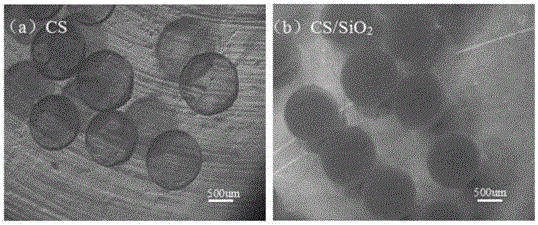

Preparation method for SiO2 nanoparticle reinforced chitosan composite microcapsule

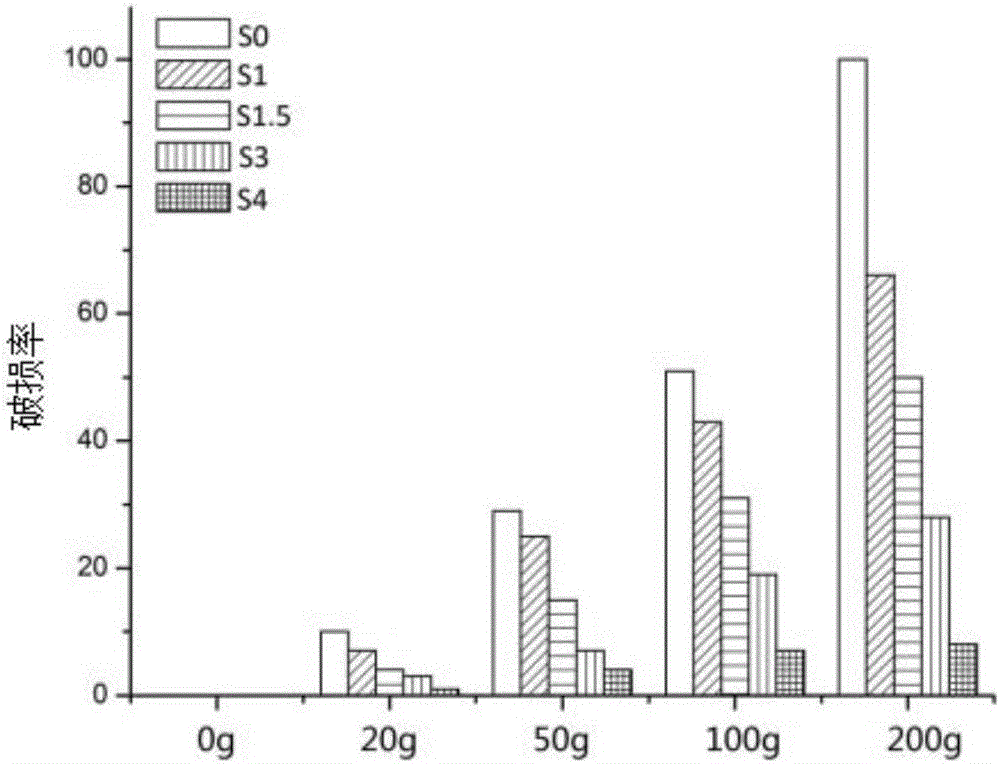

A technology of compounding microcapsules and nanoparticles, which is applied in the directions of microcapsule preparation and microsphere preparation to achieve the effects of microscopically controllable process, dense capsule wall and environmental protection of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

