Process of industrialize for waste acid concentrition recovering used in titanium white production by sulfuric acid method

A technology of titanium dioxide and sulfuric acid method, which is applied in the direction of sulfur trioxide/sulfuric acid, titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of easy scaling and blockage of equipment and pipelines, waste of valuable resources, unstable operation, etc., and achieve Overcoming the problems of equipment corrosion and crystallization pipe plugging, saving external steam consumption, improving efficiency and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

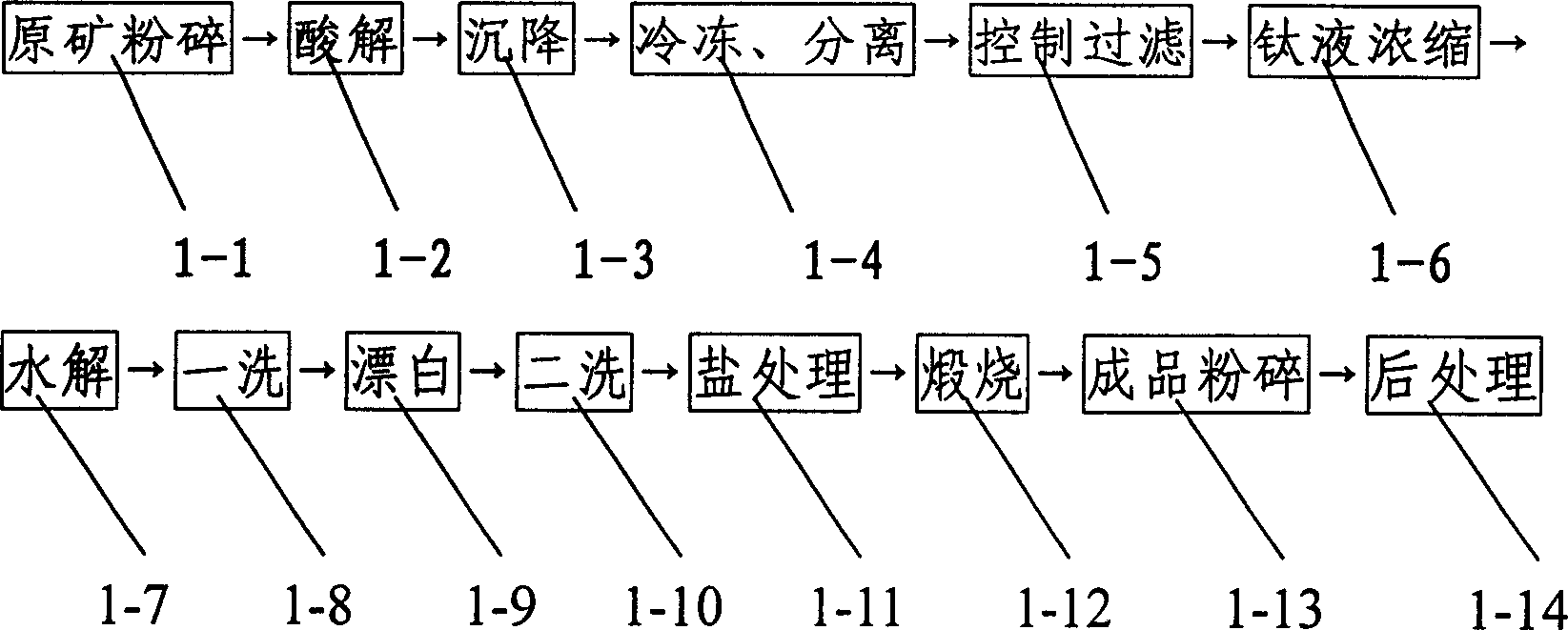

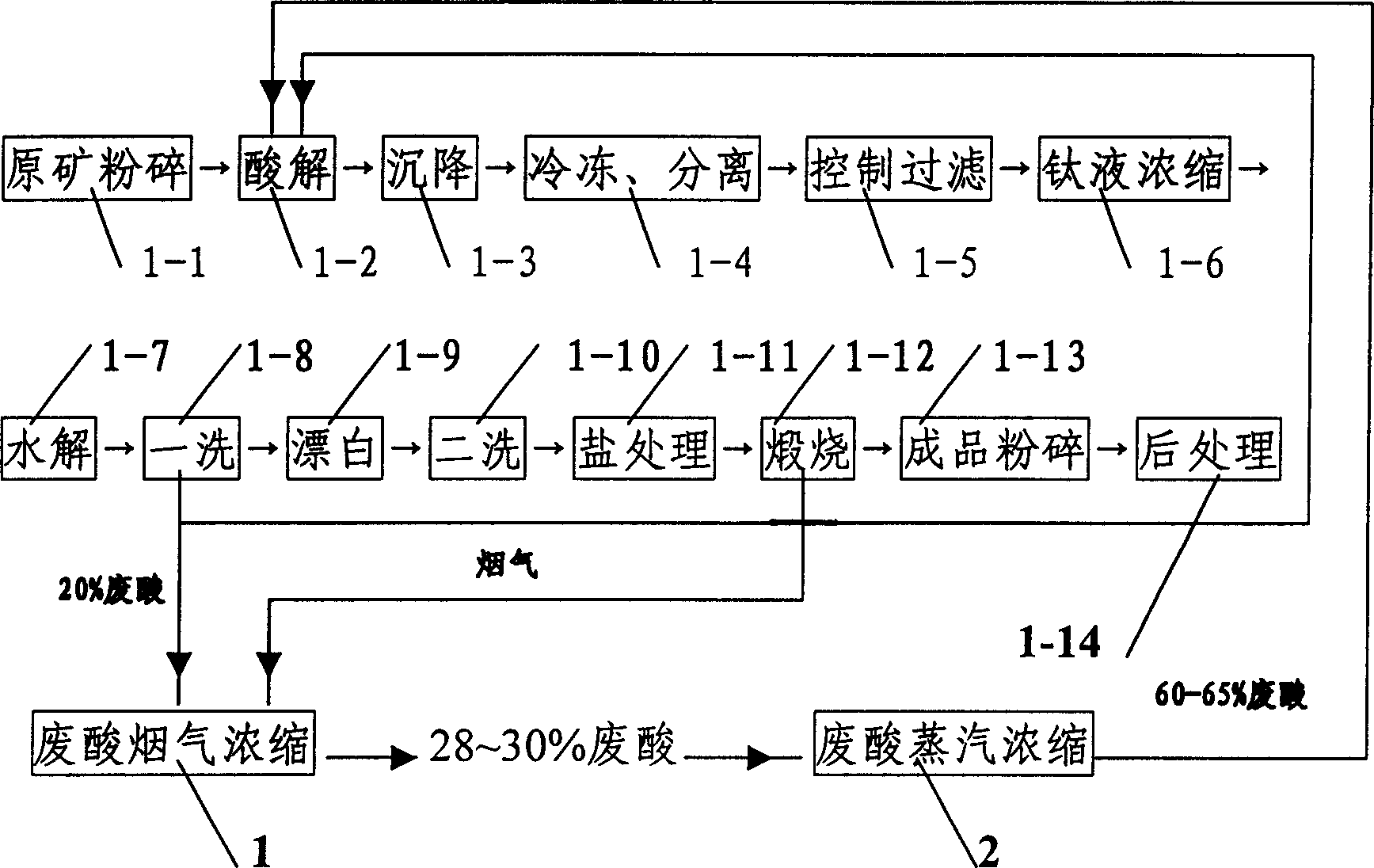

Method used

Image

Examples

Embodiment 1

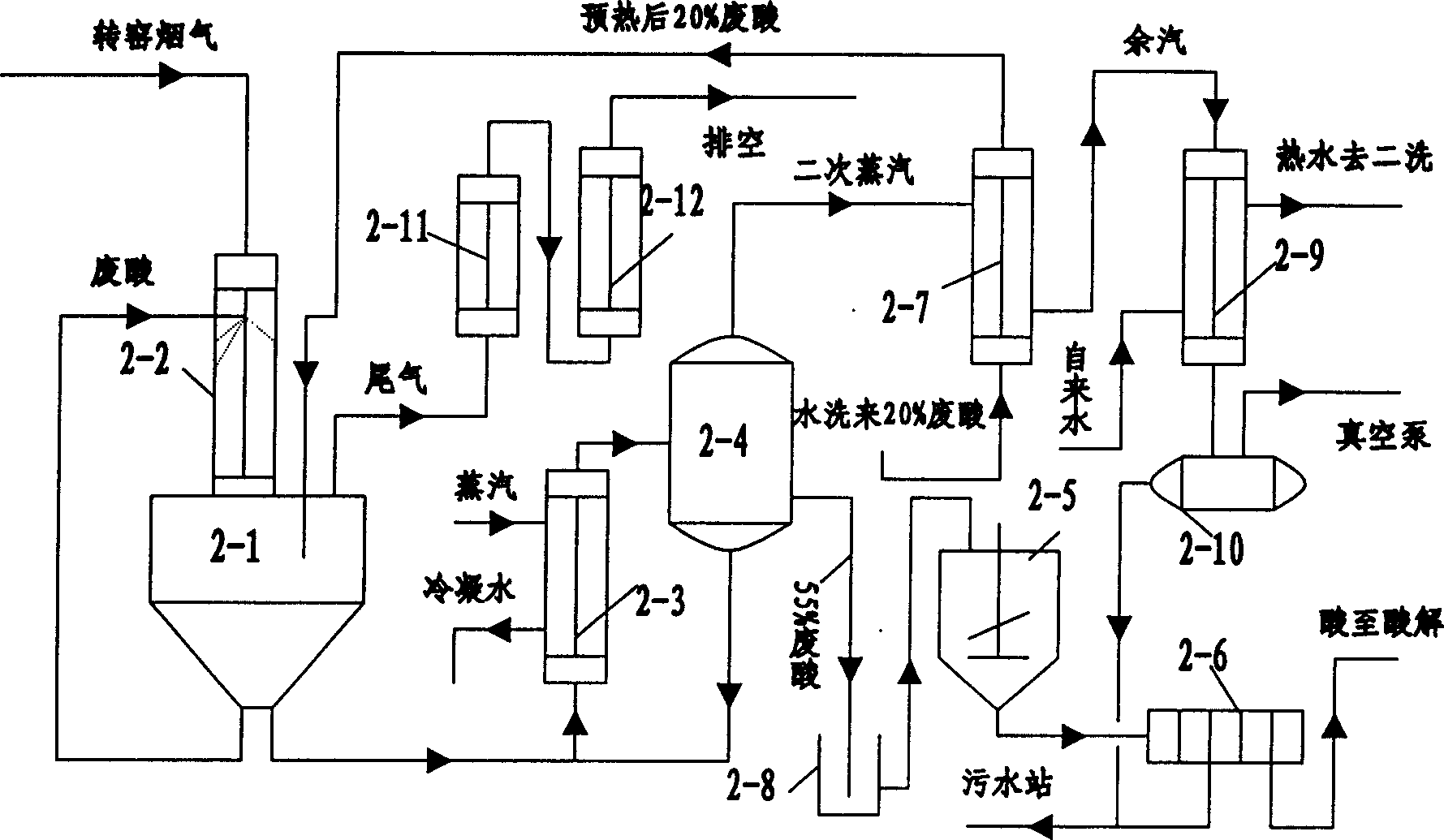

[0053] 1) Preheat about 20% of the waste acid produced in the first washing process of sulfuric acid titanium dioxide production through preheater 2-7 and pass it into the circulation pool 2-1, and at the same time pass it into the calcination process of sulfuric acid titanium dioxide production The generated rotary kiln flue gas is passed into the circulation pool 2-1 through the spray tower 2-2, and the residual steam generated in the preheater 2-7 is passed into the condenser 