Bilirubin adsorption material for treating hyperbilirubinemia

A technology for adsorbing material and bilirubin, which is applied in blood circulation treatment, other chemical processes, chemical instruments and methods, etc., can solve the problems of low bilirubin adsorption capacity, high price and low cost, and achieves enhanced safety, Easy to sterilize, small effect of non-specific adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

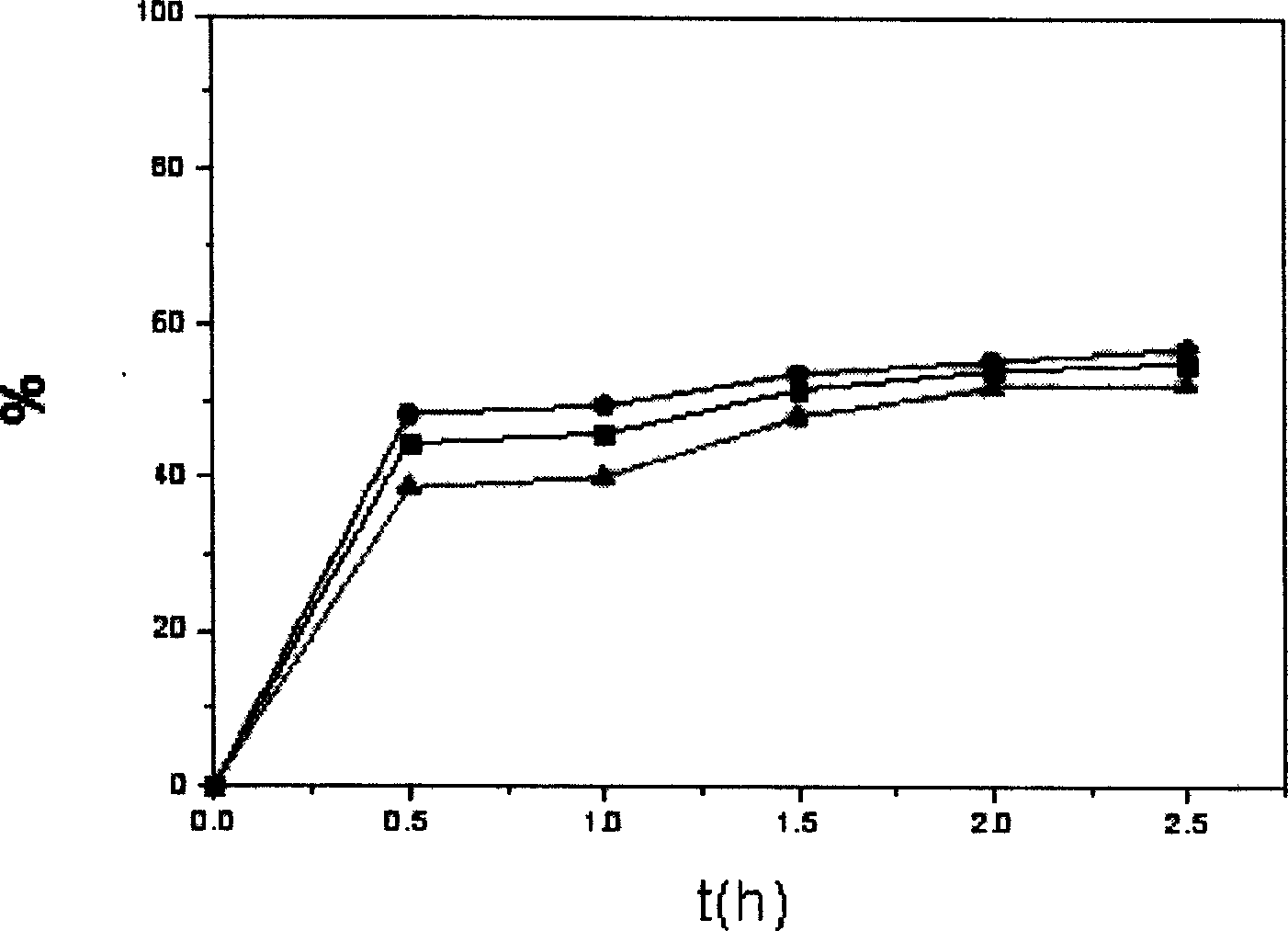

Image

Examples

Embodiment 1

[0027] Embodiment 1: N, the preparation of N'carbonyldiimidazole activated agarose gel

[0028] Weigh 0.43~1.0L of agarose gel, vacuum filter 4-5 times with deionized water to remove preservatives in the gel, wash the gel with 30%, 70%, and 100% acetone in turn, weigh 60 Dissolve ~220g of N,N'carbonyldiimidazole in 1.0L of acetone, then add the washed gel into the solution, and react in a shaker at 25~37°C and 150 rpm for 1~2 hours . After the reaction, wash the activated gel repeatedly with 6-10 times the volume of acetone, and vacuum filter to remove the imidazole produced during the reaction. At this time, the active group density on the surface of the agarose gel is 72-192mmol / Lgel.

Embodiment 2

[0029] Example 2: Preparation of bisamino reagent coupled agarose gel

[0030] Add 0.021~0.25L of diamino reagents (such as diaminodipropylimine, hexamethylenediamine, ethylenediamine, etc.) to 1.0L of acetone, then add 0.43~1.0L to activate with N,N'carbonyldiimidazole For a good agarose gel, react in a shaker at a temperature of 25-37°C and 150 rpm for 2-4 hours. After the reaction, wash the reacted gel repeatedly with 6-10 times the volume of deionized water, and then wash the gel sample with 0.15mol / L, pH8.2 boric acid buffer. At this time, the density of amino groups on the surface of the agarose gel is 50-107mmol / Lgel.

Embodiment 3

[0031] Embodiment 3: Preparation of agarose gel with aldehyde active groups

[0032] Disperse 0.43~1.0L of agarose gel coupled with diamino reagents in 1.0L of 0.15mol / L, pH8. 2 in boric acid buffer solution, reacted in a shaker at a temperature of 25-37°C and 150 rpm for 2-18 hours. After the reaction, wash the colloid with 6-10 times the volume of deionized water, 6-10 times the volume of 2mol / L acetic acid, and 6-10 times the volume of 0.15mol / L, pH8. Dry. At this time, the density of aldehyde groups on the surface of the agarose gel is 13-23 mmol / Lgel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com