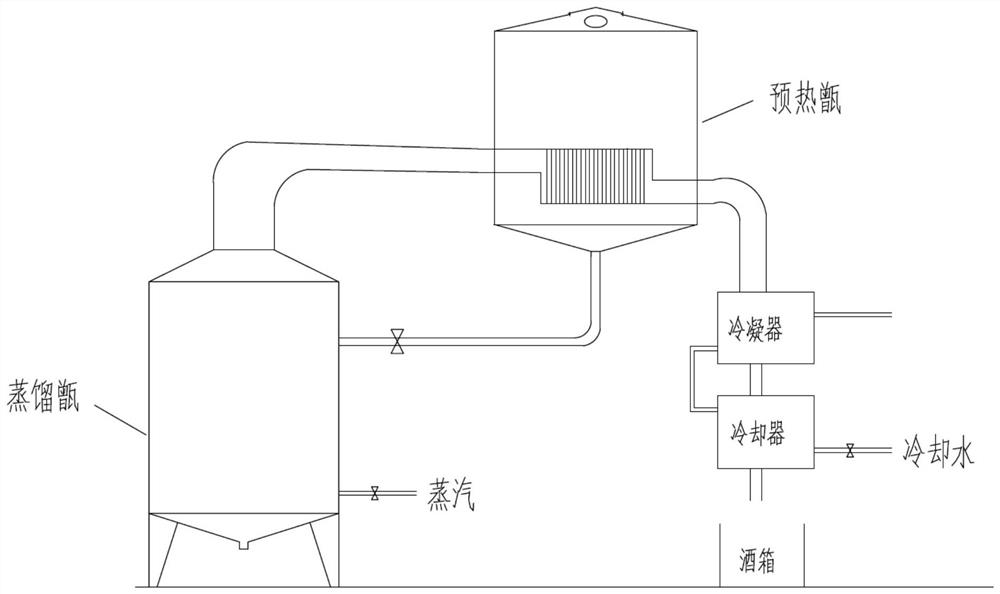

[0049] Based on the white wine distillation method of the device, including the following steps:

[0050] (1) 8M 3 Preheating to 60 ° C 12.5% Vol of the liquid pumped into the distillation, and the steam is directly heated into the distillation;

[0051] (2) The material in the distillation is heated to 90 ° C boiling, opening soft water, soft water through the cooler, the condenser and the alcohol are exchanged and then enter the cooling water storage tank, the high temperature soft water of the cooling water storage tank is from the evaporator. The set level is stopped at a high degree of level, which is lower than the set level;

[0052] (3) When the driver temperature rises to 92 ° C, when the soft water temperature in the evaporator exceeds 80 ° C, the first stage steam compressor and the second stage steam compressor, the first stage steam compressor compresses the pressure output. For -25kPa, the pressure output of the second stage steam compressor is 20 kPa;

[0053] (4)...

Embodiment 3

[0057] Based on the white wine distillation method of the device, including the following steps:

[0058] (3) When the allowance temperature rises to 94 ° C, when the soft water temperature in the evaporator exceeds 80 ° C, the first stage steam compressor and the second stage steam compressor, the first stage steam compressor compresses the pressure output. For -10 kPa, the pressure of the second-stage steam compressor is 25 kPa;

[0059] The rest of the steps are in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com