Method for preparing hollow zeolite socony mobil-5 (ZSM-5) nanometer zeolite

A ZSM-5, nano-zeolite technology, applied in nano-technology, crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc. Problems such as low crystallinity, to achieve the effect of low cost, simple method and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

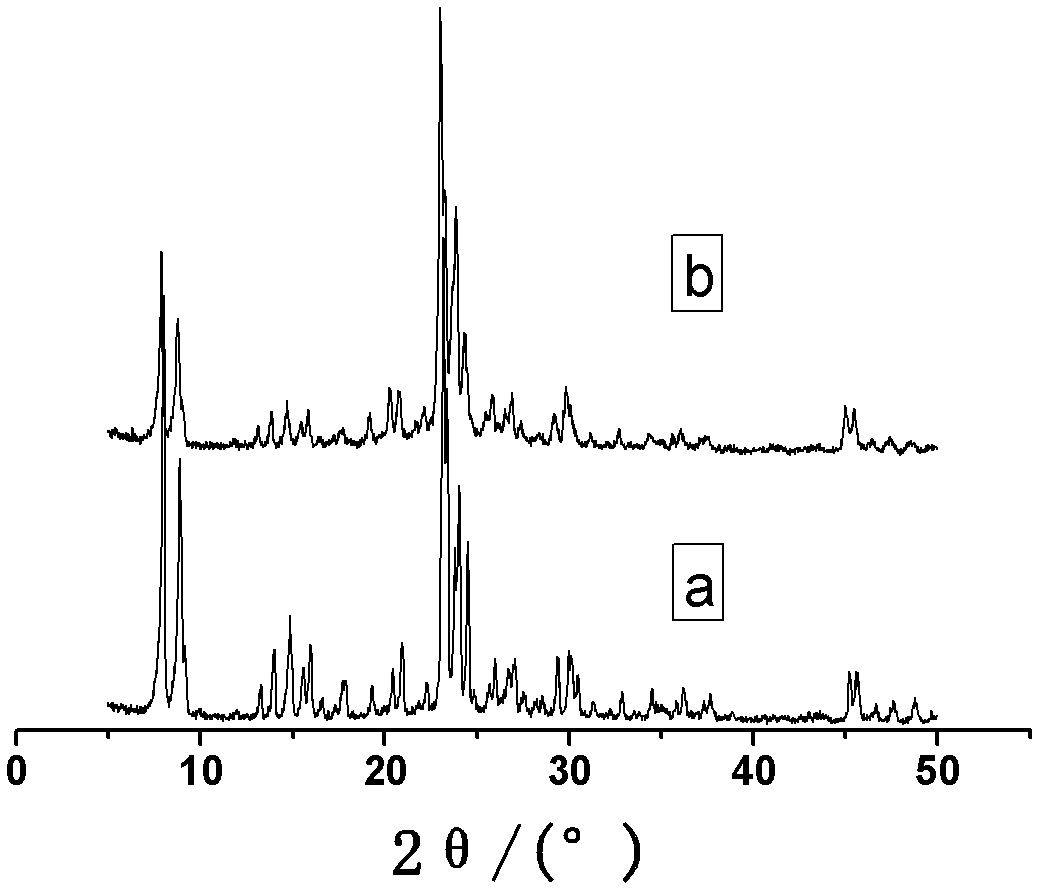

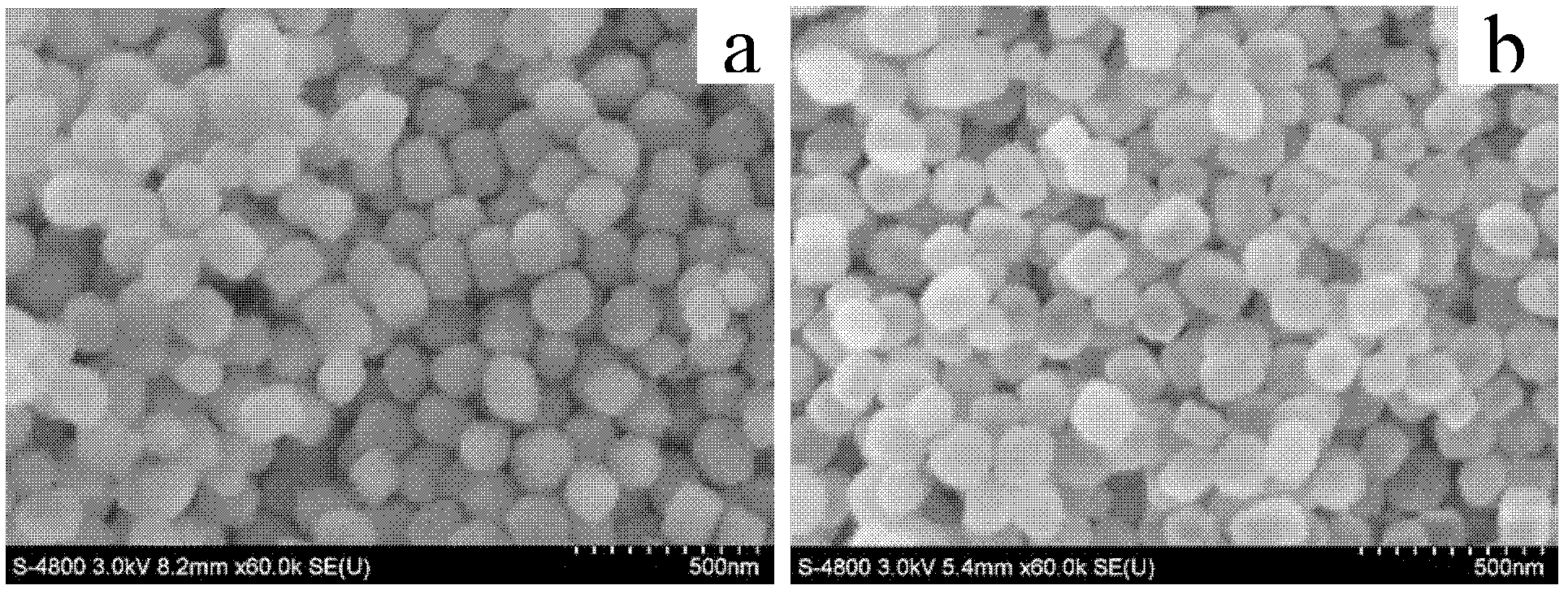

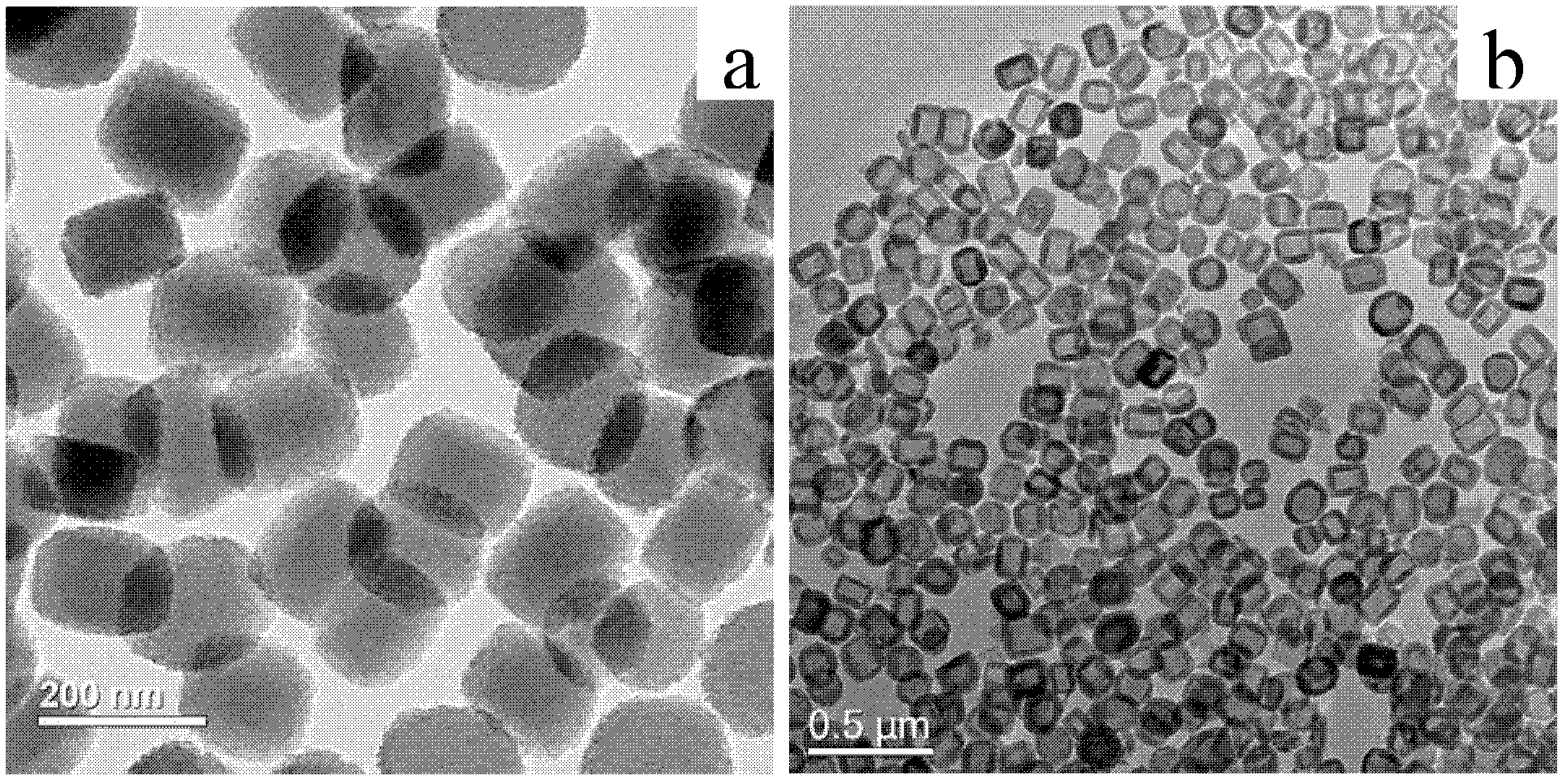

[0040] Preparation of silicon-aluminum molar ratio SiO 2 / Al 2 o 3 For 80 monodisperse ZSM-5 nano zeolites:

[0041]①Mix 30.8ml tetrapropylammonium hydroxide (TPAOH) aqueous solution with 30.8ml tetrapropylammonium hydroxide (TPAOH) of 1.14mol / L, hydrolyze at 35°C for 3h, and define it as solution A;

