Method for preparing m-phenylenediamine based on continuous catalytic hydrogenation of fixed bed microreactor

A micro-reactor, catalytic hydrogenation technology, applied in the preparation of amino compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of product purity, increase production cost, long reaction time, etc., and achieve high reaction efficiency. and product yield, reducing the production of azo compounds, the effect of high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

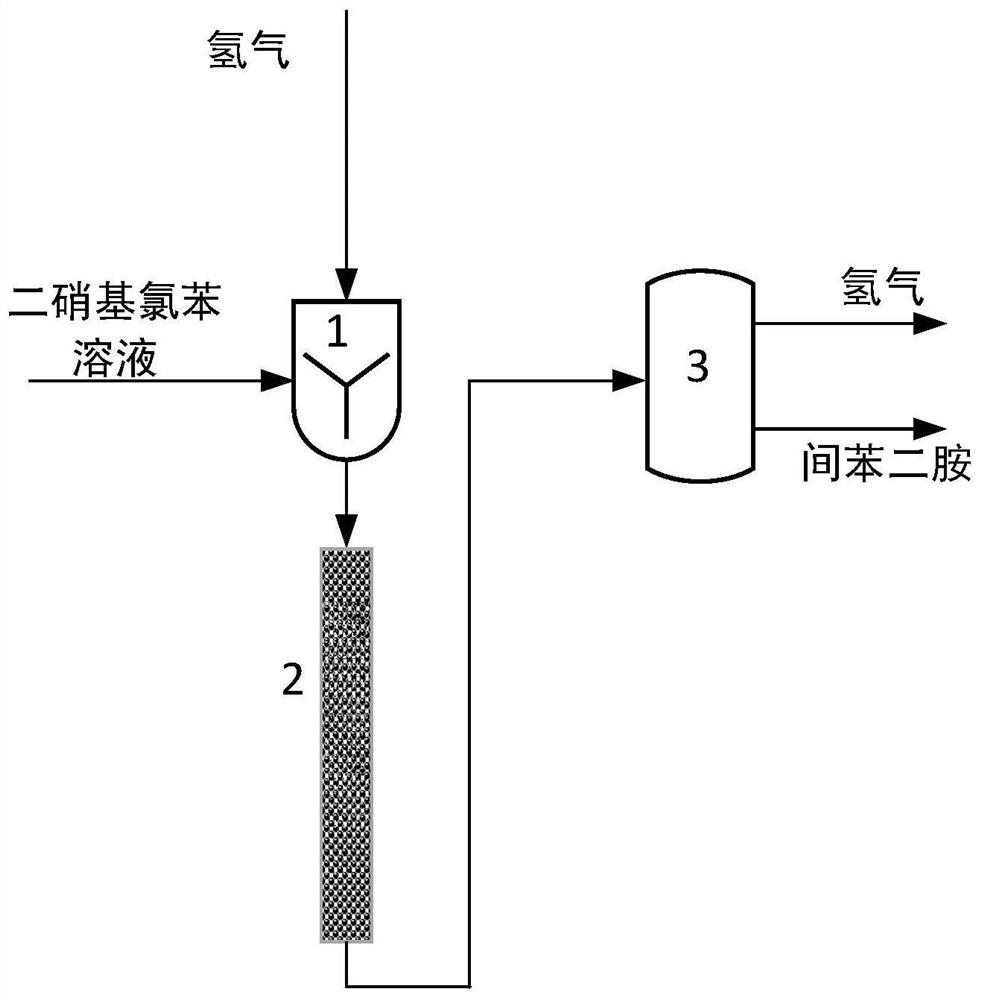

Image

Examples

Embodiment 1

[0047] Carry out experiment according to the method of the present invention, configure the ethanol solution of 2,4-dinitrochlorobenzene, concentration is 10wt%, the mol ratio of control hydrogen and 2,4-dinitrochlorobenzene is 10:1; Solution and hydrogen are in Mix in the entrance T-type micro-mixer, the gas-liquid mixture that forms passes through the micro-reactor that is packed with palladium-carbon catalyst (catalyst size 50 microns), setting reaction temperature is 90 ℃, reaction pressure 2.5MPa, residence time is 80s, in micro-reactor The reaction product was collected at the outlet of the reactor, and the obtained product was analyzed. The conversion rate of the obtained 2,4-dinitrochlorobenzene was 100%, the yield of m-phenylenediamine was 98.3%, and the azo species was 1.2%. Chlorine substances are 0.4%.

Embodiment 2

[0049] Carry out experiment according to the method of the present invention, configure the methanol solution of 2,6-dinitrochlorobenzene, concentration is 5wt%, add triethylamine according to molar ratio 1:1.2, control hydrogen and 2,6-dinitrochlorobenzene The molar ratio is 8:1; the solution and hydrogen are mixed in the inlet membrane dispersion micro-mixer, and the formed gas-liquid mixture passes through the micro-reactor filled with platinum-carbon catalyst (catalyst size 200 microns), and the reaction temperature is set at 70°C, and the reaction The pressure is 2.0MPa, the residence time is 70s, the reaction product is collected at the outlet of the microreactor, and the resulting product is analyzed. The conversion rate of the obtained 2,6-dinitrochlorobenzene is 100%, and the yield of m-phenylenediamine is 98.7%. , 0.84% for azo substances, and 0.23% for non-dechlorinated substances.

Embodiment 3

[0051] Carry out experiment according to the method of the present invention, configure the tetrahydrofuran solution of 3,5-dinitrochlorobenzene, concentration is 15wt%, add sodium bicarbonate according to molar ratio 1:1.5, control hydrogen and 3,5-dinitrochlorobenzene The molar ratio is 11:1; the solution and hydrogen are mixed in the inlet micro-mesh micro-mixer, and the gas-liquid mixture formed passes through the micro-reactor filled with palladium-carbon catalyst (catalyst size 800 microns), and the reaction temperature is set to 120 ° C. The reaction pressure is 3.0MPa, the residence time is 50s, the reaction product is collected at the outlet of the microreactor, and the resulting product is analyzed. The conversion rate of the obtained 3,5-dinitrochlorobenzene is 100%, and the yield of m-phenylenediamine is 99.4 %, azo substances are 0.14%, and non-dechlorinated substances are 0.33%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com