Cheap and high efficiency rectification filler and preparation method thereof

A rectification packing and high-efficiency technology, applied in chemical instruments and methods, chemical/physical/physicochemical processes, chemical/physical processes, etc., can solve the problems of limiting the application range of packing, high cost and price, and low corrosion resistance , achieve the effects of reducing tower investment, reducing porosity, and stabilizing chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

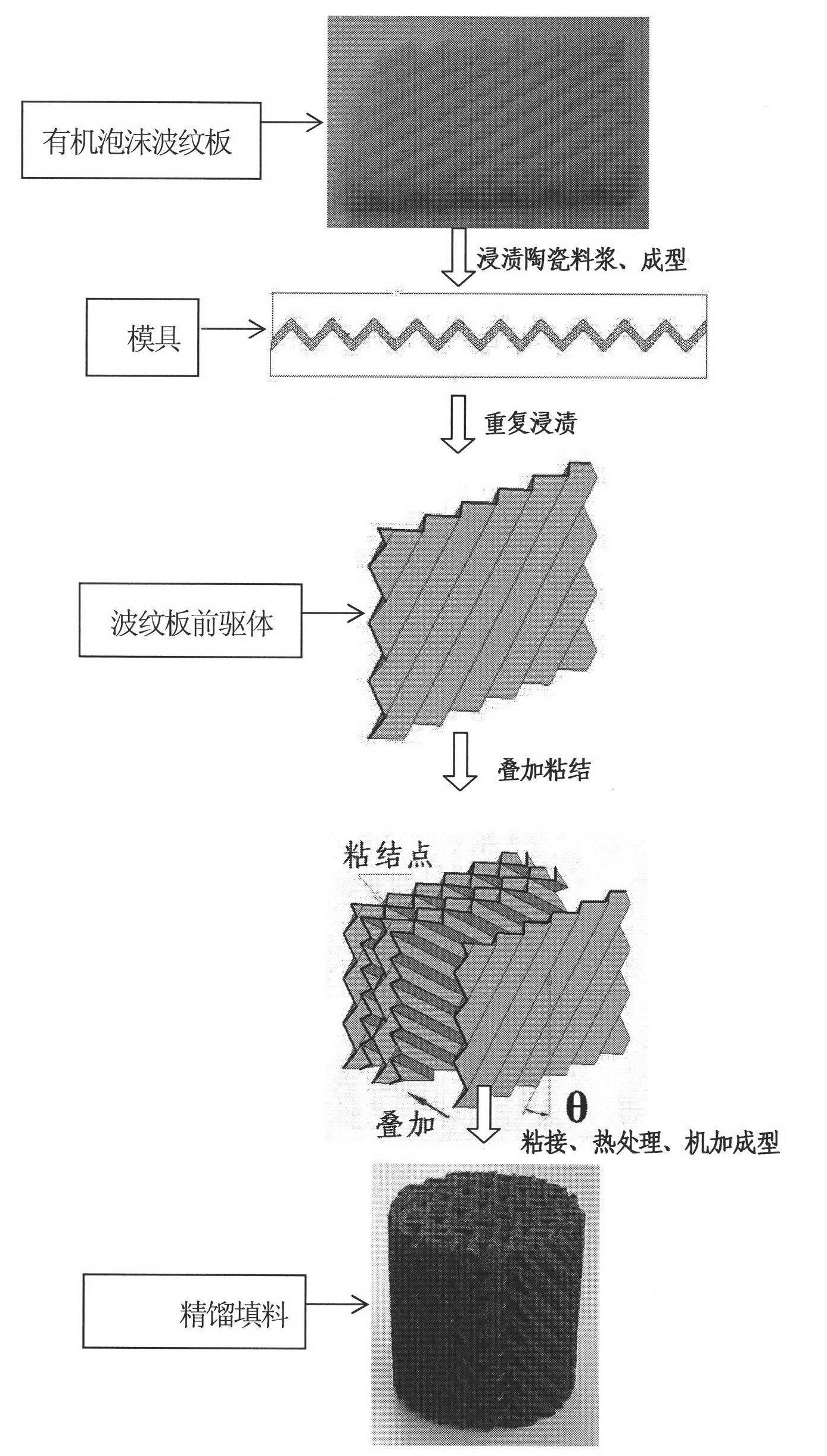

[0042] In the present embodiment, the preparation method of rectification packing comprises the following steps:

[0043] (1) Mix the above-mentioned raw materials with the weight ratio of phenolic resin: silicon carbide microparticles: p-toluenesulfonic acid: ethanol=100:100:15:80, and obtain a slurry after ball milling for 1 hour; the particle size of the silicon carbide microparticles is 5 microns .

