Preparation method for bisphenol A hydrogenated catalyst

A hydrogenation catalyst and catalyst technology are applied in hydrogenation preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., and can solve the problems of many by-products in hydrogenation reaction and harsh reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

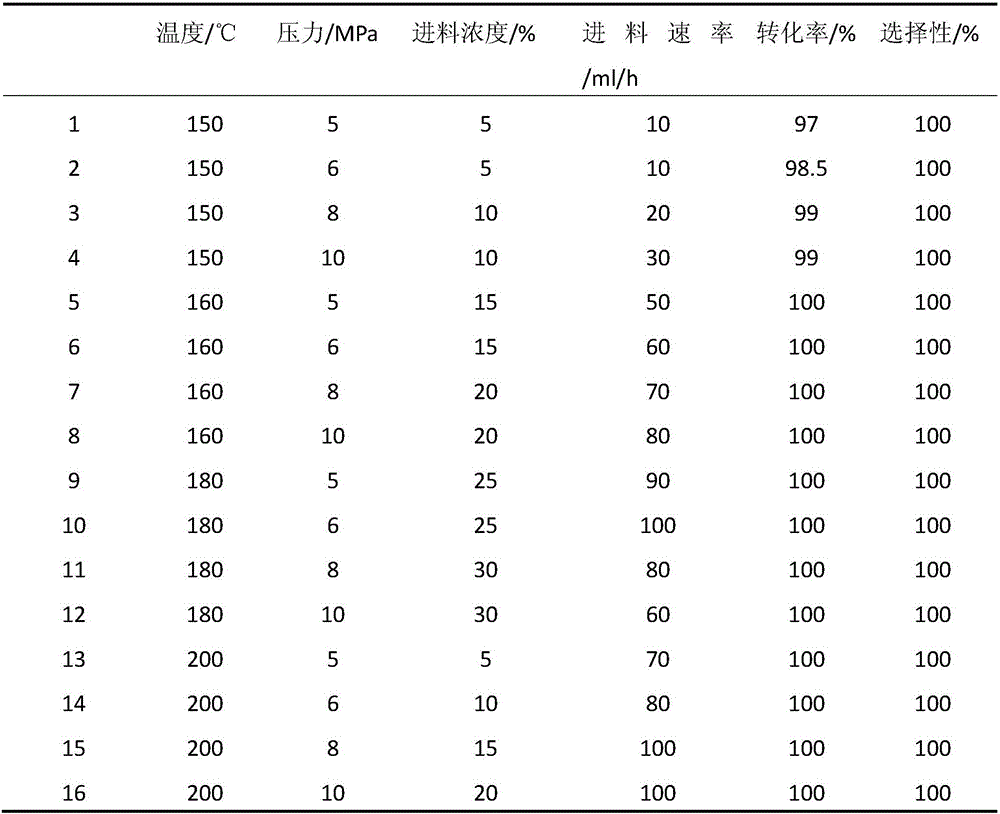

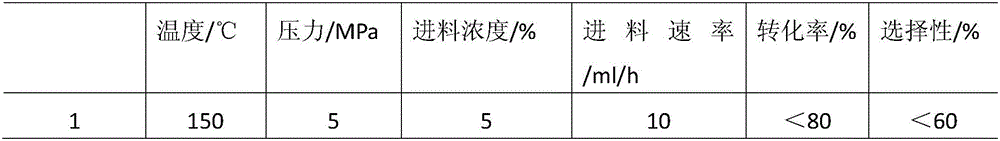

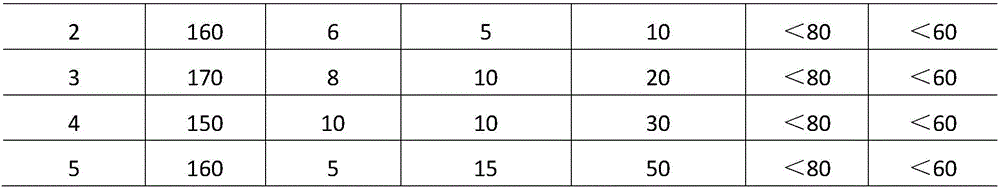

Examples

Embodiment 1

[0023] Embodiment 1 with the Al of 100g 2 o 3 The carrier is ground into a fine powder, mixed with 2g of pyrrolidine and extruded into strips The volume of the liquid is equal to 30% of the total volume of the carrier, and then calcined at a high temperature of 600° C. to obtain the catalyst carrier. 1gRhCl 3 The solid is melted at 100°C, sprayed on the above-mentioned catalyst carrier in mist form, and then reduced at 300°C to obtain a hydrogenation catalyst.

Embodiment 2

[0024] Embodiment 2 with the TiO of 100g 2 The carrier is ground into a fine powder, mixed with 3g of pyrrolidine and extruded into strips The volume of the liquid is equal to 30% of the total volume of the carrier, and then calcined at a high temperature of 600° C. to obtain the catalyst carrier. 1gRhCl 3 The solid is melted at 100°C, sprayed on the above-mentioned catalyst carrier in mist form, and then reduced at 300°C to obtain a hydrogenation catalyst.

Embodiment 3

[0025] Embodiment 3 with the SiO of 100g 2 The carrier is ground into a fine powder, mixed with 4g pyrrolidine and extruded into strips The volume of the liquid is equal to 30% of the total volume of the carrier, and then calcined at a high temperature of 600° C. to obtain the catalyst carrier. 1gRhCl 3 The solid is melted at 100°C, sprayed on the above-mentioned catalyst carrier in mist form, and then reduced at 300°C to obtain a hydrogenation catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com