Preparation method of nano spherical ferric phosphate as well as nano ferric phosphate prepared by the method, lithium ferric phosphate and lithium battery

A technology of lithium iron phosphate and iron phosphate, which is applied in the field of new energy material preparation, can solve the problems of complex components, affecting production efficiency, and long time consumption, and achieve the effects of mild synthesis conditions, controllable particle size, and excellent electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

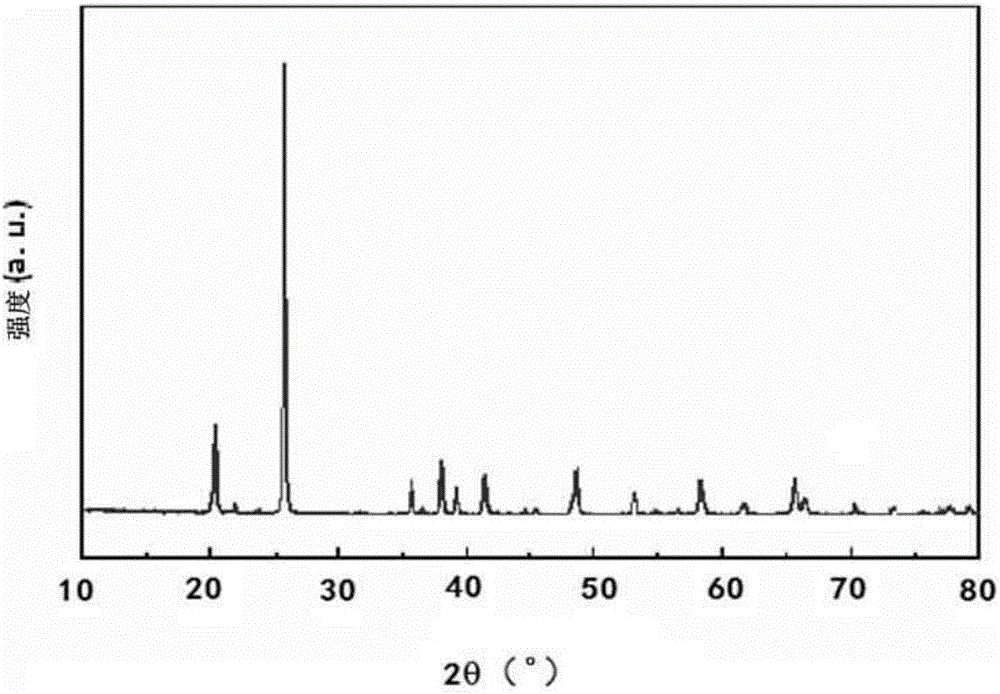

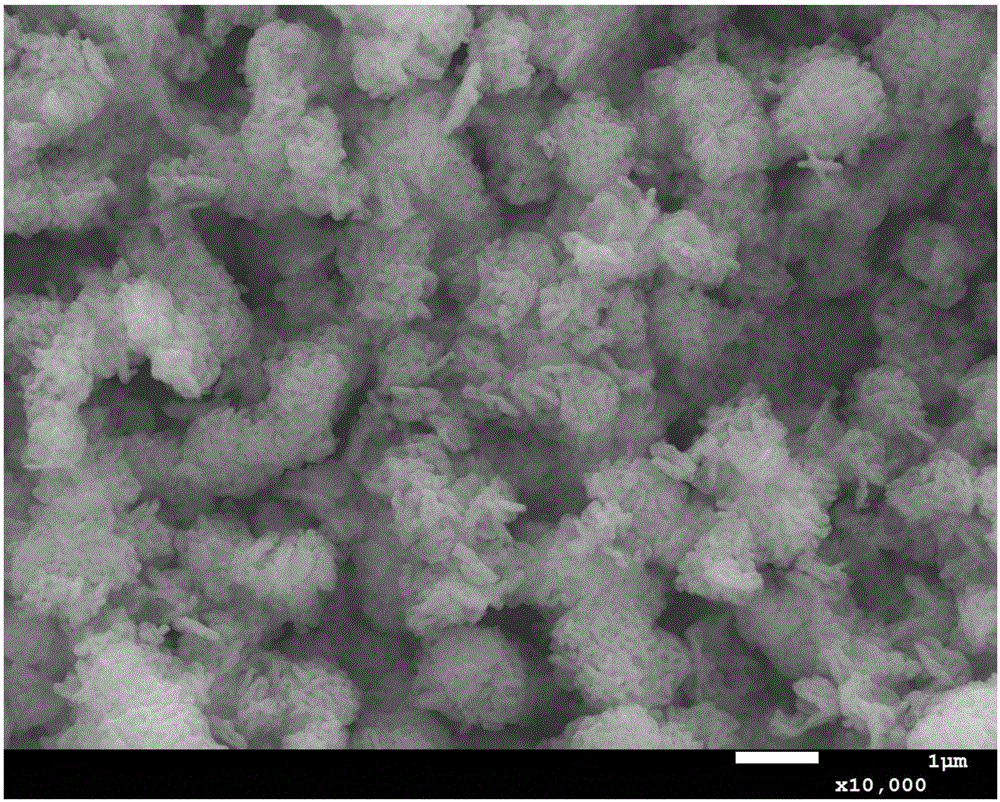

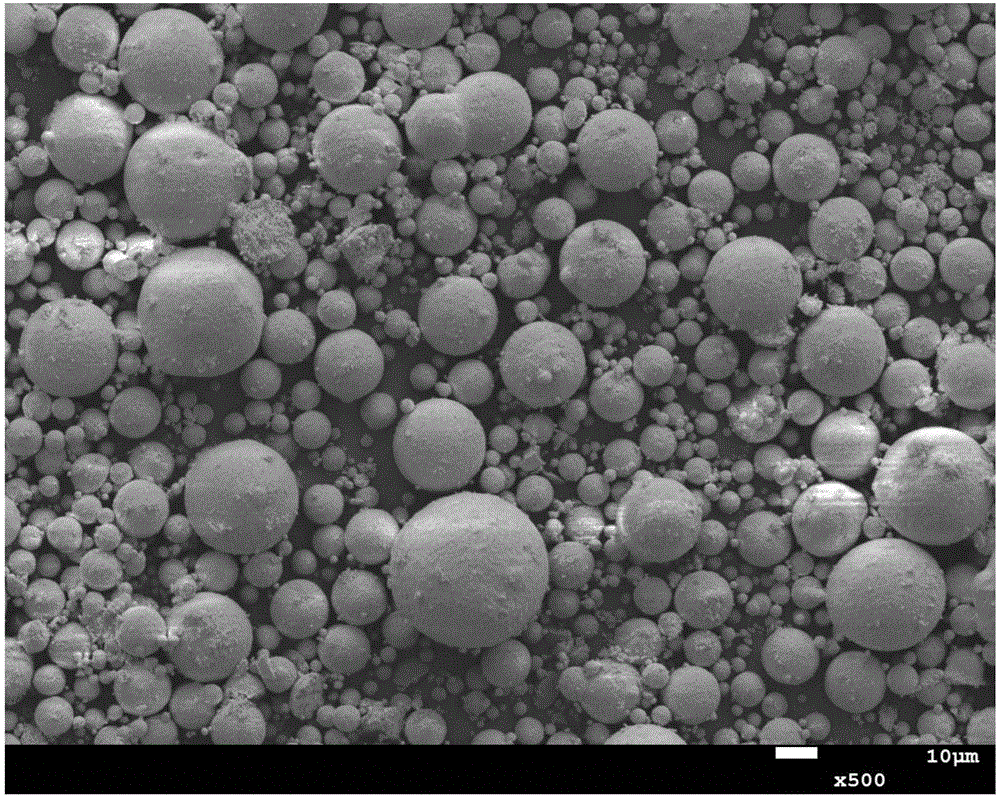

[0043] A kind of FePO containing general formula 4 ·nH 2 The preparation method of the nano-spherical ferric phosphate of O (n≤2.5), described nano-spherical ferric phosphate refers to that particle is spherical or quasi-spherical, particle size is in 1-300nm ferric phosphate particle; Described method comprises the following steps:

[0044] 1) mix : drop the mixed solution of the phosphorus source compound solution and the oxidizing agent solution in the soluble ferrous compound solution, the dropping speed is 1d / min, add the nano-spherical control agent and stir and mix at the same time;

[0045] The ferrous compound is at least one of ferrous sulfate, ferrous sulfite, ferrous chloride, ferric nitrate and ferrous dihydrogen phosphate;

[0046] The phosphorus source compound is at least one of phosphoric acid, ammonium monohydrogen phosphate, ammonium dihydrogen phosphate and ammonium phosphate;

[0047] Described oxidizing agent is hydrogen peroxide and / or ammonium persul...

