Preparation method for high-dispersion nano silicon dioxide

A nano-silicon dioxide, silicon dioxide technology, applied in the direction of silicon dioxide, silicon oxide, nanotechnology, etc., can solve the problems of uneven reaction, high surface energy, poor micro-mixing, etc. The effect of uniform saturation and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

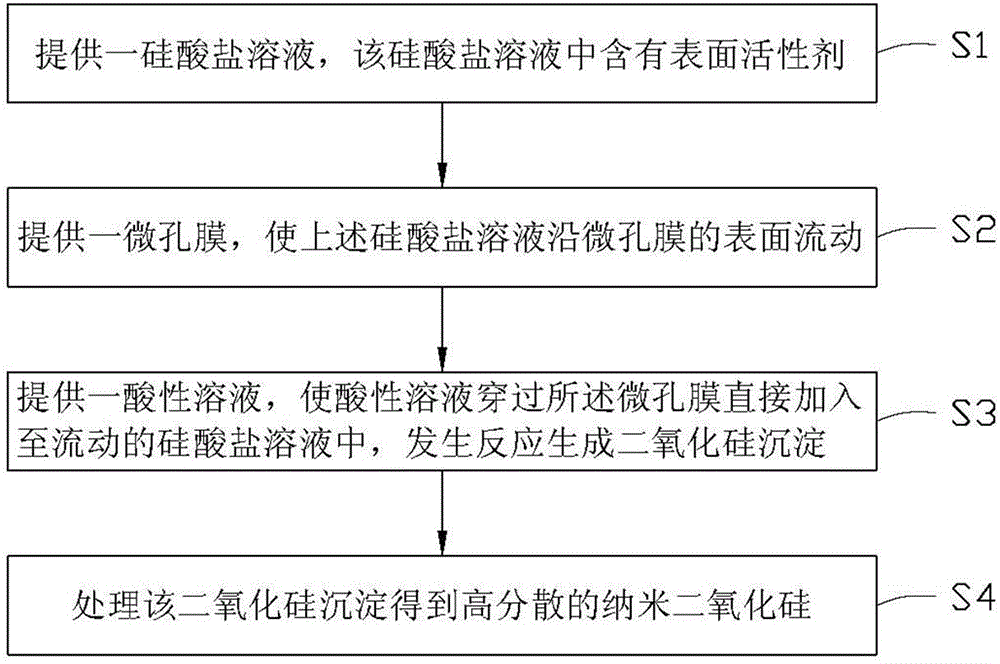

[0016] See figure 1 , the invention provides a kind of preparation method of highly dispersed nano silicon dioxide, it comprises the following steps:

[0017] S1: providing a silicate solution containing a surfactant;

