Method for preparing quantum dot of transitional metal chalcogenide compound

A transition metal chalcogenide and compound technology, which is applied in the field of colloidal chemical preparation of nanomaterials, can solve the problems of high reaction yield, short reaction time, slow reaction speed, etc., and achieves high reaction yield and poor generality. , the effect of short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

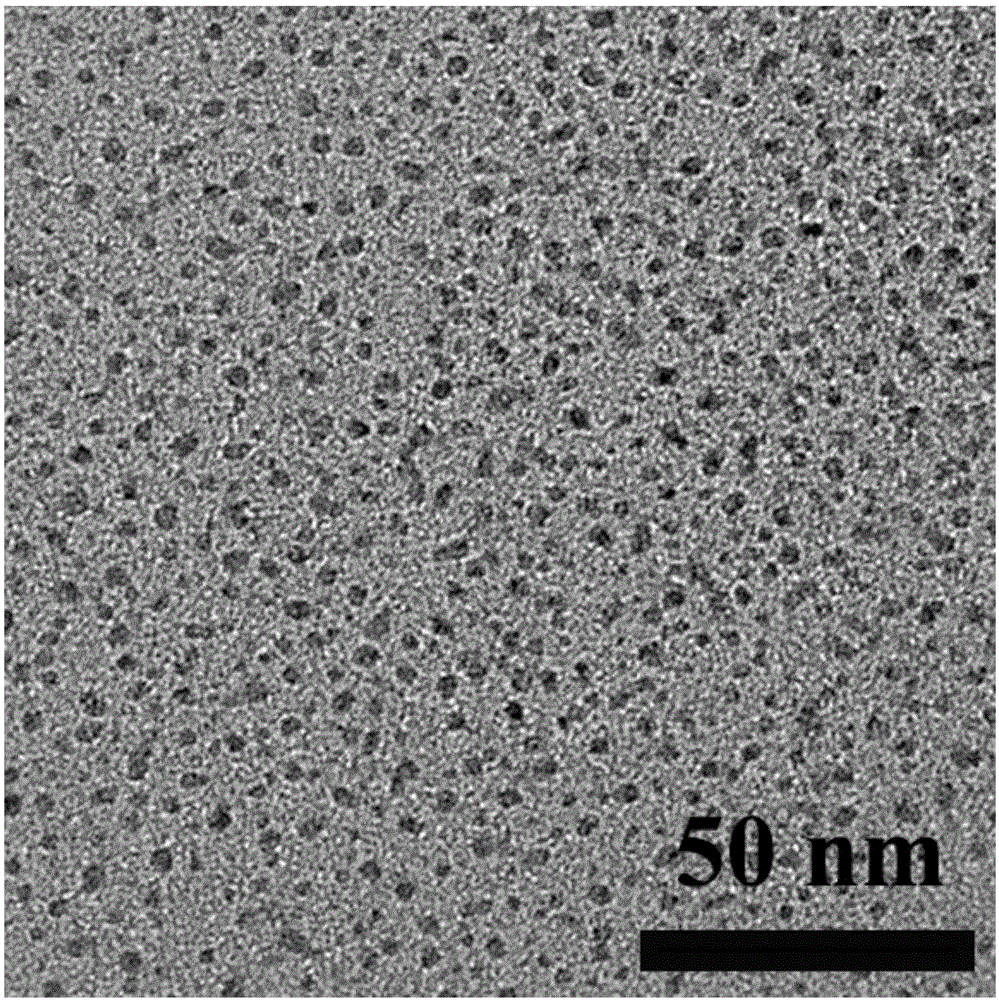

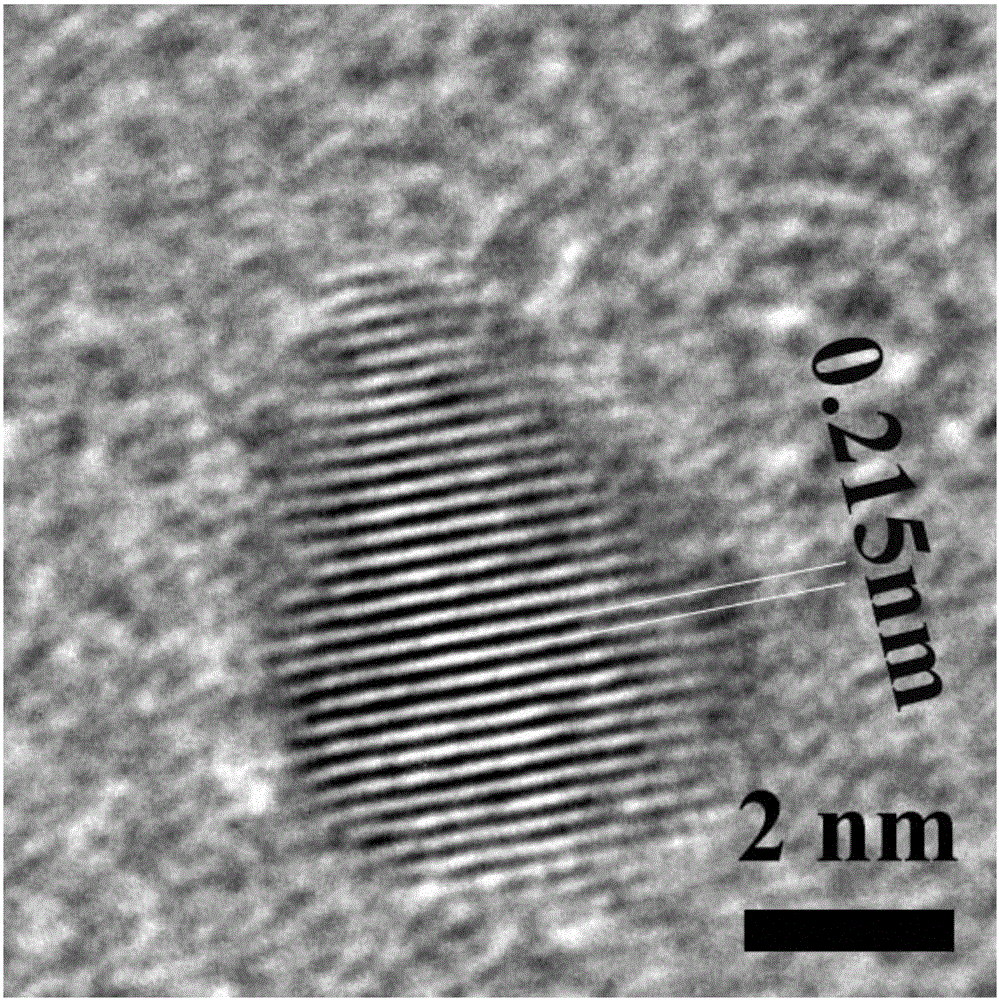

Embodiment 1

[0029] (a) Preparation of metal source reaction system

[0030] Add 105.6 mg of molybdenum hexacarbonyl powder and 309.3 mg of trioctylphosphine oxide powder into a 50 ml three-necked round bottom flask, heat to 50 ° C to dissolve, then add 5 mL of octadecene solution, repeat vacuuming-argon three times, Under the protection of high-purity argon, heat to 300°C.

[0031] (b) Preparation of non-metal source solution

[0032] Add 63.2 mg of selenium powder into the reaction bottle, add 714 μL of trioctylphosphine, ultrasonically dissolve, then add 1 mL of octadecene solution, vacuumize, and fill with argon.

[0033] (c) hot injection

[0034]After part (a) is heated to 300°C, all the selenium source solution prepared in (b) is injected into the molybdenum source reaction system, and kept at 300°C for 2 hours.

[0035] (d) centrifugal purification

[0036] Measure a certain amount of methanol, make a suspension with the molybdenum selenide quantum dots obtained in (c), centrif...