[0042] ② Mix 1.2g of aluminum isopropoxide with 66ml of water, hydrolyze at 80°C for 3h, and define it as solution B;

[0043] ③Add solution B to solution A dropwise, react at 35°C for 2 hours, remove alcohol at 80°C for 2 hours, add water to 130ml, crystallize at 170°C for 72 hours, centrifuge, dry at 80°C, and roast at 540°C.

[0044] Preparation of hollow ZSM-5 nano zeolite:

[0045] 1. the ZSM-5 nanometer zeolite prepared by 6g is mixed with the tetrapropylammonium hydroxide (TPAOH) aqueous solution of 60ml, 0.1mol / L;

[0046] ②At 170°C, stir for 72 hours, and centrifuge;

[0047] ③ After drying at 80°C, bake at 540°C.

[0048] The silicon-aluminum molar ratio SiO of ...

Embodiment 2

[0050] Preparation of silicon-aluminum molar ratio SiO 2 / Al 2 o 3 Be 80 monodisperse ZSM-5 nanometer zeolite: Same as embodiment 1.

[0051] Preparation of hollow ZSM-5 nano zeolite:

[0052] 1. the ZSM-5 nanometer zeolite prepared by 6g is mixed with the tetrapropylammonium hydroxide (TPAOH) aqueous solution of 60ml, 0.1mol / L;

[0053] ② Stir at 170°C for 54 hours and centrifuge;

[0054] ③ After drying at 80°C, bake at 540°C.

Embodiment 3

[0056] Preparation of silicon-aluminum molar ratio SiO 2 / Al 2 o 3 Be 80 monodisperse ZSM-5 nanometer zeolite: Same as embodiment 1.

[0057] Preparation of hollow ZSM-5 nano zeolite:

[0058] 1. the ZSM-5 nanometer zeolite prepared by 6g is mixed with the tetrapropylammonium hydroxide (TPAOH) aqueous solution of 60ml, 0.1mol / L;

[0059] ②Stir at 170°C for 60 hours, and centrifuge;

[0060] ③ After drying at 80°C, bake at 540°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com