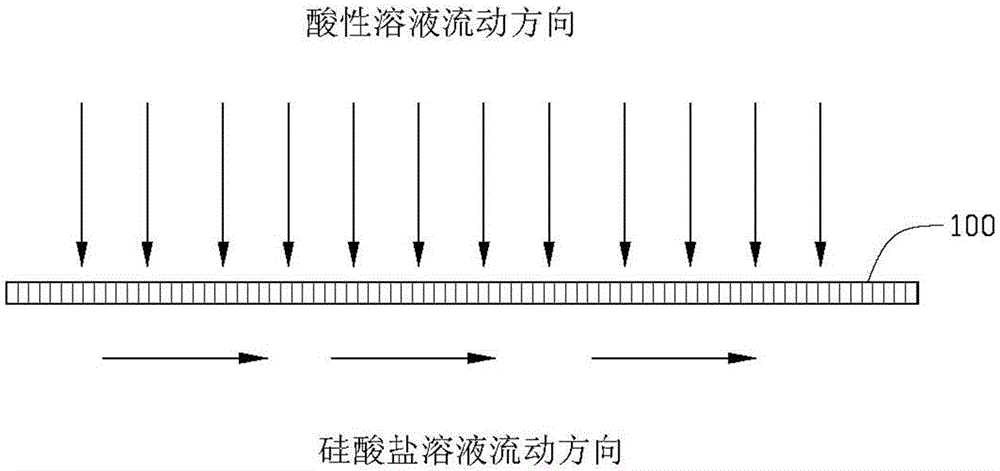

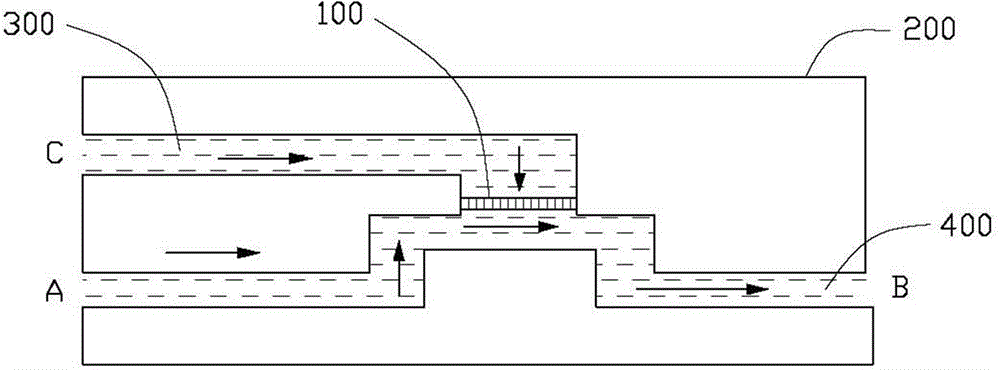

[0018] S2: Provide a microporous membrane, so that the above-mentioned silicate solution flows along the surface of the microporous membrane;

[0019] S3: Provide an acidic solution, make the acidic solution pass through the microporous membrane and directly add to the flowing silicate solution, and react to form silica precipitation; and,

[0020] S4: Treating the silica precipitate to obtain highly dispersed nano silica.

[0021] In step S1, the silicate is a soluble salt of silicic acid, which may be sodium silicate, potassium silicate, or ammonium silicate. In this embodiment, the silicate is sodium silicate solution. The sodium silicate solution is an aqueous sodium silicate solution with a concentration of 0.2-2 mol / L (mol / L). The surfactant can be s...

Embodiment 1

[0028] 1) Prepare a sodium silicate aqueous solution with a concentration of 1 mol / L, add a surfactant sodium carboxymethylcellulose with a mass fraction of 0.20%, and make it flow at a flow rate of 10 m / s.

[0029] 2) Prepare a sulfuric acid aqueous solution with a concentration of 0.75 mol / L, and make it pass through the microporous membrane at a flow rate of 6 m / s, and disperse from the vertical direction to the sodium silicate aqueous solution with the surfactant sodium carboxymethyl cellulose added middle.

[0030] 3) Sulfuric acid droplets diffuse and react in sodium silicate aqueous solution at 70°C to form silica precipitates, and then undergo aging, filtration, washing, drying, and crushing to obtain highly dispersed nano-silica particles. Its specific surface area is 130 square meters per gram (m 2 / g), the primary particle size is 15 nanometers (nm), the transmission electron microscope photo of the product is as follows image 3 shown.

Embodiment 2

[0032] 1) Prepare a sodium silicate aqueous solution with a concentration of 2 mol / L, add a surfactant sodium carboxymethylcellulose with a mass fraction of 0.50%, and make it flow at a flow rate of 12 m / s.

[0033] 2) Prepare a sulfuric acid aqueous solution with a concentration of 1.5 mol / L, and make it pass through the microporous membrane at a flow rate of 8 m / s, and disperse from the vertical direction to the sodium silicate aqueous solution with the surfactant sodium carboxymethyl cellulose added middle.

[0034] 3) Sulfuric acid droplets diffuse and react in sodium silicate aqueous solution at 50°C to form silica precipitates, and then undergo aging, filtration, washing, drying, and crushing to obtain highly dispersed nano-silica particles. Its specific surface area is 160 m 2 / g, the primary particle size is 12nm, the transmission electron microscope photo of this product is as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com