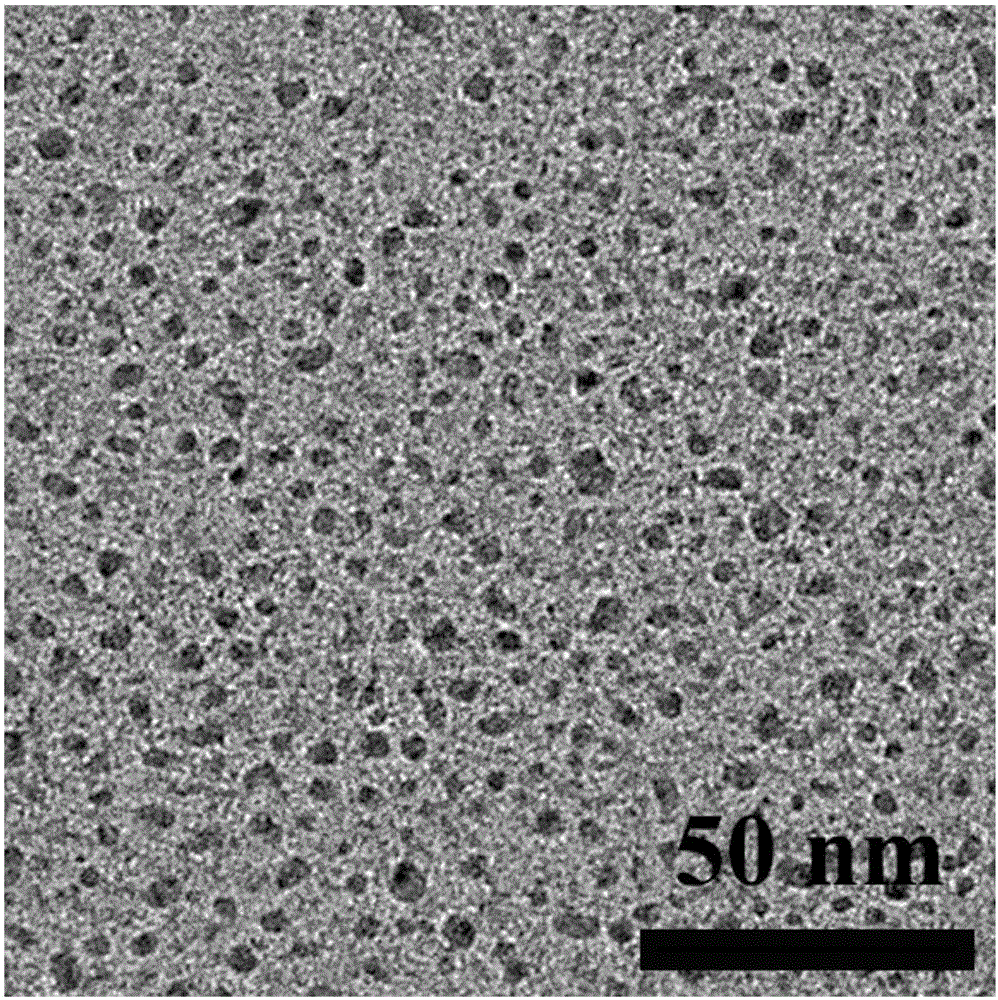

Embodiment 2

[0039] (a) Preparation of metal source reaction system

[0040] Add 105.6 mg of molybdenum hexacarbonyl powder and 309.3 mg of trioctylphosphine oxide powder into a 50 ml three-necked round bottom flask, heat to 50 ° C to dissolve, then add 5 mL of octadecene solution, repeat vacuuming-argon three times, Under the protection of high-purity argon, it was heated to 320°C.

[0041] (b) Preparation of non-metal source solution

[0042] Add 102.1 mg of tellurium powder and 3.57 mL of trioctylphosphine into the reaction flask, dissolve it by ultrasonic, then add 1 mL of octadecene solution, vacuumize and fill with argon.

[0043] (c) hot injection

[0044] After (a) was heated to 320°C, all the tellurium source solution prepared in (b) was injected into the molybdenum source reaction system, and kept at 320°C for 3 hours to react.

[0045] (d) centrifugal purification

[0046] Measure a certain amount of methanol, make a suspension with the molybdenum telluride quantum dots obta...

Embodiment 3

[0048] (a) Preparation of metal source reaction system

[0049] Add 140.8mg of tungsten hexacarbonyl powder and 309.3mg of trioctylphosphine oxide powder into a 50ml three-neck round bottom flask, heat to 50°C to dissolve, then add 5mL of octadecene solution, repeat vacuuming-argon three times, Under the protection of high-purity argon, heat to 350°C.

[0050] (b) Preparation of non-metal source solution

[0051] Add 63.2 mg of selenium powder into the reaction bottle, add 714 μL of trioctylphosphine, ultrasonically dissolve, then add 1 mL of octadecene solution, vacuumize, and fill with argon.

[0052] (c) hot injection

[0053] After part (a) is heated to 350°C, all the selenium source solution prepared in (b) is injected into the tungsten source reaction system, and kept at 350°C for 1 hour to react.

[0054] (d) centrifugal purification

[0055] Measure a certain amount of methanol, make a suspension with the tungsten selenide quantum dots obtained in (c), centrifuge a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com