specific Embodiment

[0062] How to measure electrical conductivity

[0063] The method for measuring the electrical conductivity is that firstly the mold is pressed into a solid body through the obtained ferric phosphate, the diameter of the molded body is 12 mm, the thickness of the molded body is about 3 mm, and the final thickness is measured by a micron thread gauge. The multifunctional measuring device of the voltage source is a digital multimeter (M4660), which measures the electrode voltage and the resistance through the test body.

Embodiment 1

[0065] In the solution containing 1 mole of ferrous sulfate, drop the mixed solution of ammonium phosphate solution and hydrogen peroxide solution; the mixed solution contains 1 mole of ammonium phosphate solution, and the quality of hydrogen peroxide is 30% of the theoretical output of ferric phosphate, and the dropping speed is 1d / min, add nano-spherical control agent (1) simultaneously and mix, stir, stirring speed is 300 revs / min, and the control agent add-on is 10wt% of the ferric phosphate theoretical output; The chemical equation of reaction is:

[0066] FeSO 4 +NH 4 h 2 PO 4 +H 2 O+ control agent (1)------FePO 4 (Spherical Nano Iron Phosphate)

[0067] The nano-spherical control agent (1) is:

[0068]

[0069] Under reflux condition, in the reactor of 500ml, react for 8 hours, reaction temperature is 60 ℃, adopt high magnetic filter to filter then, remove magnetic substance (iron oxide and iron hydroxide), then press filter, press filter The obtained ferric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com