2-9, and the condenser 2-9 is cooled by tap water, and the heat The water is removed from the secondary washing process in the production of sulfuric acid titanium dioxide; the condensed water is discharged to the sewage station for neutralization through the pouring tank 2-10, and the uncondensed steam (gas) is connected to the vacuum pump to be emptied.

[0054] The waste acid is circulated and concentrated between the circulation pool 2-1 and the spray tower 2-2 to about 28-30%, and the tail gas in t...

Embodiment 2

[0057] 1) Preheat about 20% of the waste acid produced in the first washing process of sulfuric acid titanium dioxide production through preheater 2-7 and pass it into the circulation pool 2-1, and at the same time pass it into the calcination process of sulfuric acid titanium dioxide production The generated rotary kiln flue gas is passed into the circulation pool 2-1 through the spray tower 2-2, and the residual steam generated in the preheater 2-7 is passed into the condenser 2-9, and the condenser 2-9 is cooled by tap water, and the heat The first water washing process in the production of titanium dioxide by the sulfuric acid method; the condensed water is discharged to the sewage station for neutralization through the pouring tank 2-10, and the uncondensed steam (gas) is connected to the vacuum pump to be emptied.

[0058] The waste acid is circulated and concentrated to about 28-30% between the circulation pool 2-1 and the spray tower 2-2, and the tail gas in the circula...

Embodiment 3

[0061] 1) Preheat about 20% of the waste acid produced in the primary water washing process of sulfuric acid titanium dioxide production through preheater 2-7 and pass it into the circulation pool 2-1, and at the same time pass it into the calcination process of sulfuric acid titanium dioxide production The generated rotary kiln flue gas is passed into the circulation pool 2-1 through the spray tower 2-2, and the residual steam generated in the preheater 2-7 is passed into the condenser 2-9, and the condenser 2-9 is cooled by tap water, and the heat The secondary water washing process in the production of titanium dioxide by the sulfuric acid method; the condensed water is discharged through the pouring tank 2-10 to the sewage station for neutralization treatment, and the uncondensed steam (gas) is connected to the vacuum pump to be emptied.

[0062] The waste acid is circulated and concentrated between the circulation pool 2-1 and the spray tower 2-2 to about 28-30%, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com