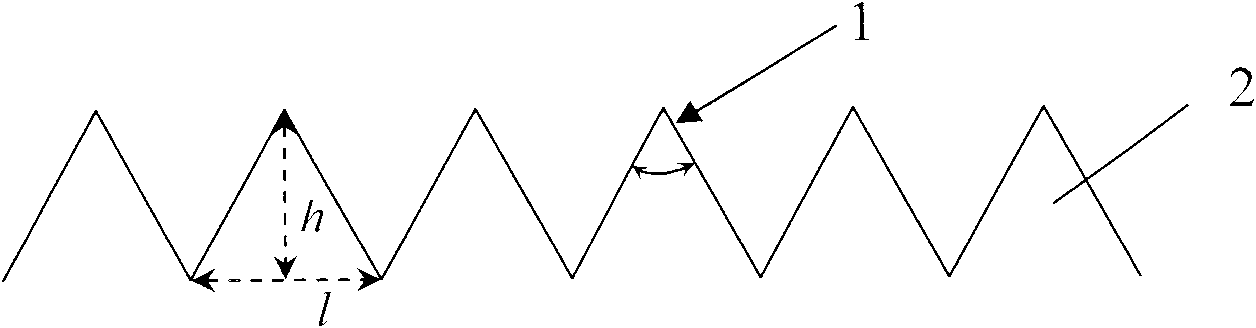

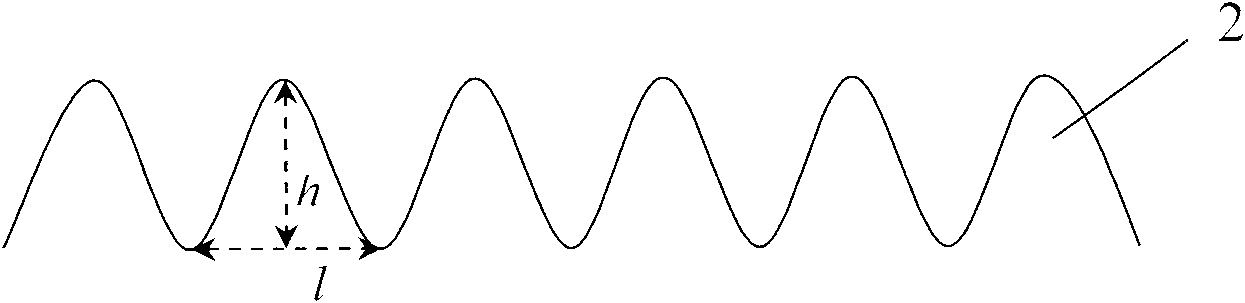

[0044] (2) Pre-cut polyurethane foam into crests wave distance A corrugated foam board with a corrugation angle 2=72°, the thickness of the board is 4mm; the average pore diameter of the polyurethane foam is 30-40PPi, and the opening rate is more than 99%;

[0045] (3) Dip the foamed plastic corrugated board obtained in step (2) into the slurry obtained in step (1) to ensure that all parts of the foamed plastic corrugated board have slurry attached, then take out the foamed plastic corrugated board and blow off the foamed plastic with compressed air The excess slurry in t...

Embodiment 2

[0053] In the present embodiment, the preparation method of rectification packing comprises the following steps:

[0054] (1) Mix the above raw materials in a weight ratio of epoxy resin: alumina particles: citric acid: acetone = 100:50:5:100, and ball mill for 2 hours to obtain a slurry; the particle size of the alumina particles is 2 microns.

[0055] (2) Pre-cut polyurethane foam into crests wave distance A corrugated foam board with a corrugation angle 2=78°, the thickness of the board is 4mm; the average pore diameter of the polyurethane foam is 30-40PPi, and the opening rate is more than 99%;

[0056] (3) Dip the foamed plastic corrugated board obtained in step (2) into the slurry obtained in step (1) to ensure that all parts of the foamed plastic corrugated board have slurry attached, then take out the foamed plastic corrugated board and blow off the foamed plastic with compressed air The excess slurry in the holes of the corrugated plate should be dried at room tem...

Embodiment 3

[0070] HCl acid was used as the medium to study and compare the corrosion resistance of materials. Three kinds of HCl acid solutions with different concentrations (5wt%, 10wt%, and 25wt%) were prepared, and foam resin-based corrugated structured packing and BX packing (316L ) soaked in three different concentration solutions for 3 weeks, and then measured the mass change rate before and after, showing that the foam resin-based corrugated structured packing did not find any signs of corrosion, while the BX packing (316L) lost weight obviously, and some areas had been spot-corroded, and even holes appeared ;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com