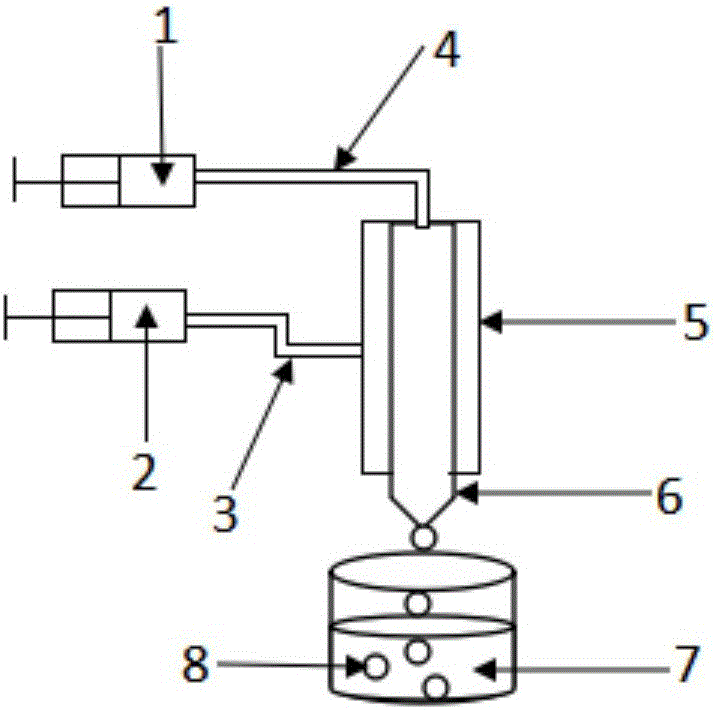

Method used

Image

Examples

Embodiment 1

[0035] Accurately weigh 0.40g of medium-viscosity (viscosity 200-400mPa.s) chitosan, add it to 20mL of 0.2mol / L acetic acid solution, stir at a constant speed at room temperature for 1h to fully dissolve the chitosan, and then let it stand for 1h , eliminate the air bubbles in the chitosan solution, and finally obtain a chitosan solution with a mass concentration of 2%.

[0036] Measure 10ml of silica sol, use a micro syringe to slowly add a total of 0.6ml of 2mol / L hydrochloric acid six times to adjust the pH of the silica sol, and slowly stir the solution at room temperature during the dropping process to obtain a pretreated pH of 2.2-2.7 of silica sol solution.

[0037] Take the prepared chitosan acetic acid solution 10mL, slowly add 1.5mL pretreated silica sol solution under stirring at room temperature. The mixed system was stirred at room temperature for 30 minutes, then placed in an ultrasonic device for ultrasonic treatment for 30 minutes to allow the system to mix ev...

Embodiment 2

[0040] Change chitosan viscosity (viscosity is 20-100mPa.s) to low viscosity chitosan.

[0041] Accurately weigh 0.40g of low-viscosity (viscosity 20-100mPa.s) chitosan, add it to 20mL of 0.2mol / L acetic acid solution, stir at a constant speed at room temperature for 1h to fully dissolve the chitosan, and then let it stand for 1h , eliminate the air bubbles in the chitosan solution, and finally obtain a chitosan solution with a mass concentration of 2%.

[0042] Measure 10ml of silica sol, use a micro syringe to slowly add a total of 0.6ml of 2mol / L hydrochloric acid six times to adjust the pH of the silica sol, and slowly stir the solution at room temperature during the dropping process to obtain a pretreated pH of 2.2-2.7 of silica sol solution.

[0043] Take the prepared chitosan acetic acid solution 10mL, slowly add 1.5mL pretreated silica sol solution under stirring at room temperature. The mixed system was stirred at room temperature for 30 minutes, then placed in an u...

Embodiment 3

[0046] Change chitosan viscosity (viscosity is 1000-1400mPa.s) to high viscosity chitosan.

[0047] Accurately weigh 0.40g of high-viscosity (viscosity 1000-1400mPa.s) chitosan, add it to 20mL of 0.2mol / L acetic acid solution, stir at a constant speed at room temperature for 1h to fully dissolve the chitosan, and then let it stand for 1h , eliminate the air bubbles in the chitosan solution, and finally obtain a chitosan solution with a mass concentration of 2%.

[0048] Measure 10ml of silica sol, use a micro syringe to slowly add a total of 0.6ml of 2mol / L hydrochloric acid six times to adjust the pH of the silica sol, and slowly stir the solution at room temperature during the dropping process to obtain a pretreated pH of 2.2-2.7 of silica sol solution.

[0049] Take the prepared chitosan acetic acid solution 10mL, slowly add 1.5mL pretreated silica sol solution under stirring at room temperature. The mixed system was stirred at room temperature for 30 minutes, then placed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com